To Other TR6

Pages

November 22, 2014

Differential

[Click the pics for a

better view]

I've

always been terrified of differentials. I was intimidated by all

the ominous warnings about the specialized tools needed, and the

very precise clearance and preload specs. For this project, I

decided

to suck it up and at least dig into what I'd need to tackle the job.

The manuals I had didn't really ease my trepidation much at

first. Some of them started off by advising against

attempting

the rebuild, and then launched into a bewildering series of complicated

steps.

I persevered, though,

and finally deciphered and

understood the logic behind the processes. With better

understanding, I was pretty sure I could devise substitutes for the

factory tools, and have a better than even chance of being

successful. So

here is the story of this journey.

The TR6 differential is a 70 pound lump of cast iron crammed with beefy

gears and bearings. It is mounted in a fixed

position on the frame, and delivers power to the rear drive wheels

through articulated half axles.

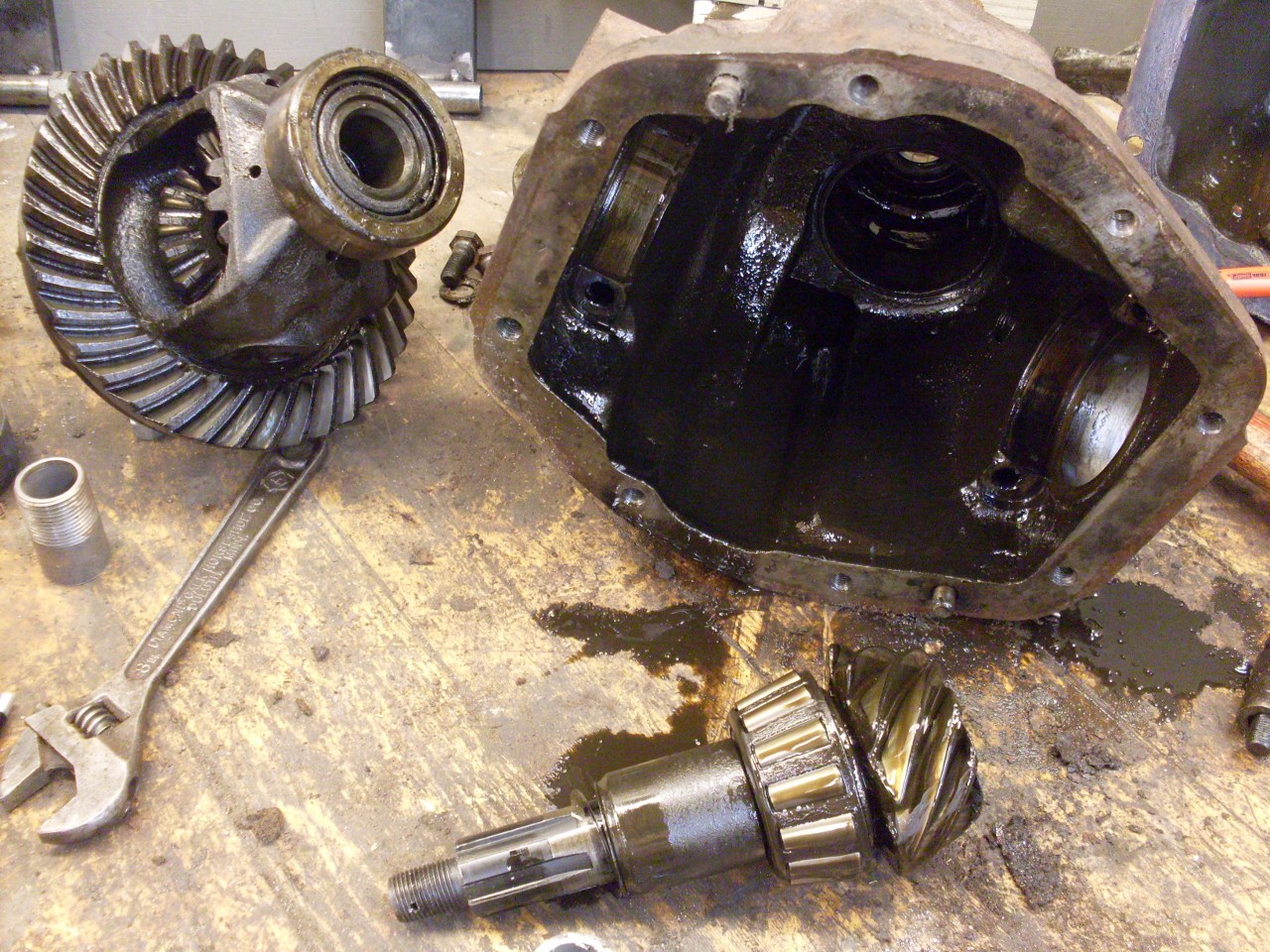

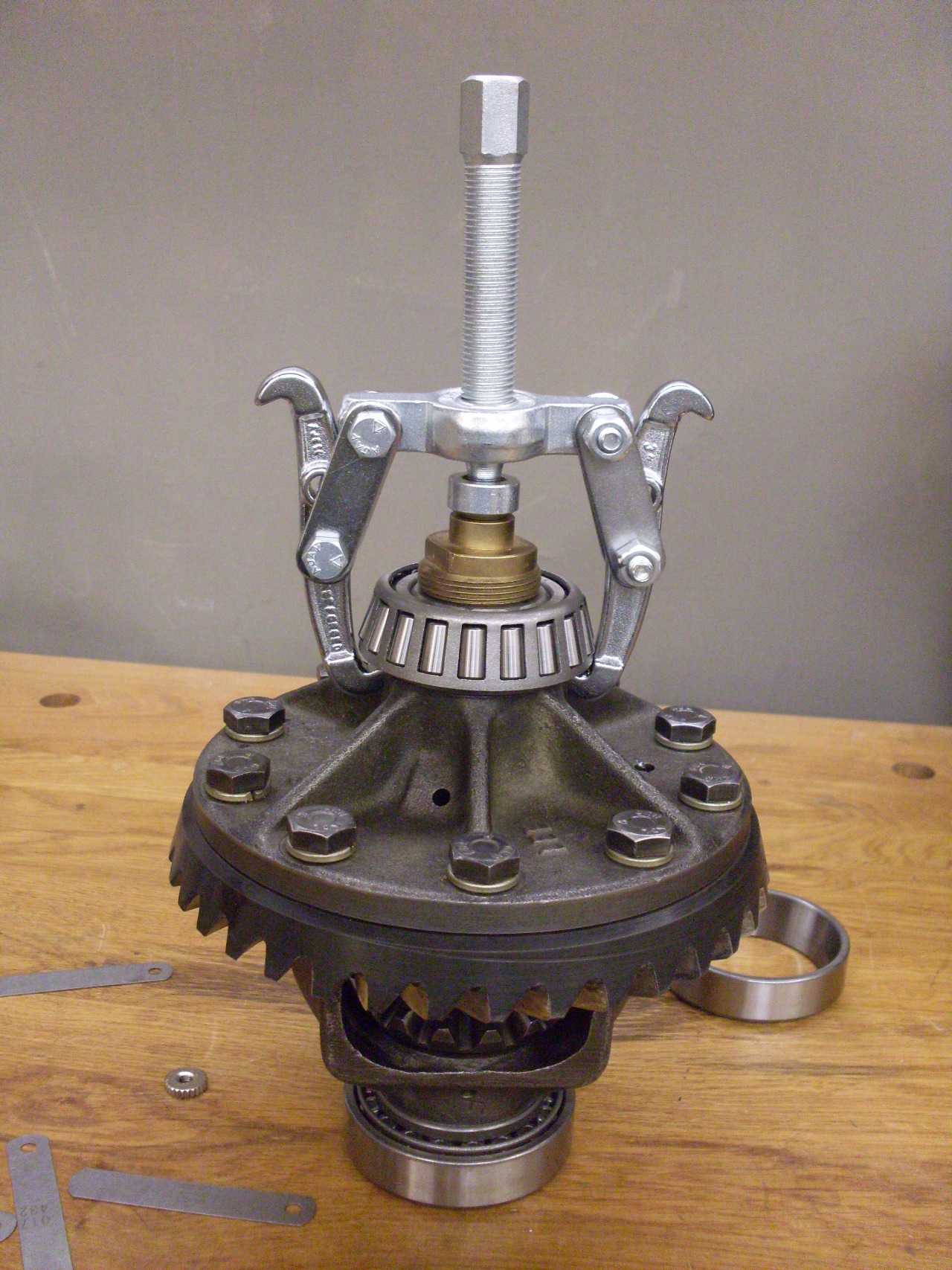

Disassembly starts with

removing the rear cover and the inner axle shaft assemblies.

Inside, we find a 37-tooth crown wheel driven by a 10-tooth

pinion still hidden deep inside. These two gears provide a 3.70

gear ratio, proving my Haynes manual, which claims the ratio is 3.45,

wrong.

The

inner differential carrier assembly is what allows the two rear wheels

to turn at different speeds. It is held in place with two bearing

caps. The manuals say to heed the markings on the caps and

matching ones stamped onto the case flange to ensure they go back in

their original positions. I assume this is because bearing

pockets in the housing were machined with the caps on place.

On

my unit, which I'm pretty certain has never been apart before, the caps

were reversed, judging by the markings. The markings on the

other

side are the reverse of that in the pic ("4" on the cap and

"7" on

the housing flange).

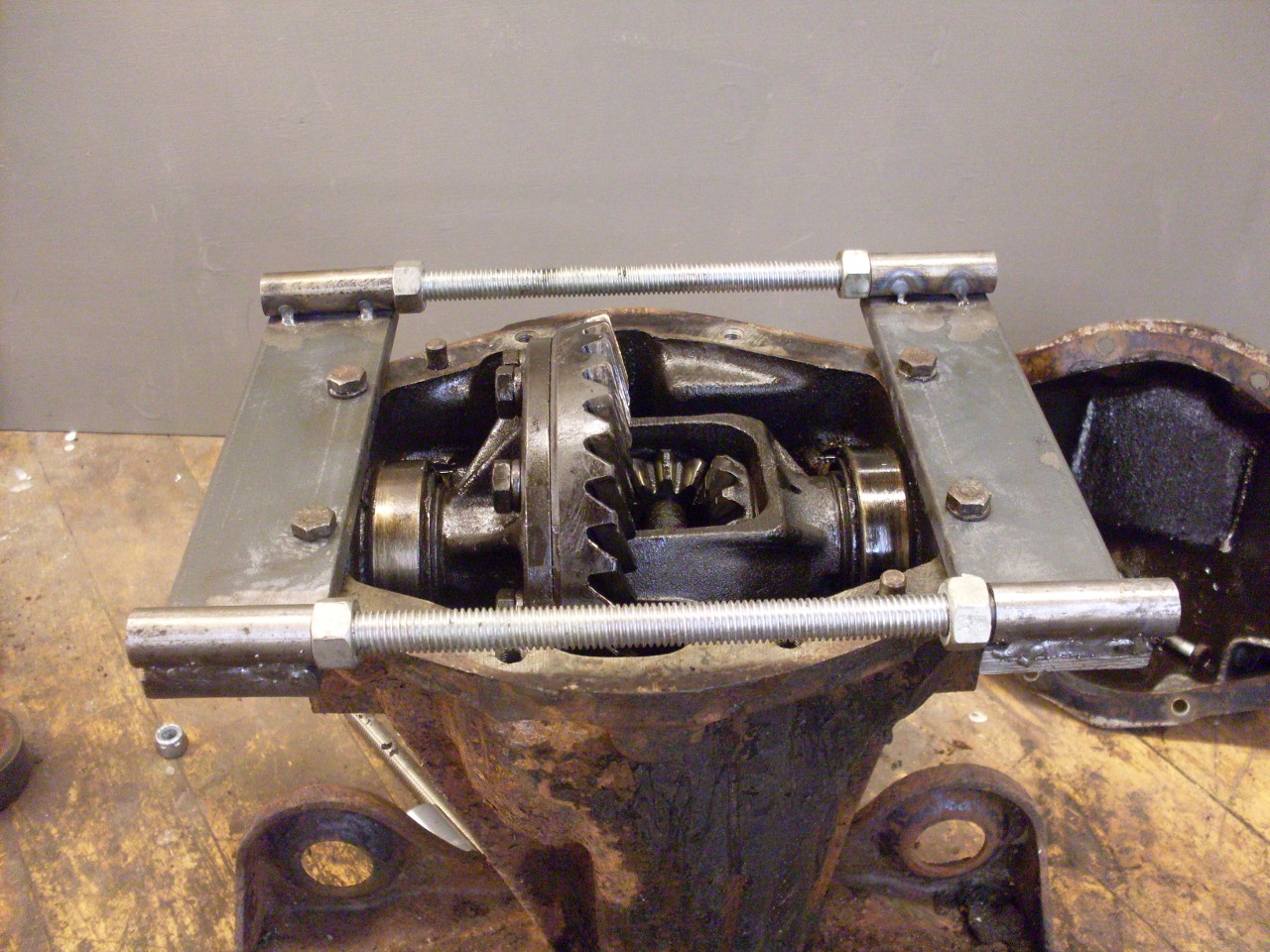

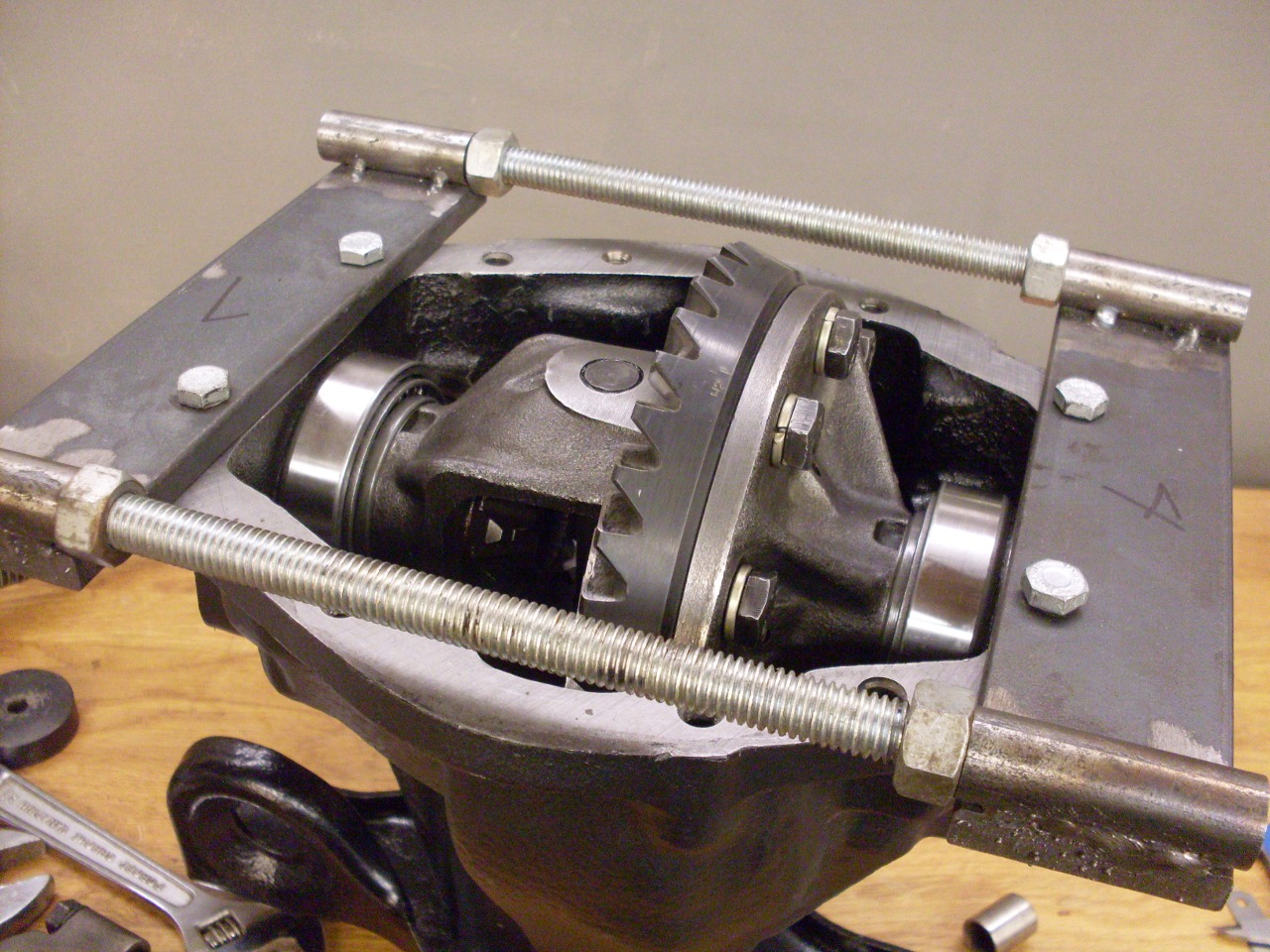

After

the caps are removed, the differential carrier still won't come out

because it is "pinched" in the case with an interference fit.

This effectively preloads the differential carrier bearings

so

there is no play. To relieve the preload and unpinch the

differential assembly, the case has to be stretched. There is

a

factory tool for this, but many rebuilders fabricate their own.

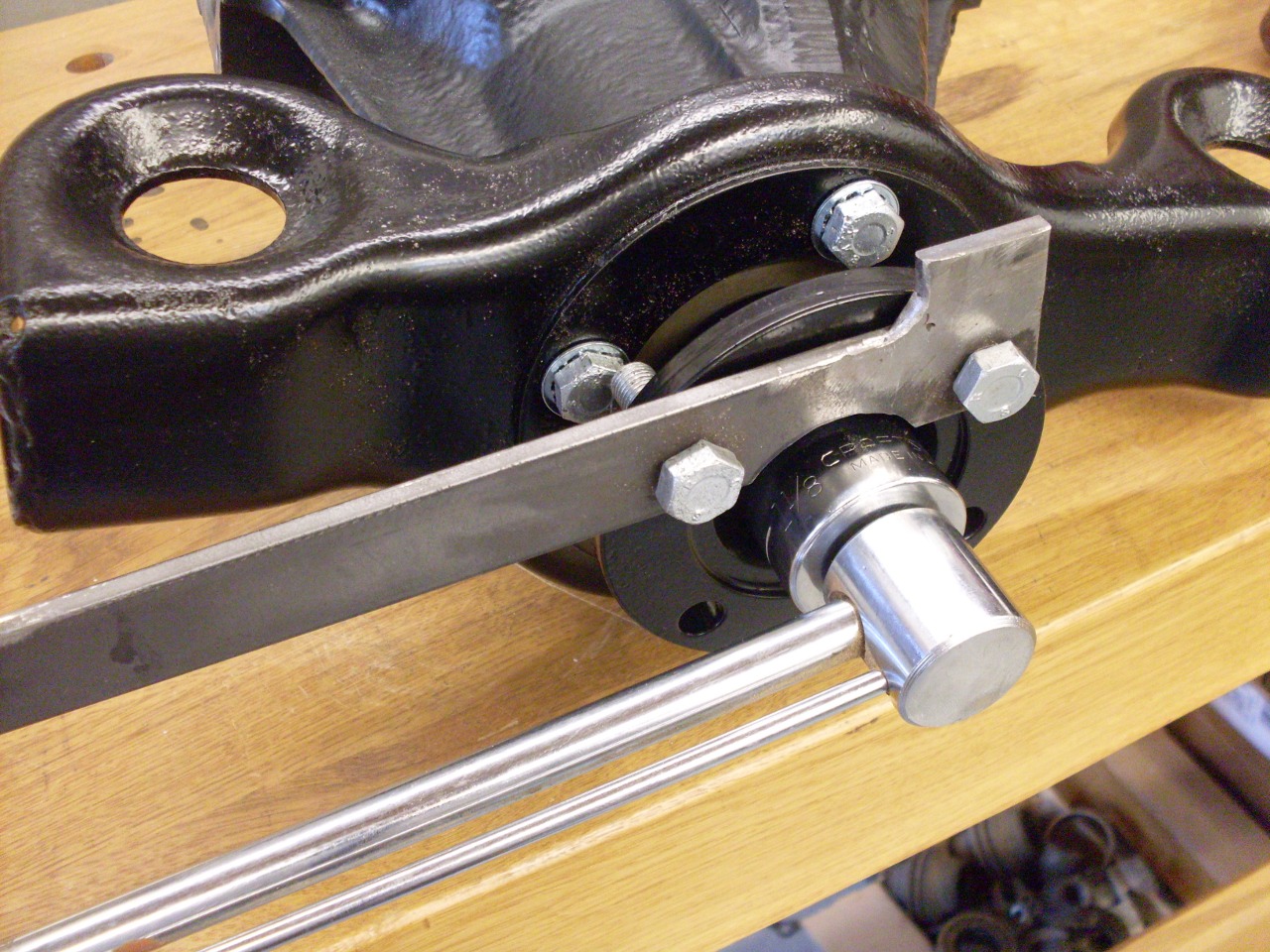

Mine consists of a bar screwed to each end of the case, and

some

threaded rods arranged so that turning nuts on them forces the bars

apart. The tool only has to distort the case by a few

thousandths

of an inch. When it does this, the differential caririer can

be

pulled out.

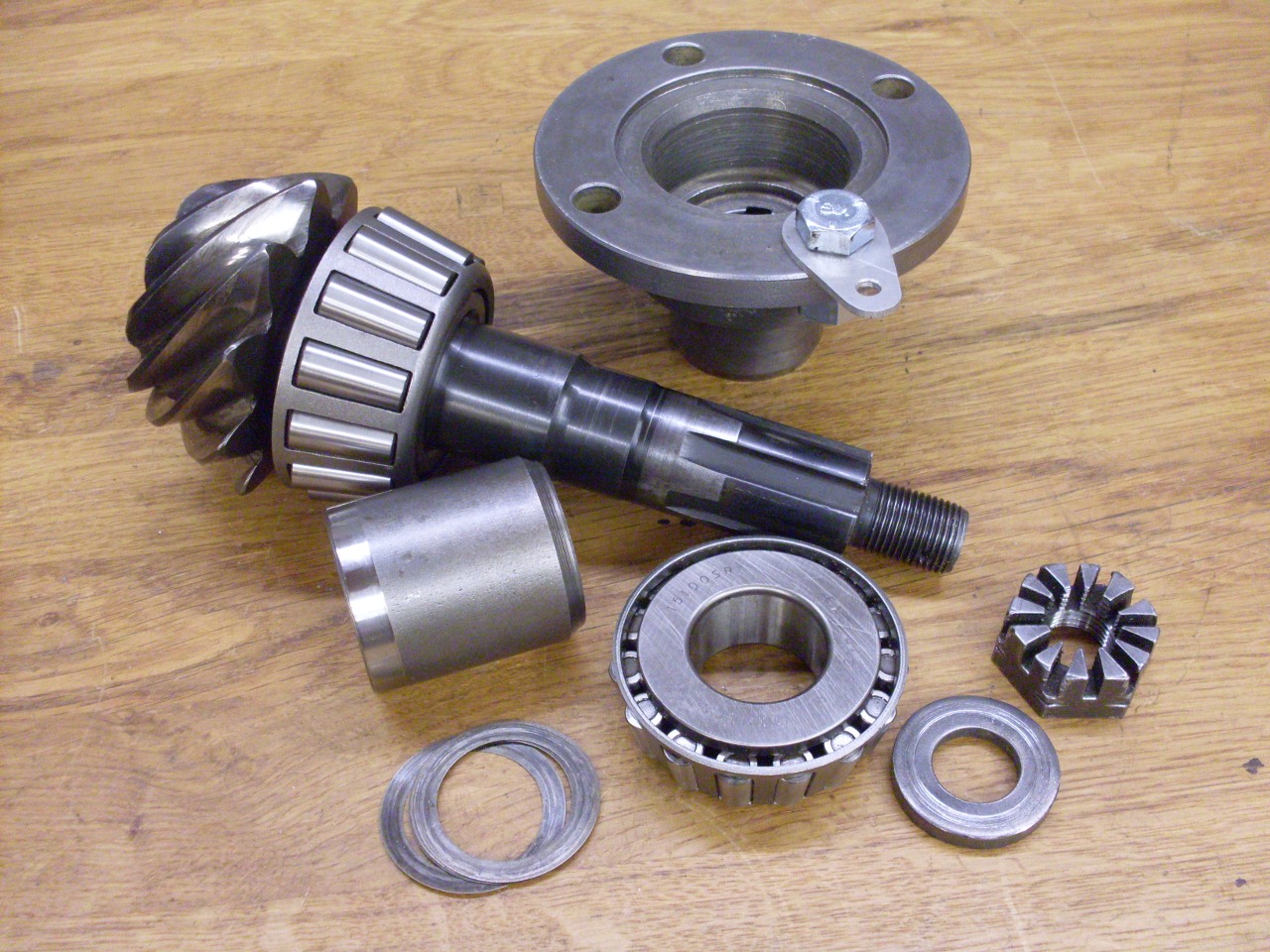

The next major part in the case is the pinion gear. It runs

in

two good sized tapered roller bearings, and can be pressed or

tapped out

after the drive flange is removed.

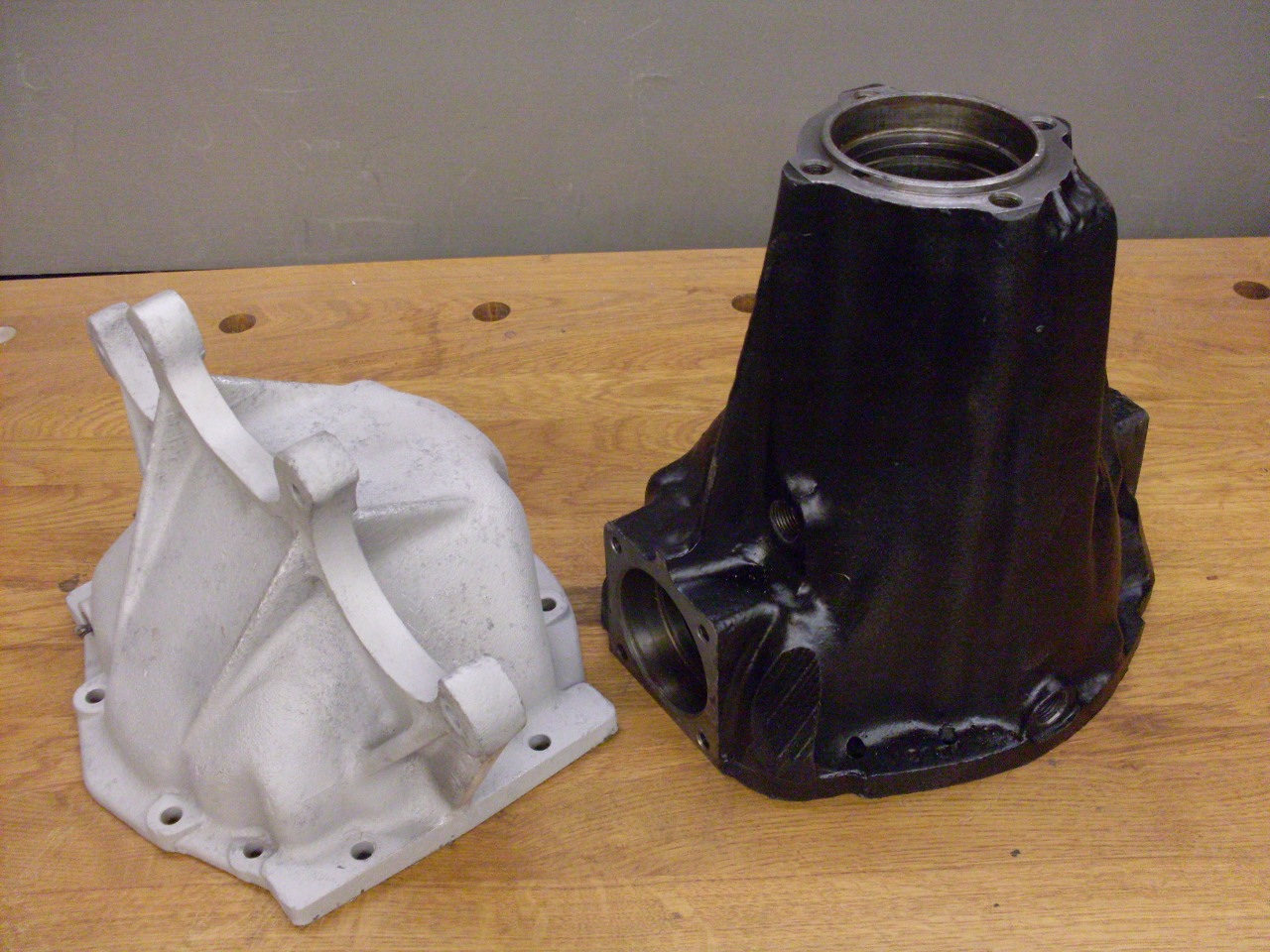

With

everything taken apart, I ordered new bearings and seals, and started

working on the case. I masked the openings and machined

surfaces

and blasted the rust and grime off of it.

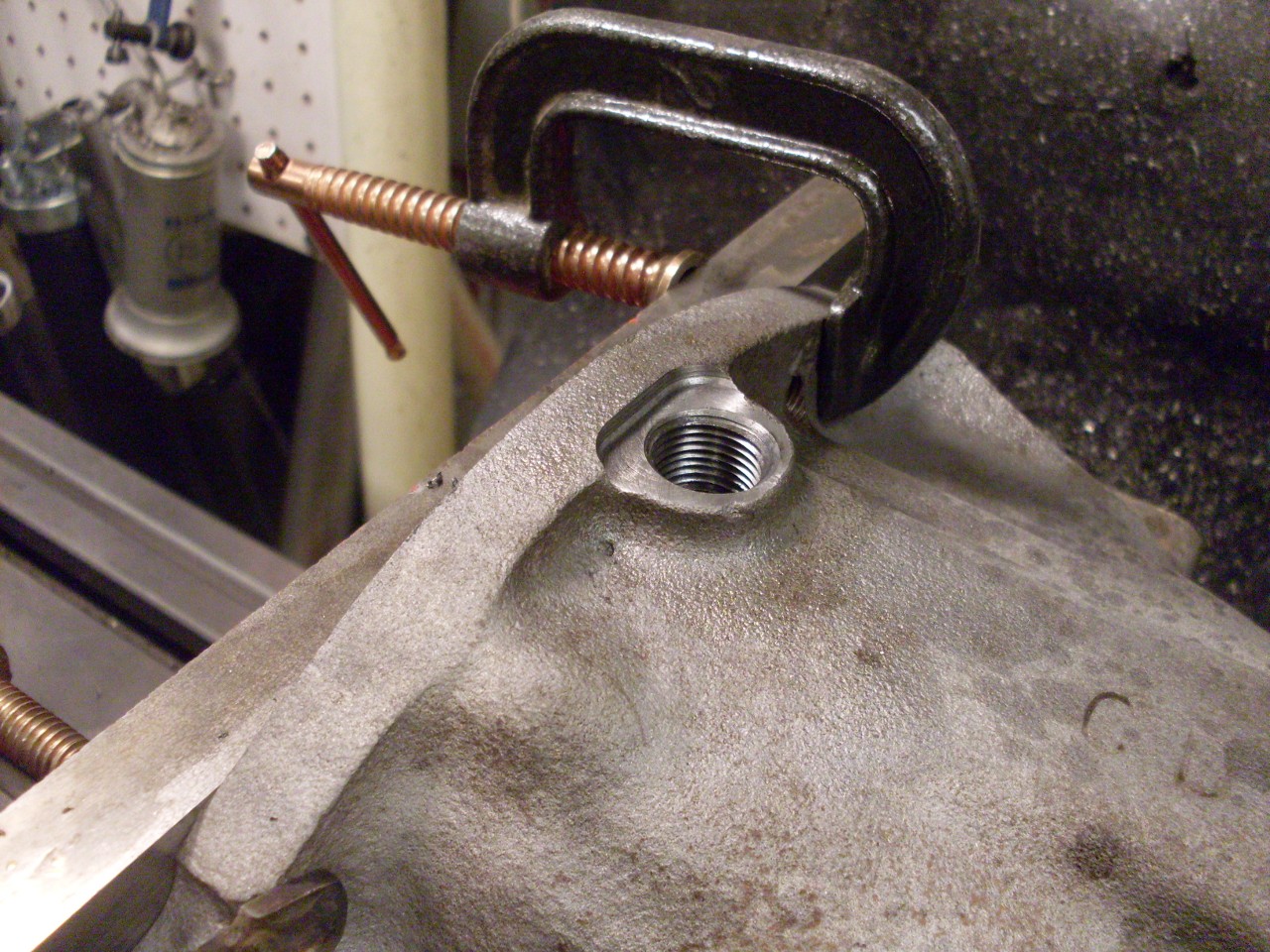

Looking

over the clean case, I noticed that there was a boss where a drain plug

would logically go, but there was no drain. This seemed odd,

so I

decided to finish the job that Triumph saved a few pennies by not doing.

I

painted the case with a high operformance urethane paint (POR15), and

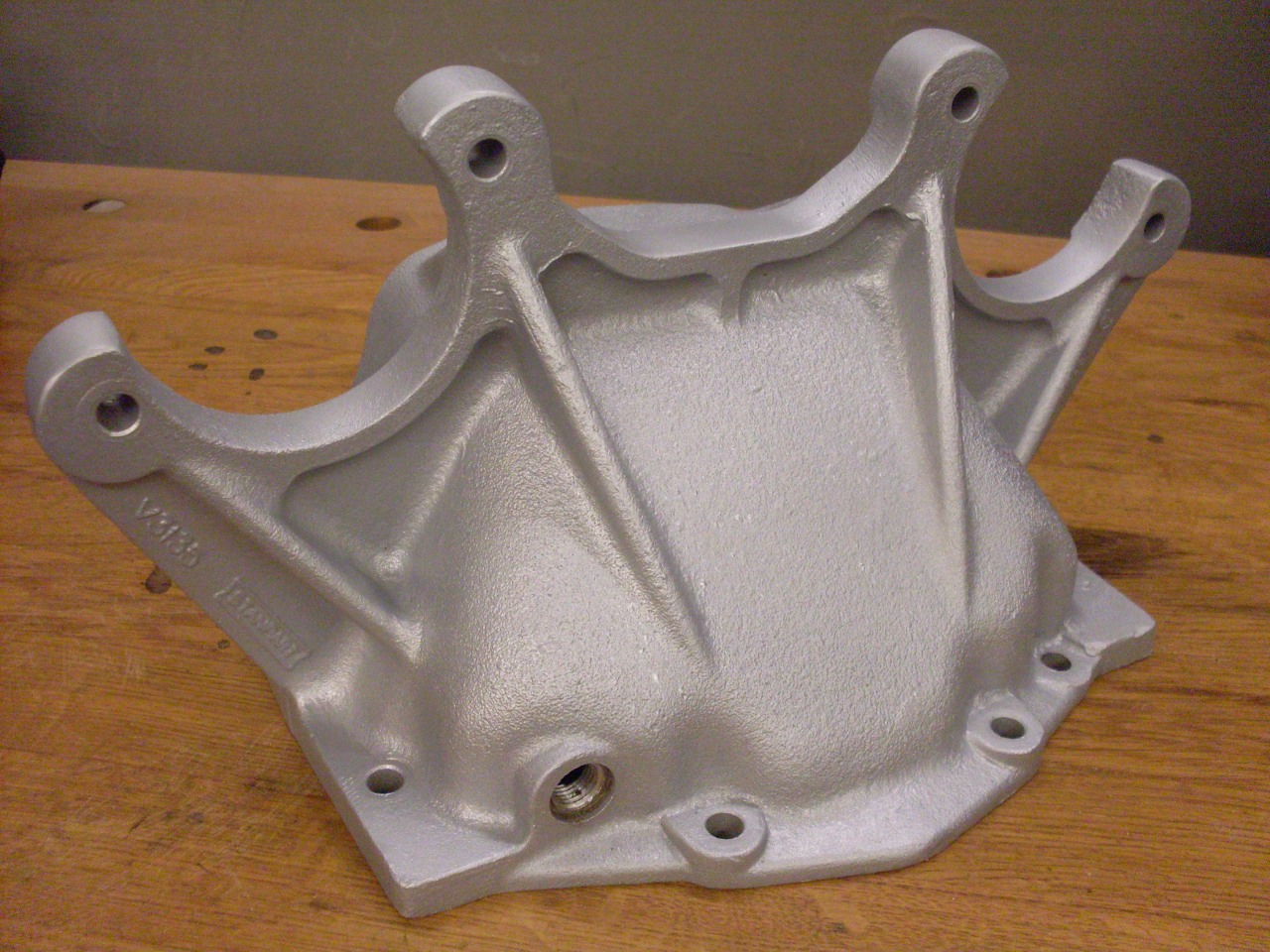

while waiting for it to dry, I blasted the aluminum rear cover.

There

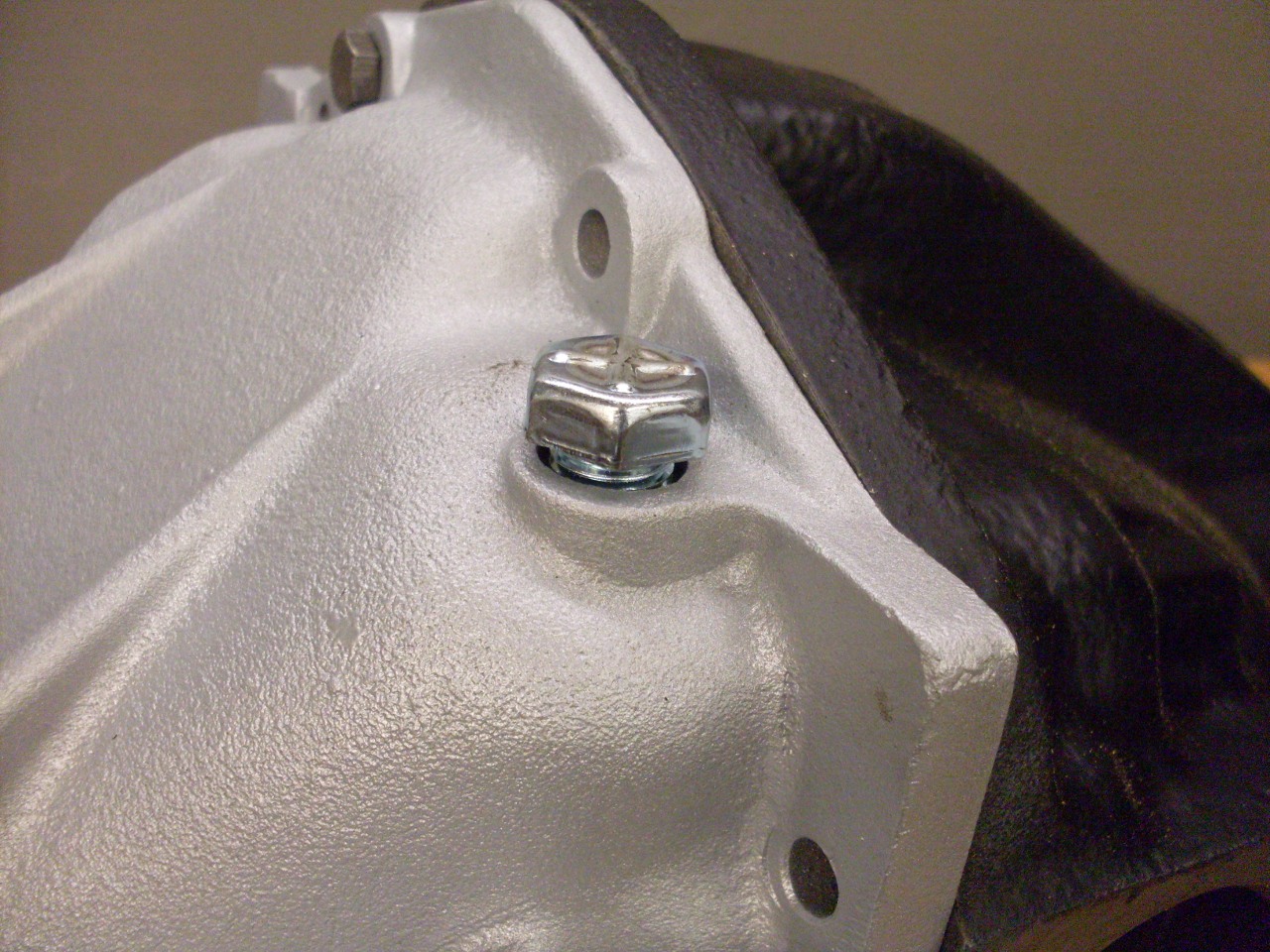

is a potential trouble spot on the rear cover in the vent arrangement.

The vent is important because without it, higher temperatures

will increase the pressure within the sealed case, which can force oil

past seals or gaskets. The stock vent is just a disk with a

small

hole with a cotter pin loosely in it. Apparently, the cotter

pin's job is to rattle around and keep the hole open. This

doesn't always work, and the vent can become clogged with road grime.

This is the vent with the cotter pin removed:

This

seemed like another opportunity for a simple upgrade. There

are

purpose made vents designed for differentials and

transmissions. They are much less prone to clogging and even

come with in internal filter.

I removed the vent disk

and opened up the existing vent hole and threaded it for the new vent.

Then powder coated the

cover and installed the vent. I'm not sure if the original

cover was natural or painted black.

By

this time, the replacement bearings had arrived, and I started with the

pinion assembly. The two critical adjustments for the pinion

gear

are its fore/aft position, and the preload on its two tapered roller

bearings. There is an interesting thing about the fore/aft

adjustment. The factory set the pinion position with shims

directly adjacent to the pinion head--between the head and the rear

bearing cone. The ring on the left in the left pic is a

0.060"

factory shim. However, these shims are apparently no longer

supplied by most of the regular parts suppliers. For rebuild

or

repair work, shims are supplied to go under the rear bearing's outer

race. While either method moves the pinion position, the

factory

method does it without affecting the preload, since it just moves the

pinion, not the rear bearing. I'd be interested in hearing

the

reasoning behind this situation. I decided to install the

pinion

with just the factory shim, then check pinion position.

The

pinion preload is set by adjusting the distance between the two pinion

bearing cones. Most of this distance is provided by the

spacer

cylinder, while fine adjustment is done by adding shims. To

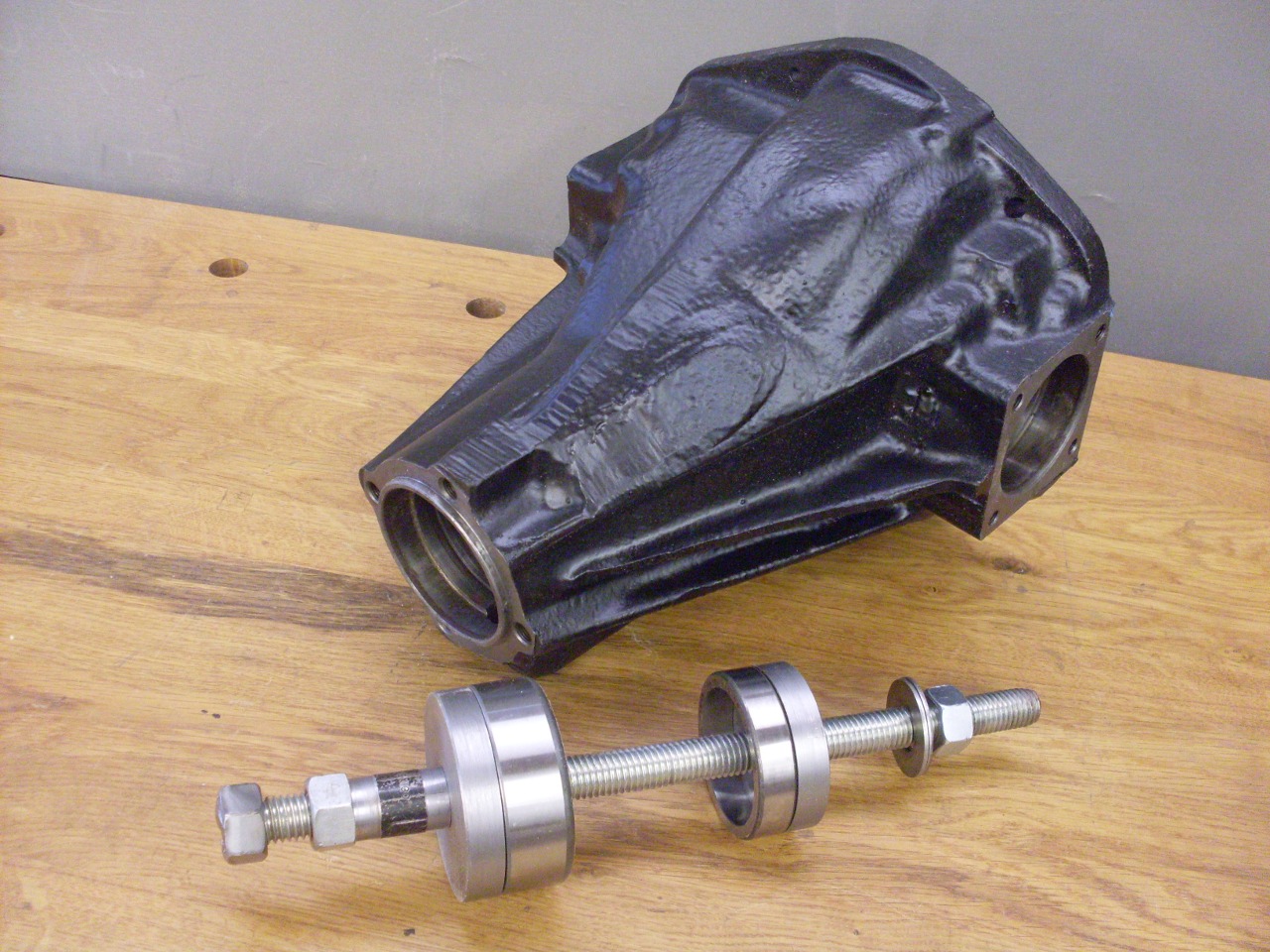

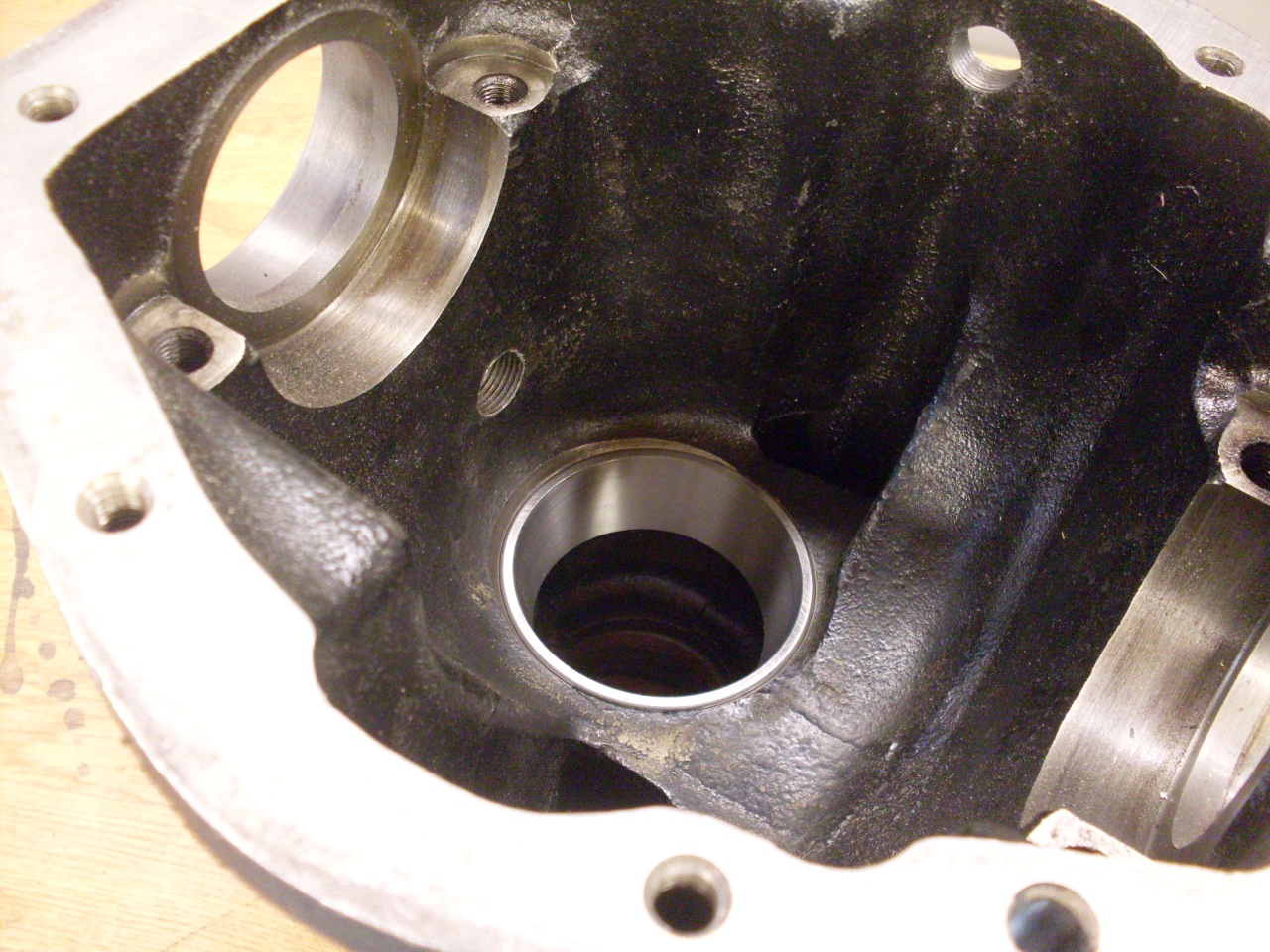

install the pinion assembly, the two bearing outer races must first be

installed into the case. The pics below show my version of the race

install tool. It keeps the races square and pulls them both

into

place at once.

In

the attempt to install the pinion and set its preload, I hit the first

real snag. With the pinion shaft installed with the new

bearings, I

wasn't able to get the necessary preload. With the original

preload shim pack and the pinion nut tightened to 100 ft-lb, the pinion

still had significant end play. With the shim pack removed, I

could get the end play down to essentially zero, but could still not

get anywhere near the preload spec.

After a lot of head

scratching and consultations on some TR6 forums, it seemed obvious that

something was different with the bearings. On close

inspection, I

found that the new front bearing had a much thicker internal race than

the original bearing.

The

original bearing was marked with part number 15100SR, while the

replacement bearing, supplied from one of the major British car parts

suppliers, was marked 15100. A search of bearing

manufacturer's

web sites confirmed that the two bearings are not just variants of

each other--they have one important dimension that is different.

My supplier tried to be helpful, and did acknowledge the

difference, but still insisted that the bearing they supplied was the

correct one. It baffles me that after 40 years supplying

parts

for these cars, this is apparently the first time they have heard of

this problem. In hindsight, I believe that the supplied

bearing

would probably work in the later differentials where the solid spacer is

replaced by a crush tube. Also, if a differential had a

preload

shim pack larger than about 0.036", the supplied bearing might

work if most or all of the shims were removed.

It was at this

point that I was preparing to shorten the spacer to make up for the

extra bearing thickness, but in the end, I was able to get a

correct bearing from a kind member of one of the popular TR6 forums.

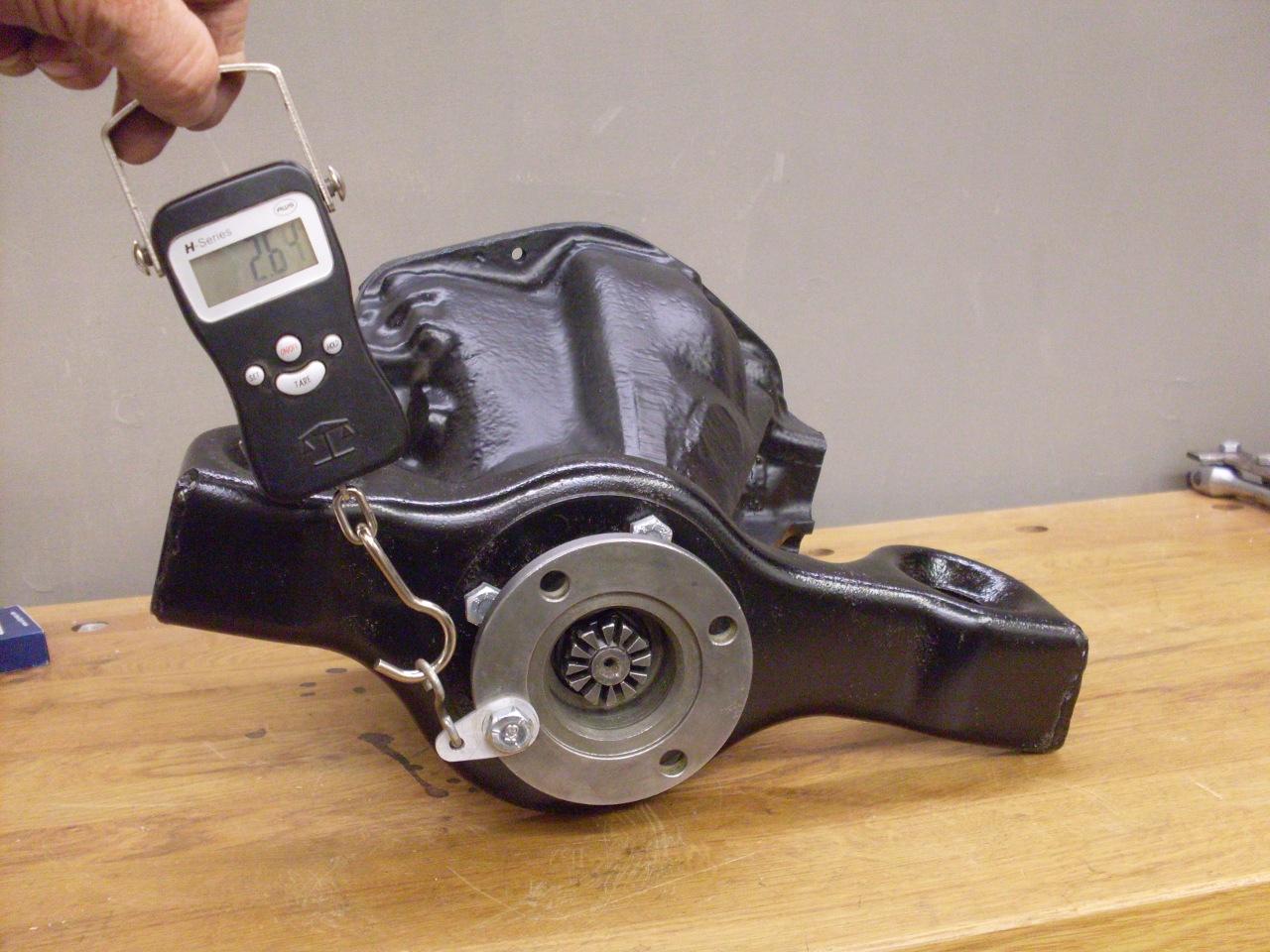

Preloading

bearings not only removes any free play, but also causes the bearings

to stiffen their rotation. The preload for the pinion is

correct

when it takes 15 to 18 inch-pounds of torque to rotate the shaft.

Torque

can be easily determined by measuring the force required to turn the

shaft when applied at the end of an arm of known length.

The product of the force and the arm length is the torque.

It took me three iterations of adjusting the preload shim

pack to

get the preload within spec.

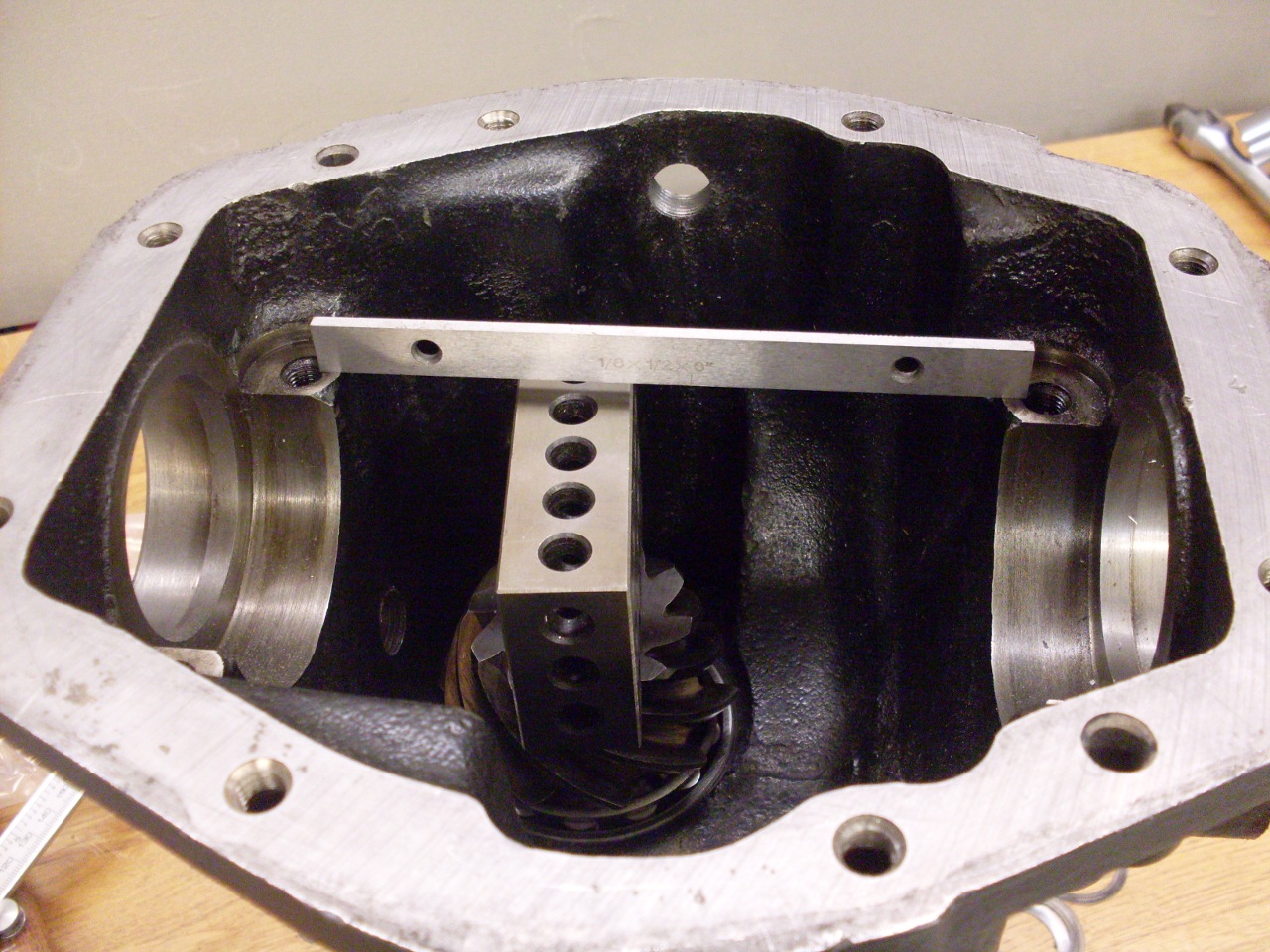

The

final check on the pinion is its fore/aft position.

There is

a fancy factory tool for this which probably can't be found, but a

little tinkering produced a way to accurately determine pinion

position. The block and bar in the pic are precision

machinist's

tools, but aren't really expensive. The bar is 0.500" high,

and

the block is 2.000" inches high. Measuring with a caliper

from

the top of the bar to the top of the block, and doing a little

arithmetic told me that the pinion position was correct.

This

method is based loosely on one described in one of the very helpful "Six Tech

Manuals", available here:

http://www.74tr6.com/pdfs/Differential.pdf

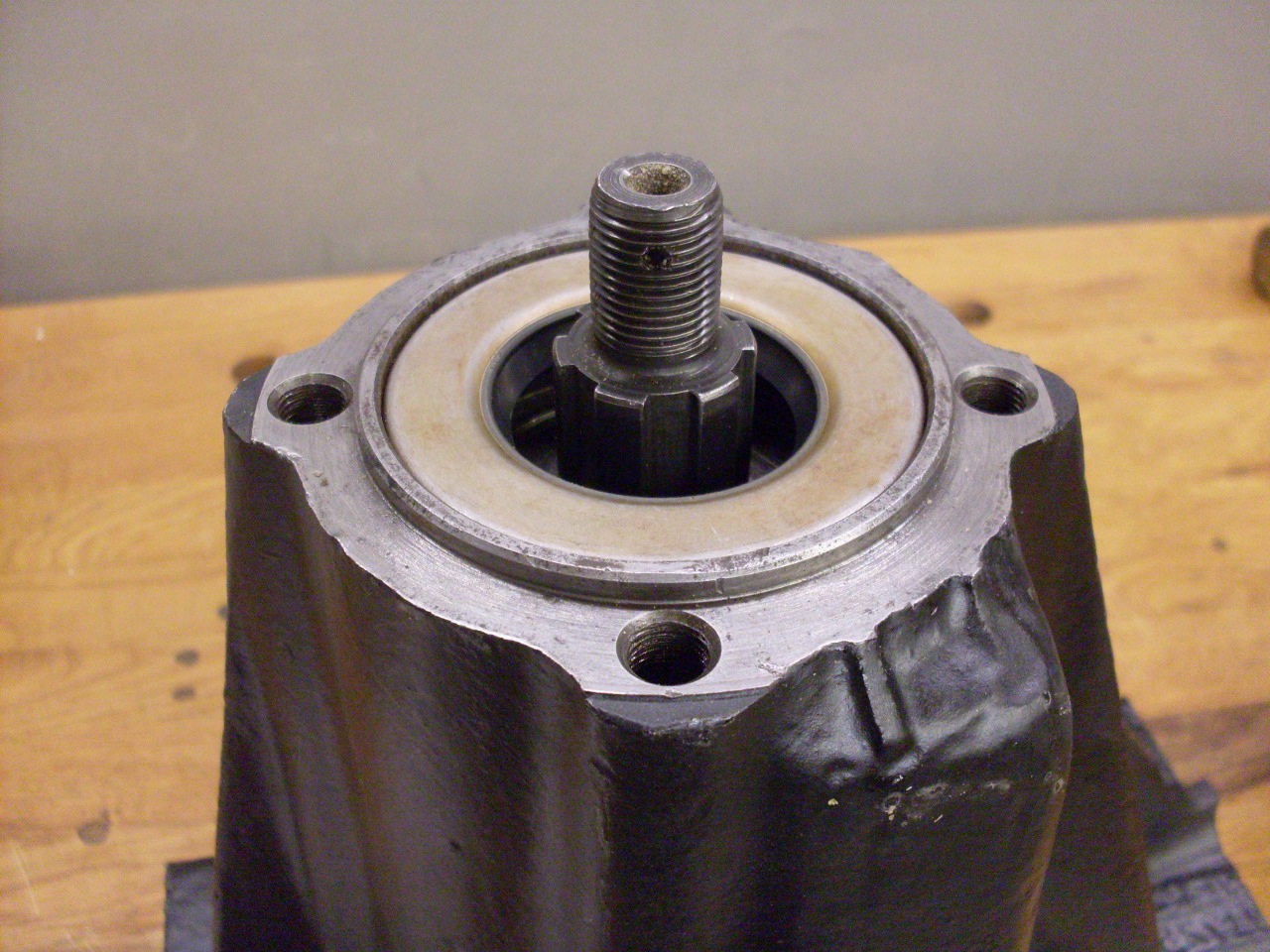

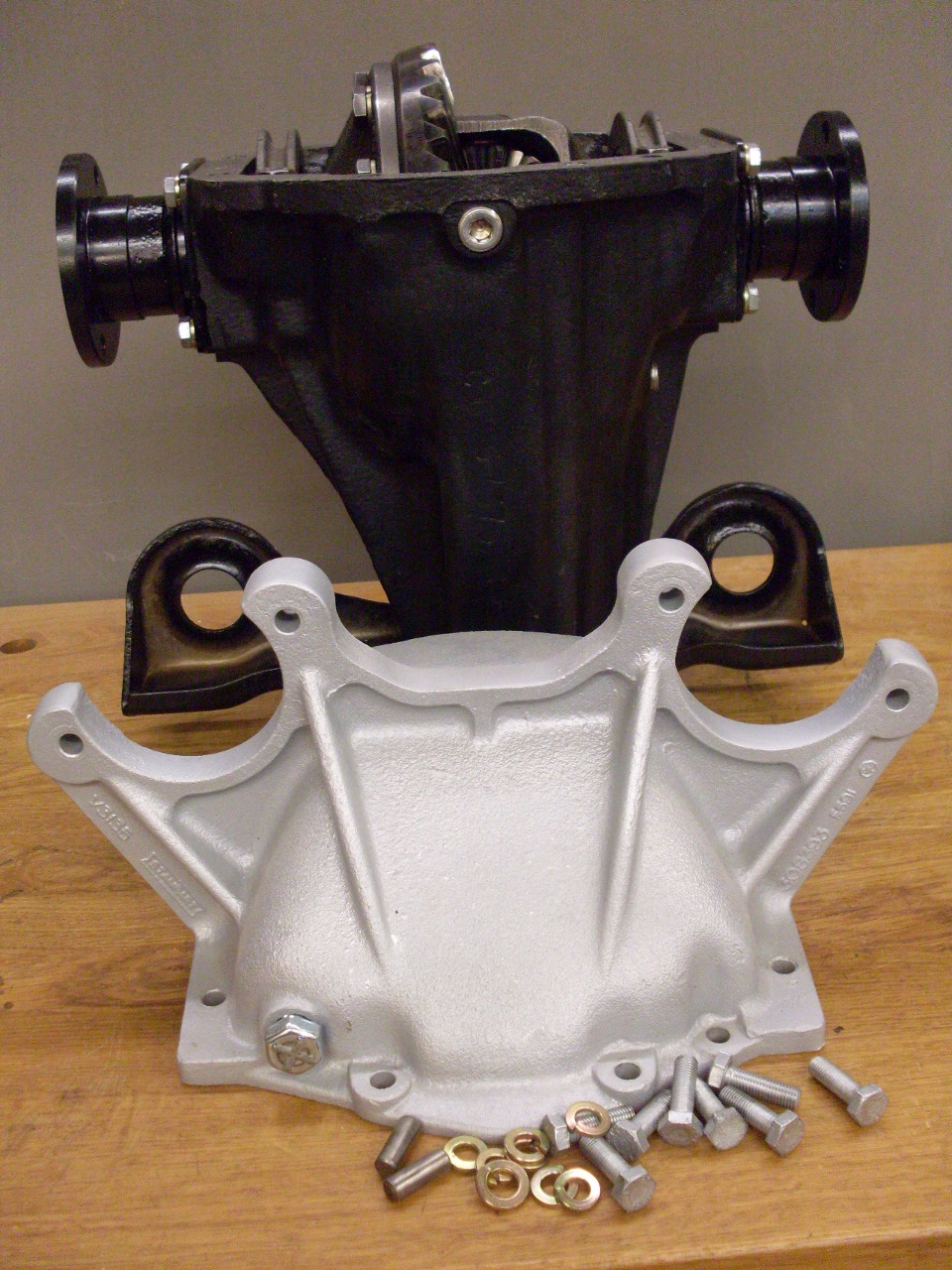

With

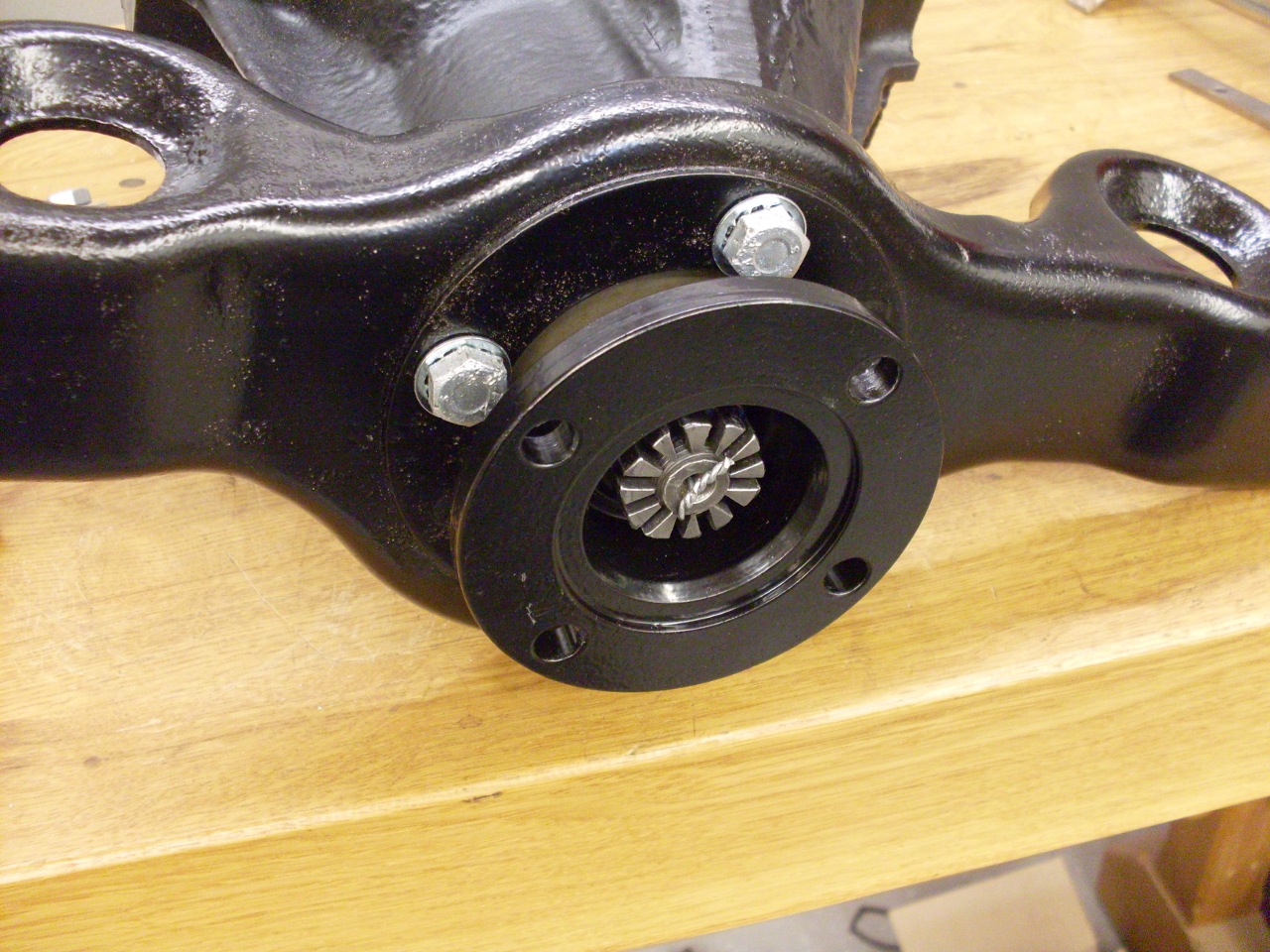

the pinion finally in good shape, I installed the new oil seal, added

the powder coated mounting plate, and did the final torque of the

pinion nut.

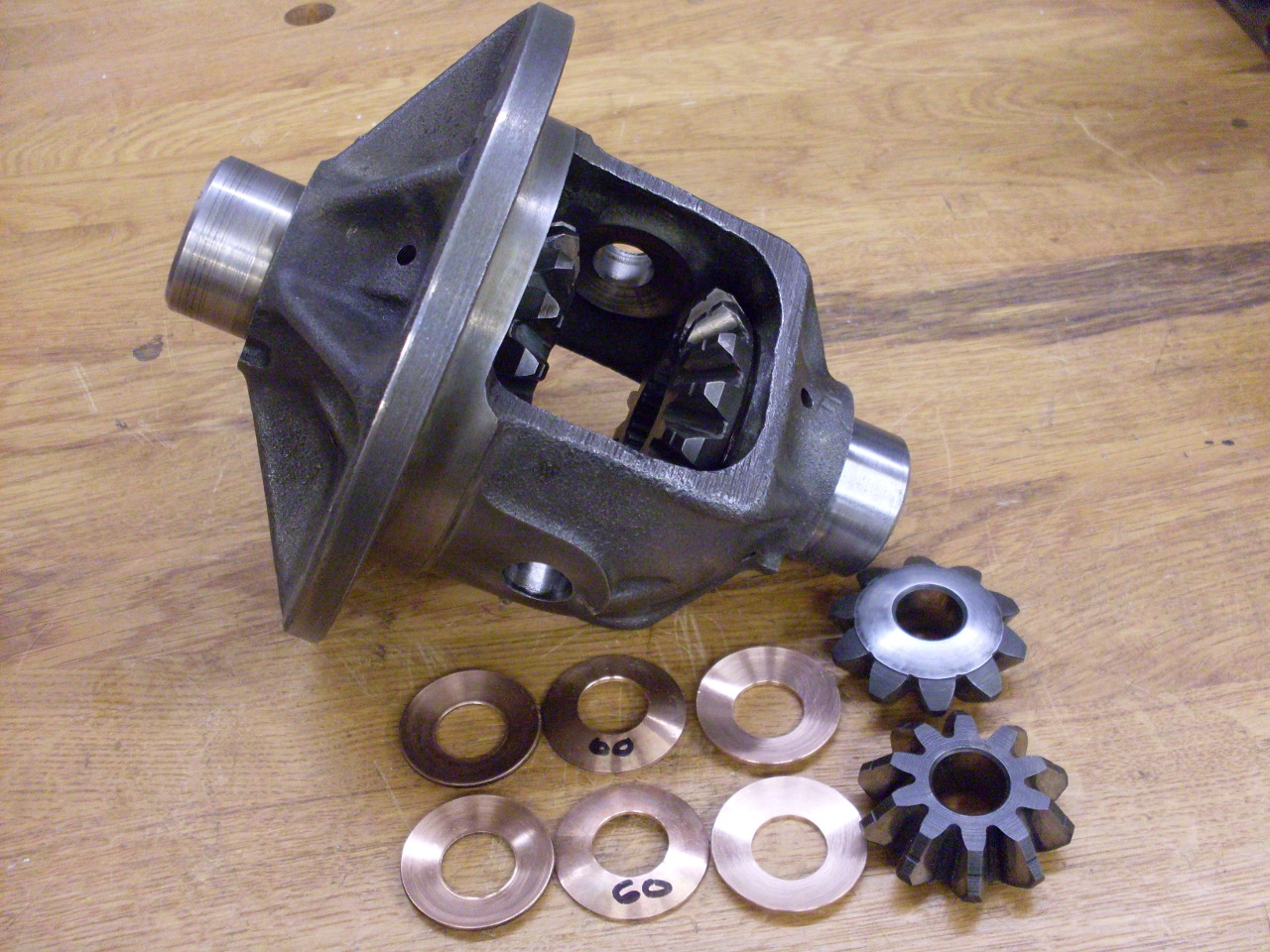

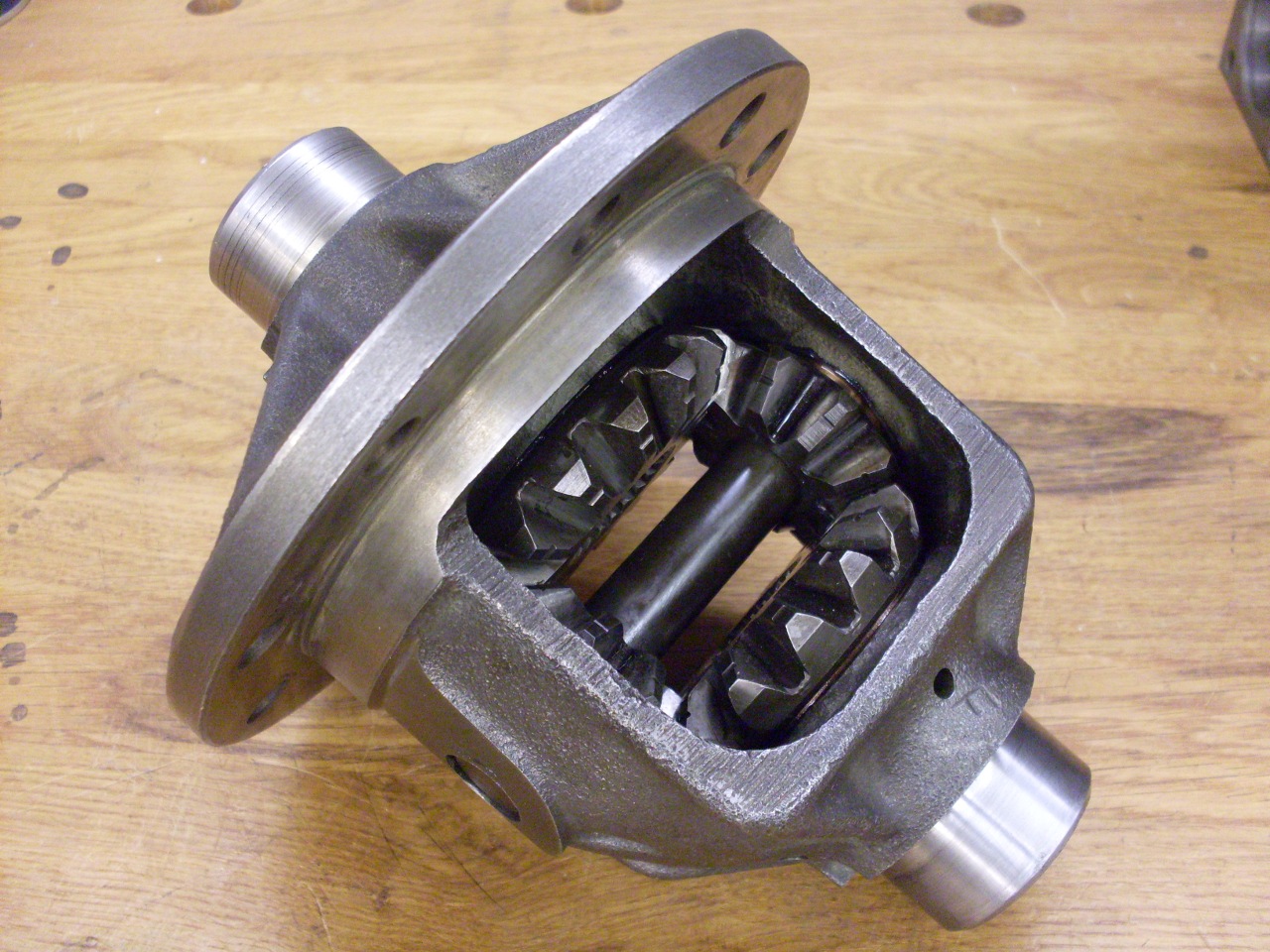

Next

up was the differential carrier. It carries the crown gear

which

meshes with the pinion, and also two sun and two planet gears inside,

which allow the two rear wheels to turn at different speeds.

The

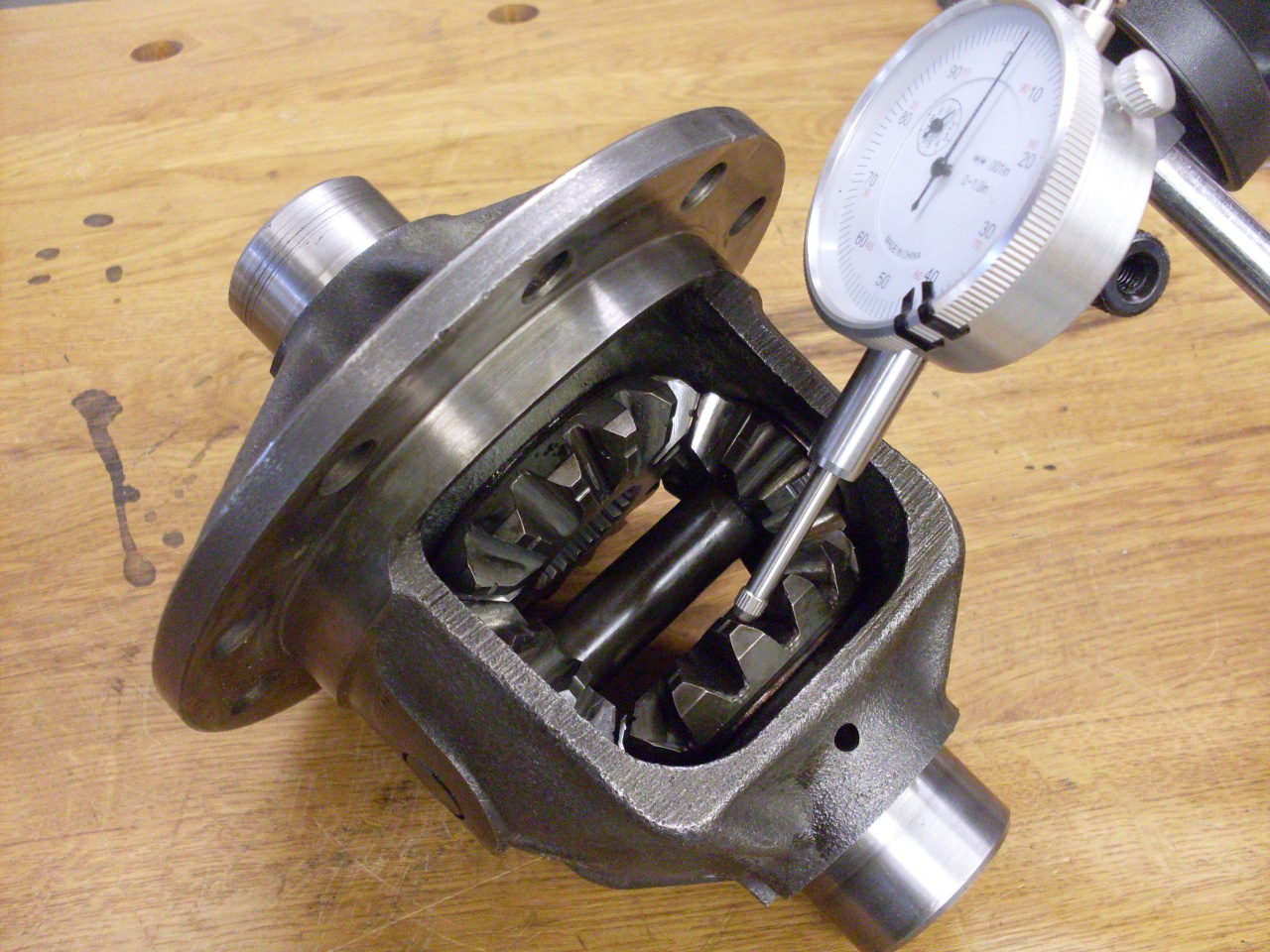

goal for the sun/planet gear arrangement is zero backlash among all the

gears. Backlash is adjusted by varying the thickness of the

spherical thrust washers behind the planet gears. I could

easily

detect backlash in my gears. It only measured about 0.002",

but

was easy to feel.

I

first tried installing a pair of new 0.060" washers--the same as I

found in the unit--on the theory that most of the wear would

have been in

the washers. This didn't seem to change the backlash very

much,

so I then tried a pair of 0.062" washers. This resulted in no

detectable backlash. The gears were slightly stiff, but with

good

lubrication and a few miles, I expect they will loosen up.

So here is the

differential carrier all back together (except for the crown wheel,

which has to come later).

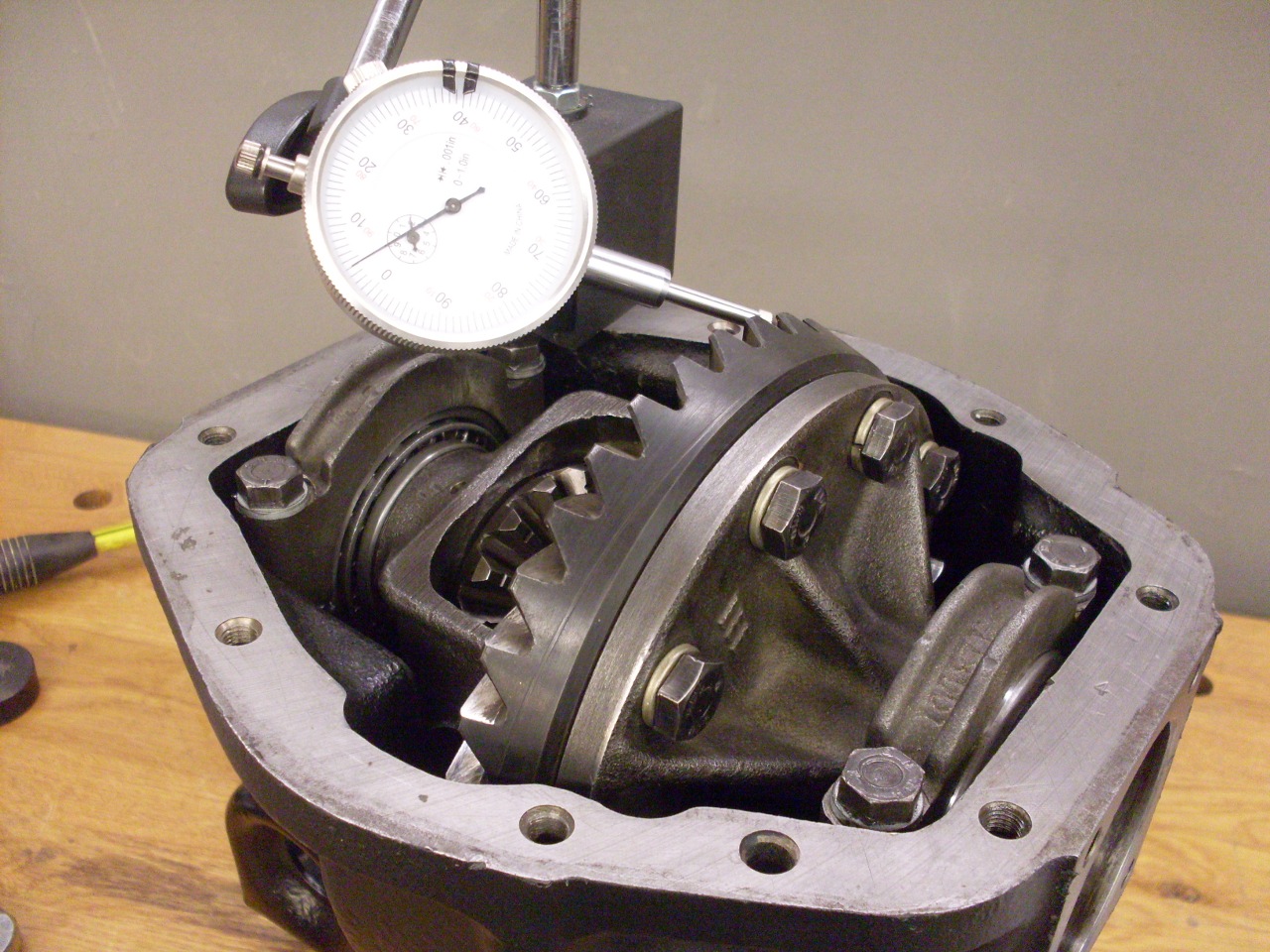

Two

more critical specs in the differential are the preload of the

differential carrier bearings, and the side-to-side position of the

crown wheel. There is a shim pack under each differential

carrier

bearing cone. The total thickness of these shims determines

the

preload, while the distribution of them (some on the right, the rest on

the left) changes the crown wheel position. The process for

determining the size and distribution of the shims seems complex at

first, but it is entirely straightforward and logical.

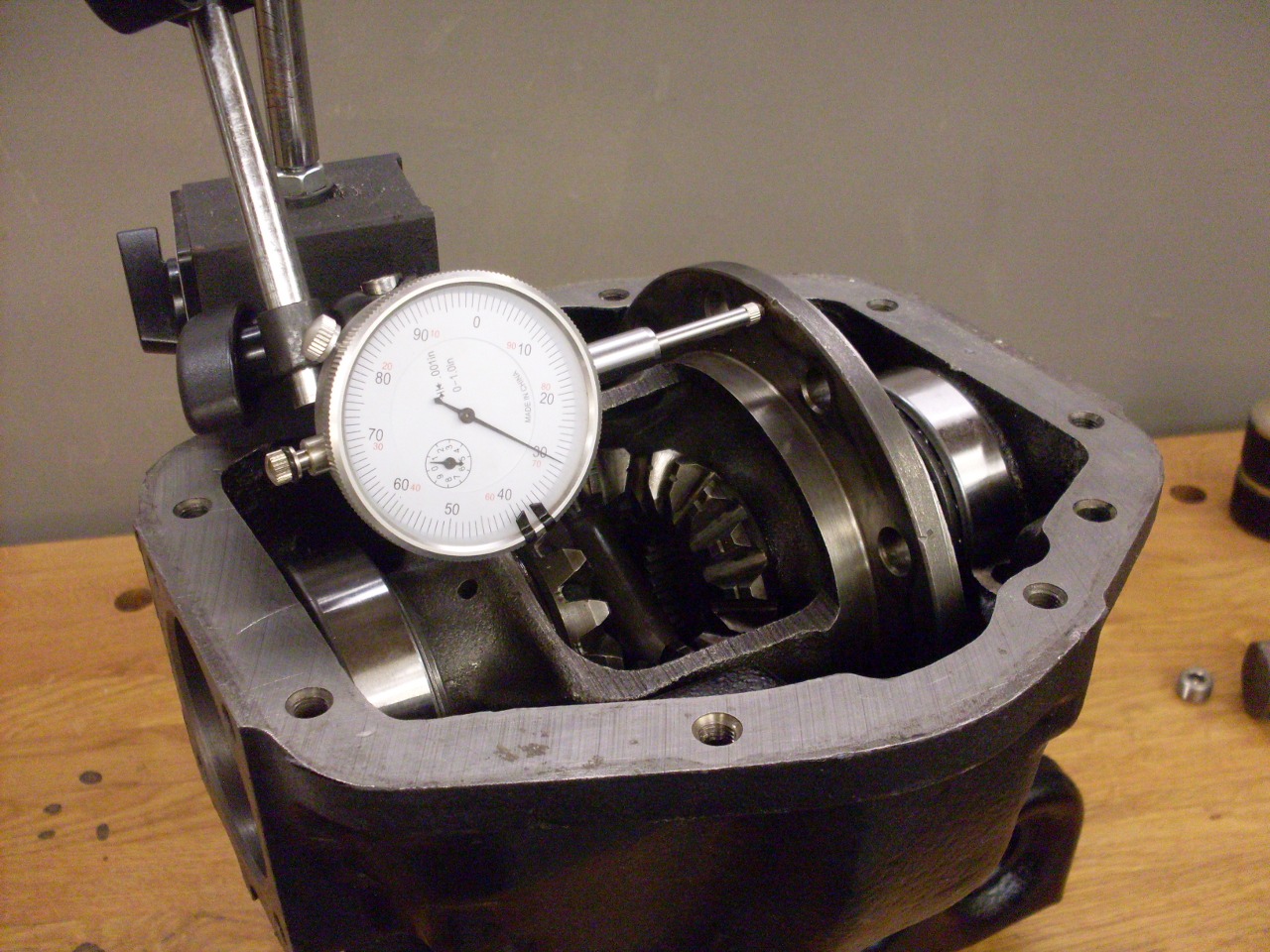

First, the differential

carrier bearing cones are mounted without any shims.

The

carrier is then set into the case, and the end float measured.

This measurement is how much wider the case is than the

carrier

with bearings. To this measurement, we add 0.003" for

preload.

The total is the thickness of shims that will increase the

width

of the carrier (including bearings) to 0.003" wider than the case.

I

actually found it a little easier and more repeatable to measure the

float with loose feeler guages behind one of the carrier outer races

(second pic). In my case, the end float was 0.045", so the

total

preload shim pack would need to be 0.048".

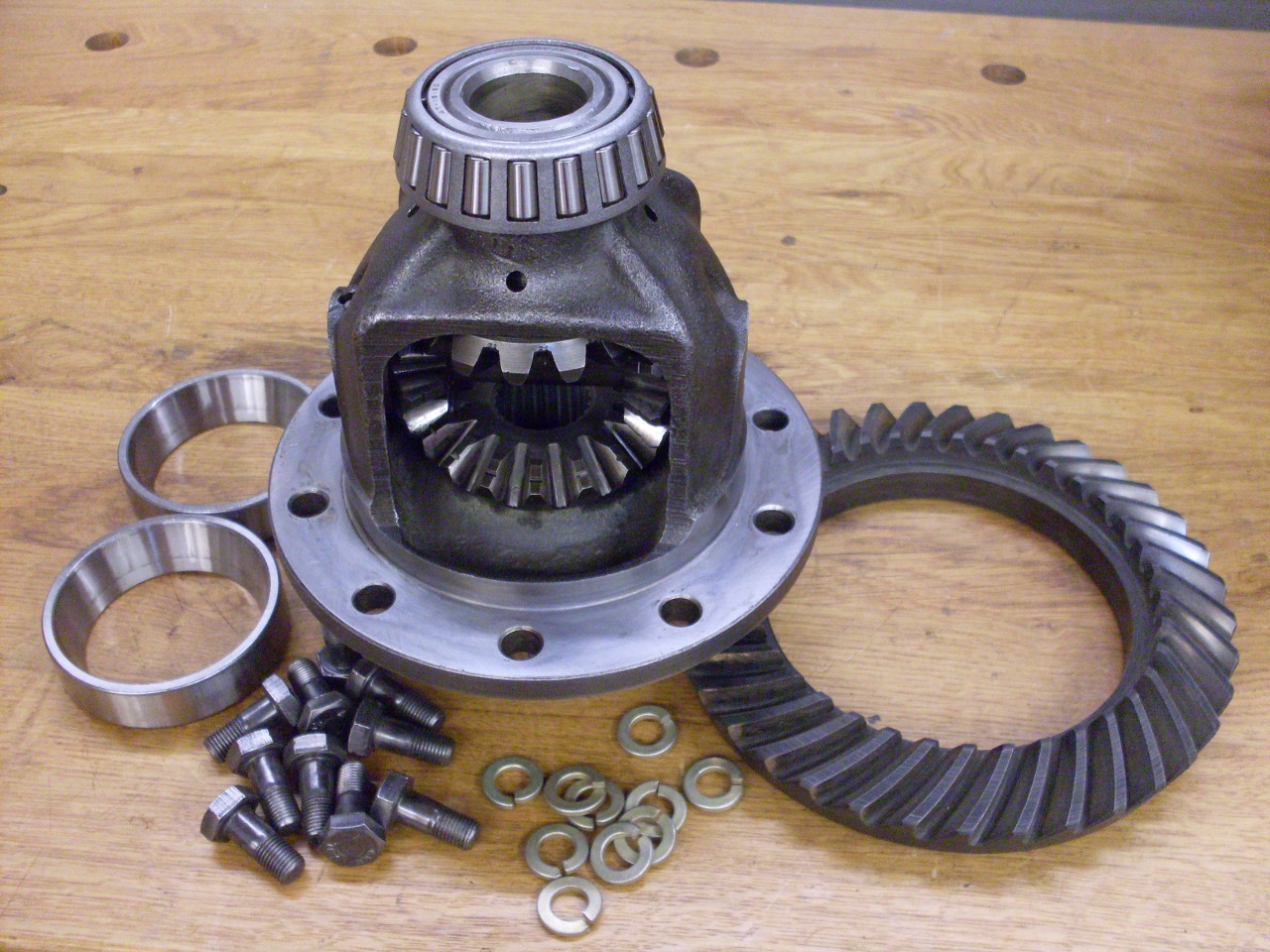

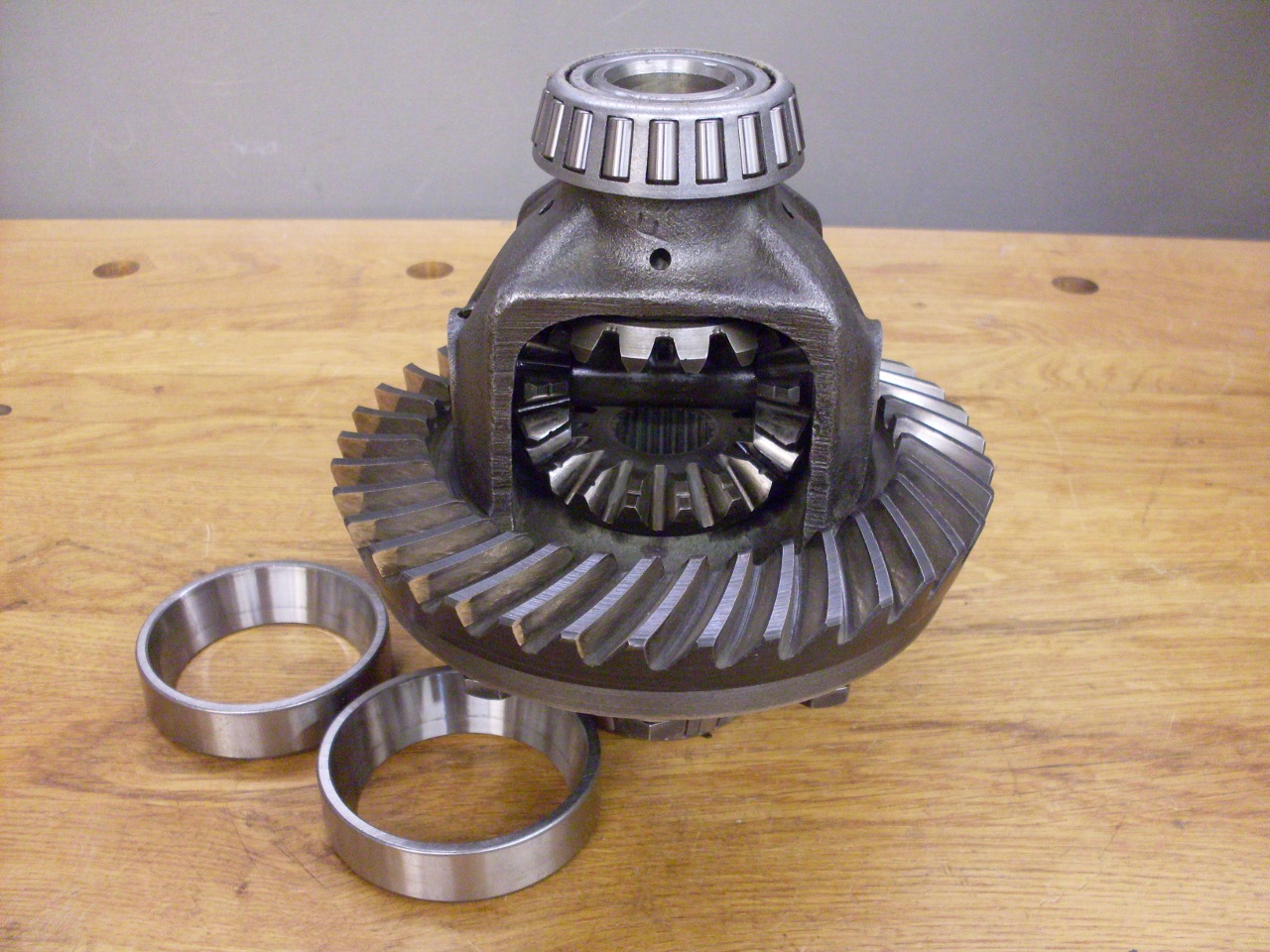

Then

it was time to mount the crown wheel back in its previously marked

position on the carrier. The crown wheel fasteners are grade

"T"

(close to SAE Grade 8), so it's not a place to use hardware store

screws. I used new grade 8 lock washers, and Locktite, per

the

manual.

The

carrier with crown wheel is then placed back in the case without preload shims, and the end

float measured again. This time, since the pinion gear will

now

limit the movement of the carrier in one direction, the measurement

represents the

difference between zero and maximum clearance between the crown wheel

and the pinion gear. Subtracting 0.005" from this measurement

gives the shim thickness that would give a crown wheel-pinion

clearance of 0.005". This is the shim pack that goes inder

the

bearing cone on the crown wheel side. The remainder of the

total

preload shim thickness then goes on the other side. In my

case,

of the 0.048" preload shim pack thickness, 0.030" went on the crown

wheel side, and 0.018" went on the other side.

The bearing cones

had to come back off to install the shims. One of the carrier

bearings got fairly loose on its journal, so I helped it out by adding

some bearing mount compound.

Then

the case spreader was mounted again to open the case enough to alow the

carrier to drop in. The bearing caps were installed and torqued,

and the final backlash measured. I saw with a sigh of relief

that

my backlash was 0.004" and compliant with the spec.

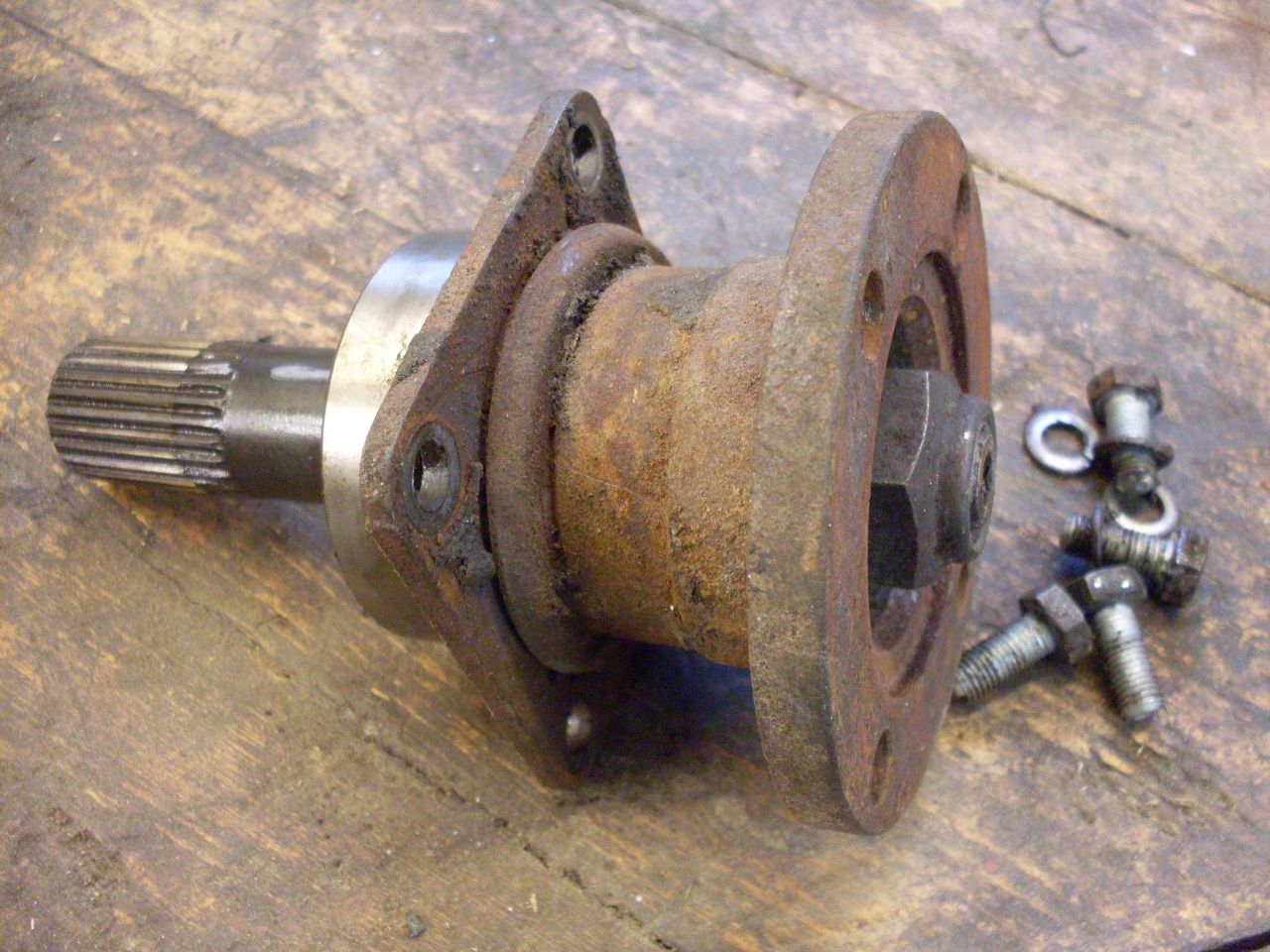

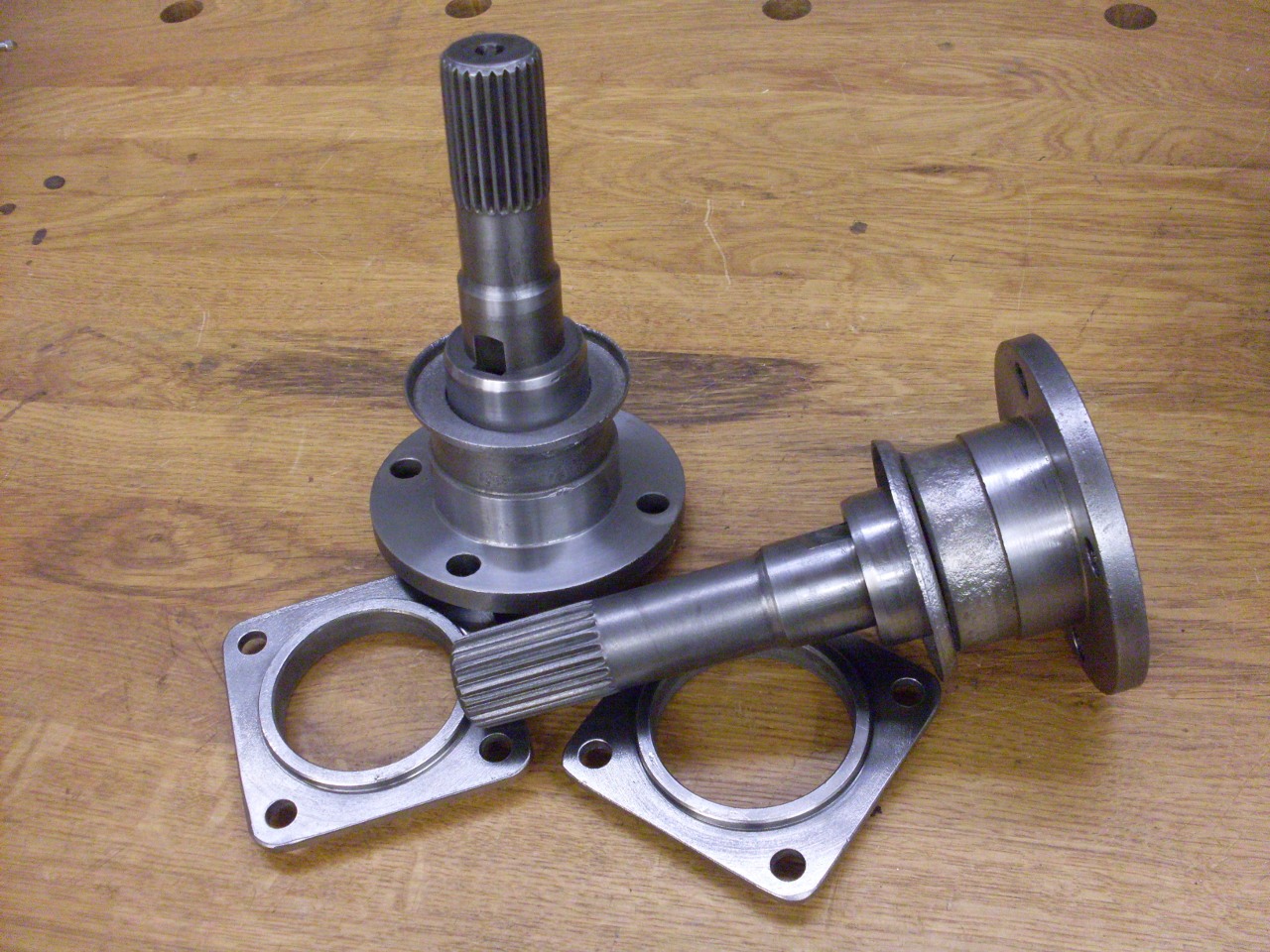

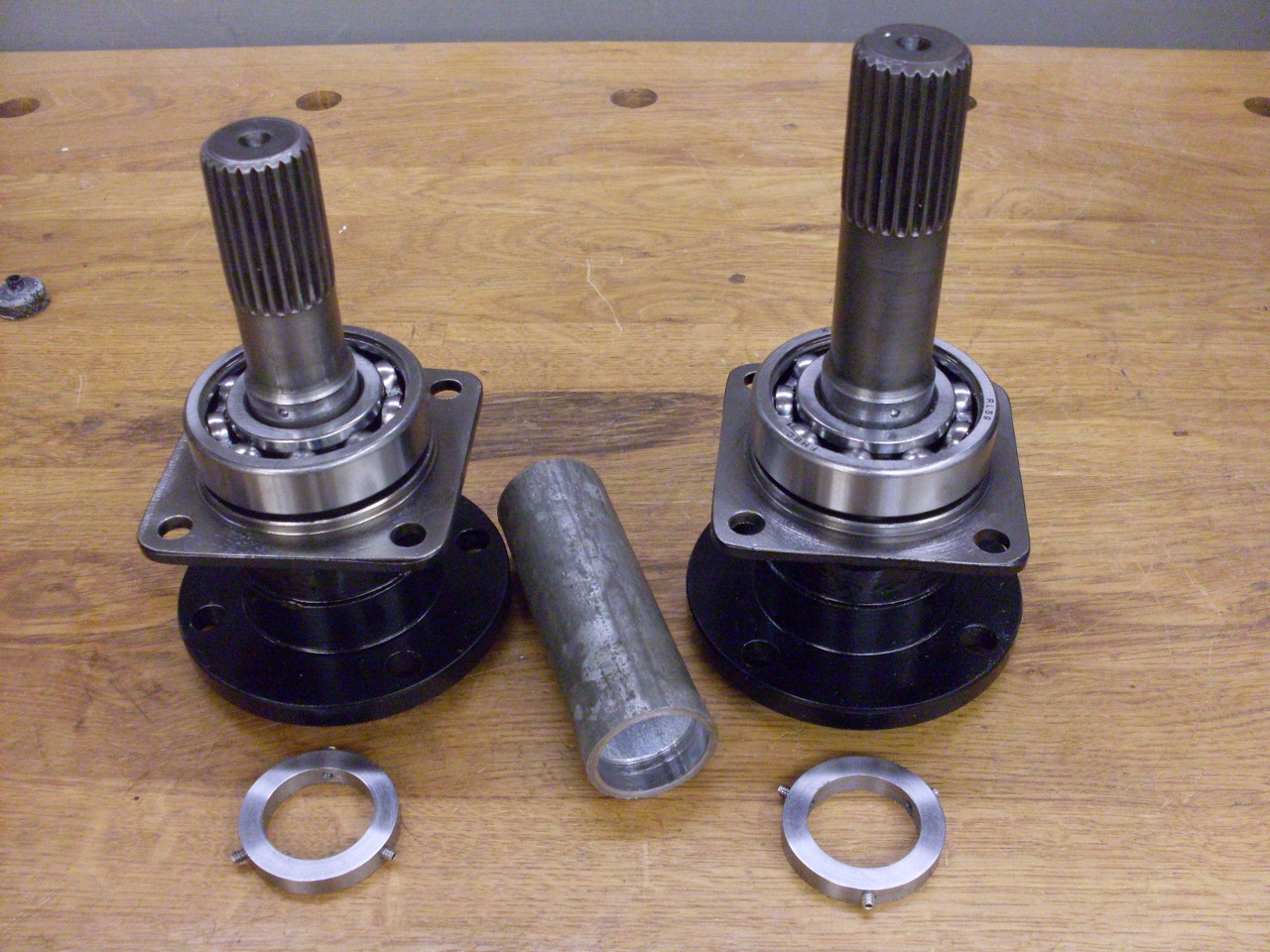

The last major part of the differential unit was the inner axles.

These axles deliver power to the external flanges that the

rear half axles attach to. The inner axles consist of short

splined shafts that each carry a ball bearing and an external flange.

The flange is mounted on a taper on the outer end of the

shaft, and it has to be removed to withdraw the bearing and oil seal.

This is where the trouble started.

Now, I'm not a novice at dislodging things that are pressed on, or

wedged on, such as with a taper. I have a decent hydraulic

press and the wherewithall to create a wide range of implements of

seperation. I tried the press first, and got it to the point

where it was creaking ominously. I then added heat to the

mix. The axle mocked me.

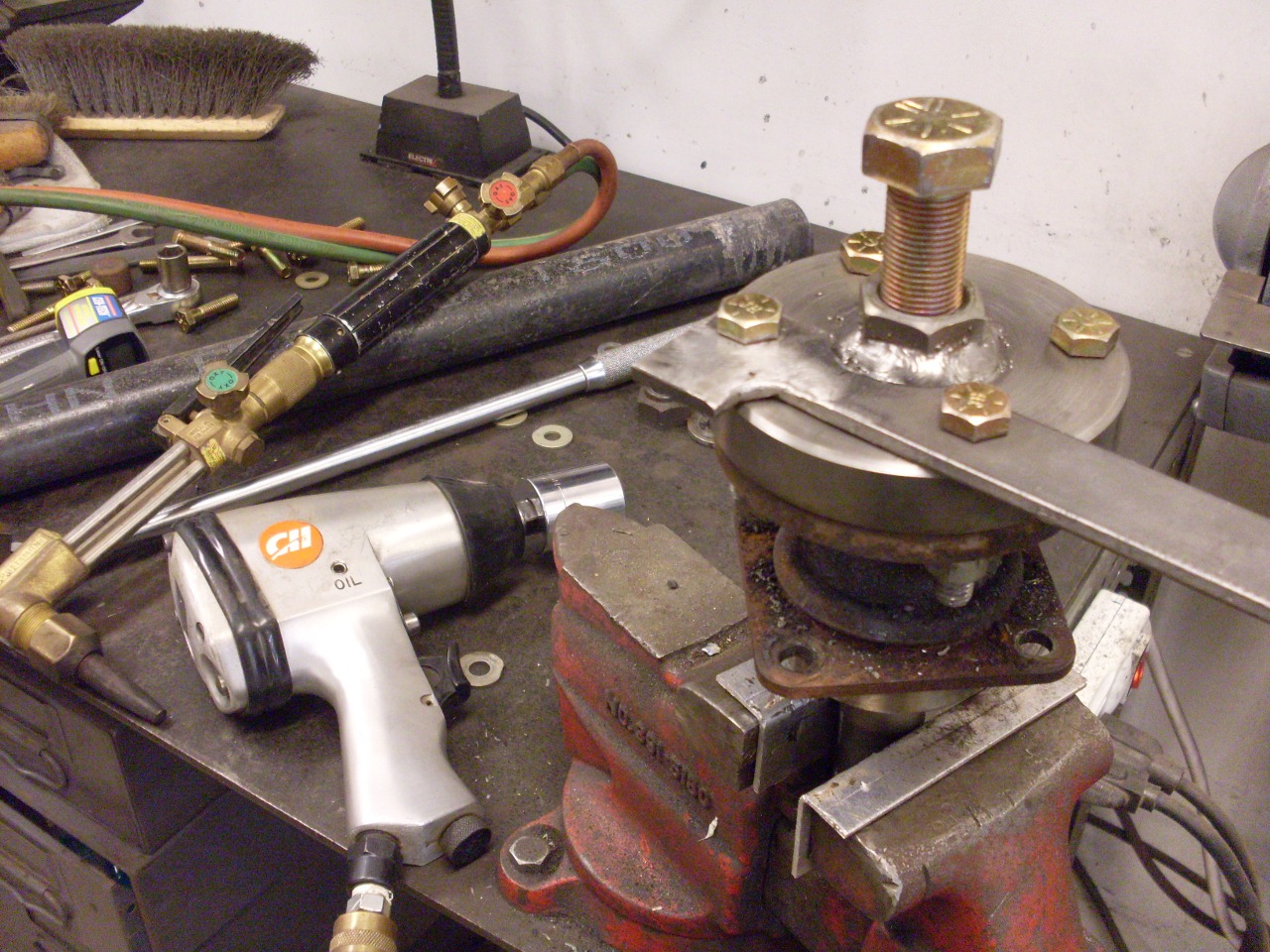

Not to be bested by an intert lump of steel, I made a custom puller

whose grade 8 hardware would be able to apply as much pressure as my

press, but with the added pursuading power of an impact driver.

After several intense cycles of pressure, heat, impact, and

swearing, the axle remained aloof. I was pushing the system

to the point where I was concerned about damaging the axle flange.

As I paused to catch my breath and assess the situation, my more

analytical self began to consider whether there may be a smarter, less

brutish way to solve the problem. The bearing on both axles

was mounted up against the hub, but the machined 1-1/8" bearing journal

extended about 1/8" beyond the bearing to a shallow shoulder.

The shoulder was only about 0.006" high and 1/8" wide, and

was the only thing standing between that bearing and sweet liberation.

Now I don't have much doubt that, given enough acetylene and

violence, I would have eventually triumphed over those hubs, but

on the other hand, the prospect of pulling the bearings off from the

other direction began to look much more civilized. It was

just that little wisp of metal to deal with, and removing it

would be trivial. I considered the shoulder and whether it

was there intentionally for some purpose. It certainly wasn't

a locating shoulder, since the bearing was an eighth of an inch away from it.

Possibly it was a retaining shoulder, to prevent the axle

from creeping out of the bearing. Neither bearing showed any

evidence of creeping, and further, it seems that if that were its

purpose, it would have been closer to the bearing and a little more

prominent than 0.006".

In the end, I decided to do away with the shoulder and think later

about replacing its function, if any.

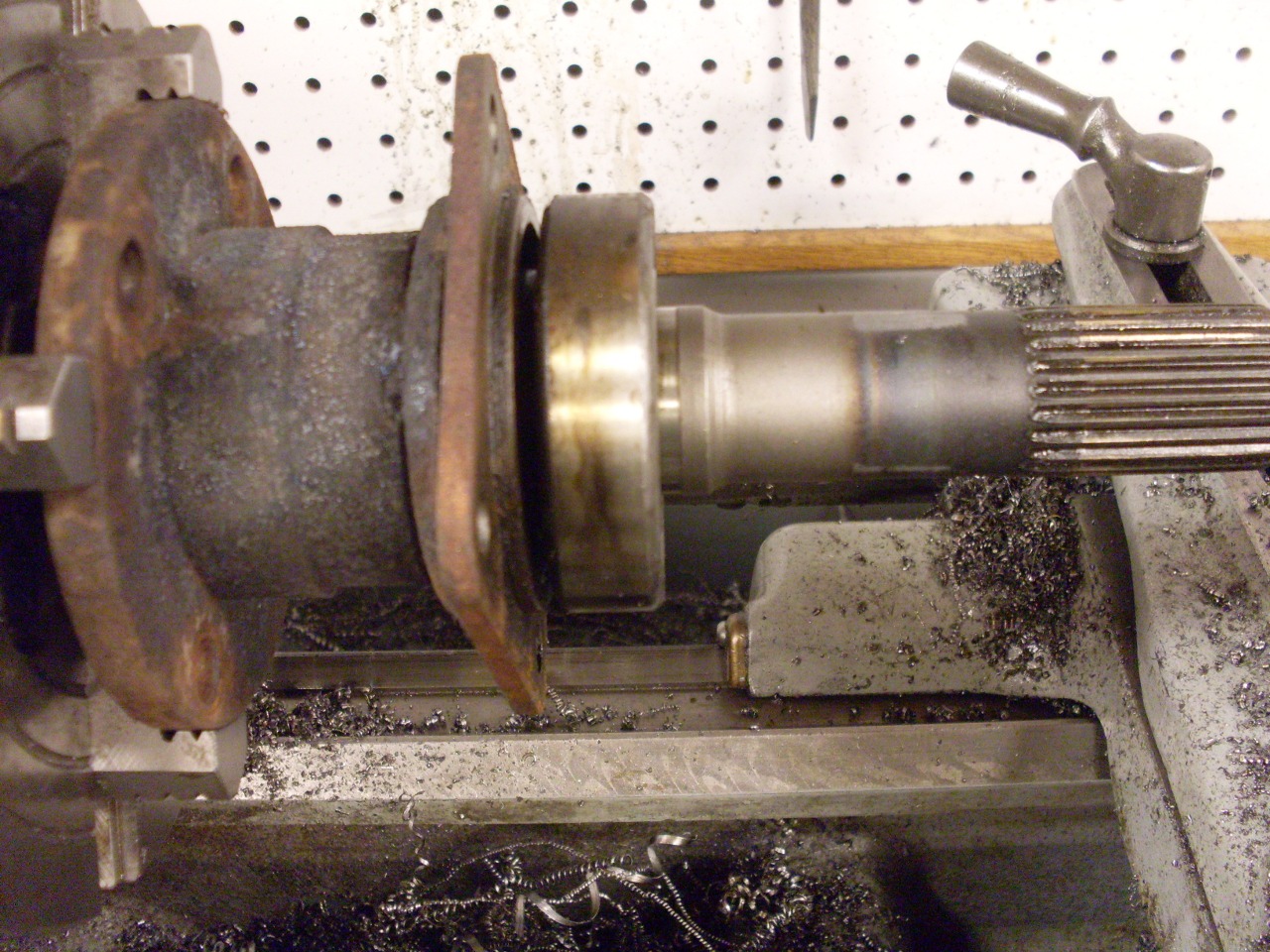

Ten minutes to turn off the shoulder, ten minutes to set up the press,

and the bearing was off. I now consider the axle and hub to

be one piece.

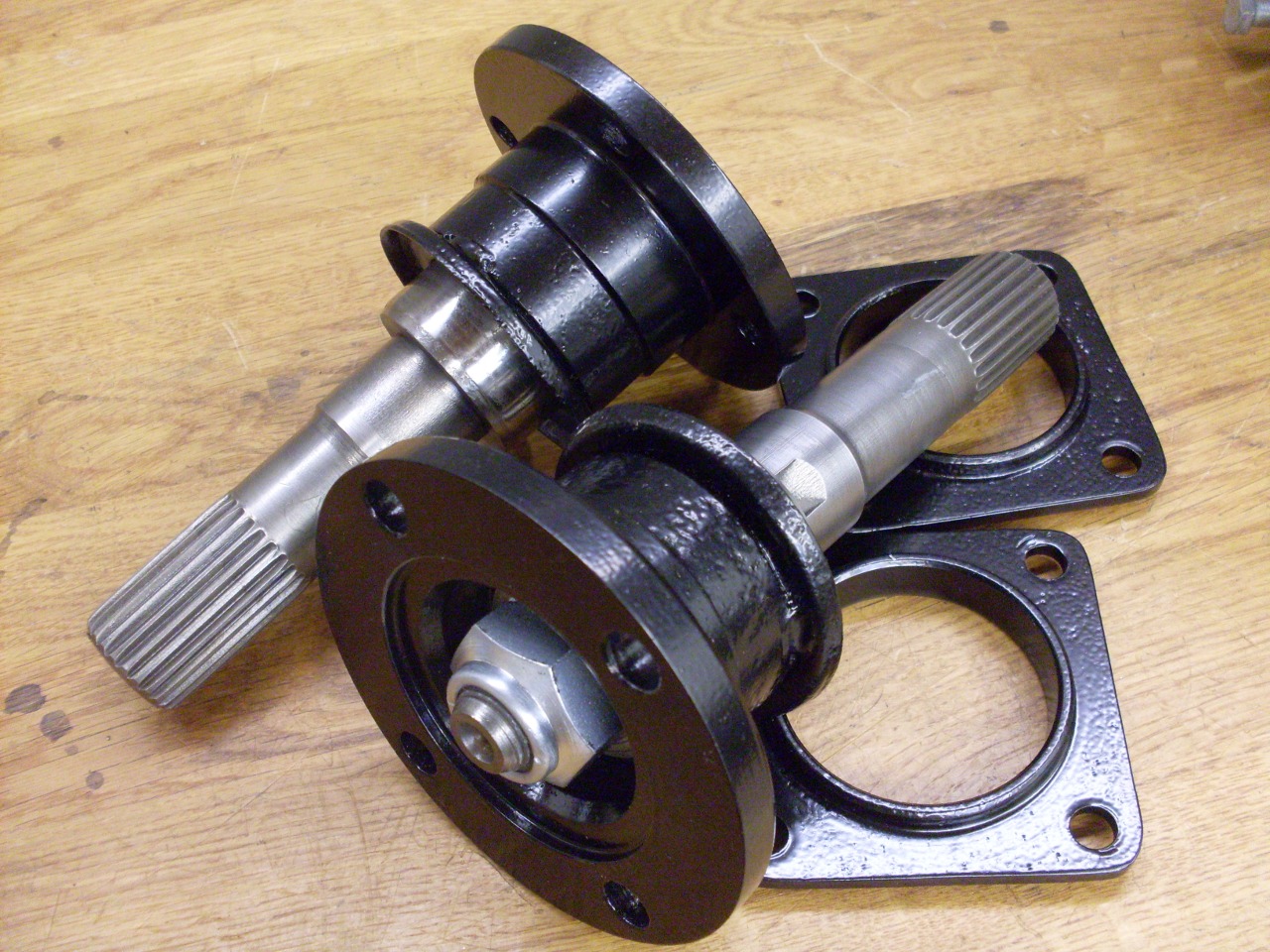

Then a pleasant degrease and derust, and a nice powder coat.

Now,

about the late shoulder. The only earthly purpose I can imagine

for it is that it would keep the shaft from pulling out of the bearing.

Even though it appeared unlikely that this would happen, it

seemed prudent to restore that function, even if it wasn't intended in

the original design. I decided to fashion a collar to go next to

the bearing to stand in for the missing shoulder.

I started out with a hunk of really good steel...

...and turned a couple of rings with the same ID as the bearings.

Then

drilled and tapped three holes in each one for set screws. The

set screws are the kind that have a little nose on the end that goes

into matching holes in the shaft.

Pressed the seals into their carriers.

Here are all the parts for the inner axles.

Pushed on the bearings with that little pipe thingy, and installed the collars with a little Locktite on the setscrews.

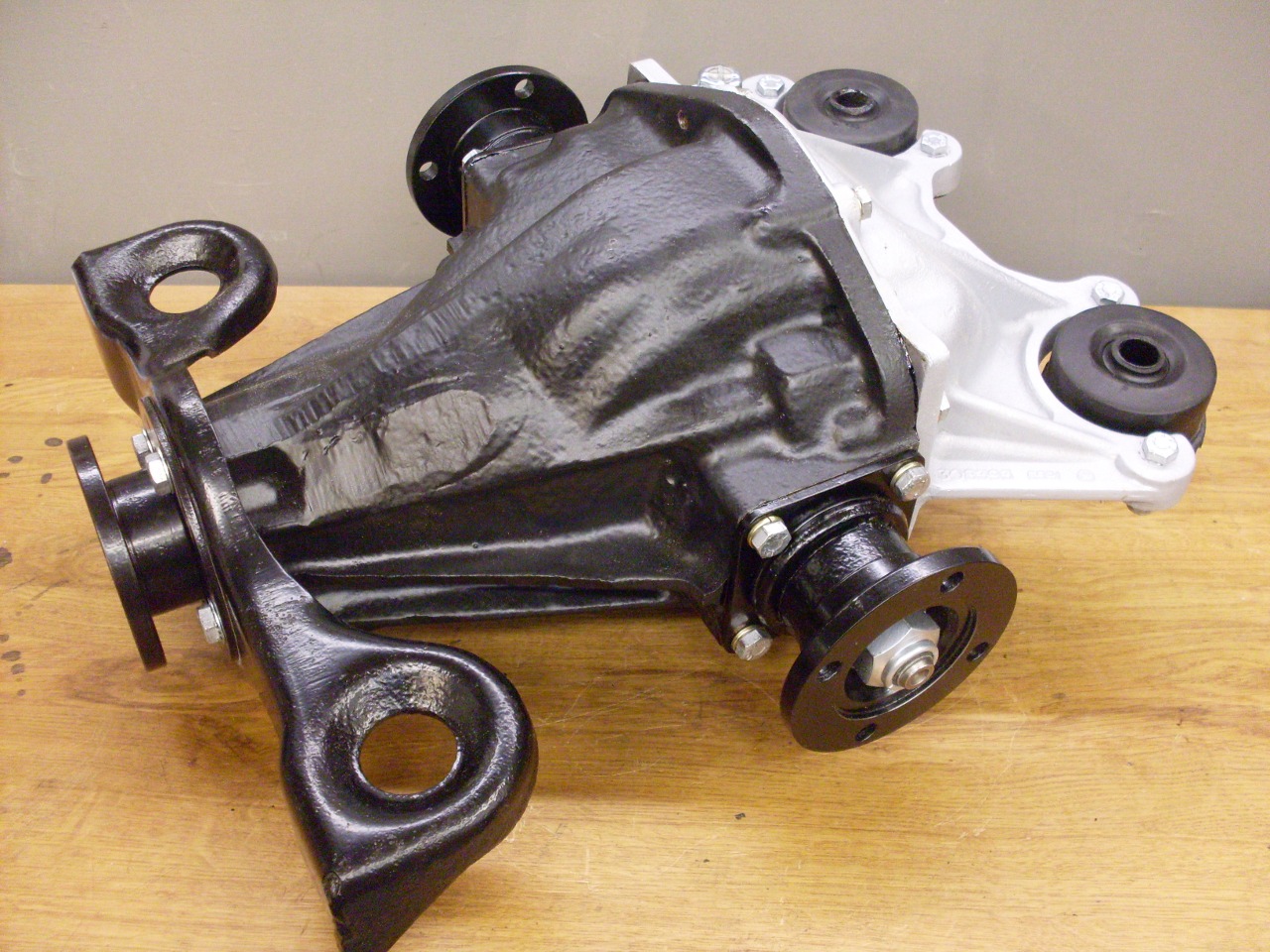

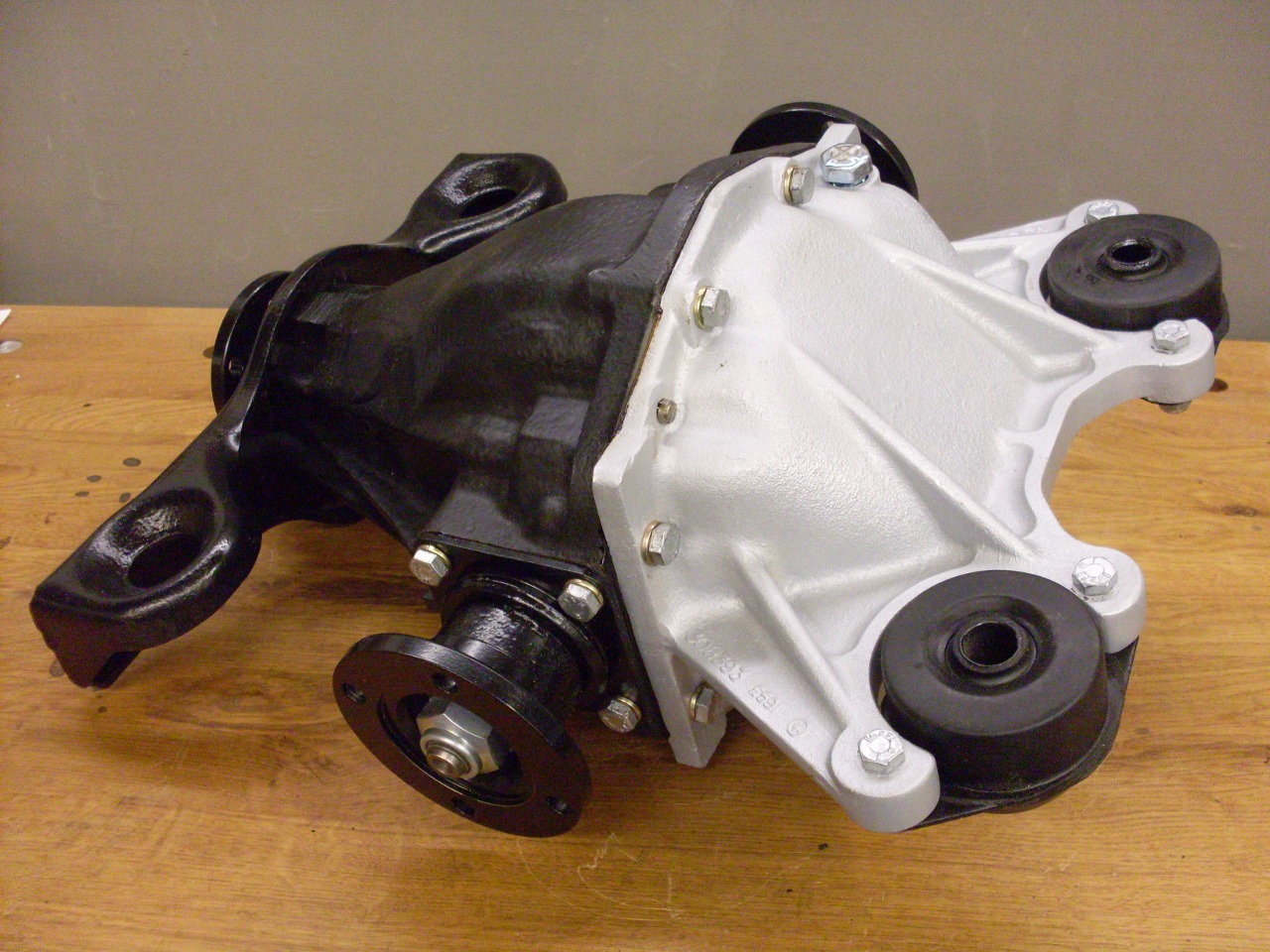

Shoved

in the axles and tightened down the seal flange. The flanges

don't have gaskets, but some sealer seemed like a good idea, so I broke

out my trusty Permatex 3D. I considered making some gaskets, but

the flange also captures the bearing's outer race, which is otherwise a

fairly loose fit in the case. A gasket might give the race enough

room to shift a little, or even turn. Also installed stainless fill and drain plugs.

Rounded up all the replated fasteners for the rear cover, using new lockwashers. A couple of dowels locate the cover.

Buttoned

up the cover, and added new mounts to it. This puppy goes on the

shelf to make some bench space for something else.

So

was the creativity with the axle shafts a good idea? I don't know

yet, but for the time being, it keeps me from admitting that the axle

shafts beat me.

Send comments to:

elhollin1@yahoo.com

To Other TR6

Pages