To my other TR6 pages

August 1, 2014

Rack & Pinion

[Click the pics for a bigger view.]

The

TR6 uses a simple rack and pinion assembly for steering. Each end

of the rack carries an inner ball joint for tie rods to the steering

arms.

My rack & pinion assembly looked about as bad as the

rest of the car on the outside. However, as a pleasant surprise,

I found the internals to still be very well lubricated, and in very

good condition.

Now

I normally don't dwell on my mistakes, let alone document them for the

world to see, but I'll describe here a bonehead moment that occured

when disassembling the rack housing. I had removed the pinion

gear, and wanted to remove the bottom bushing that it rides in. I

was somehow under the impression that the hole in the bottom of the

housing was blanked off by a welch plug that had to be driven out from

the inside. Even though a little thought would have shown that

this is silly, I proceeded to try to drift out the plug from the pinion

side. Even the fact that the "plug" refused to move despite

considerable force didn't phase me. Only after I finally broke

out the bottom of the alloy housing did it dawn on me that the bush and

the thrust bearing, which I thought was the plug, would have easily

pushed out from the bottom up.

I

was doubly frustrated because I thought I'd just ruined a rack and

pinion assembly that was in excellent shape. I finally resolved

that as penance for such a stupid mistake, I'd go to whatever heroic

lengths it would take to repair the damage I caused. After a

little thought, I came up with a plan that was simple, though it took a

while.

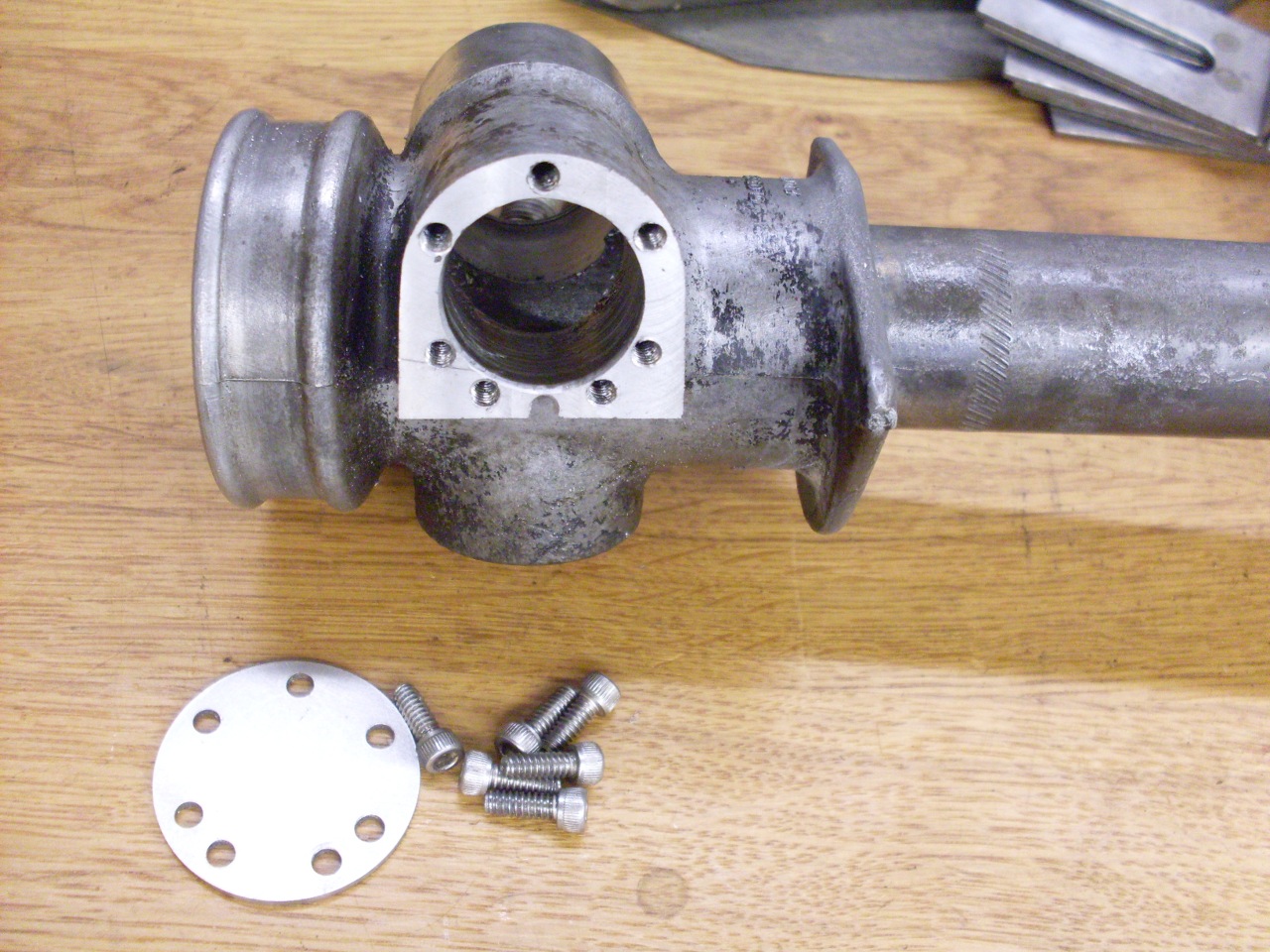

First, I milled off the bottom broken surface down

approximately to where the bottom of the internal bore had been.

Then drilled and tapped six 8-32 holes around the perimeter to

hold a stainless cap. The picture shows evidence of another

maddening lack of forethought. The lowest of the six holes didn't

have enough meat, and broke through the edge of the casting slightly.

It would still hod a screw, but not with much torque. If I

had only just rotated the hex pattern by 30 degrees, it wouldn't have

happened. To compensate, I placed two additional tapped holes,

one on either side of the bad hole. This explains the odd screw

pattern.

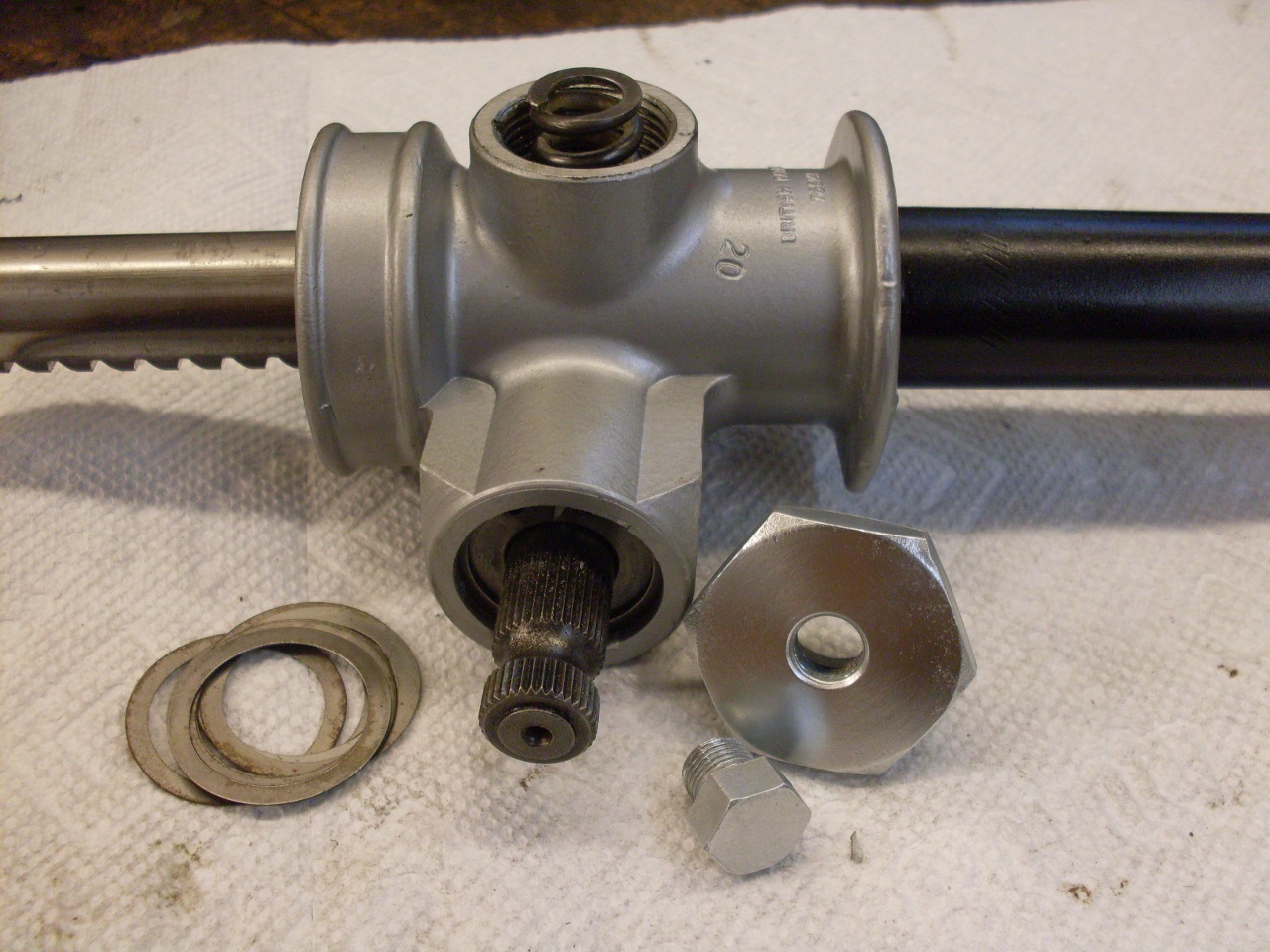

With

that barely controlled disaster behind me, I resumed the

reassembly of the rest of the pinion part of the unit. I checked

the fit of all the bushes and they were so good, I couldn't see how new

parts could provide any improvement. Likewisewith the rack bush.

The only new parts in the assembly was the O ring for the pinion

shaft, an a couple of additional shims (because of my "redesign").

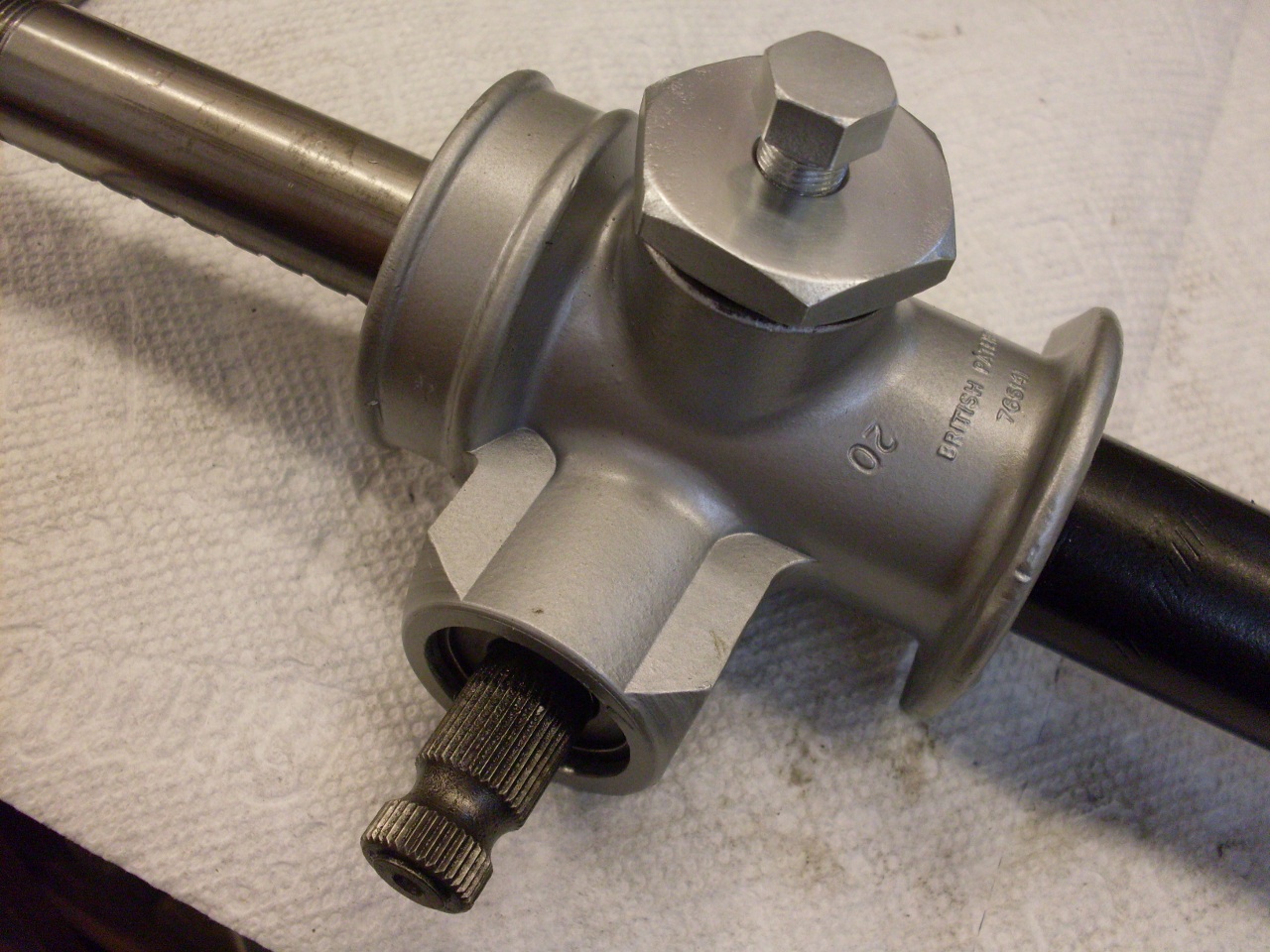

After painting the rack & pinion housings and replating

damper cap and plug, I started to put it all back together. The

parts inside the pinion housing are put together as stock,

including the thrust bearing, so the pinion shouldn't know the

difference.

I even managed not to lose the little plastic plug. I'm not sure of the purpose for this. Pressure relief, maybe?

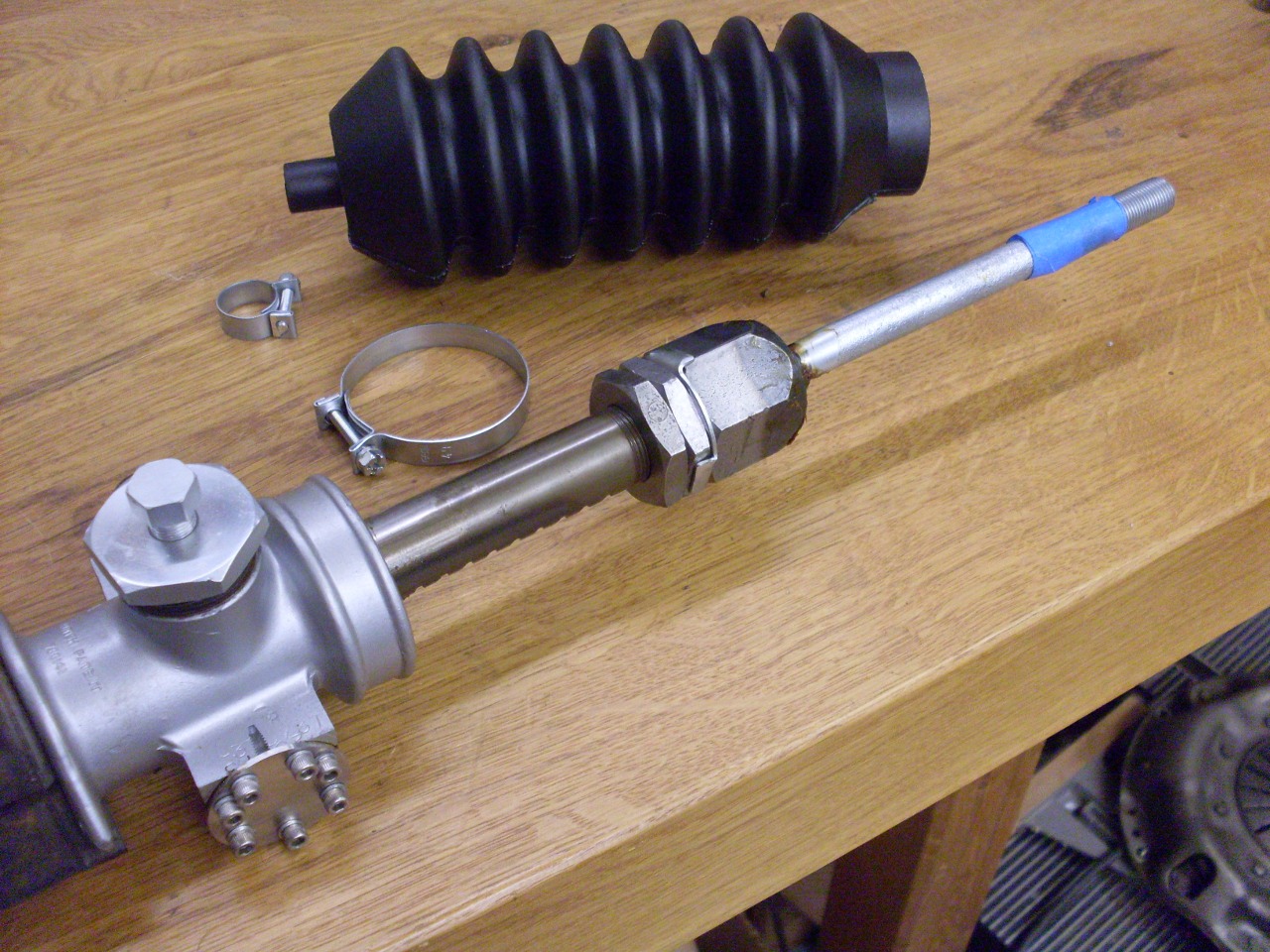

Next

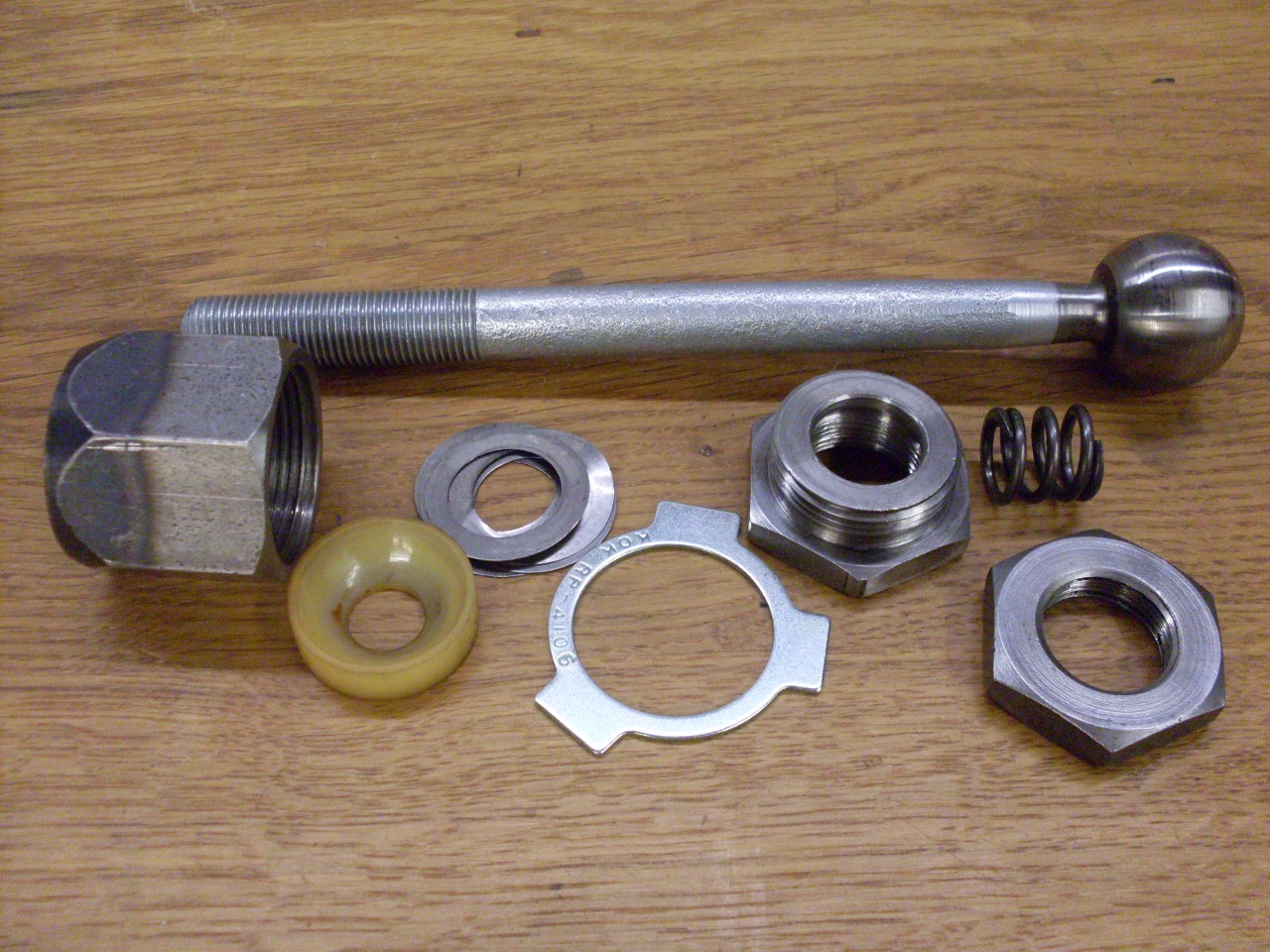

up was the tie rods with their inner ball joints. Everything in

the joints was still covered with clean looking grease, and felt tight

and smooth. The balls were bright and shiny, with hardly any

evidence of wear. The rod part of the tie rods were pretty rusty.

Most

of the ball joint parts live out their lives bathed in grease, so

plating is unnecessary. The exception is the rod part of the tie

rods. These are at least partially exposed to the elements where

the gaiters don't cover. I thought zinc plating the tie rods

would be worthwhile, but didn't want to interfere with the nice surface

of the ball. I ended up selectively plating the tie rods by

spraying a couple of coats of lacquer paint on the ball parts to act as

a resist to the plating. Lacquer dries fast and is easy to

remove. It worked out well.

After

close inspection, I decided that as for the pinion parts, there was

nothing to gain by buying anything new. The reassembled the ball

joints with the original parts (except foir the tab washer) and shims,

and fresh grease, showed firm but smooth movement.

Tie

rods attached to the rack. There is a spec for the distance

between the face of the ball joint lock nut and teh center of the tie

rod end. This is dificult to measure with the gaiter in place, so

that's what the tape is for--it marks how far the tie rod end should be

screwed on.

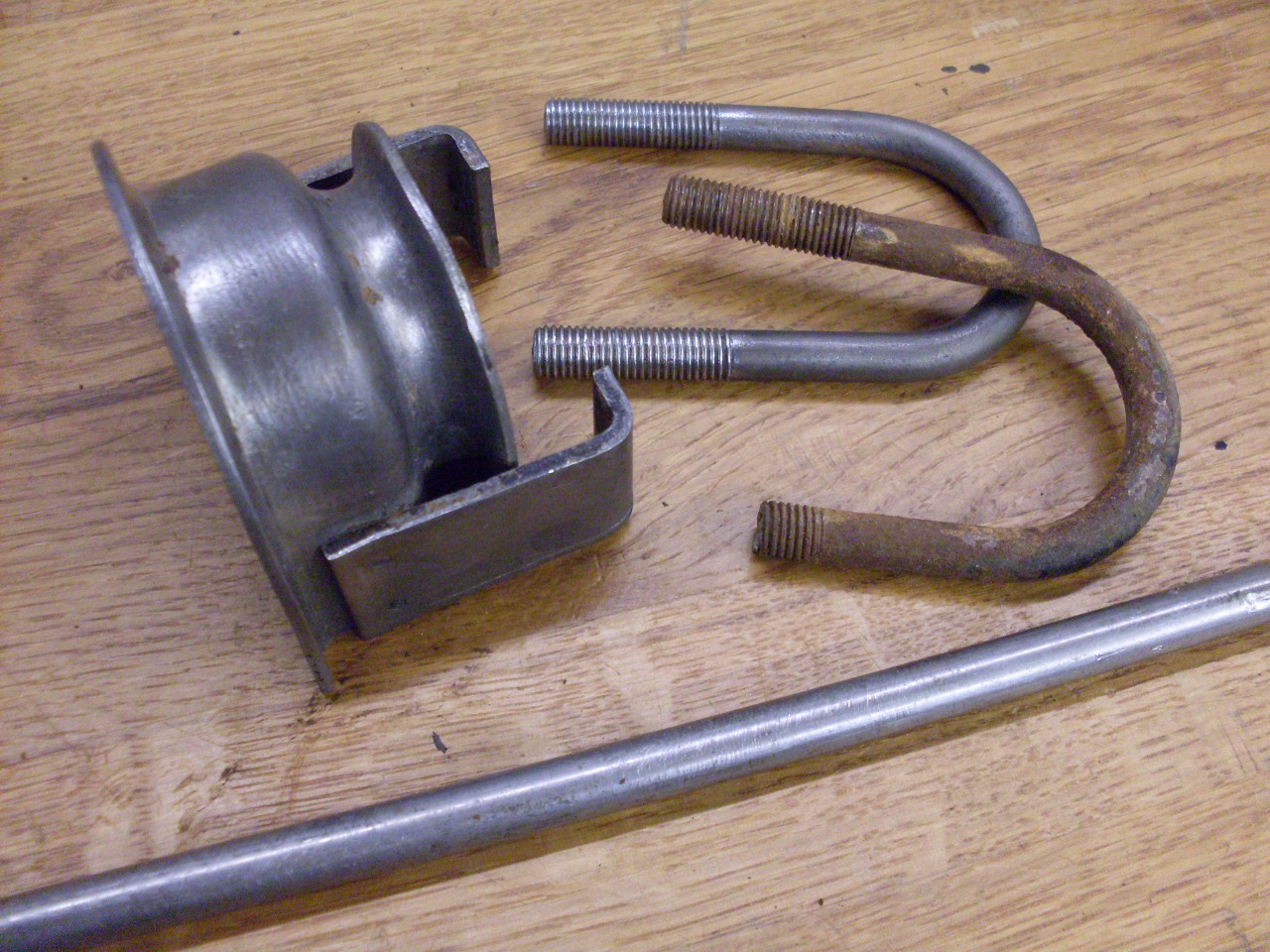

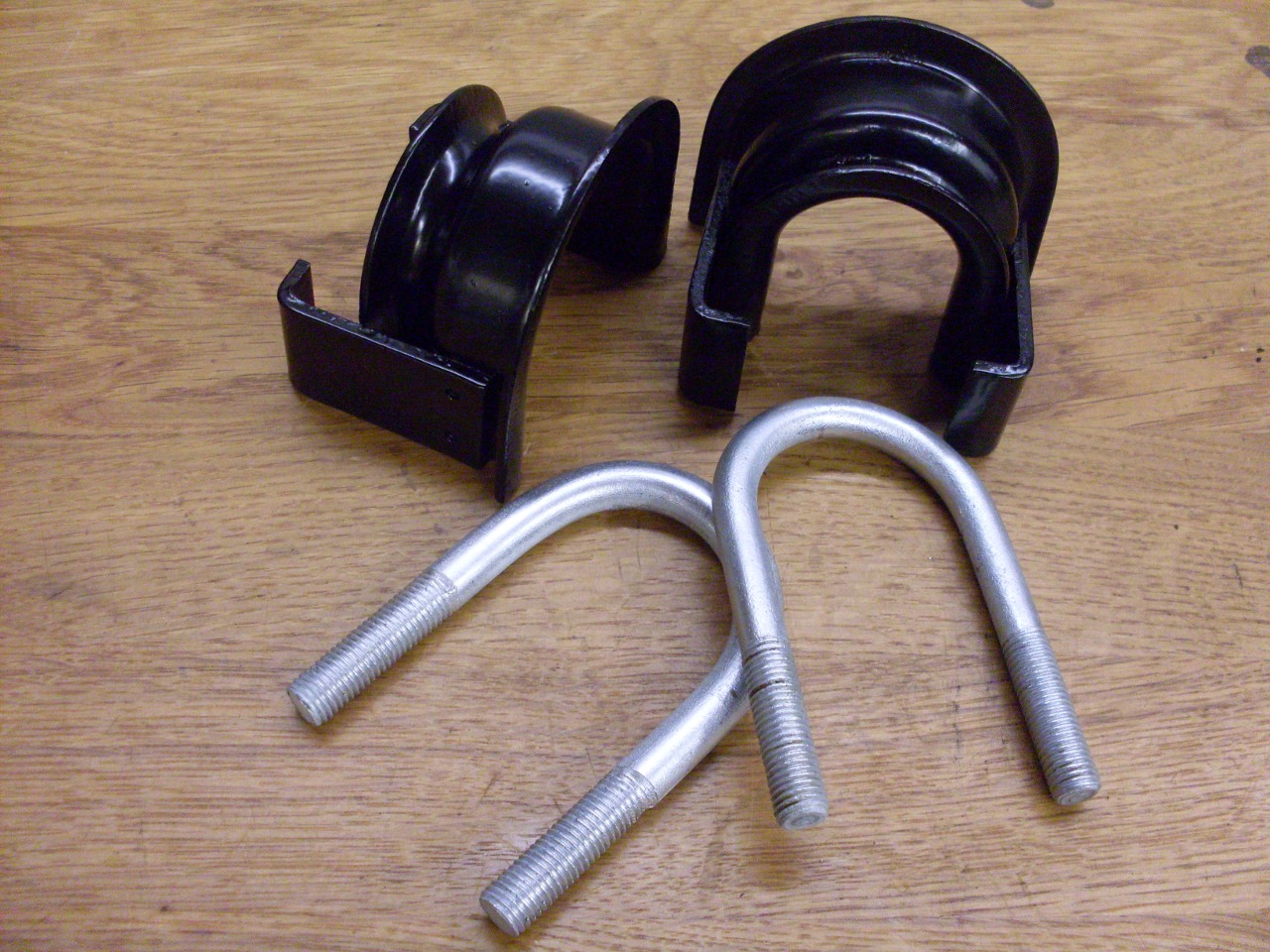

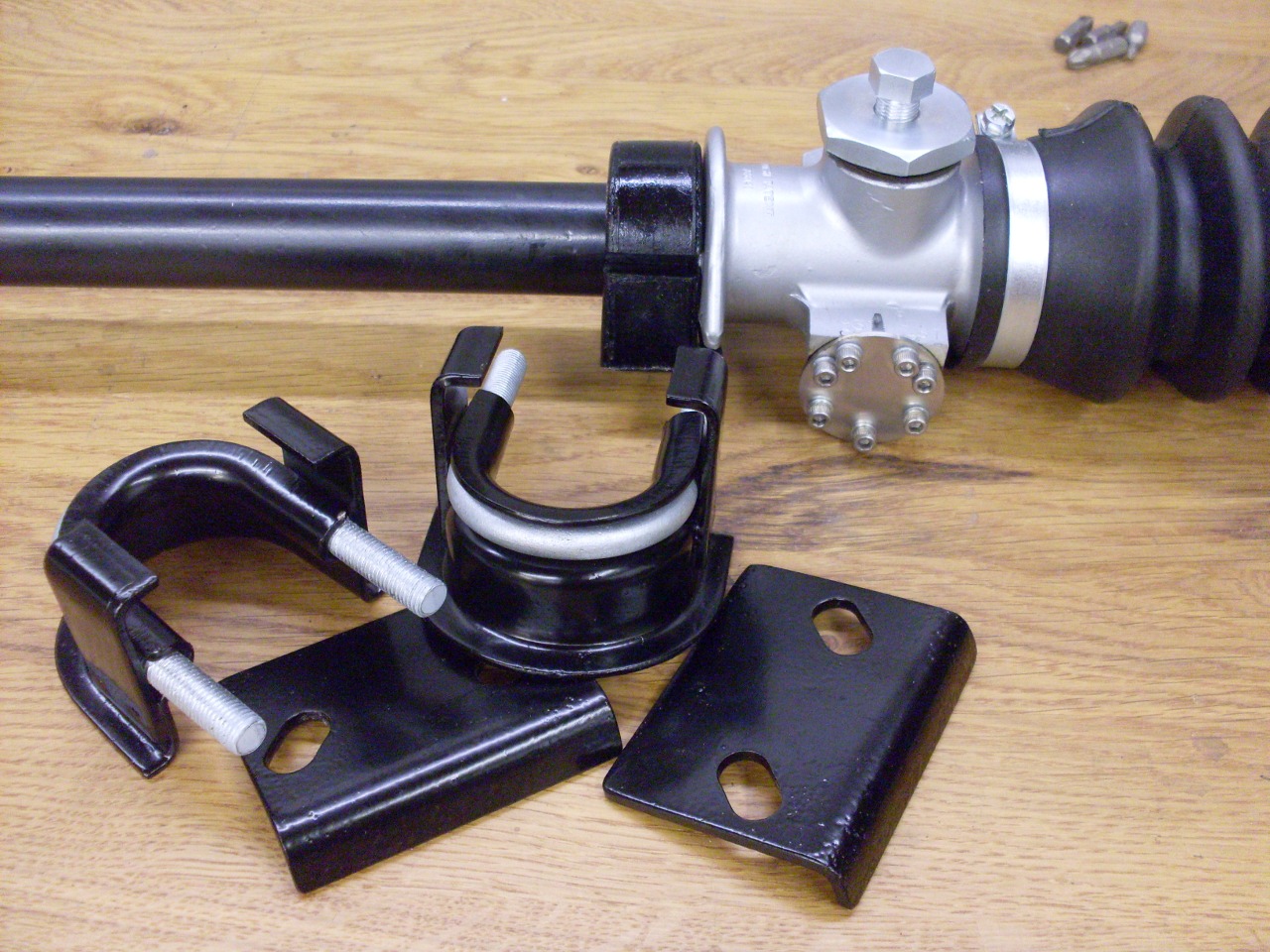

Last

parts to deal with were the mounting clamps for the rack and pinion

assembly. One of the U bolts had broken during teardown, and I

had some trouble trying to source an exact replacement. Some

places wanted me to buy the entire clamp, which was silly. I

figured a simple U bolt shouldn't be hard to make, and it wasn't, but

it did take a little time. The original bolts have 5/16-24

threads, but they must have been rolled on, since the actual rod is

only about 0.280". My bolt made from 5/16 rod is a little fatter,

but finally fit OK.

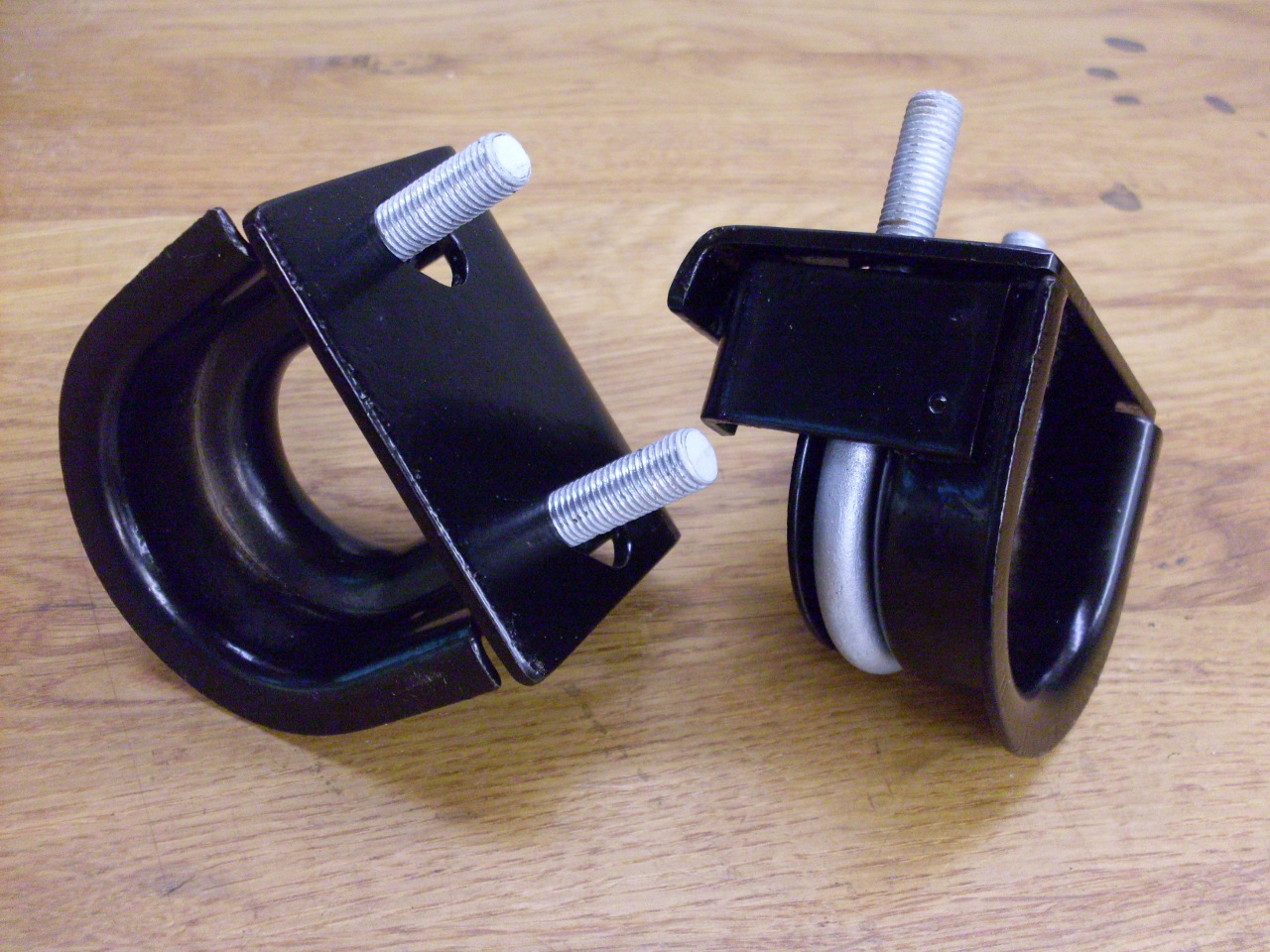

After

plating and powder coating, the old clamps are ready for service again.

Last pic includes one of the new poly rack mounts.

New tie rod end. Oops, forgot the lock nut.

The

resilient mounts need to be preloaded before tightening the U bolt

clamps. There is a factory tool for this, but this is my version.

Everything bolted in. Time to move to the rear suspension.

Comments to: elhollin1@yahoo.com

To my other TR6 pages