To my other TR6 pages

November 28, 2015

Exhaust System

One

of the last things left to do before reuniting body and frame is to

install the exhaust system. Though this could be done later, it

seems that it would be much easier now.

I bought a stainless

steel system that is a copy of the original factory system. It

consists of a dual downpipe weldment, a pair of intermediate pipes, a

pair of rear pipes, and the dual input dual output muffler.

As

with most things I've bought for this project, there were a few things

to clean up. One item was sloppy dressing of the joint between

the down pipes and the flange. Another was some damage to one of

the muffler stubs, probably in shipping. That short piece of pipe

made a nice mandrel to reshape the collapsed tubing.

The

system I ordered was supposed to be for a '74, but what I got was for

an earlier car. Luckily, the only difference is that the earlier

intermediate pipes had hanger tabs welded on, while the '74 system

used a separate hanger for the intermediate pipes, so I just cut the

superfluous tabs off. The hanger kit I bought had the

correct intermediate hanger.

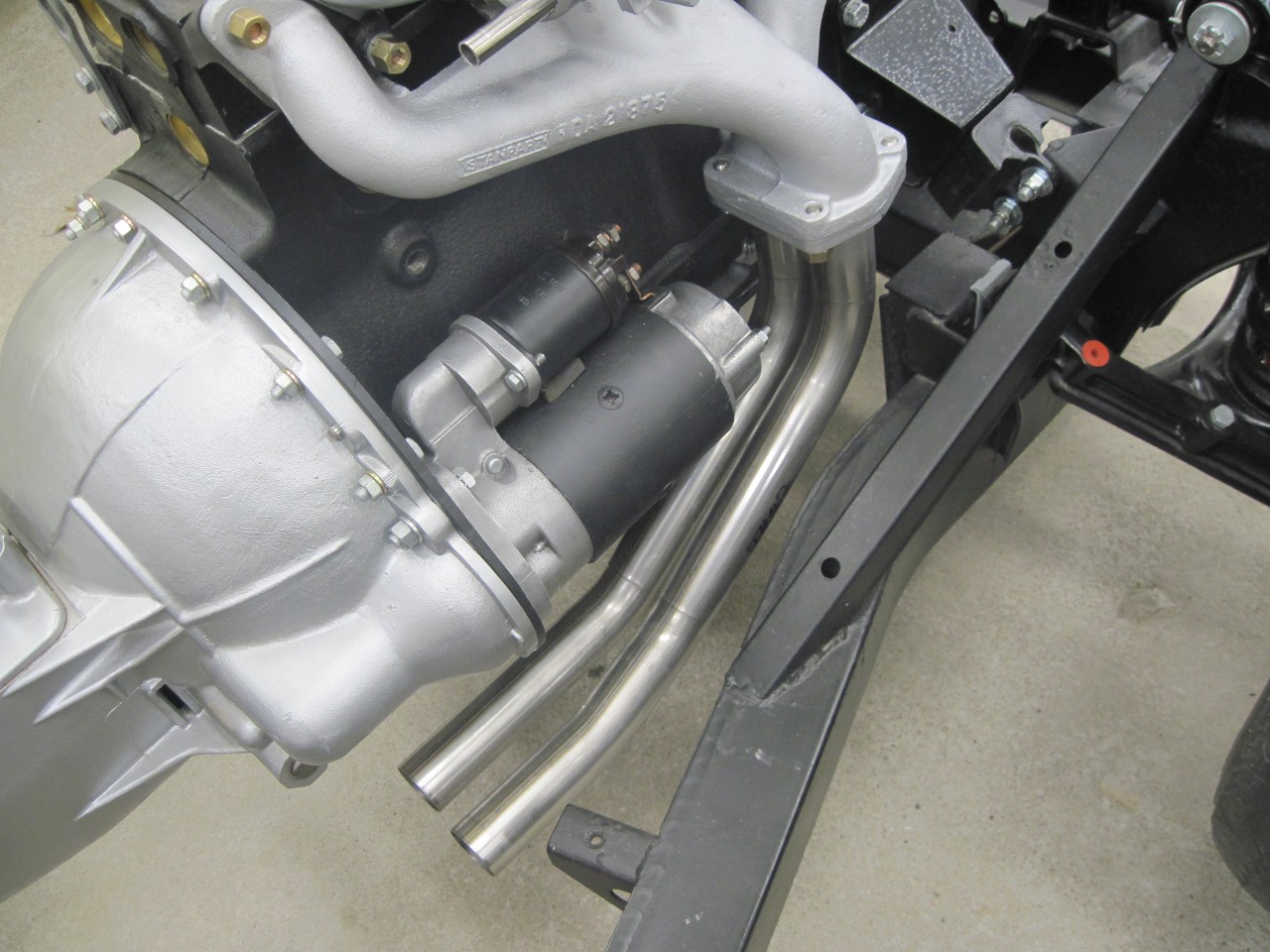

The

next job was to add bungs for oxygen sensors. The TR6 engine can

for some purposes be thought of as a pair of three cylinder engines,

each with its own carburettor and exhaust. There are balance

passages between the two halves of the engine in both the intake and

exhaust manifold, but in a well tuned engine, there shouldn't be too

much intermixing of air/fuel mixture or exhaust gasses, especially at

midrange and higher RPMs. This dual system just cries out

for two oxygen sensors so that air/fuel ratios can be determined for

individual carbs. I had originally considered installing the

bungs in the exhaust manifold, but putting in two of them was going to

be tricky. I decided it would be easier and just as effective to

put the sensors high up on the downpipe. A mockup showed me that

there was a little more room to put the sensors on the front side ofthe

pipes rather than on the rear, where the sensors would make removing

the starter a pain. Even in the front, there was a potential

issue with fouling the motor mount.

I

first bought a pretty common Bosch sensor, but found that it was a

little too long. I ended up with a slightly smaller universal

replacement sensor that would just fit.

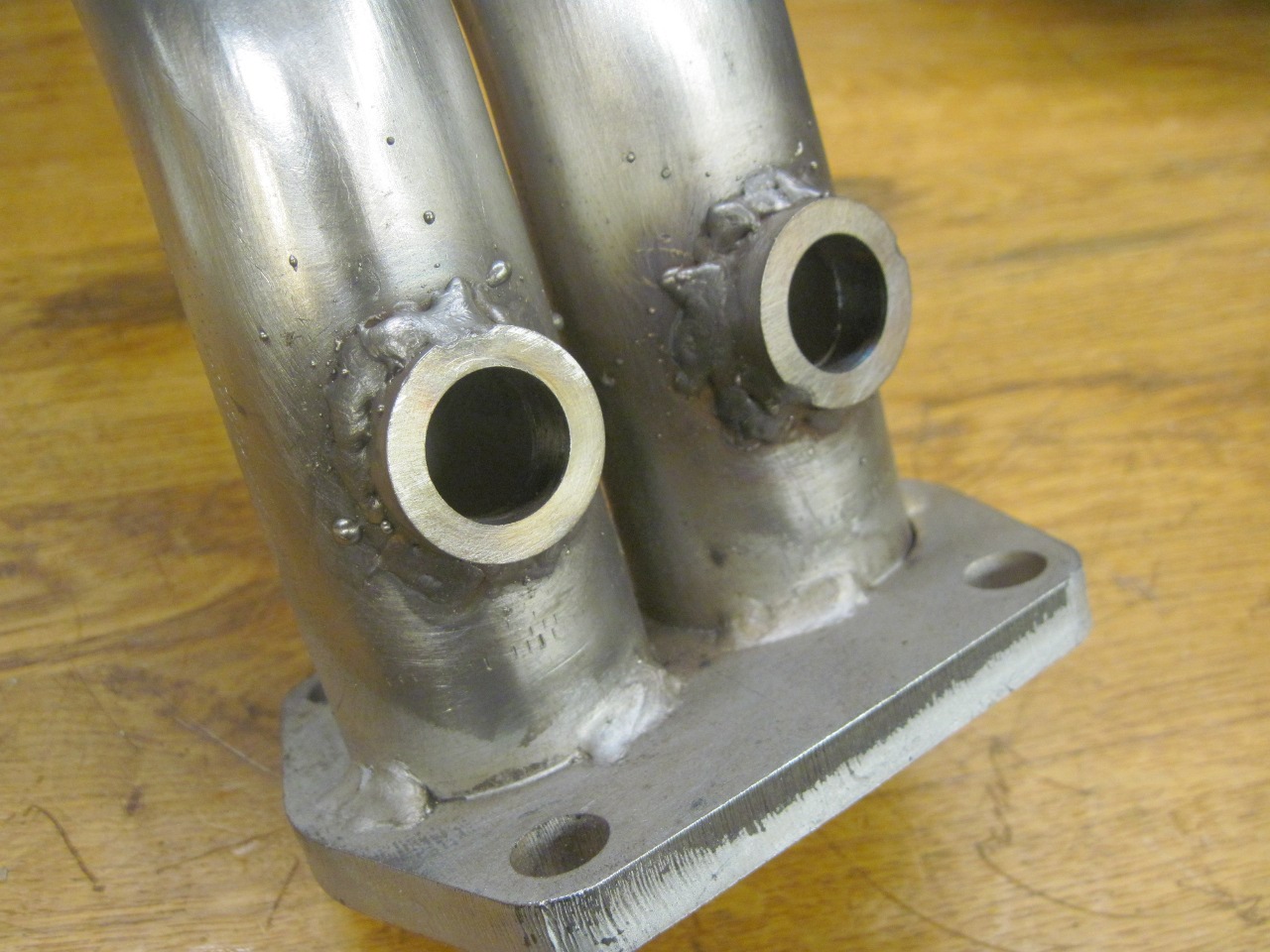

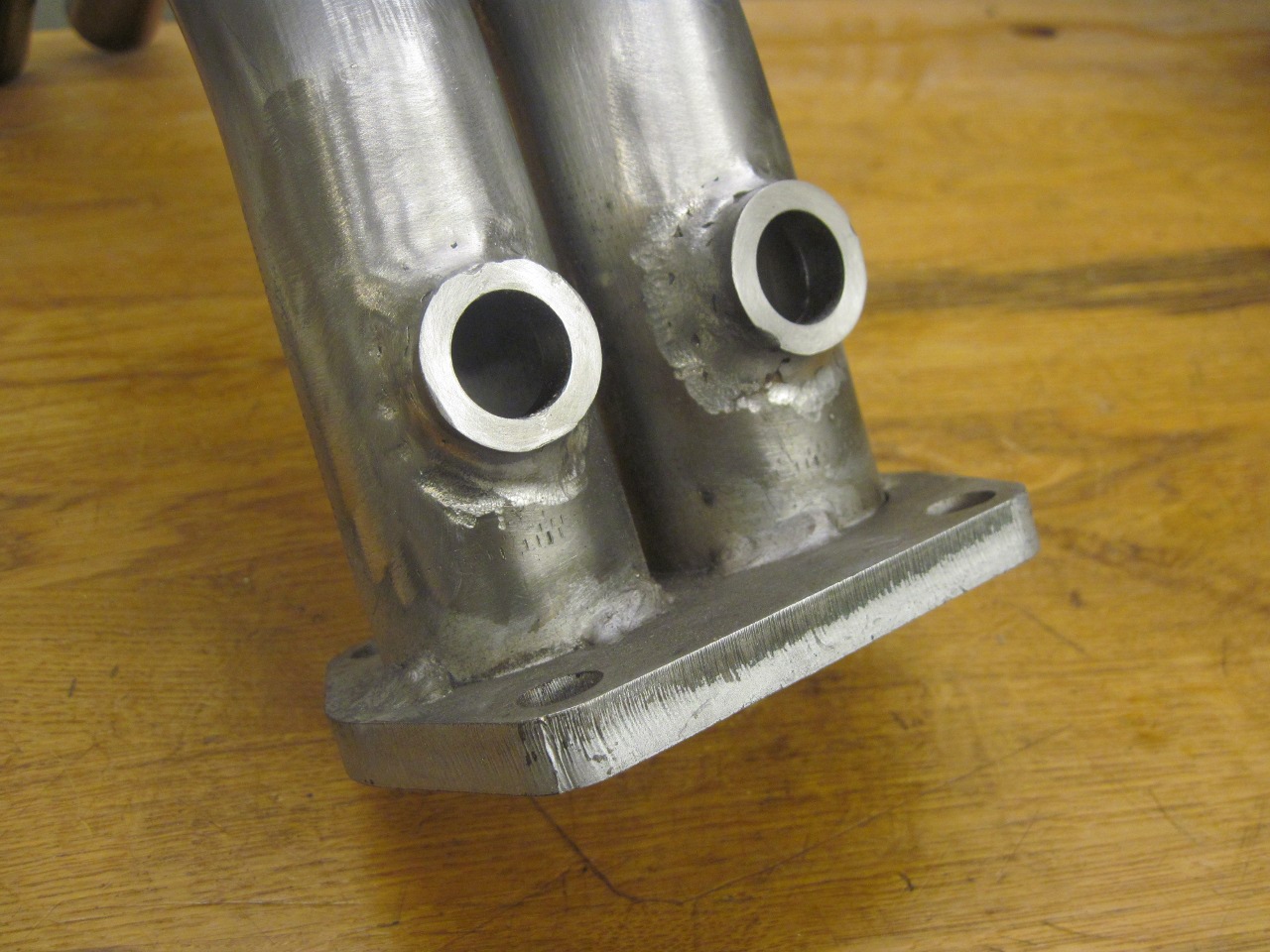

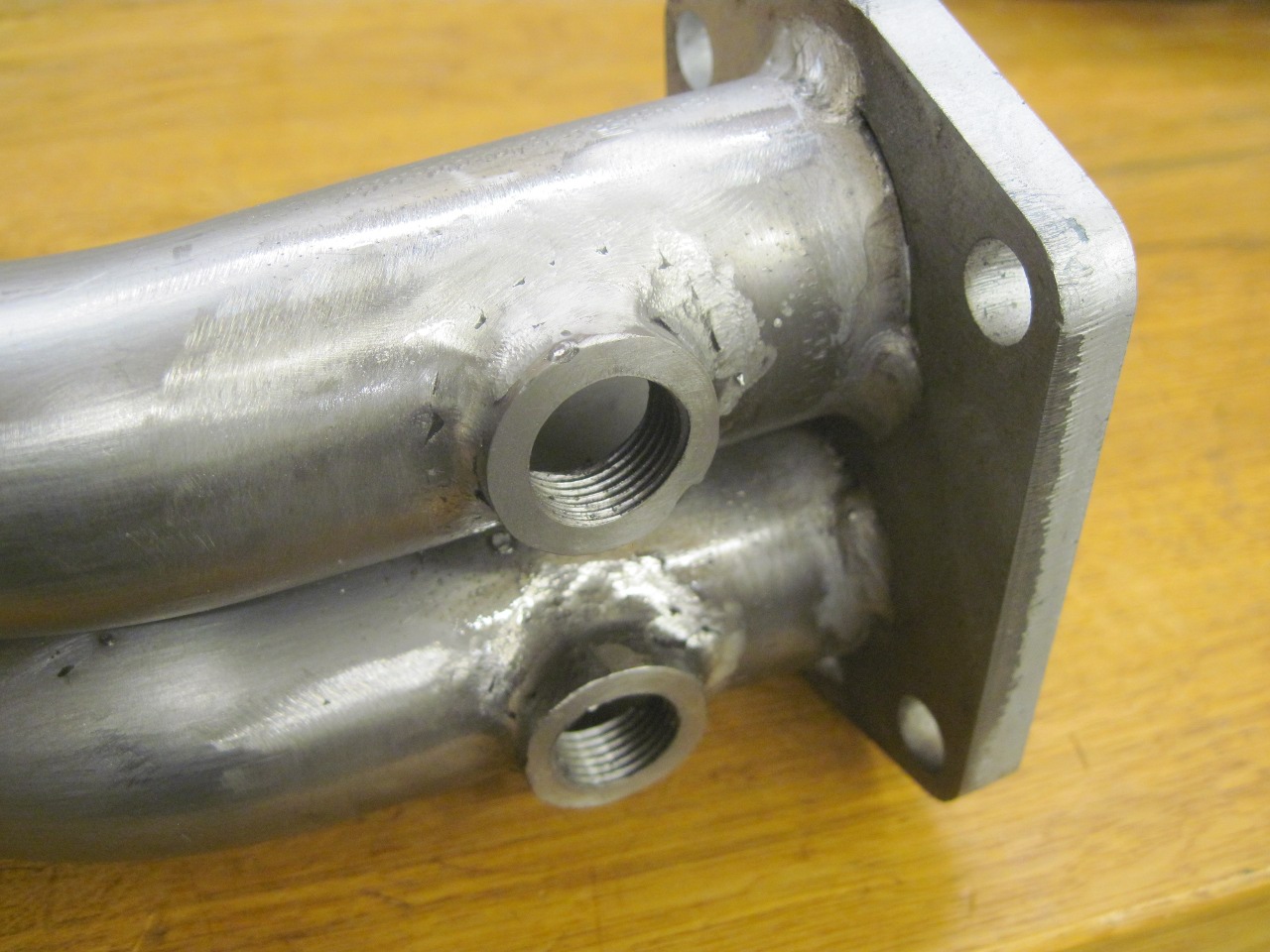

For

the bungs, I got a short piece of 1-inch stainless steel and fashioned

a pair of saddle-shaped fittings that matched the diameter of the down

tubes.

Then cut a pair of matching holes in the tubes, and made a little slug to align the holes in the bungs with those in the tube.

I'm

a mediocre MIG weldor at best, and I quickly found that welding

stainless (with stainless wire) has its own challenges. While I

don't fret the strength of the welds, I decided to dress them to avoid

publicly embarassing myself. Then threaded the bungs to the

standard (for oxygen sensors) M18-1.5.

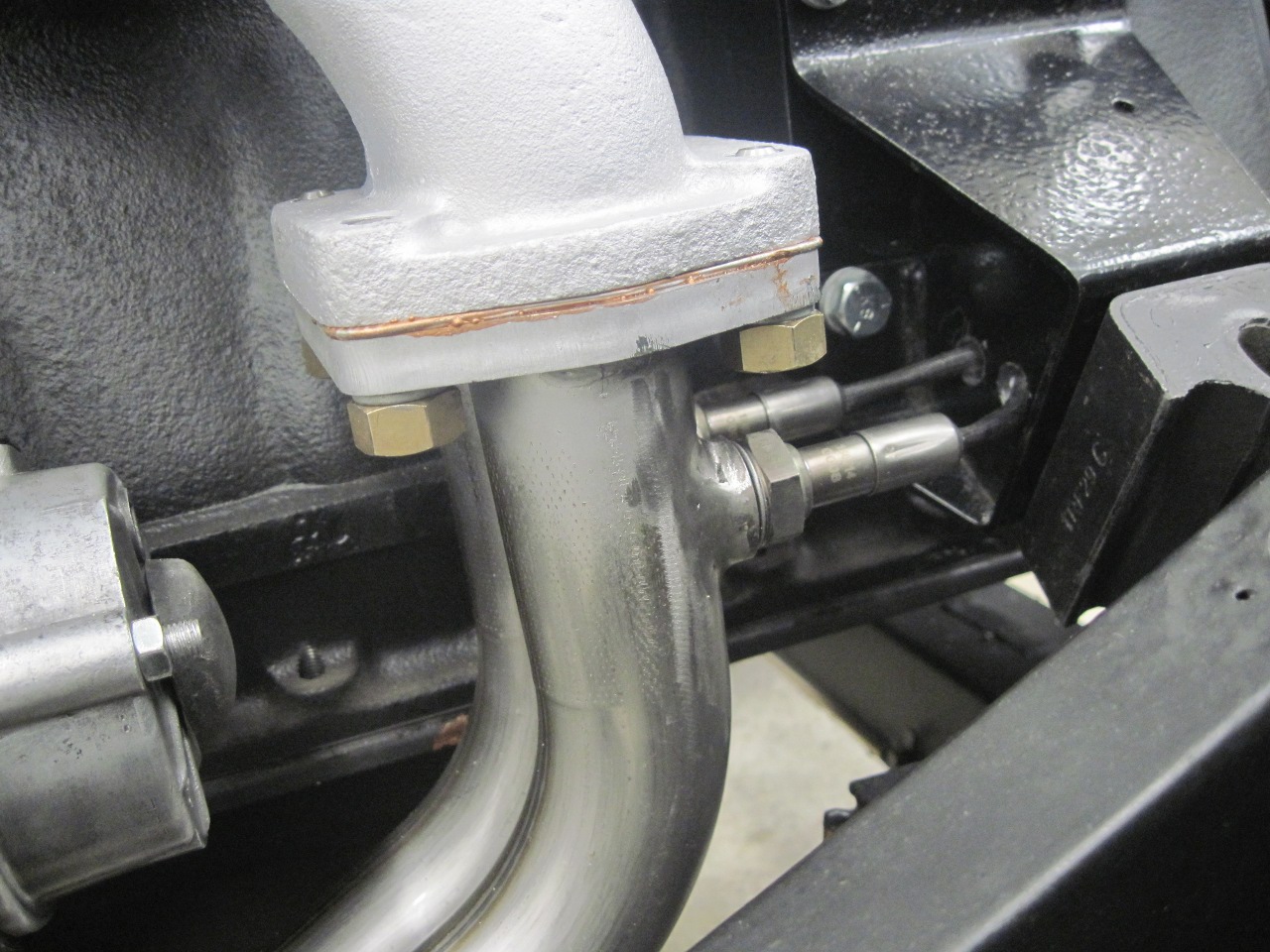

I

mounted the downpipes on the manifold and installed the sensors with

liberal anti-sieze. I decided to drill a couple of holes on the

internal web of the motor mount for the wires. I'll install

grommets, but I didn't have them on hand.

After

that, it was just laying pipe all the way to the back of the car.

The intermediate pipes were next. The stainless band clamps

provide a good seal without distorting the pipes the way that more

traditional clamps can. I found that one of the clamps, though

the correct size (1.75 inch/44.5 mm), wouldn't clamp down far enough to

eliminate motion in the joint. I had to put a layer of thin shim

stock under the clamp.

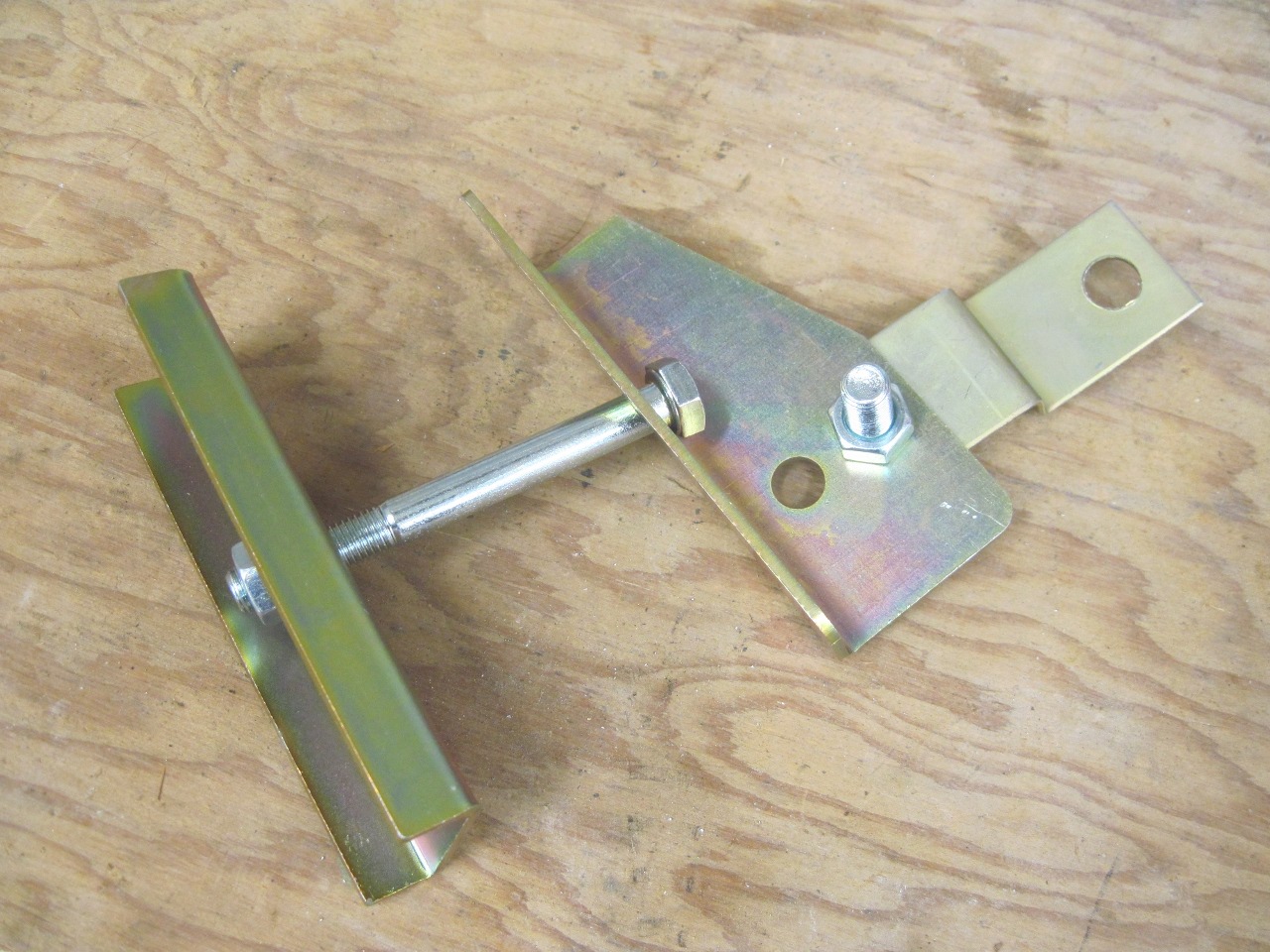

This

is the intermediate hanger. It attaches to one of the rear

transmission mount bolts. Some builders find this hanger

troublesome and just leave it out. I'll just watch it and if it

becomes a problem, I'll modify it somehow, but I want to keep its

function.

The

rear tubes take an upward jog and disappear into the tunnel between the

cruciate plates. I'm still considering whether to install some

kind of heat shield in the tunnel to keep some of the exhaust heat away

from the fuel and brake lines.

The

next hanger is where the rear pipes connect to the front of the

muffler. This hangar incorporates the clamps, so I couldn't use

the band clamps here. I did modify the clamps slightly,though, so

they could be side by side without interfering with each other.

This hanger mounts to the bridge that supports the rear of the

differential. Since I had boxed in that bridge, I lost access to

the inside where the bolt head had to go. I cut a one inch access

hole so I could get a wrench in there.

The last hanger holds up the tailpipe.

The

tailpipe seems very close to the frame tail--about 1/4" clearance.

I can probably get some more space, but this is clearly where it

wants to be. I might even fashion a rubber pad with a hanger here

so it can't thump against the frame.

Exhaust

pretty much all done, except for possible tweaking mentioned above.

I think I'll wait until the body is on for that.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages