To my other TR6 pages

May 20, 2016

Mounting The Tub

After

a long winter of waiting, I was finally ready to re-mount the refurbed

tub onto the refurbed frame a few weeks ago. I was really looking

forward to this event, partly because it would generate an additional

parking space in the garage and give me more working room.

In

preparation for the mating ceremony, I did a few last minute things.

I filled the gearbox and differential with GL4 gear oil,

then did a little precautionary trimming of the reinforcing brackets on

the differential bridge. I wasn't sure it was necessary, but

didn't want to take the chance.

Then

I did a final corrosion preventative treatment to the interior of the

frame. I had used a popular "Internal Frame Coating" as I

finished the frame repair, but as far as I can tell, it is just an

ordinarty zinc phosphate primer. It's one of those products that

is probably sold under a number of very application-specific names,

but I think the only thing about it that makes it uniquely suited

for the inside of frames is the extended spray nozzle that comes with

it. Beyond that, it is just a paint, and I don't have high

confidence in its effectiveness on metal surfaces that can't be

properly prepared for paint. In my opinion, there are better

treatments for confined interior spaces.

I use a product that

appears to be a heavy wax thinned with a solvent and delivered from a

spray can. I've bought it under several names, but it all seems

to be the same stuff. It smells, looks, and feels the same as

what Ziebart uses. It clings to surfaces, then dries to a soft

gummy film that never hardens. I used the same nozzle that came with the Internal Frame

Coating.

One

thing that complicates the application of anything inside the frame members is

the numerous internal stiffening baffles. I used a feeler to

find the baffles and mark them to make sure I didn't miss any areas. In a couple of places, I drilled holes for access.

With

the inside of the frame finished up, I turned to the outside. I

bought a body mounting kit form one of the big three suppliers. I

don't remember which supplier it was, but it was a huge

disappointment. I didn't end up using much of it. One part

that was OK was the rubber strips that get glued to the frame rails.

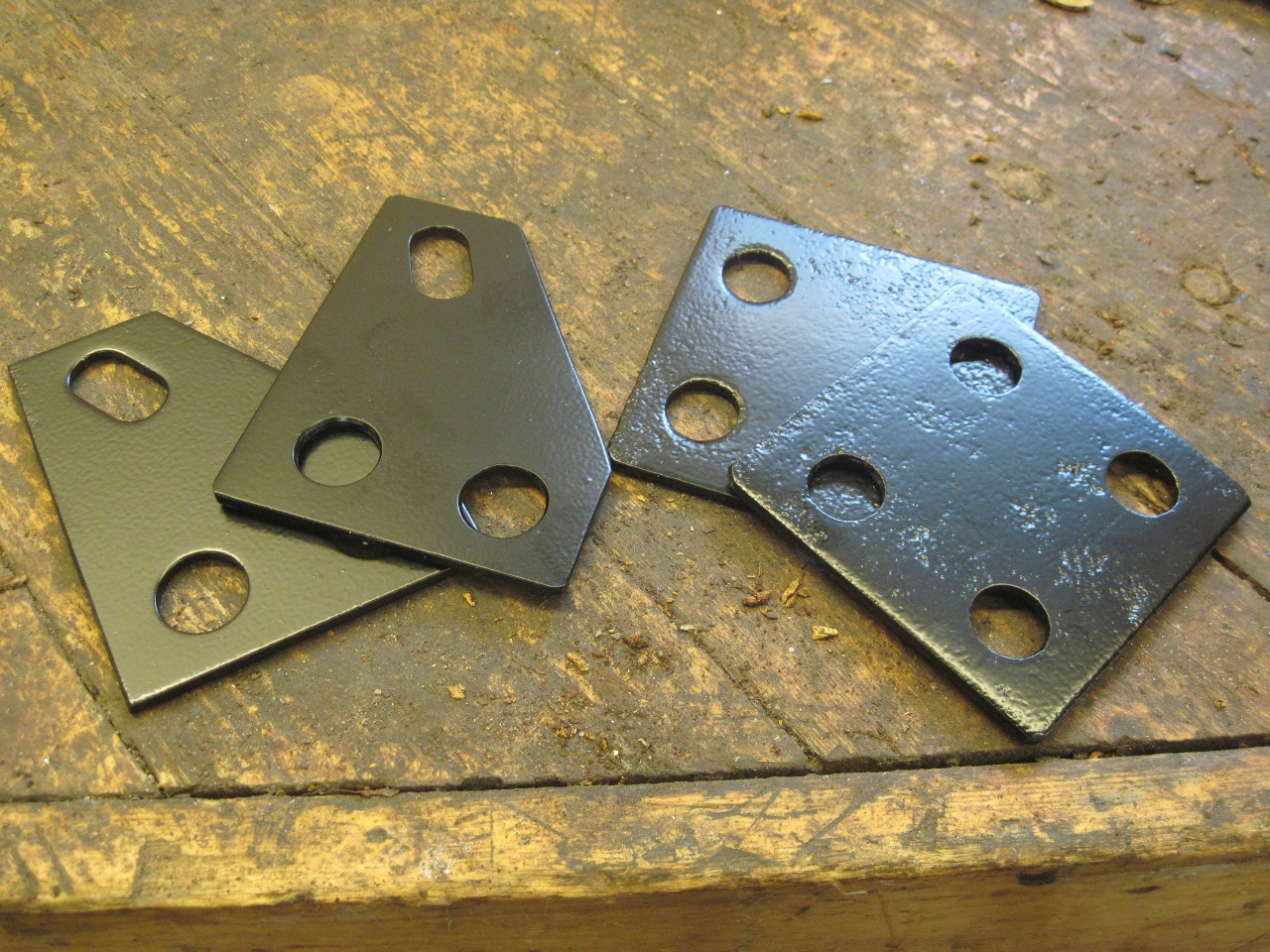

The

main body mounts on either side of the cabin floor are a combination of

metal plates and rubber pads. My car was missing one of the

trapezoidal metal plates, and I wanted to at least start with the same

mounts at all four places, so I had to make a trapezoidal plate, using

the existing one as a pattern. I derusted and powder coated all

the plates.

There

was supposed to be four trapezoidal and four square rubber pads in the

mounting kit, but it was short one of the square ones. I was

consdidering using one of the originals when I noticed that while the

original pads have a reinforcing fabric embedded in them, the new ones

were just rubber, with no reinforcement. The fabric layer serves

to prevent the rubber from distorting and extruding under pressure.

In the end, I decided to chuck all the bought pads and just make

them from a sheet of 1/8 inch reinforced rubber sheet. I was also

irritated by the sloppy shape of the purchased trapezoidal pads.

I built up mounts by sandwiching the metal plates between rubber pads.

In

sorting through the other parts in the mounting kit, I discovered that

it didn't include any of the thin rubber washers needed for some of the

mounting points, and that the thick ones in the kit also didn't have

any reinforcement. So I had to go back to my rubber sheet to

make the thick washers, and ordered the thin ones (probably from a

different supplier since they came made of reinforced material).

So

then, it was show time! Hooked up the skyhook, lifted the tub off

the rotisserie and pulled it out of the way, and gently nudged the

hanging tub over to the waiting frame.

Since

I had braced the door openings of the tub before I removed it from the

frame, and had been

pretty careful to keep the front and rear of the tub located

and supported on the rotisserie while I was doing all the repair

on it, I hoped that I'd have minimal trouble with re-mounting the tub.

At most of the mounting points, the nominal compliment of spacers

and rubber washers seemed to be about right to fill the gap between the

frame and tub. One confusion was with the holes that accept

the seat belt stalks near the central tunnel. All the catalogs

show rubber mounts there, but my car had thick steel spacers instead.

This was apparently a change made some time before '74 that the

suppliers don't acknowledge in their parts listings. (The

larger spacer in the pic is an unrelated part that I thought at the

time was a mounting shim.)

The next tense moment was removing the door

opening braces. I feared that all the welding on the tub had

built up huge forces only restrained by those braces, and removing them

would release the pent up energy by springing the tub into a twisted

shell. I measured each door opening so I'd know how much things

moved. Thankfully, removing the braces was a non-event.

Movement was minimal--well under an eighth of an inch on one side, and virtually zero on the other..

The

next milestone was to temporarily mount the doors and fenders to see if

the door gaps were out of whack. It took some fiddling, but I was

able to satisfy myself that I'll be able to get the door gaps to be OK.

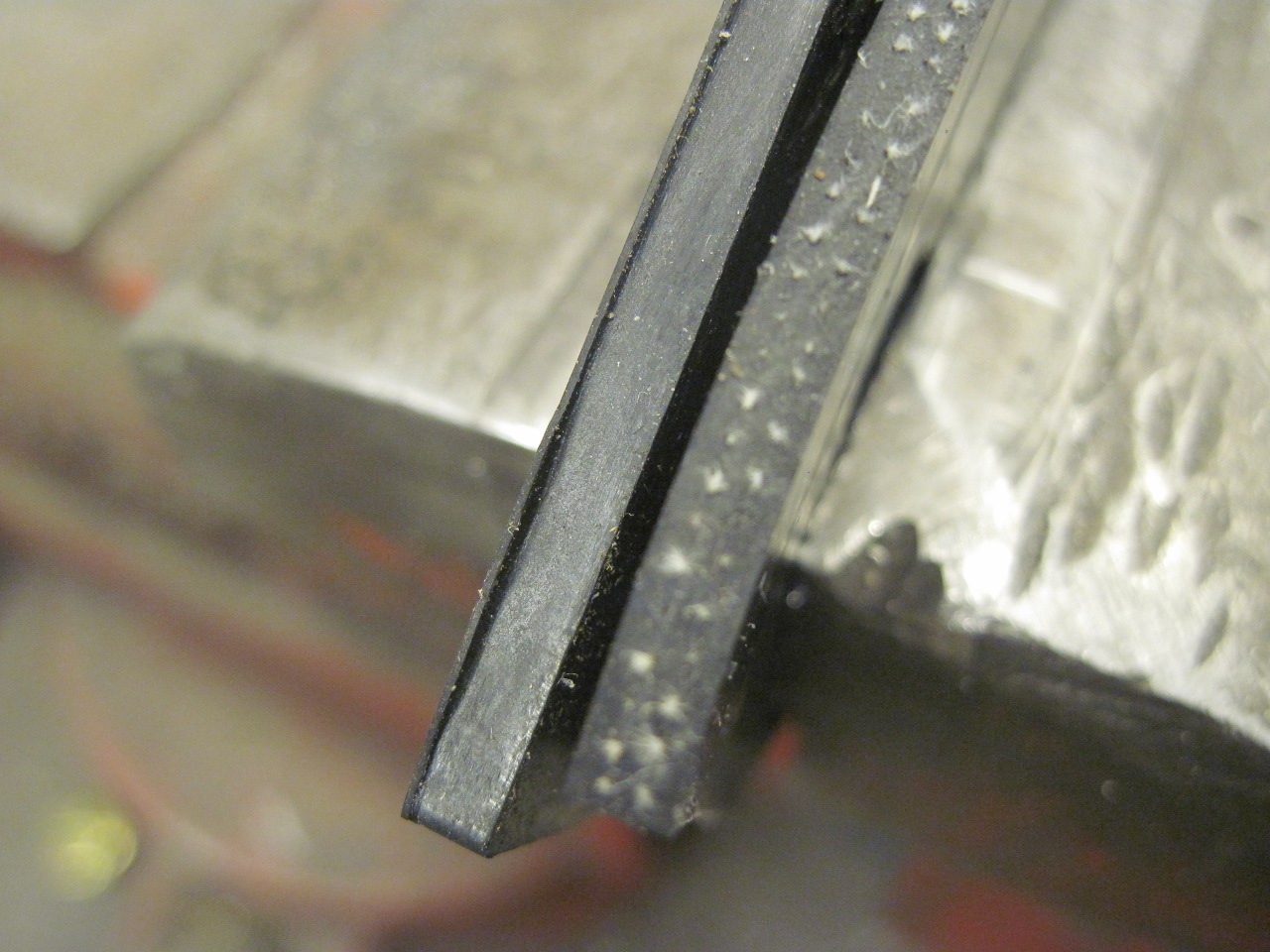

In

looking at the hardware provided in the "kit" to fasten the body, I

discovered one more outrage. The washer on the left in the pic

below is an original item used under many of the tub fixing bolts.

It is thick to ensure it doesn't distort while spreading

clamping force evenly to the sheet metal of the tub. The washer

on the right is what the "kit" supplied for the job. With some

mild cursing, I tossed the kit washers in my loose hardware

bucket. I was able to save about half of the original washers by

derusting and replating, but had to buy the rest from an industrial

supplier.

So,

in spite of the worthless mounting kit, my tub is now provisionally

mounted on the frame, I have some newfound space in the garage, and I'm

really looking forward to a summer of bolting things onto the car.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages