To my other TR6 pages

January 12, 2016

Seat Tracks

[Click the pics for a larger view]

By

modern standards, the seats that came with the TR6 were pretty simple.

The only adustments are a tilting seat back and a sliding track

mechanism that allows the seat about six inches of travel fore and aft.

The tracks are made from heavyish sheet metal, with zinc plating

that only delayed the inevitable corrosion from damp carpets.

My

tracks were in decent shape, but pretty much covered with red and white

rust (iron and zinc corrosion, respectively). I had the seats out

once in the '80s, and sprayed the bottom tracks with some red primer

then to try to slow the rusting process. I must have also thought

it was a good idea to force some grease inside the tracks, but it

probably did more harm than good.

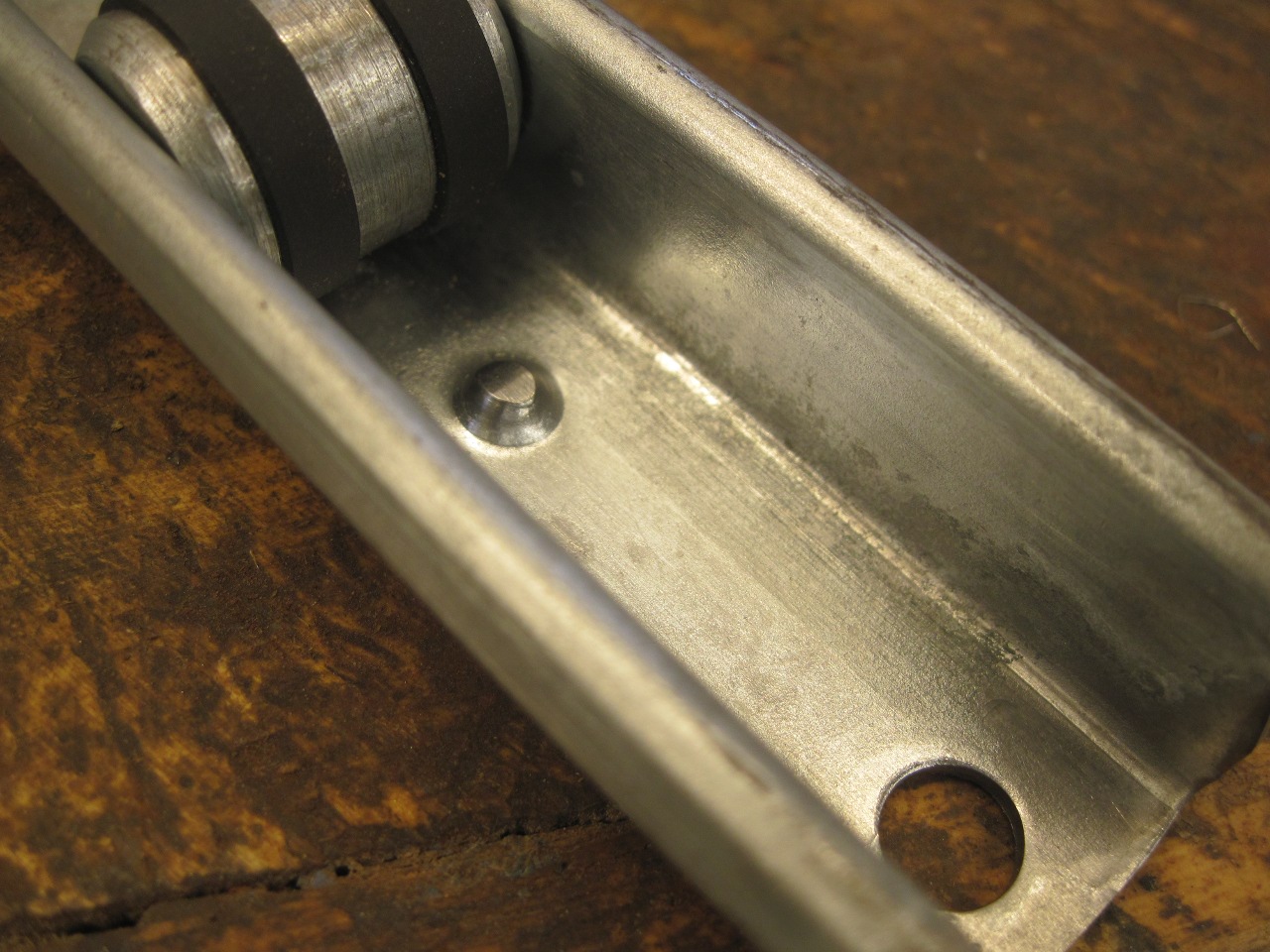

The

upper part of the mechanism which attaches to the seat rides on a pair

of lower tracks that bolt to the car's floor pan. Each seat is

actually supported on four rollers that ride inside the bottom tracks.

Each roller has a pair of rubber tires. The blue tires

probably once resembled O rings, but time had not been kind

to them. They were now distorted, misshapen, and a sloppy fit on

the rollers.

Measuring

the old tires, rollers, and tracks, I was able to surmise the

approximate original dimensions of the rubber parts, but looking

through tables of standard O rings, nothing was very close. The

closest standard part was a -311 O ring, so I ordered a bag. The

9/16 inch ID of the new rings seems to be close to correct for the

rollers, indicating how stretched out the old rings were. The

new rings were too fat though, which made the OD too big when

mounted on the rollers.

I briefly considered casting some custom O rings in the right size, but decided to try modifying the -311 parts first.

Machining

rubber is tricky. Some try freezing it and using regular lathe

tools, but I thought keeping it cold and hard enough would be a hassle.

Others report that abrading rather than machining works well.

I gave this a try, and finally hit on a method that worked

OK. I spun a ring mounted on a roller, and used either a file or

sandpaper mounted on a hard flat backing to wear away the rubber.

I experimented with final OD dimensions, and settled on 0.850".

Once I got going, each one only took a few minutes.

Next

came cleaning up and derusting the metal parts of the tracks. The

spring loaded slide lock lever is riveted to the assembly, and I didn't

feel I could properly strip or refinish the piece with it in place, so

I removed the rivet.

I

normally derust metal parts with phosphoric or muriatic acid. In

this case though, much of the original zinc plating was intact, and the

acid derusting process would attack the zinc. The parts were too

big for my plating tank, so I needed to preserve what zinc was

left. In this situation, the best method is to use a chelate

deruster. Chelates are harmless to plating, and even most paint,

and pretty much only attack metal oxides, especially rust. The

picture shows a tub with enouth solution to cover the upper track

assembly. The marbles and the big hunk of black plastic are in

there to raise the level of liquid so I didn't need so much. I

used Evaporust, but there are other good products, too.

It's

a slow process, measured in hours, not minutes, but pretty effective.

The slightly darker mottled areas are where the zinc was corroded

away.

Here's

one other piece of education I got from taking the first track apart.

There are little dimples on both the upper and lower tracks to

limit how far the rollers can travel. They also make it a real

challenge to separate the lower and upper tracks. I ended up

drilling out the dimples on the lower tracks, which made disassembly

much easier. I'll replace the dimples with screws later.

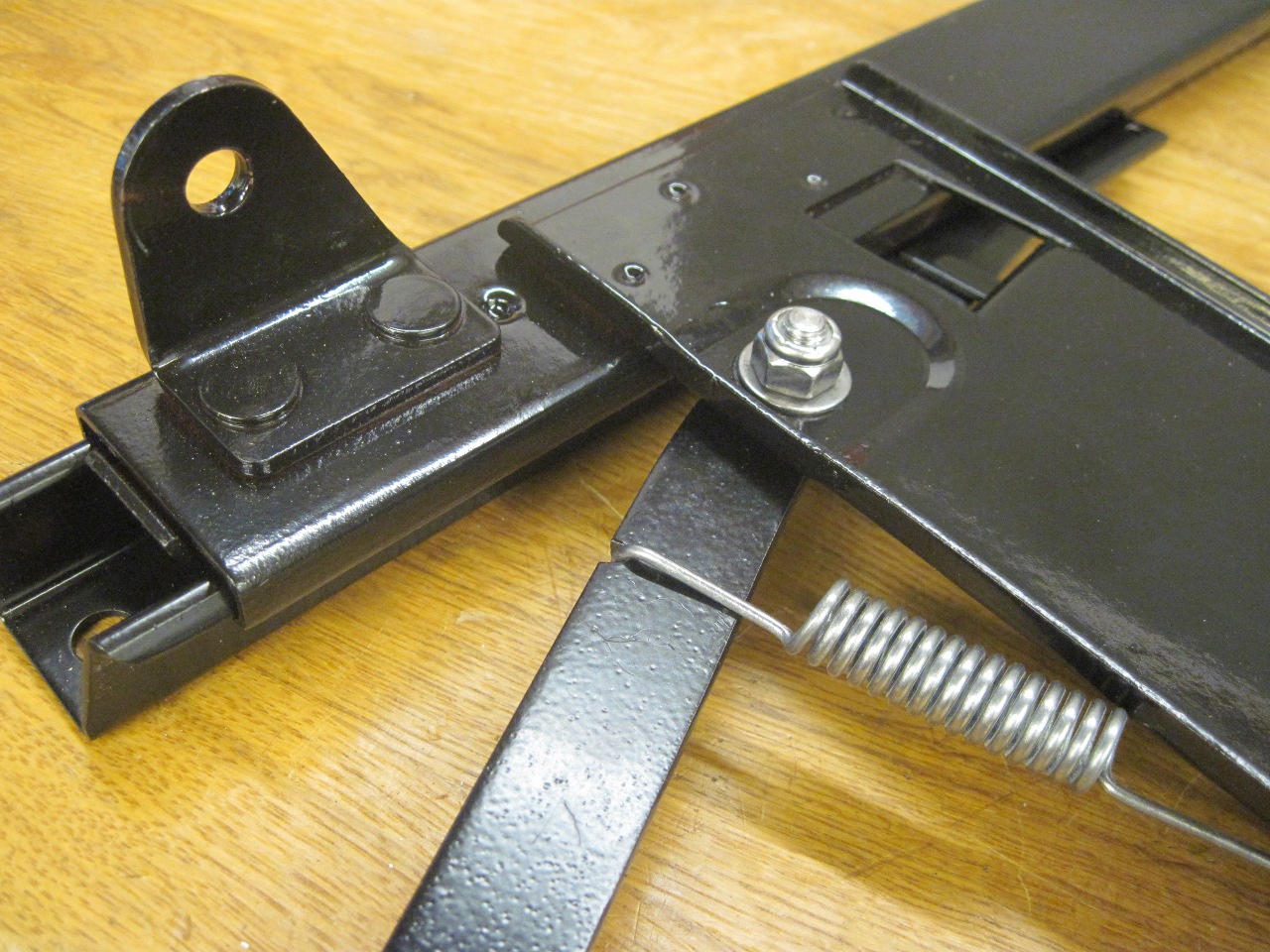

I

really wanted to powder coat all the parts, but the upper track

assembly was too tight a fit in my oven, so it was just primed and

painted. Smaller parts were powder coated. The original

parts were just bare metalic color, but it seemed to me that parts

under the seat really should be blacked out, so I went with black.

Rather

than put these sort of ratty looking plasstic covers on the ends

of the locking levers, I opted for ten or so coats of Plastidip.

These are the adjustable plates at the rear of the tracks that the seat tilt locks catch on.

Ready

to put the slide lock levers back on. Since I destroyed the

original rivet, I used a shoulder bolt instead.

Almost forgot--I had to replace the little limit bumps I drilled out to make disassembly and assembly easier.

This

was an enjoyable, if pretty involved project. The cost was

minimal--some O rings and some hardware--probably under $15.

Comments to: elhollin1@yahoo.com

To my other TR6 pages