To other TR6 pages

December 2, 2013

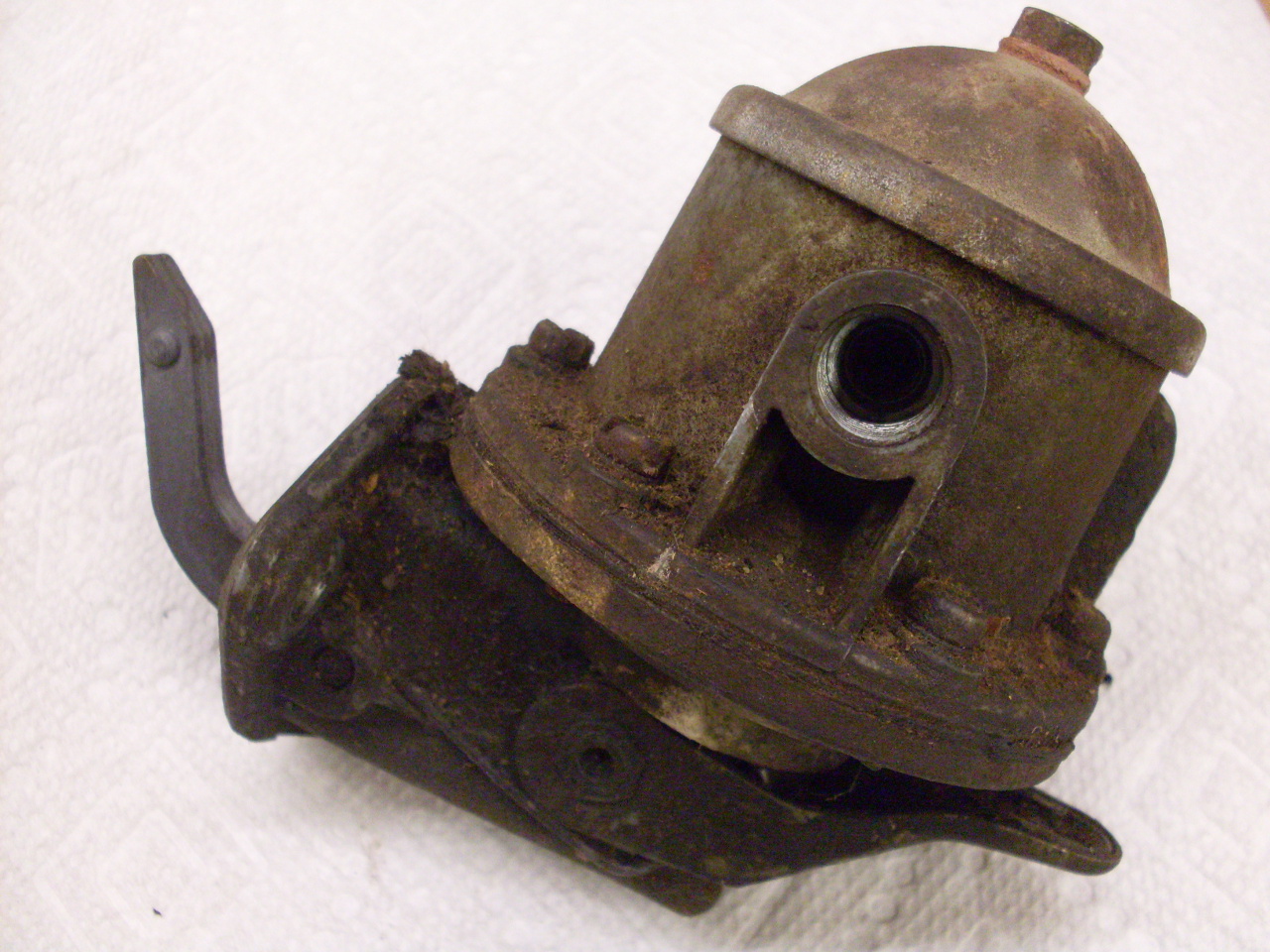

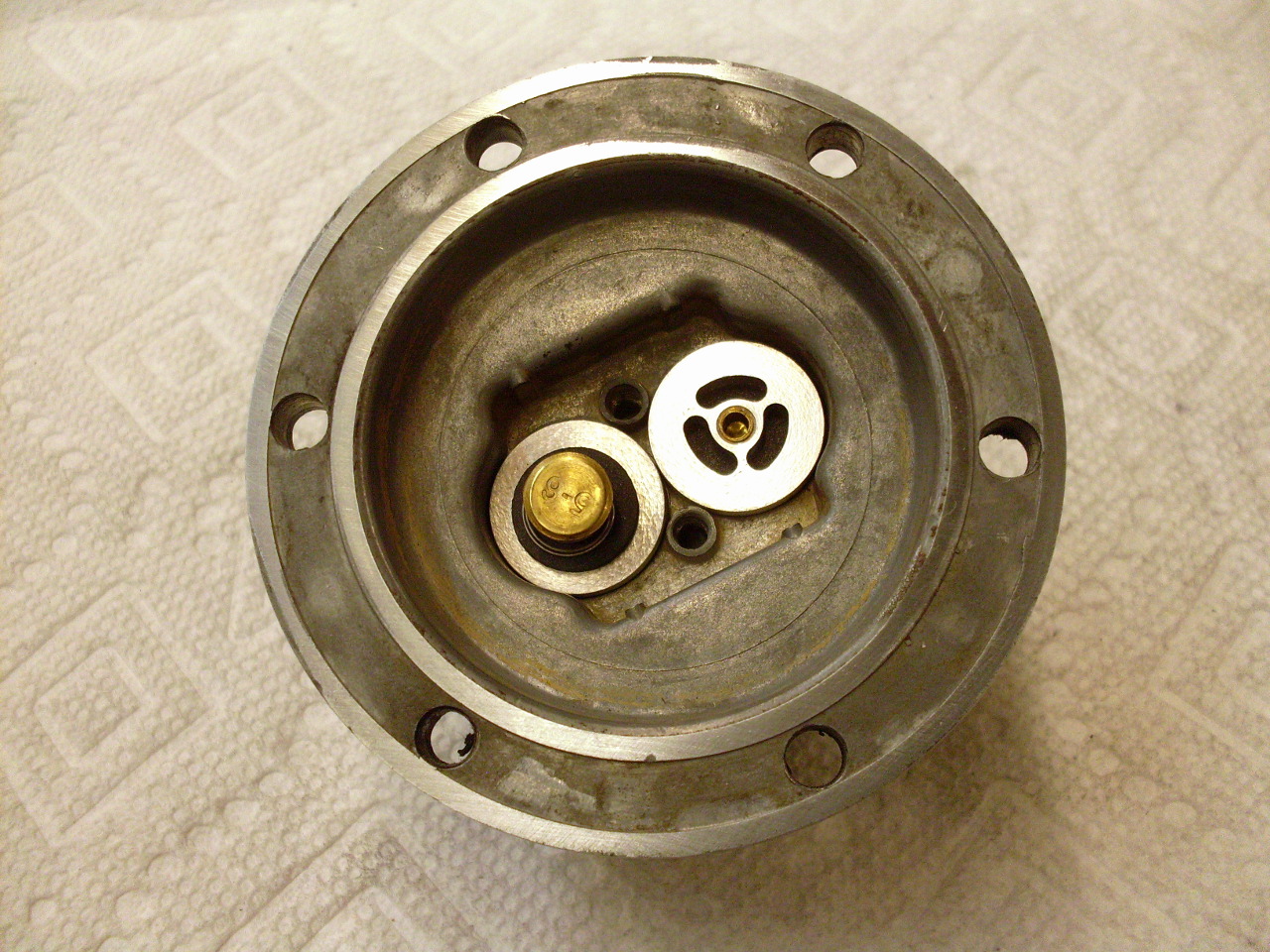

Fuel Pump

The TR6 used a pretty standard mechanical diaphragm fuel pump driven from an eccentric on the camshaft.

As

the diaphragm moves down, it pulls fuel through a check valve from

the fuel supply line into a sediment chamber, through a fine screen,

and into the cavity above the diaphragm, while on the upstroke,

it forces fuel through the other check valve to the pump outlet.

The two opposing check valves are held in place with a retainer.

After over 30 years of storage, this pump chamber still had liquid fuel residue in it.

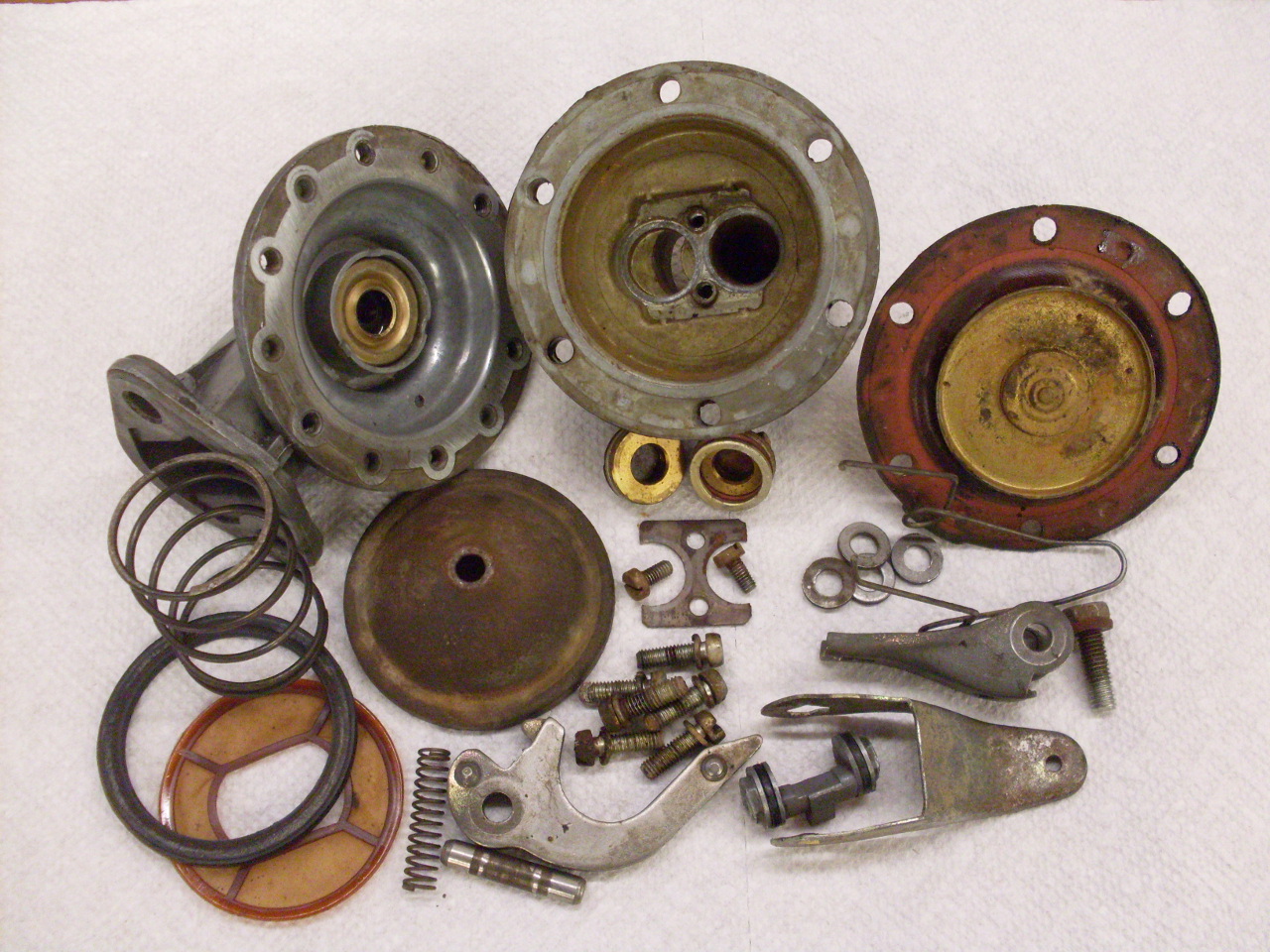

Here

are all the parts of the fuel pump. Rebuild kits are available

that include mostly "soft" parts, but they seem to be pretty generic,

so there are extra parts in the kits, and in the case of this pump, a

couple missing.

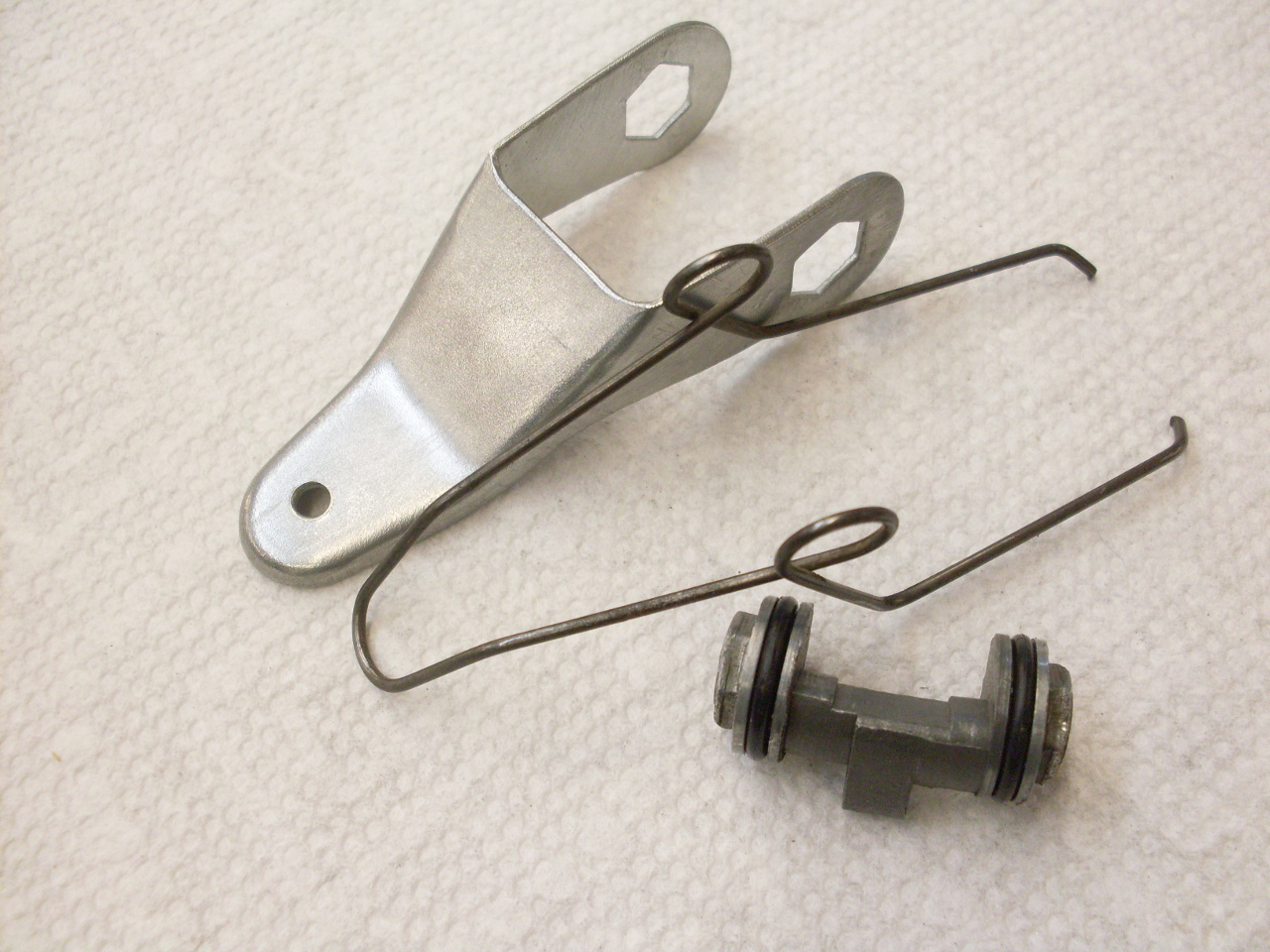

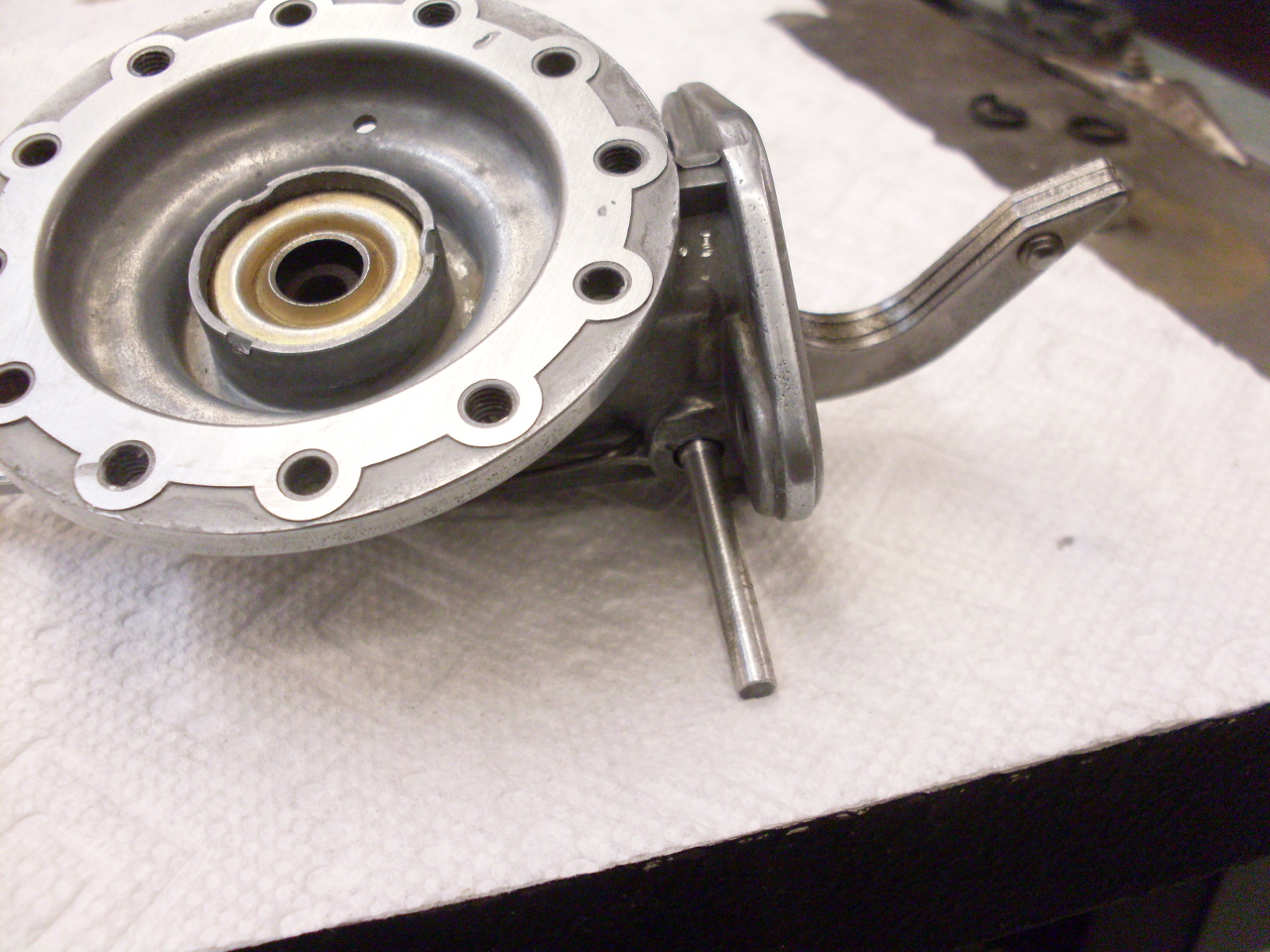

This

pump has a spring loaded lever on the underside so that the diaphram

can be moved manually. I guess this could be used to "prime" a

carb by filling its float bowl, but I'm not sure what the real intent

was. At any rate, the kit didn't include the O rings for the

lever shaft, and made no mention of it in the instructions. The

lever is fixed to a little cam shaft by hexagonal protrusions on the

ends of the shaft that are peened over slightly to lock the lever in

place. There is an O ring on either side of the cam shaft where

it passes through the pump body, When the lever is raised, the

cam presses on an internal link that moves the diaphragm. The O

rings were not in the rebuild kit, and had to be bought locally.

The second picture shows the lever after zinc plating.

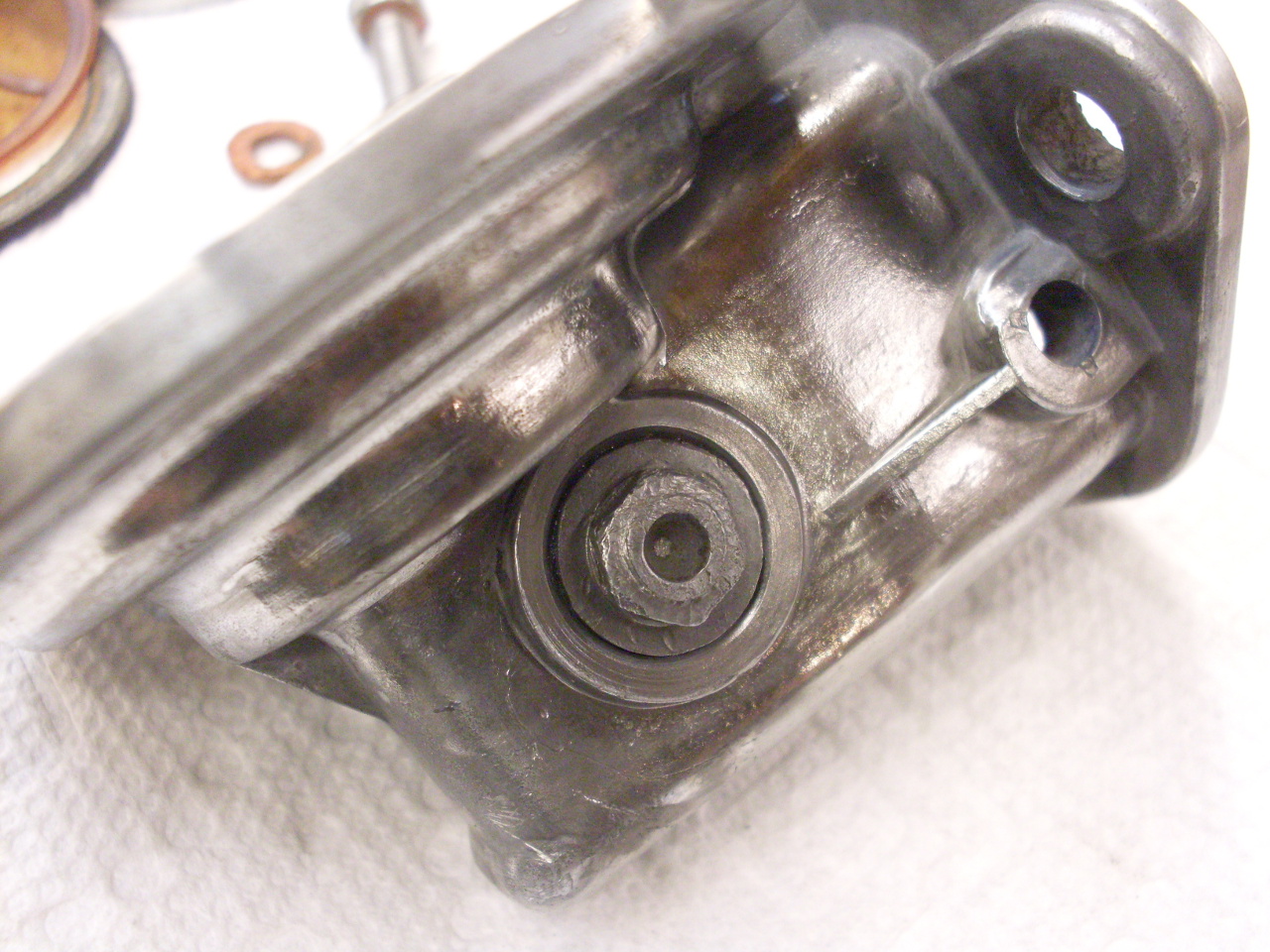

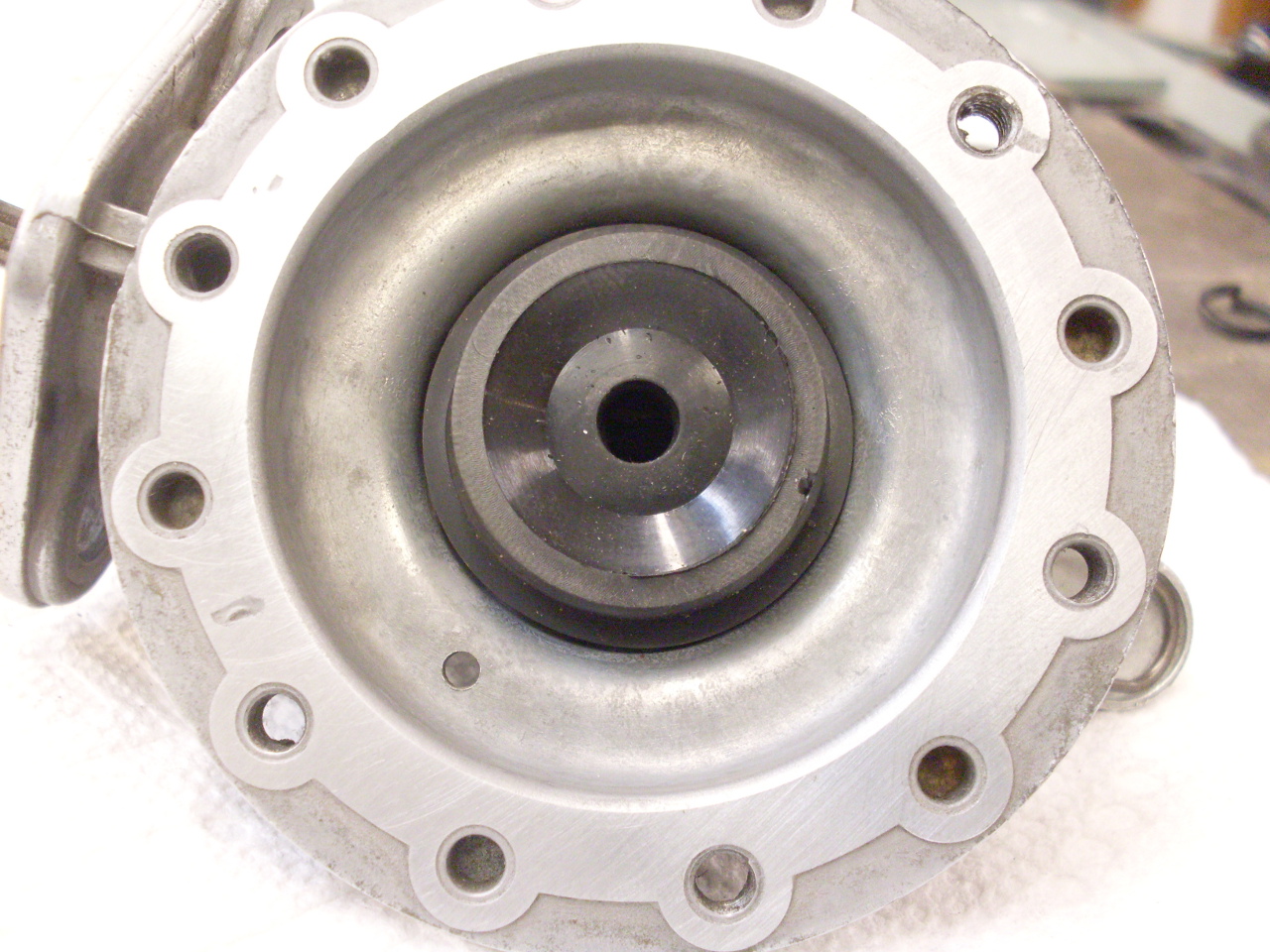

Before I started to put everything back together, I linished all the mating surfaces to see that they were flat.

There

are several interconnected linkage parts deep within the bottom part of

the body. The instructions suggest using an "assembly pin" to

help get everything together. It is just a pin that goes place of

the pivot pin, but has one end a smaller diameter than the pivot pin.

This end holds all the parts in place, but allows extra movement

to get the rocker arm spring and diaphragm installed. The

assembly pin is then shifted to the thicker end so that it locates

everything, and so that the real pivot pin can be driven in.

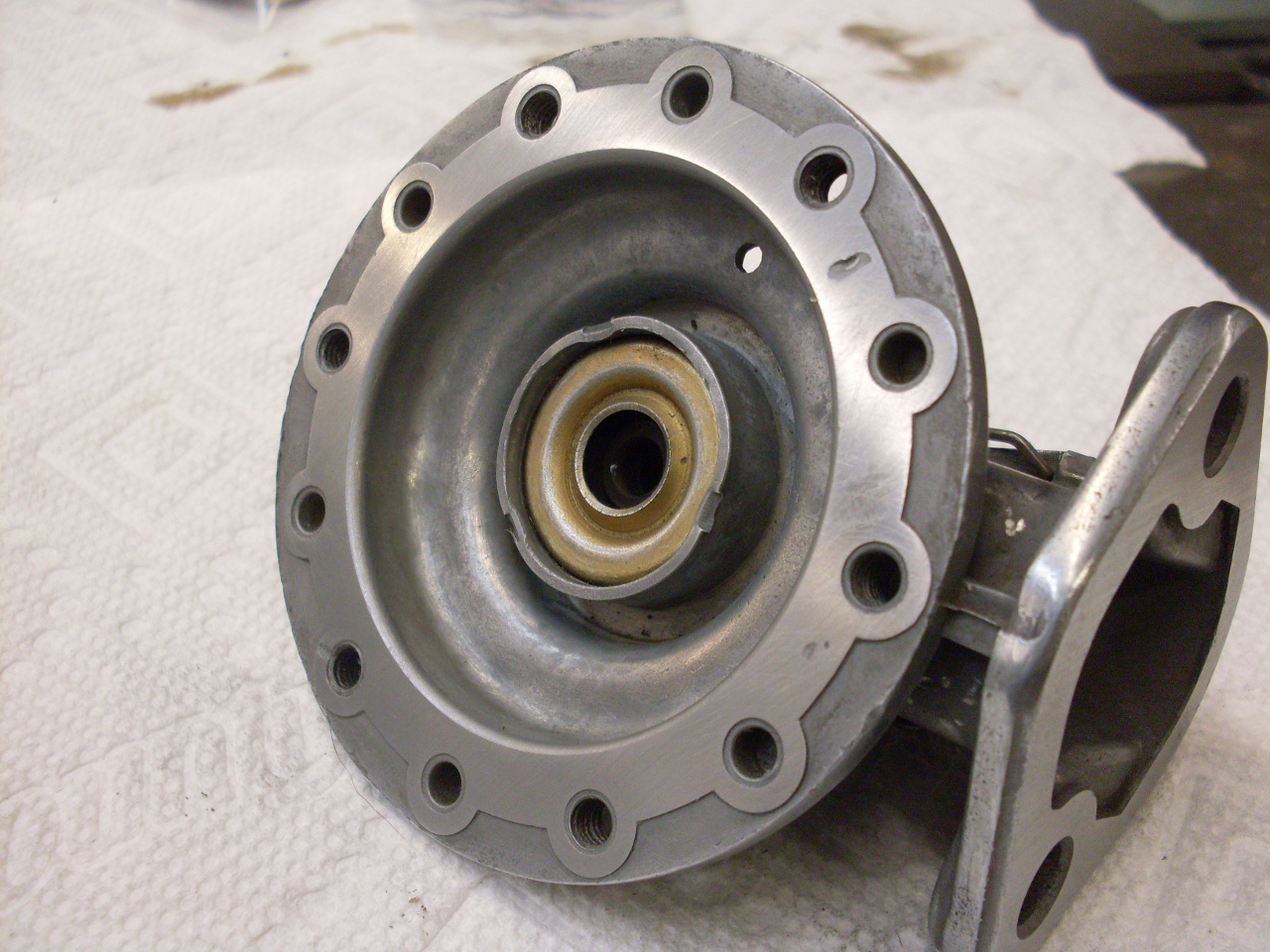

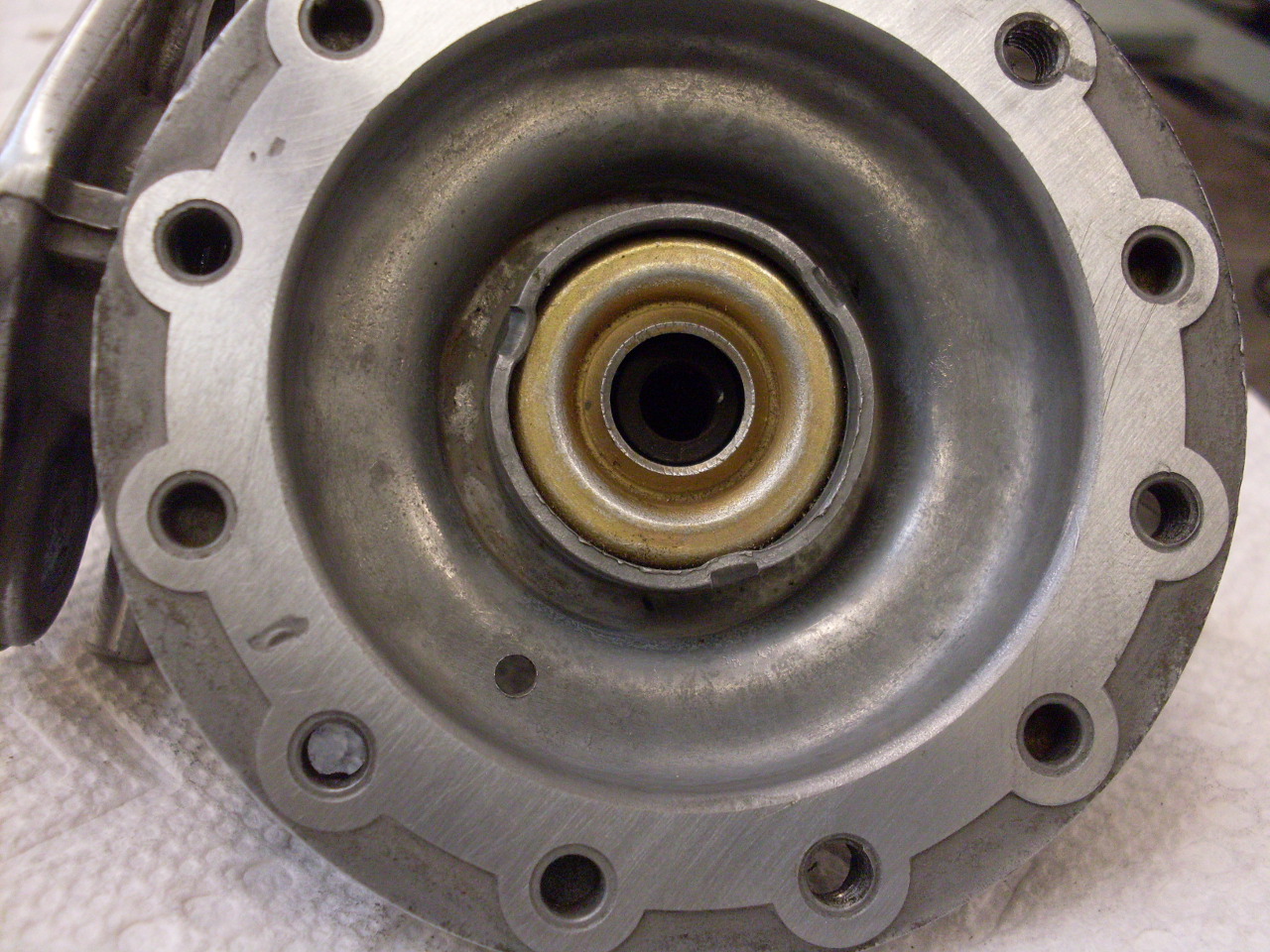

There

is an oil seal staked in the bottom body casting, which rides on

the diaphragm shaft and seals off the part of the pump that opens to

the engine crank case. Though I wouldn't have a problem unstaking

it, the seal is not part of the rebuild kit. Instead, the kit

contains a new seal "cap" that fits over the old seal housing,

and under the diaphragm spring.

Next,

the diaphragm itself. It's a little tricky trying to get the

end of the diaphragm shaft to engage properly with the actuating

linkage without being able to see it.

These

little devices are someone's idea of a cruel joke. They go into

little grooves in the ends of the rocker arm pivot shaft. I put

my odds at about even for having at least one of them launch itself to

some unknown hidden place in the shop. Surprizingly, I finally

got both of them in place with only a little swearing.

The

new check valves. Literal interpretation of the instructions

would have had me install them backwards. The text must have been

written for a different valve design. This is a case of reading

between the lines to determine what the instructions intend, not what

they say. A little Locktite buys some insurance.

The

top part of the body gets a screen and gasket under the domed cap.

The cap was pretty rusty, so I zinc plated it and its fastening

nut.

Finished pump on the shelf until it's needed.

Comments to: elhollin1@yahoo.com

To other TR6 pages