To my other TR6 pages.

January 5, 2015

Windshield Wiper Motor & Wheel Boxes

[Click the pics for a larger view]

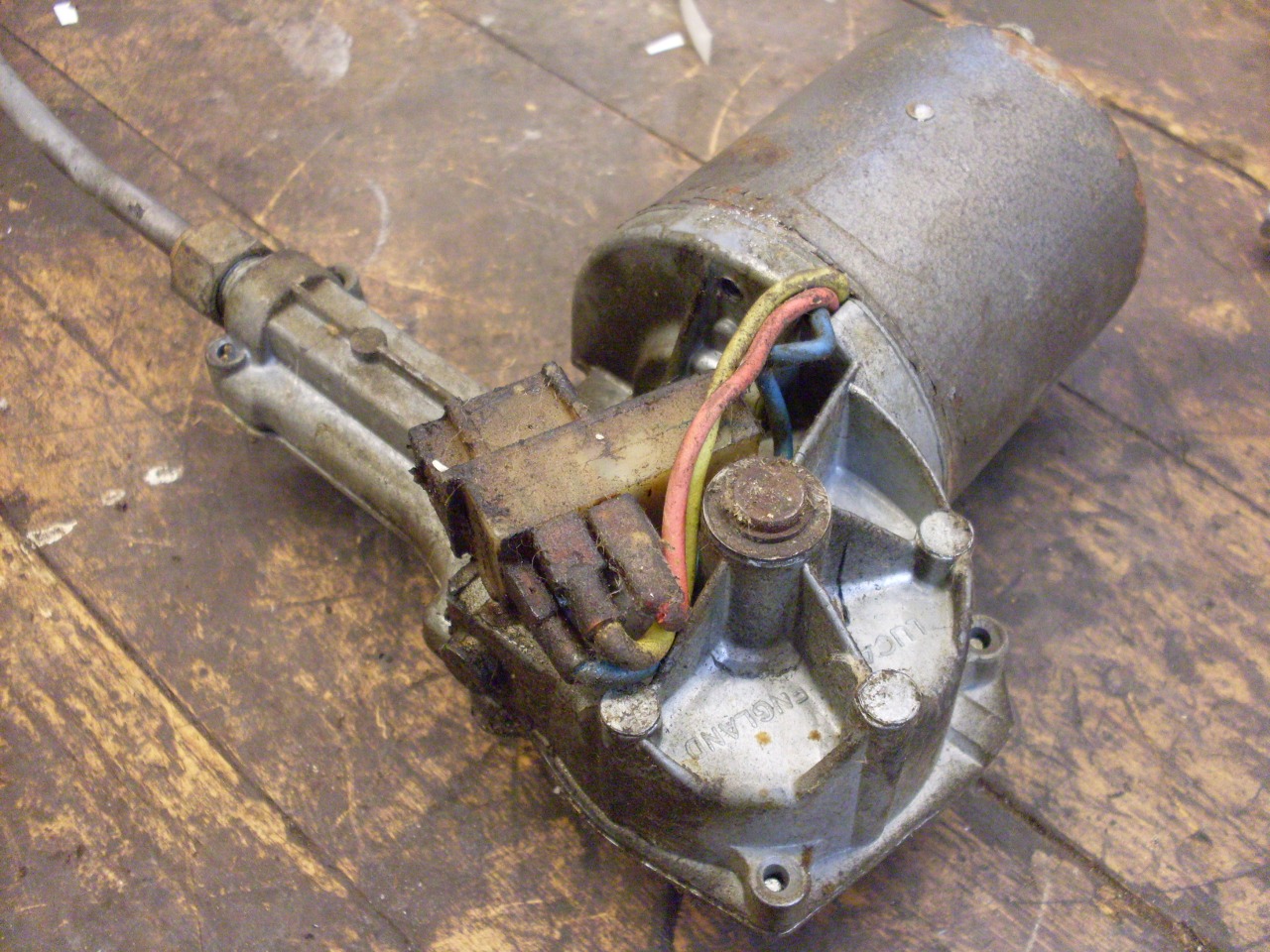

The

TR6 uses a 12 volt DC motor to operate the windshield wipers. The

motor drives an integral crank gear that moves an arm in reciprocal

motion. The arm connects to a "flexible rack" drive cable that

communicates the reciprocal motion to two wheel boxes where the wiper

arms attach.

This motor and gear assembly is used on a variety

of British cars. Mine was in working order, but old and dirty.

It seemed like a good idea to freshen up at least the internal

lubrication and whatever else might need attention.

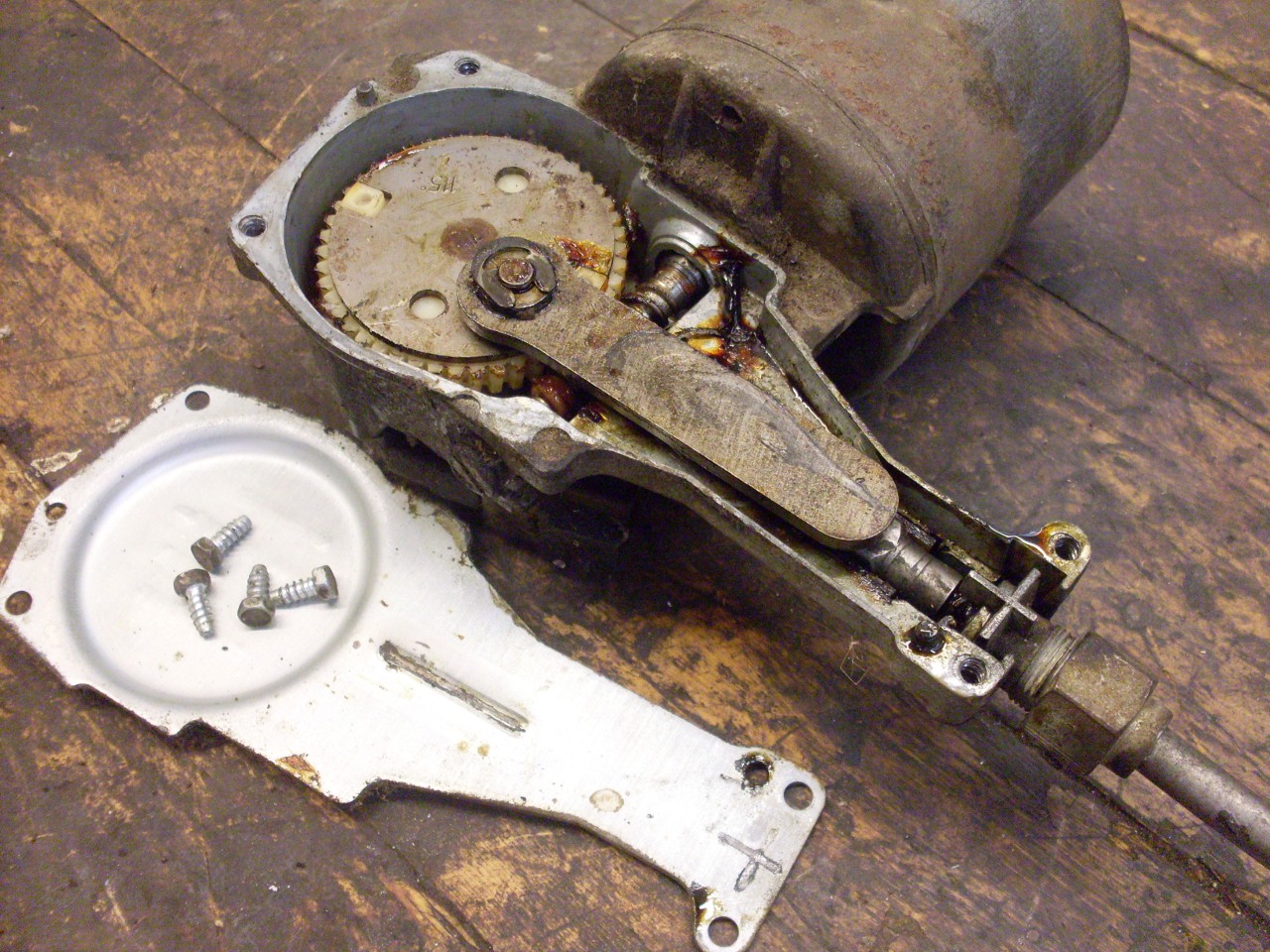

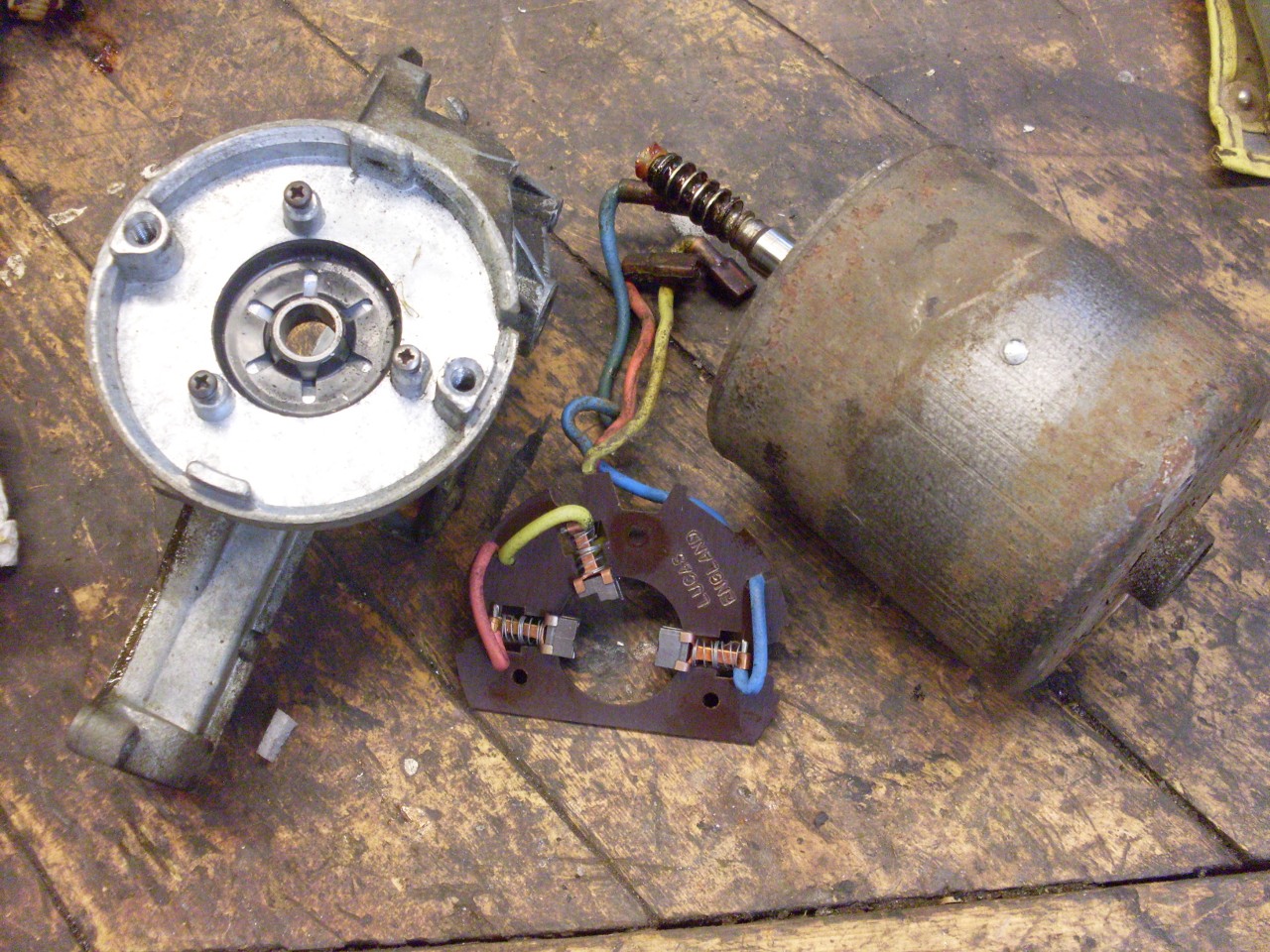

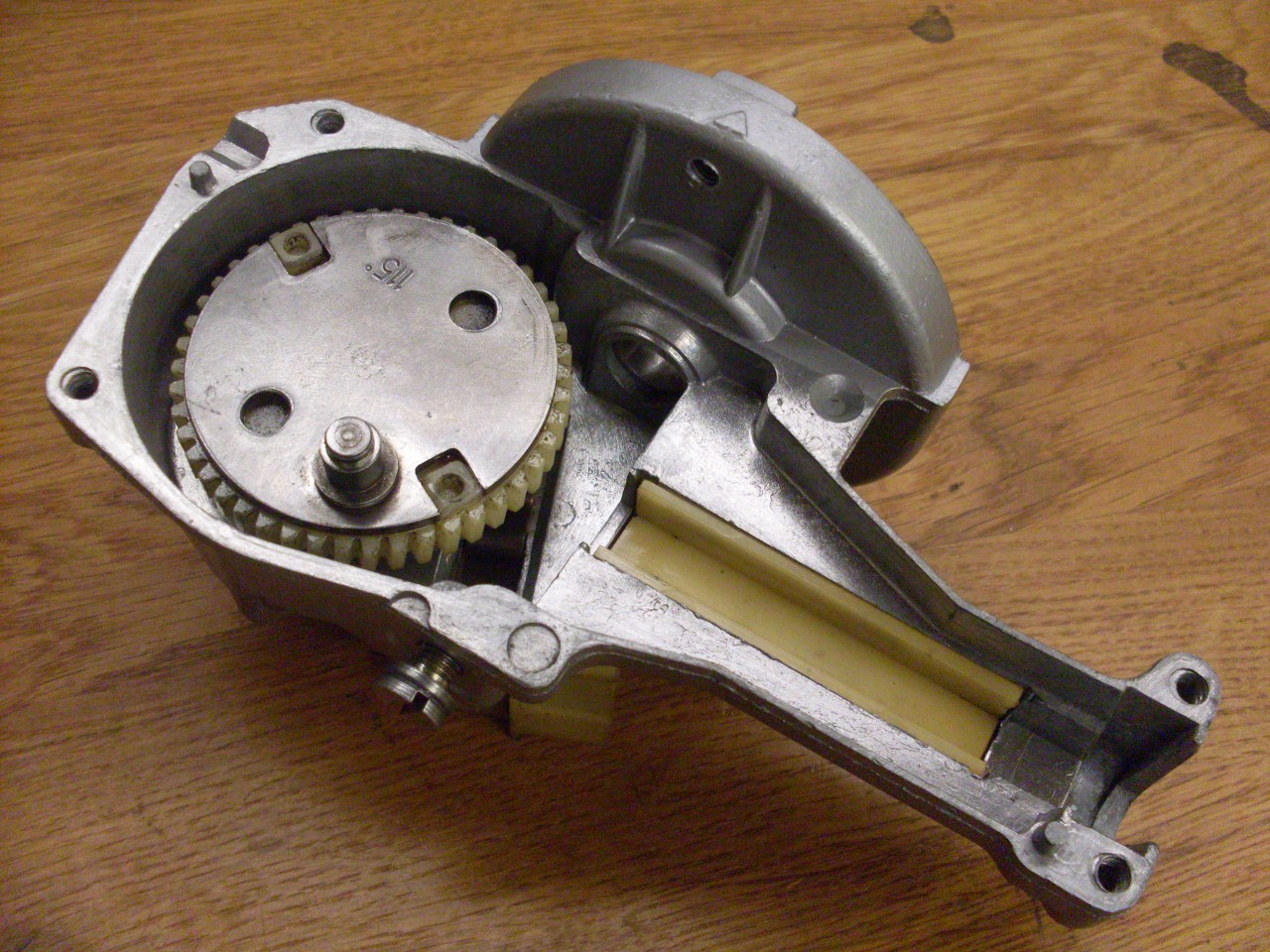

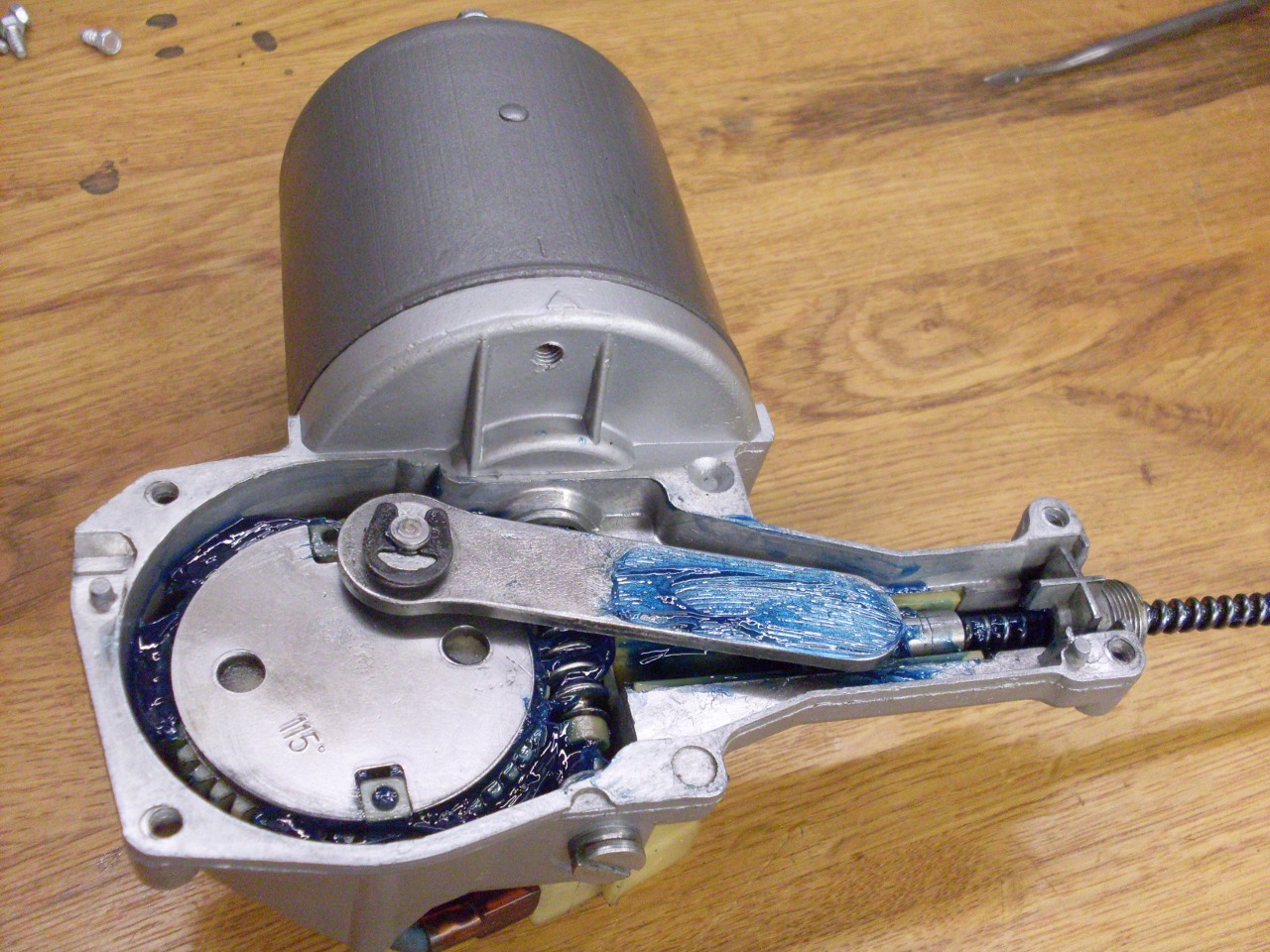

Taking

off the top cover reveals the internal mechanics of the rotary to

reciprocal conversion. A worm shaft from the motor drives a worm

wheel, which in turn drives a crank arm. The crank arm slides a

block back and forth in a nylon lined channel.

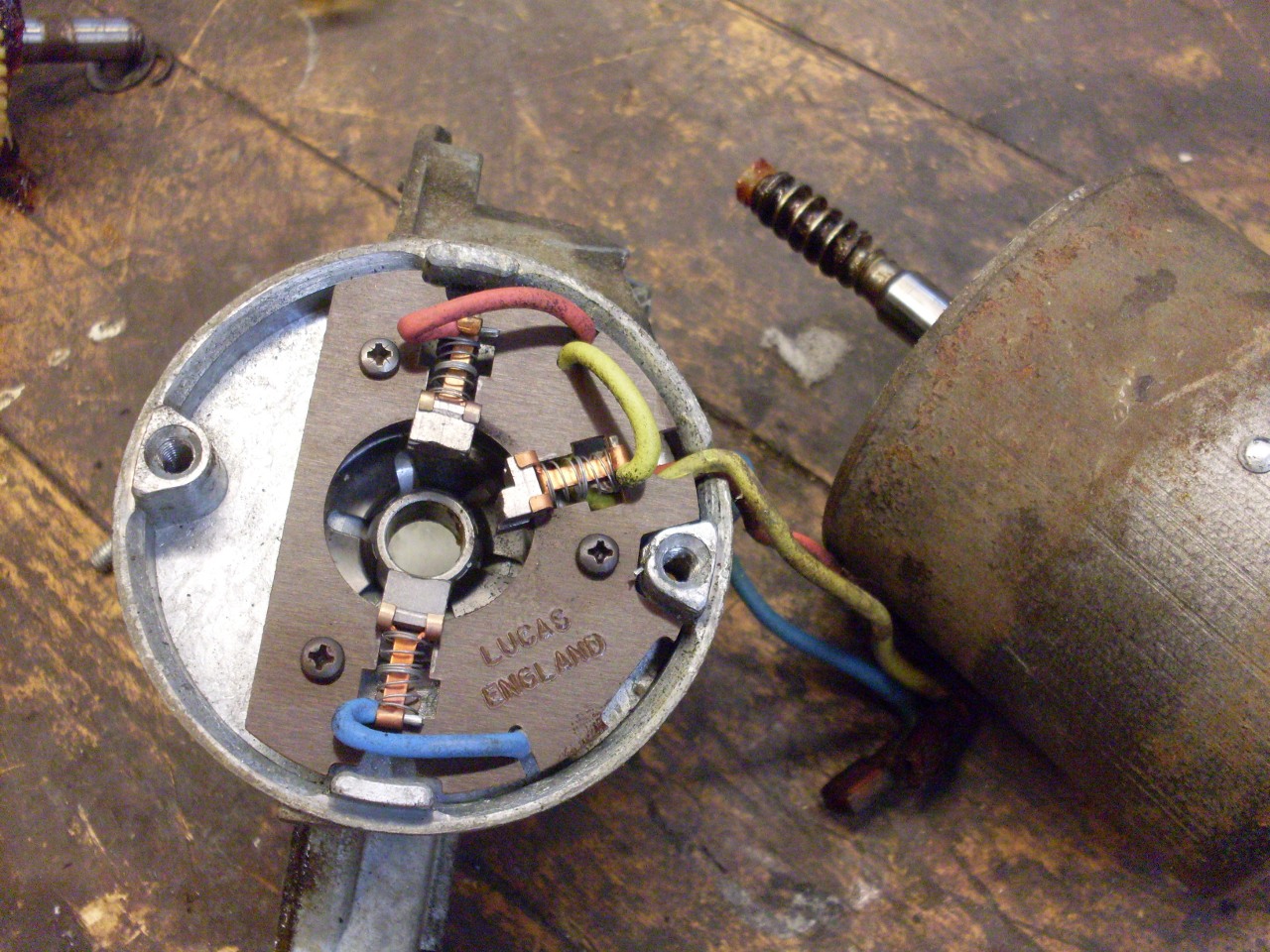

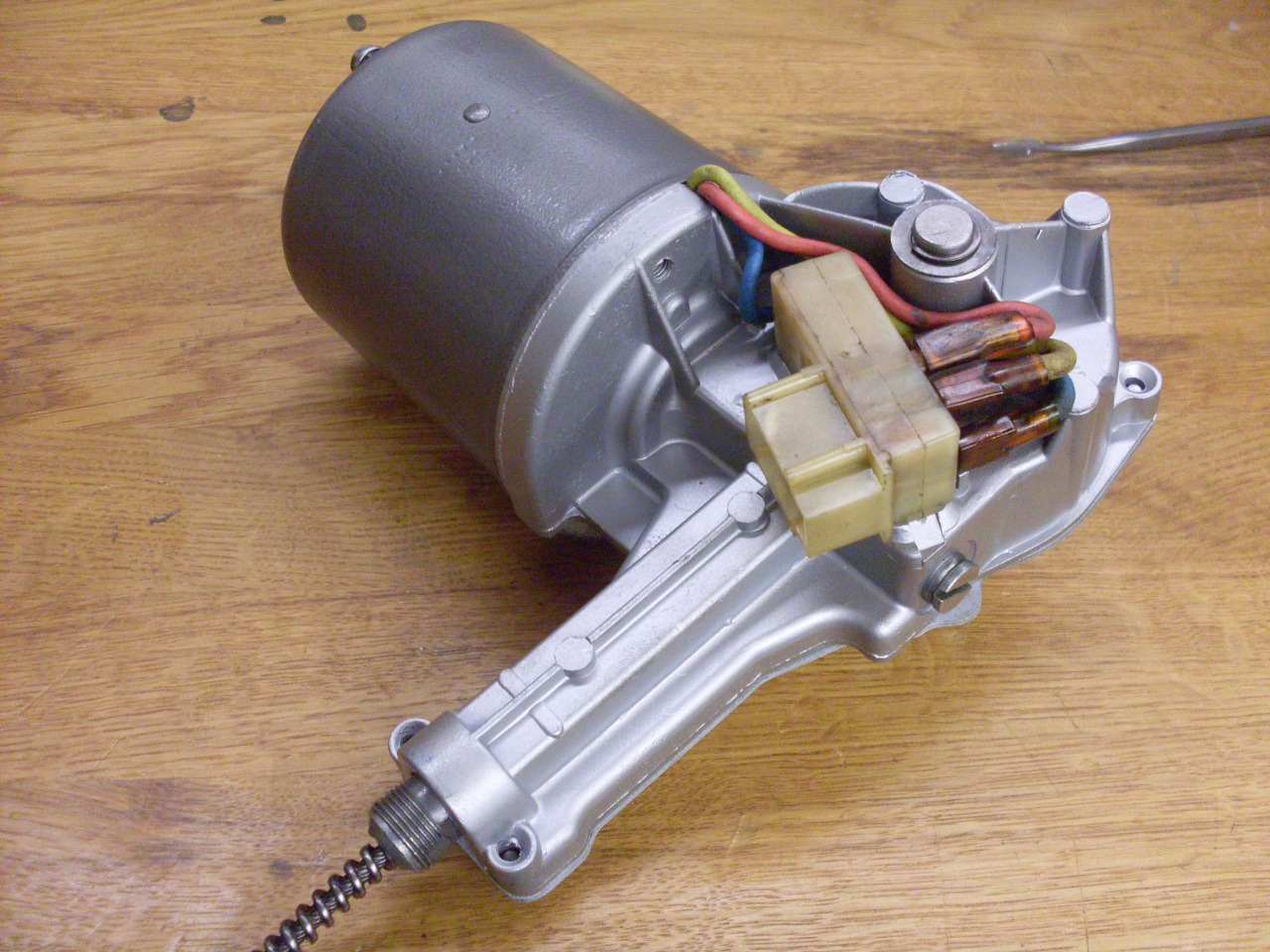

Removing

the through bolts releases the motor from the gearbox casting.

This shows the brush board. The small brush at an angle to

the others is for the slow speed.

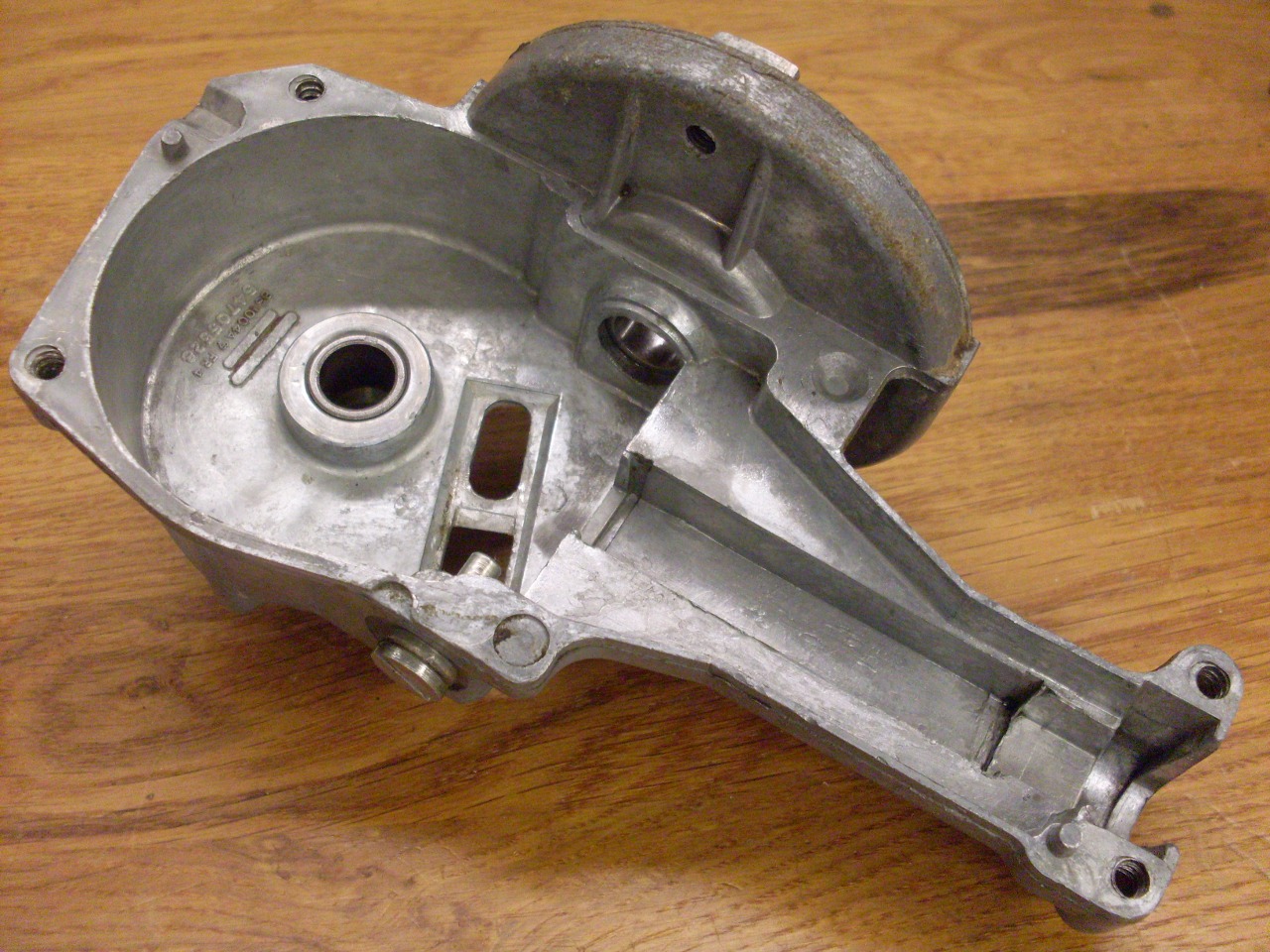

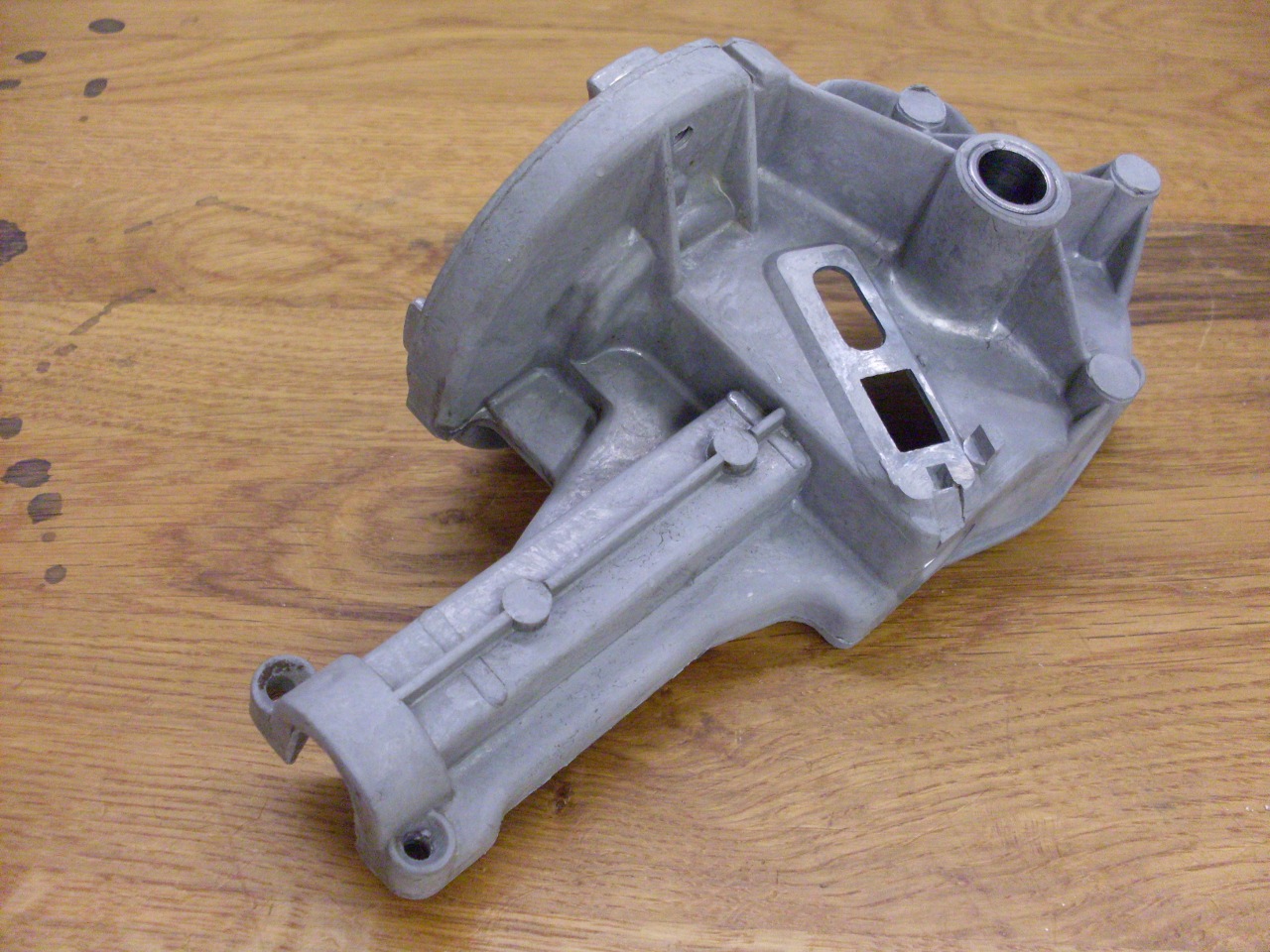

I cleaned up the main die casting and gave the exterior a light bead blast.

Before

I took the motor apart, I had ordered a new brush set. However,

the original was in such good shape, I didn't use it. My thinking

was that putting new brushes in would increase commutator wear during

the seating period of the new brushes. The original brushes were

already seated on the commutator.

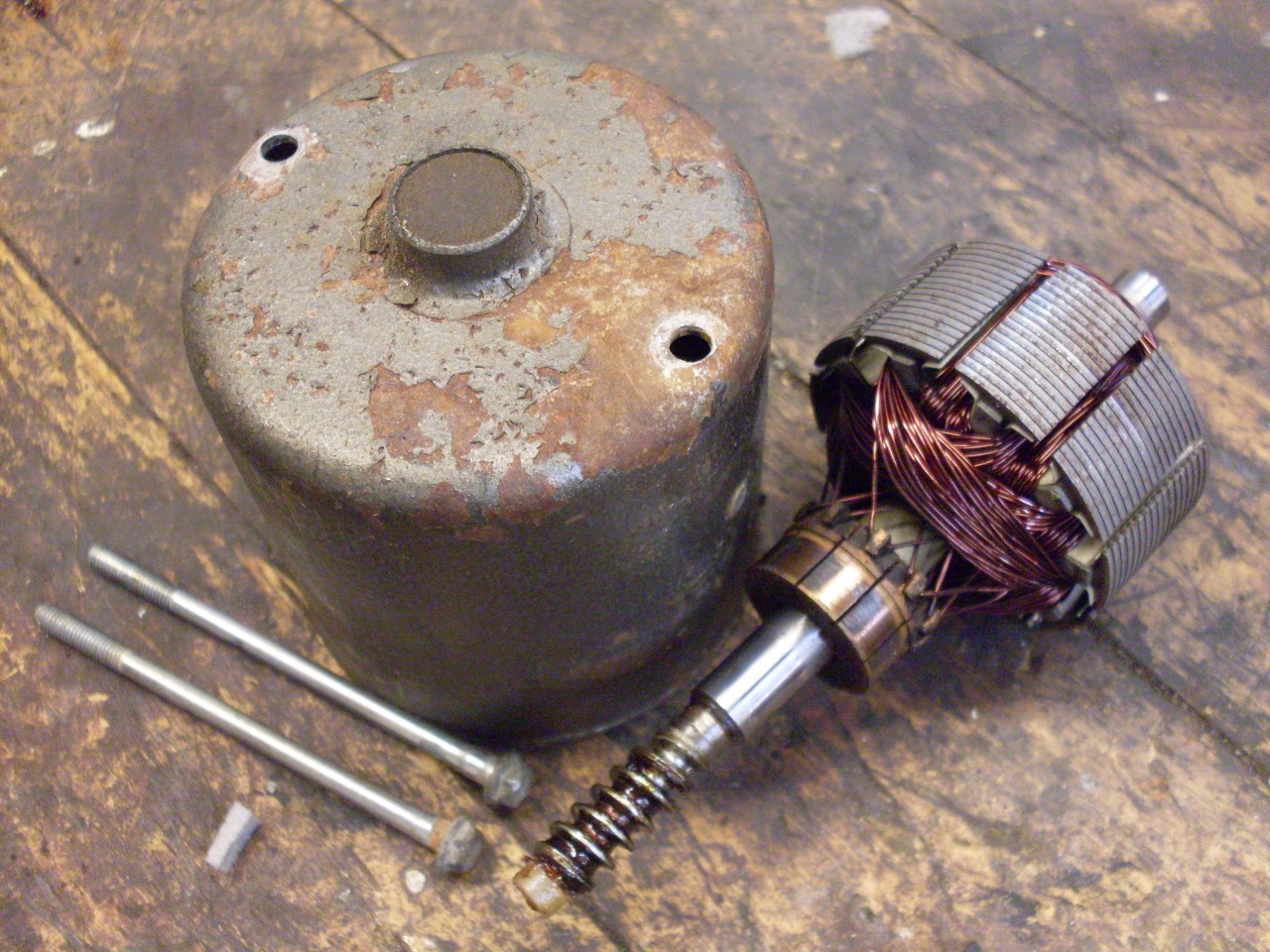

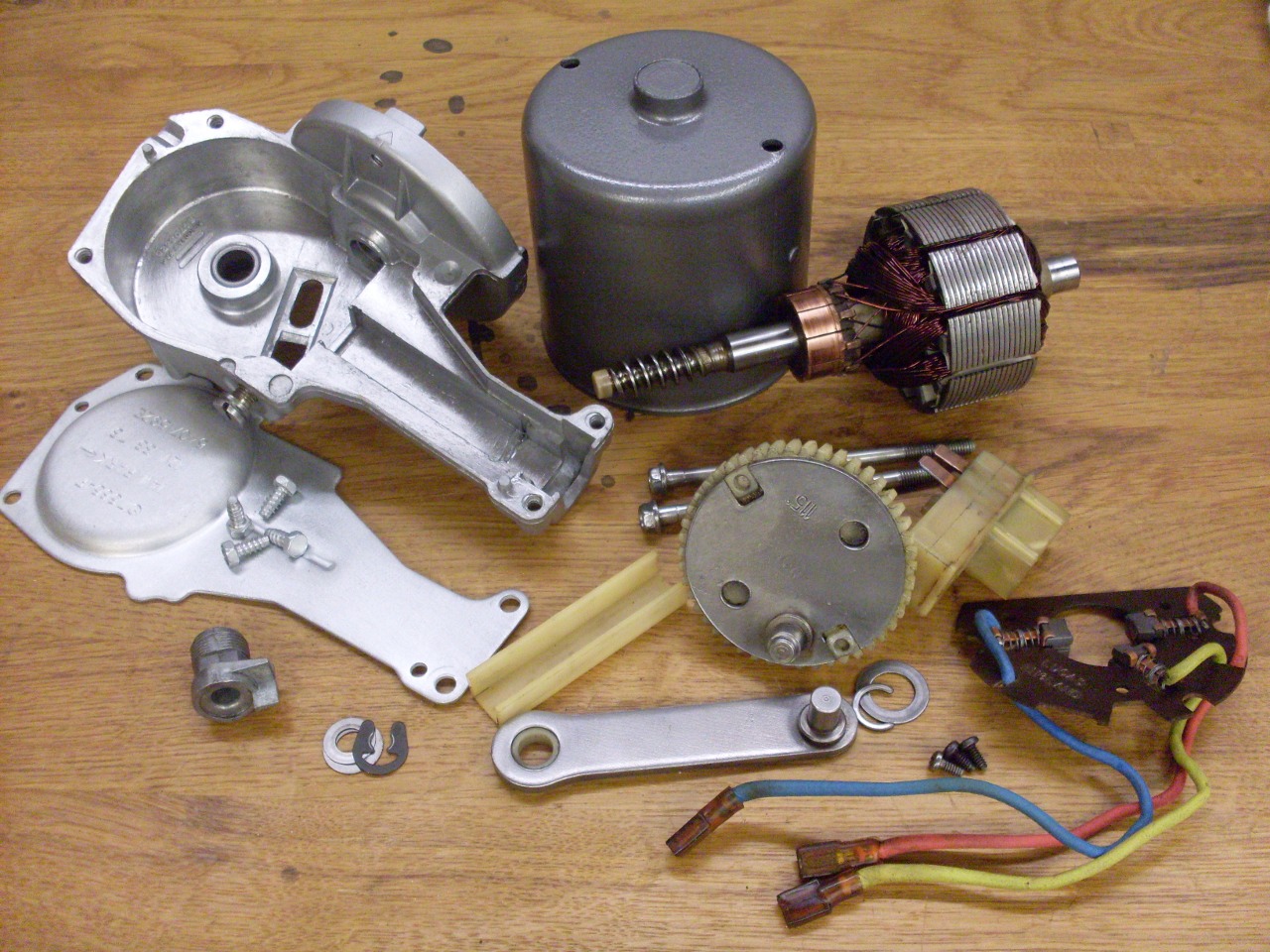

So

here are most of the parts for the wiper motor. The commutator

was lightly cleaned, the motor case and the gear case exterior were

repainted, and the gear cover was replated. All of the internal

bearing bushes were still tight and smooth, so they were just cleaned

and re-lubed.

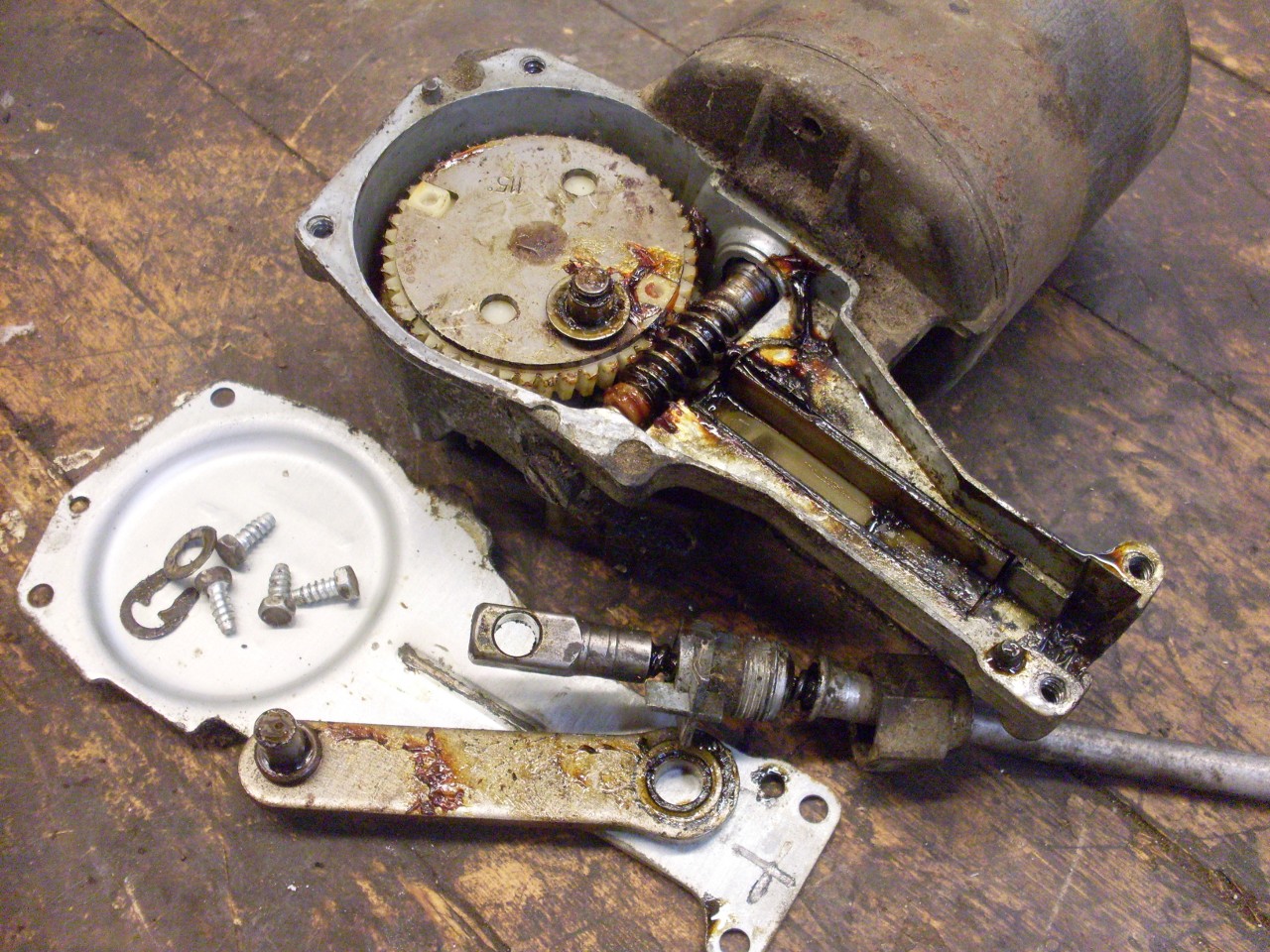

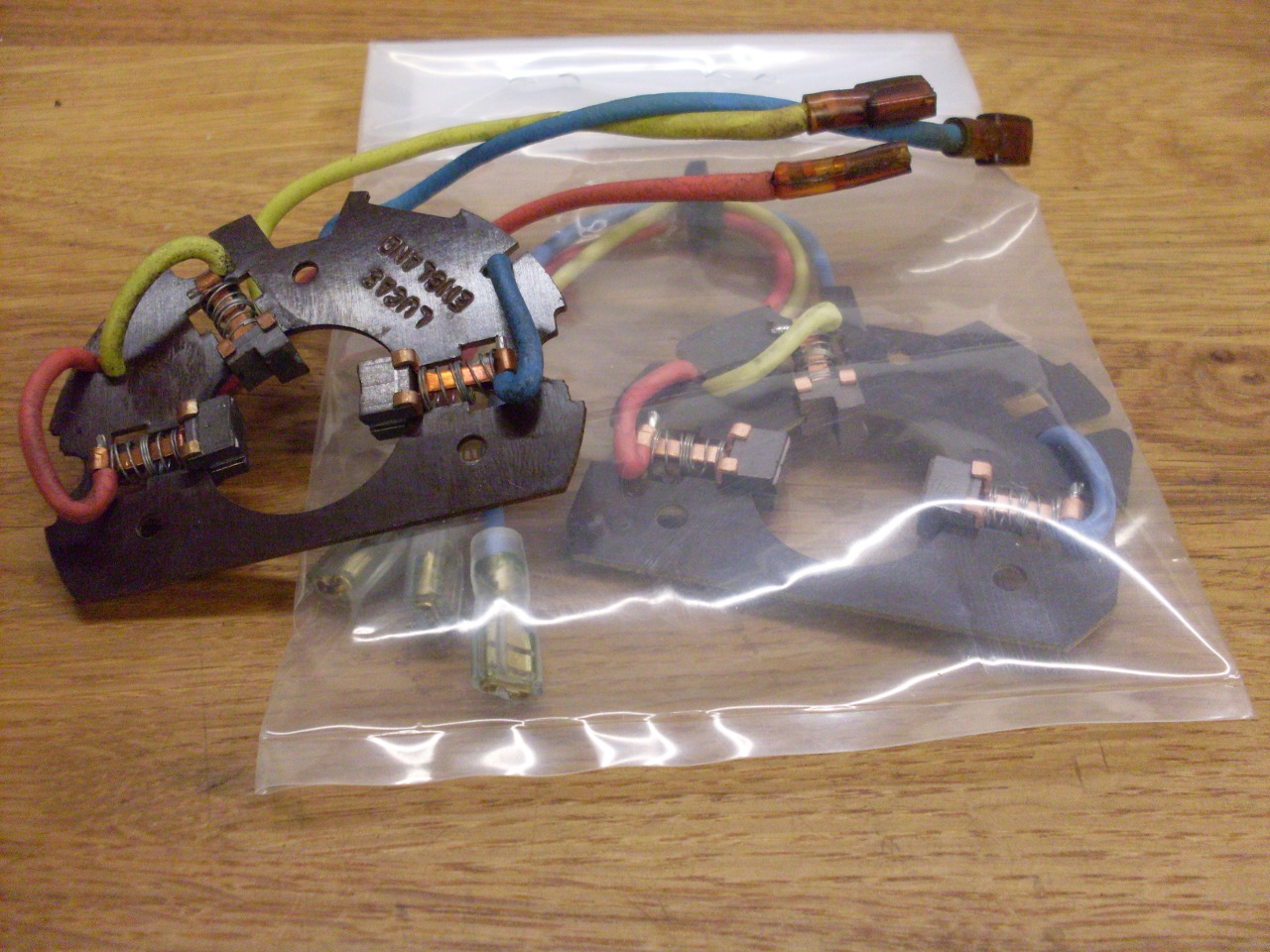

This

is the wiper park switch. It is a switch operated by a cam on the

worm gear. When the wiper switch on the dashboard is turned off,

the park switch keeps the motor energized until the wipers are in their

"parked" position.

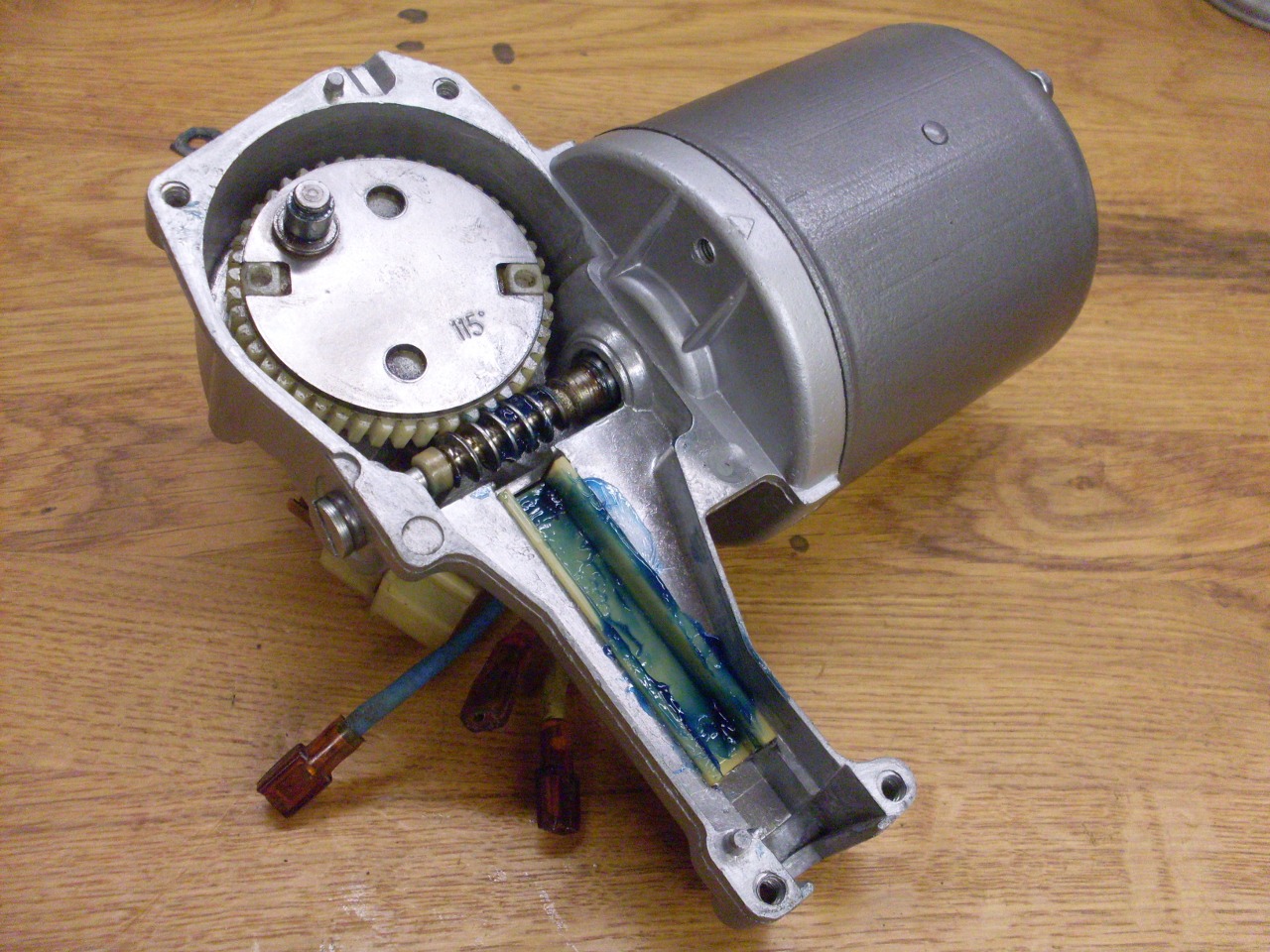

The plastic track that the reciprocating block rides in was still in good condition.

I mounted the motor and the rest of the mechanics...

...and buttoned her up.

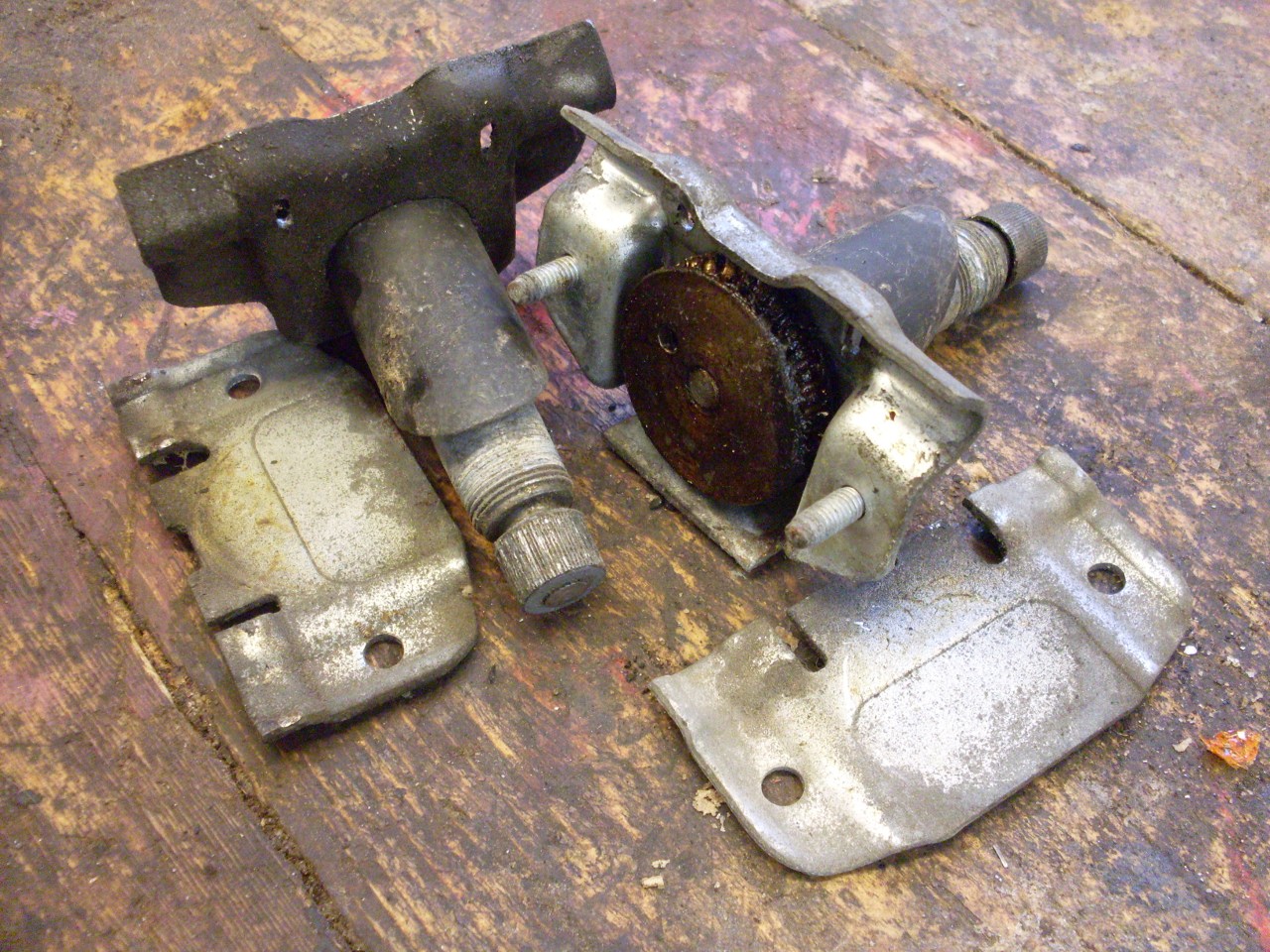

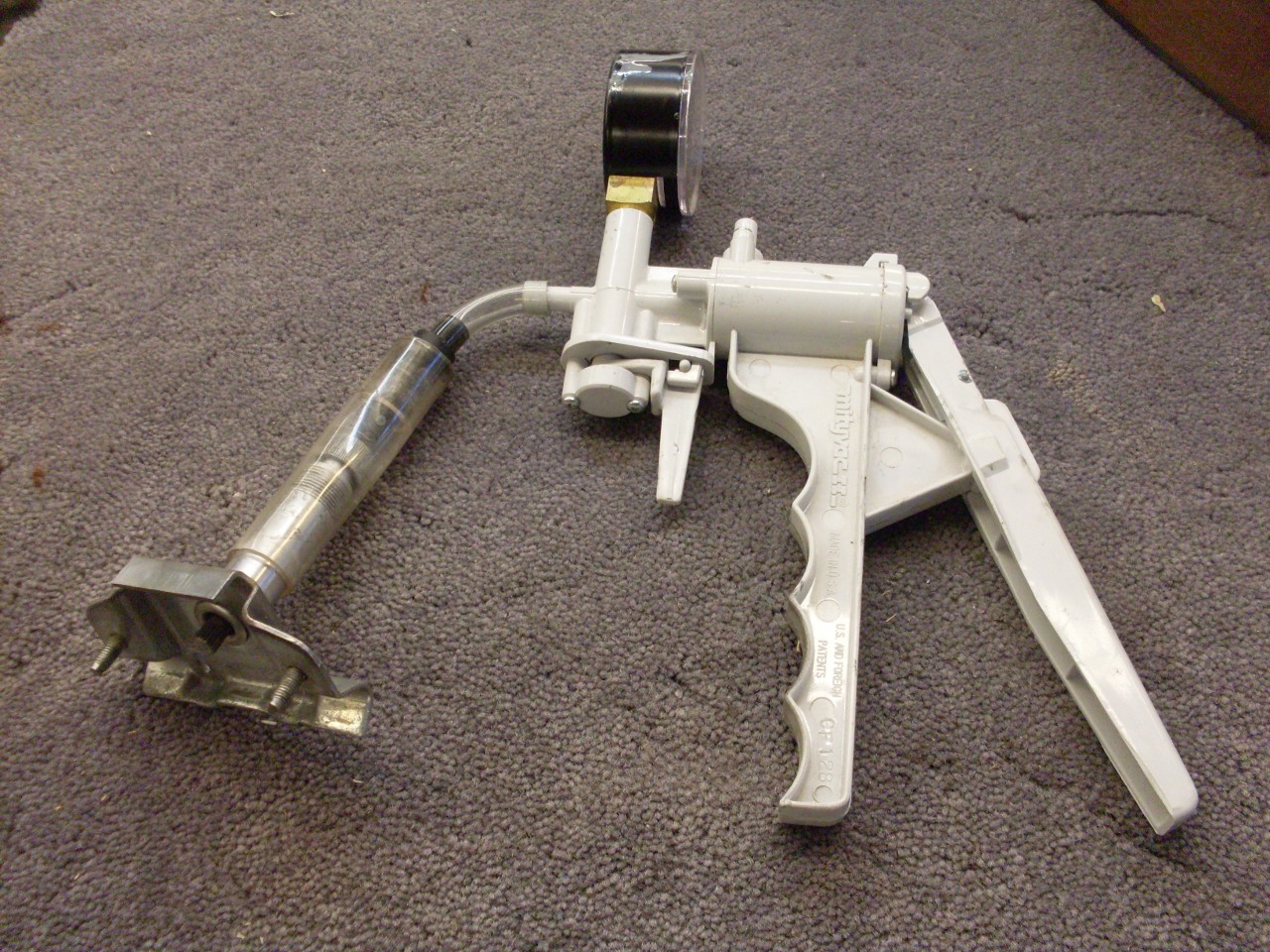

Then

there were the wheel boxes. I had a hell of a time removing them

from the car, mainly because the chromed nuts holding them in the

cowl were seized. I ended up cutting the nuts off, but not before

I'd done a good job twisting the guide tubes for the drive cable.

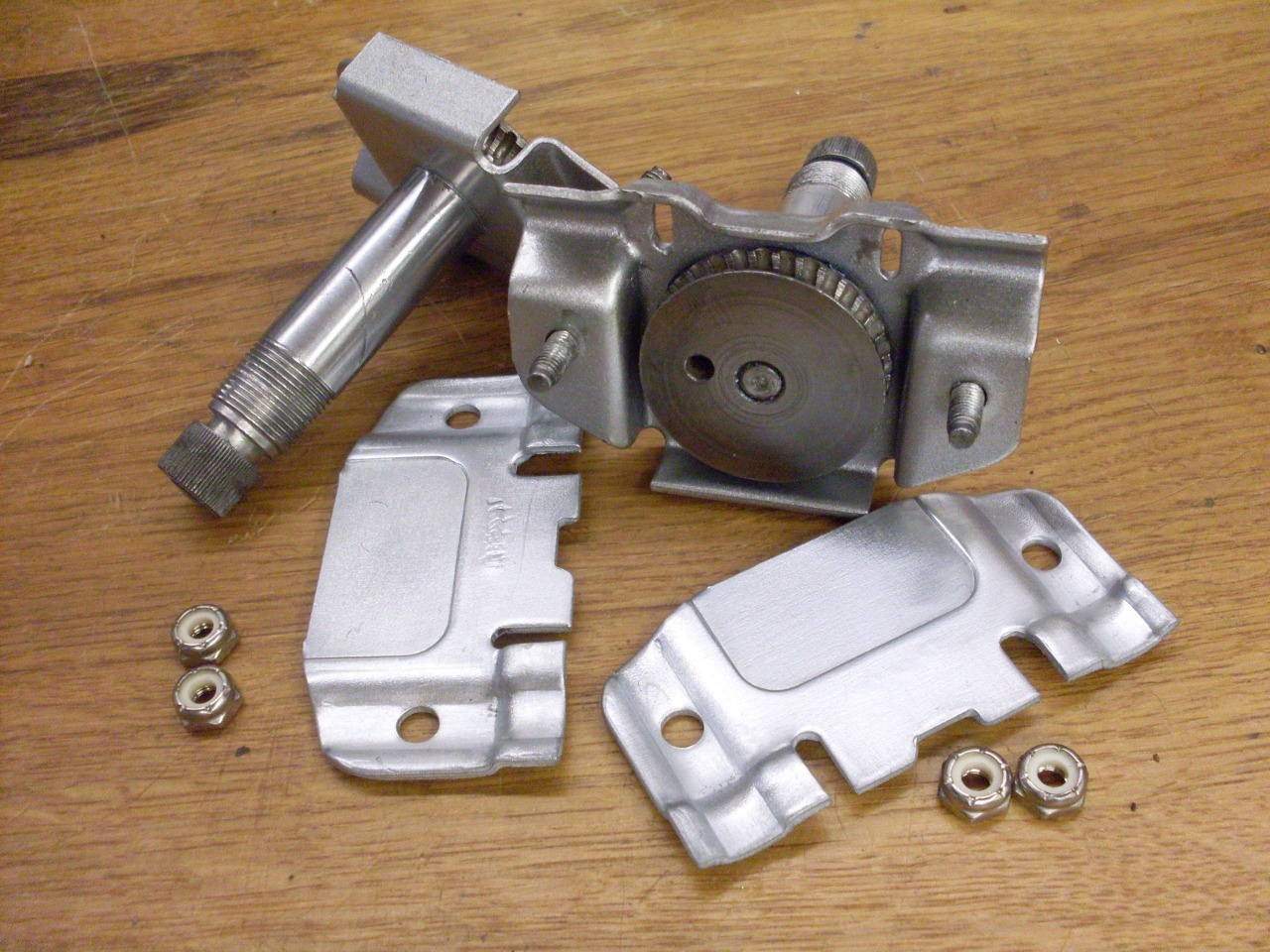

The

wheel boxes themselves consist of a special wheel that mates to the

drive cable like a pinion to a rack. The wheelbox housing carries

the shaft to the wiper arm connection, and a plate to clamp the guide

tubes in alignment with the wheel.

The

wheel boxes were rusty in places, and I wanted to remove the shafts

from the wheel boxes so I could replate the boxes and properly

lubricate the shafts. When something isn't designed to be

disassembled, it doesn't mean you can't take it apart. On the

other hand, just because you can take something apart, it doesn't mean

you should.

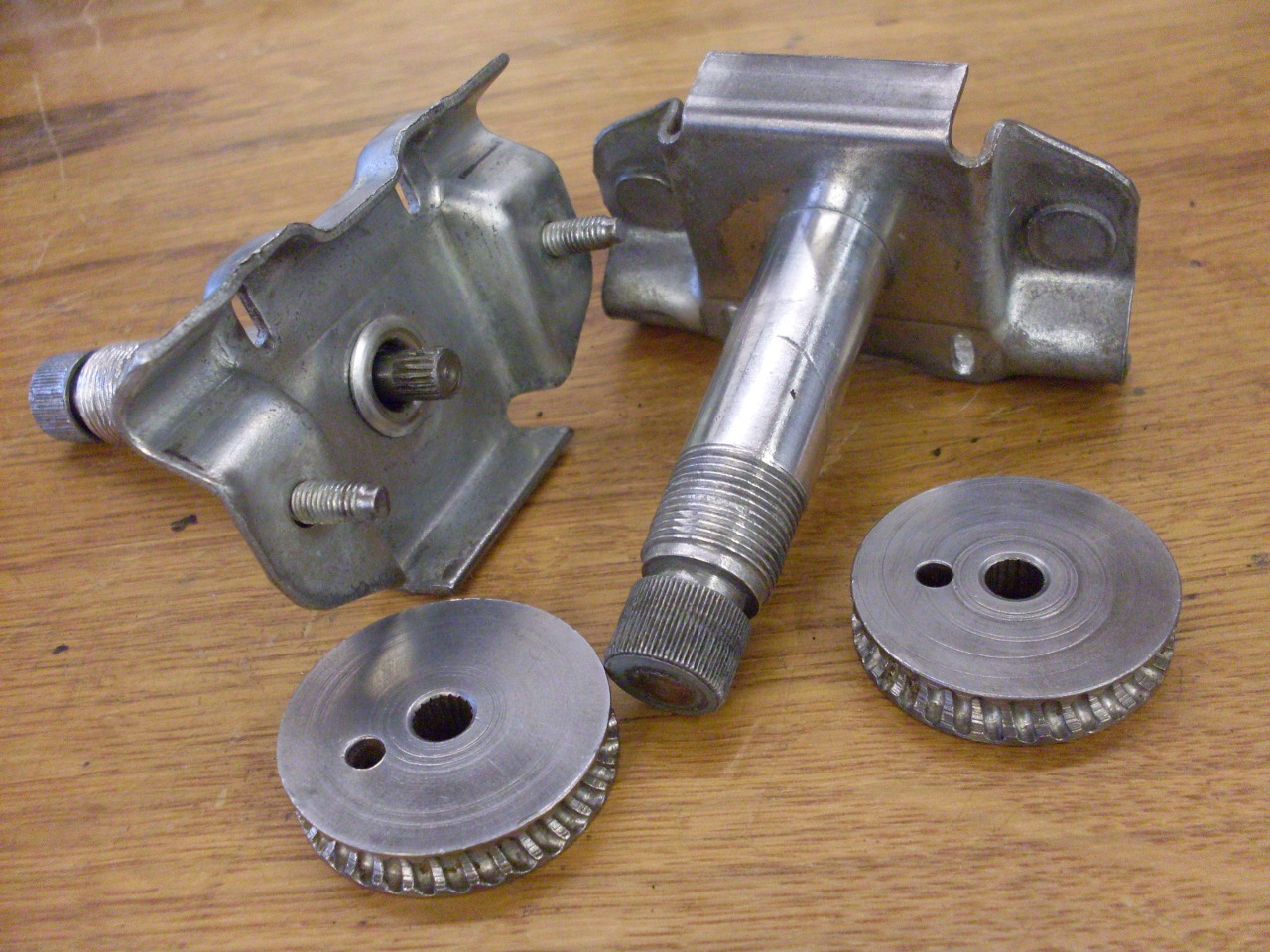

I assumed that I could remove the wheels from

the shafts, and the shafts would slide out. This turned out not

to be true. I got the wheels off, bit the splines on the shafts

were bigger than the shafts. These must have bee assembled by

putting the wheels on the shafts, then sliding the shafts in place, and

staking the wiper arm mounts to the shafts.

Removing the

wheels did make it easier to clean out the old dried up grease behind

them, and to flush out the shaft bore with solvent, so maybe it was

worth it.

Since

I washed all of the lube from the bores, I used this vacuum pump

contraption to suck grease back into the bores with the shafts in place.

Then

made some new guide tubes by putting double flare ends on 5/16" brake

line. I initially forgot the little short tube at the far

end of the cable. I had to make that later. The tube with

the connector nut has to be bent, but I'll do that when I install the

wiper system.

I

painted the wheel boxes, plated the covers, relubed the

shafts, pushed the wheels back on, and did a trial assembly and

test. Everything seemed to work quietly and smoothly..

Total

cost for this project was pretty small. I did buy the brush set,

but didn't use it. The brake line for the guide tubes was

about $6. I still have to buy the chrome nuts I destroyed, and

the plastic housings for the washer nozzles appear to be toast, but

those will come later.

Comments to: elhollin1@yahoo.com

To my other TR6 pages.