To my other TR6 pages

February 27, 2014

Carburettors

[Click the pics for a larger view]

I've

been working on the carbs off and on for the last couple of months.

I'm by no means an expert on Zenith Stromberg carbs, but I think

I've acquired a simplistic understanding of the principles behind their

operation.

The basic ZS carb had become encrusted with a

number of subcomponents over the years due mainly to US emission

regulations. Some of these were expedient bandaids, and even

though it may be true that they don't materially affect engine

performance, they certainly provide additional opportunities for

performance problems if they aren't in good working order and adjusted

correctly. My approach for these carbs is to see that all

components are brought back to original condition and function, and

then to disable the ones that don't add anything but a

failure point.

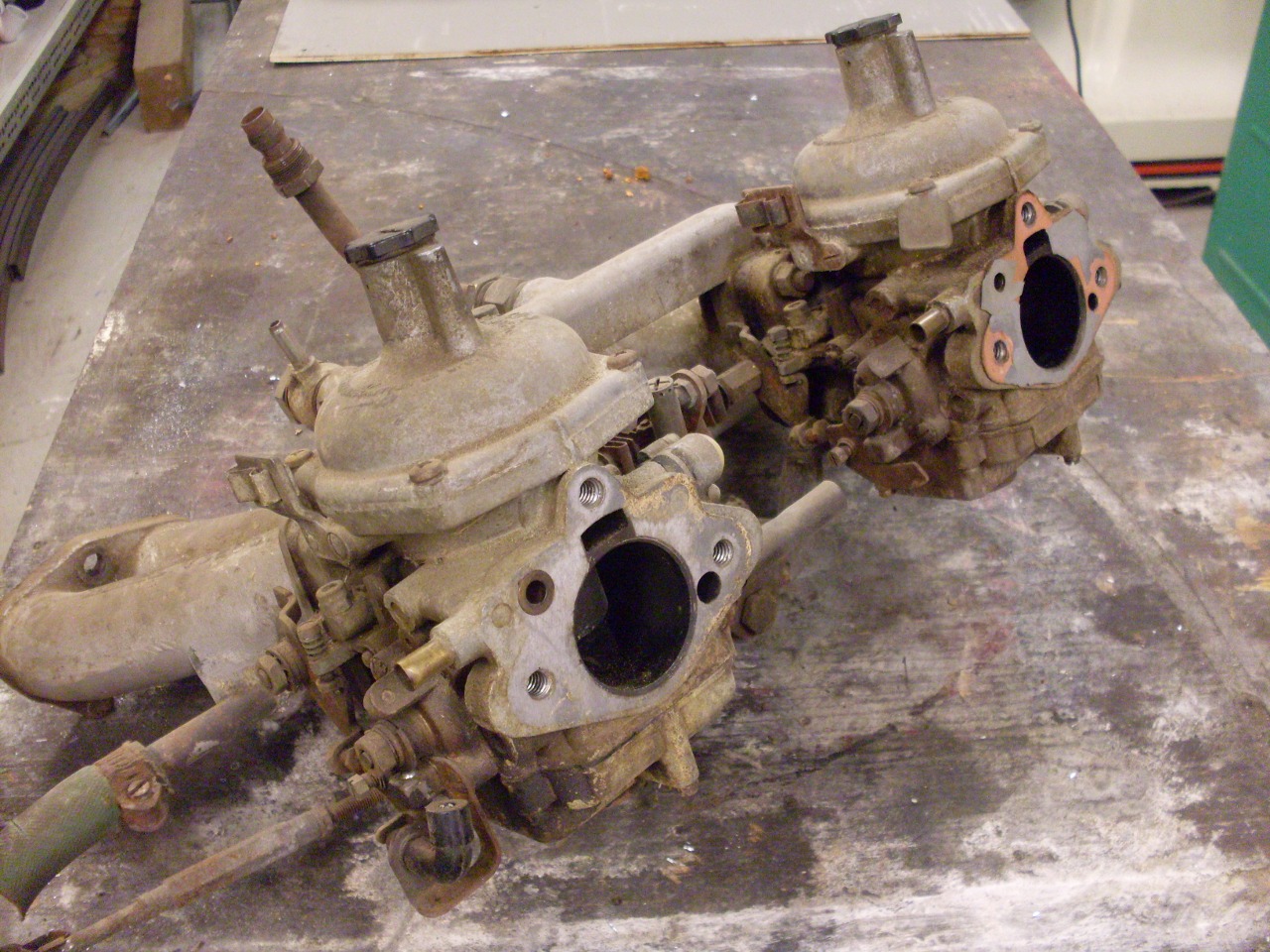

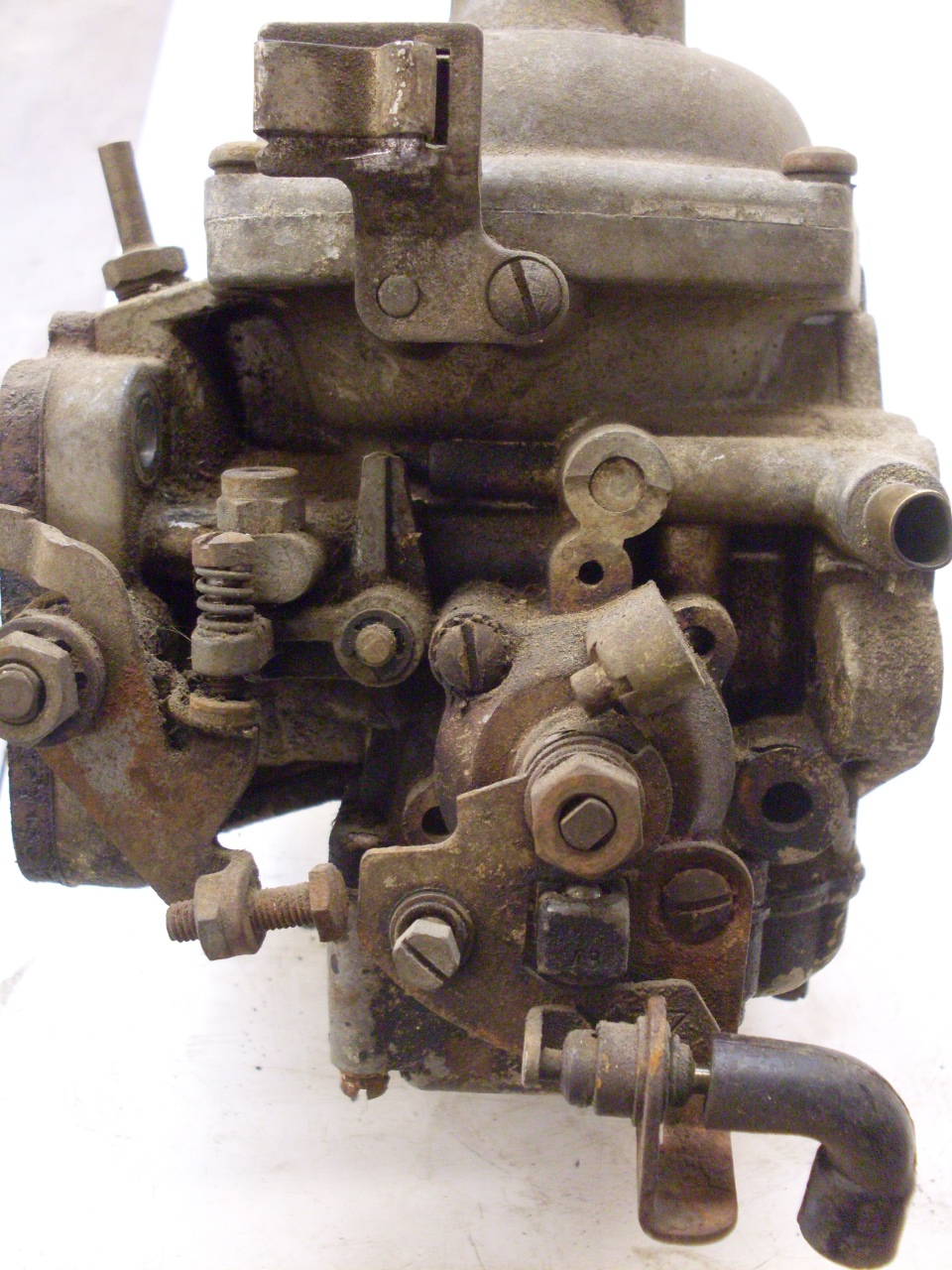

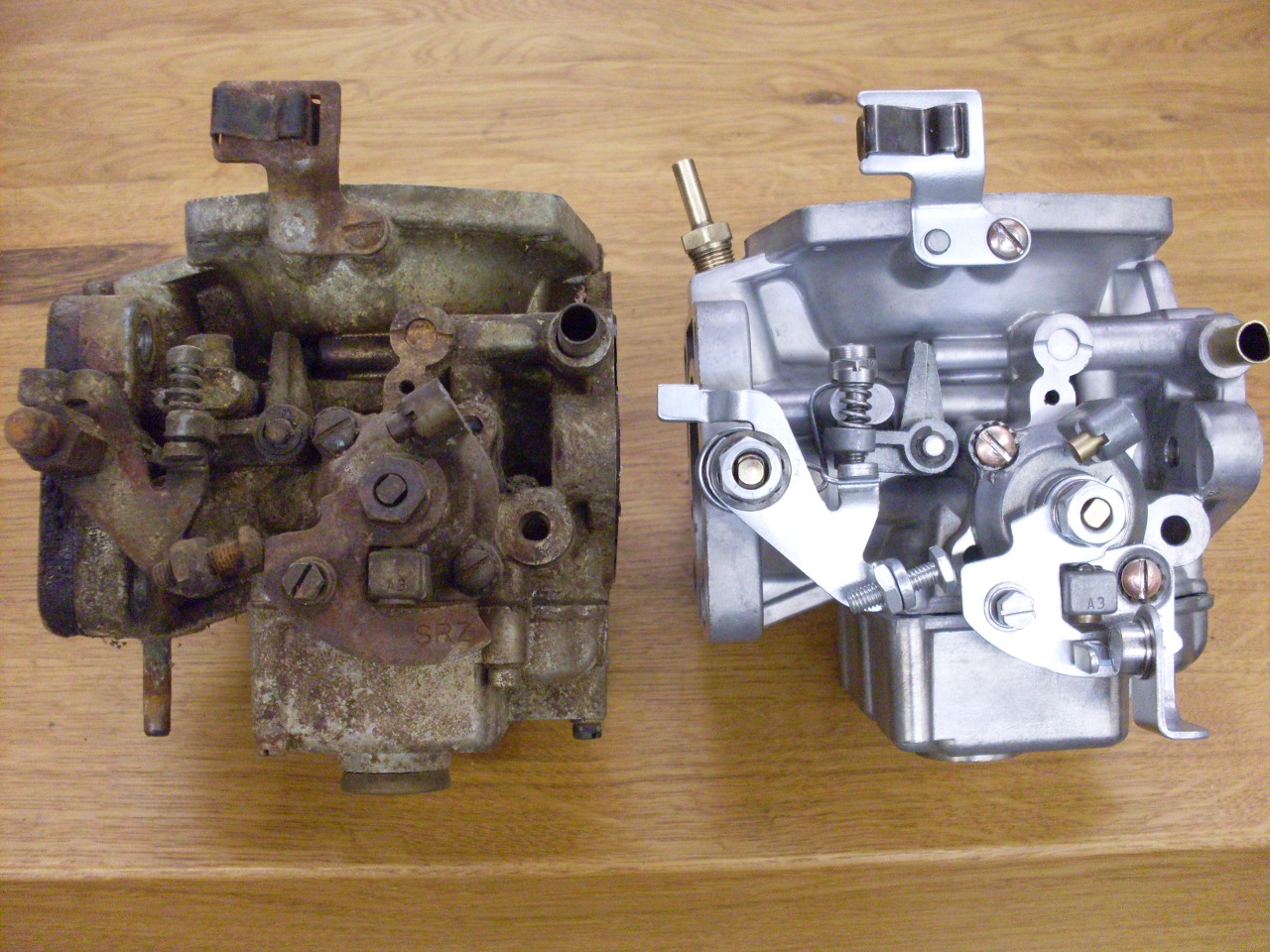

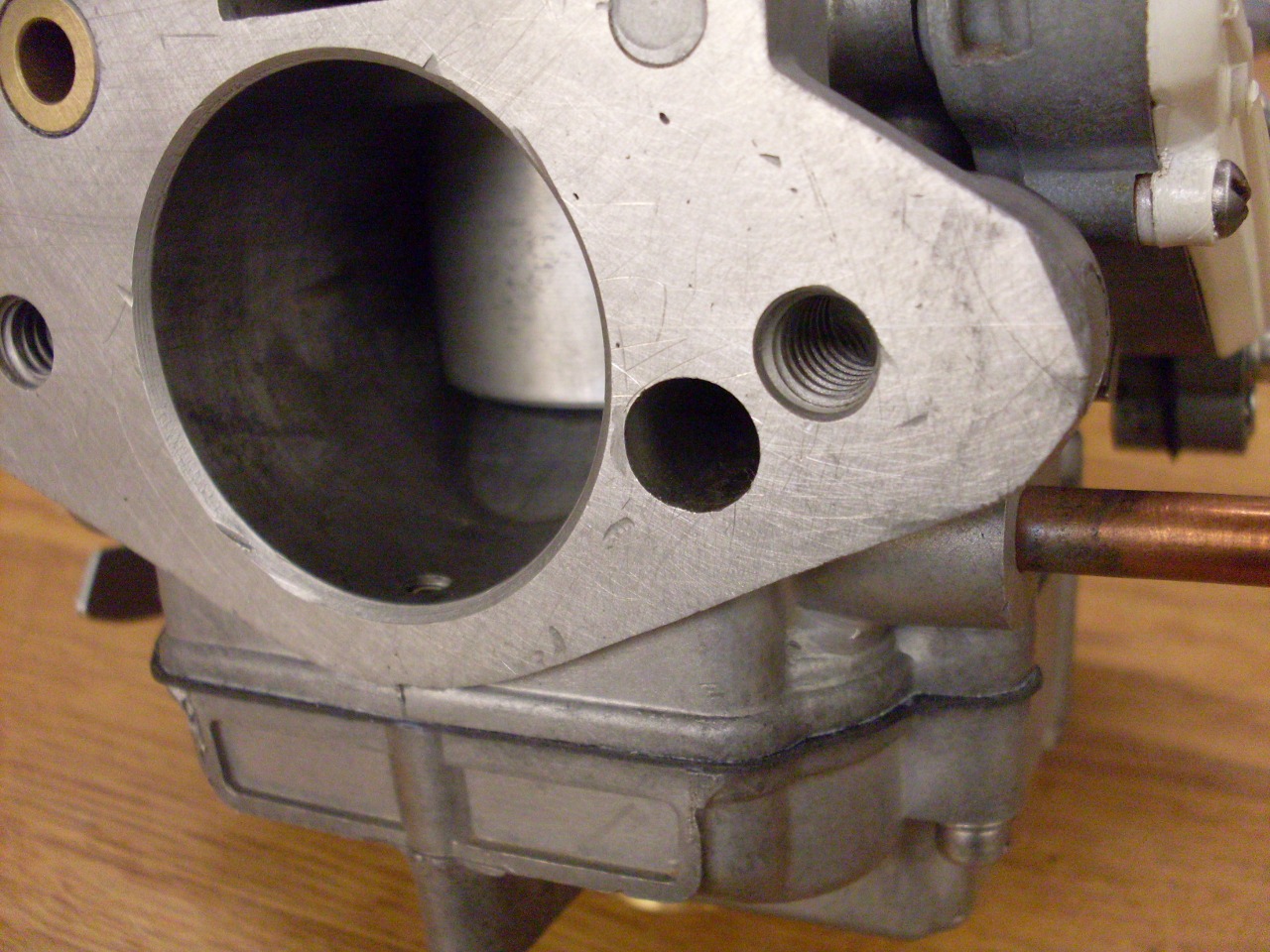

The starting point was pretty sad, inside and out:

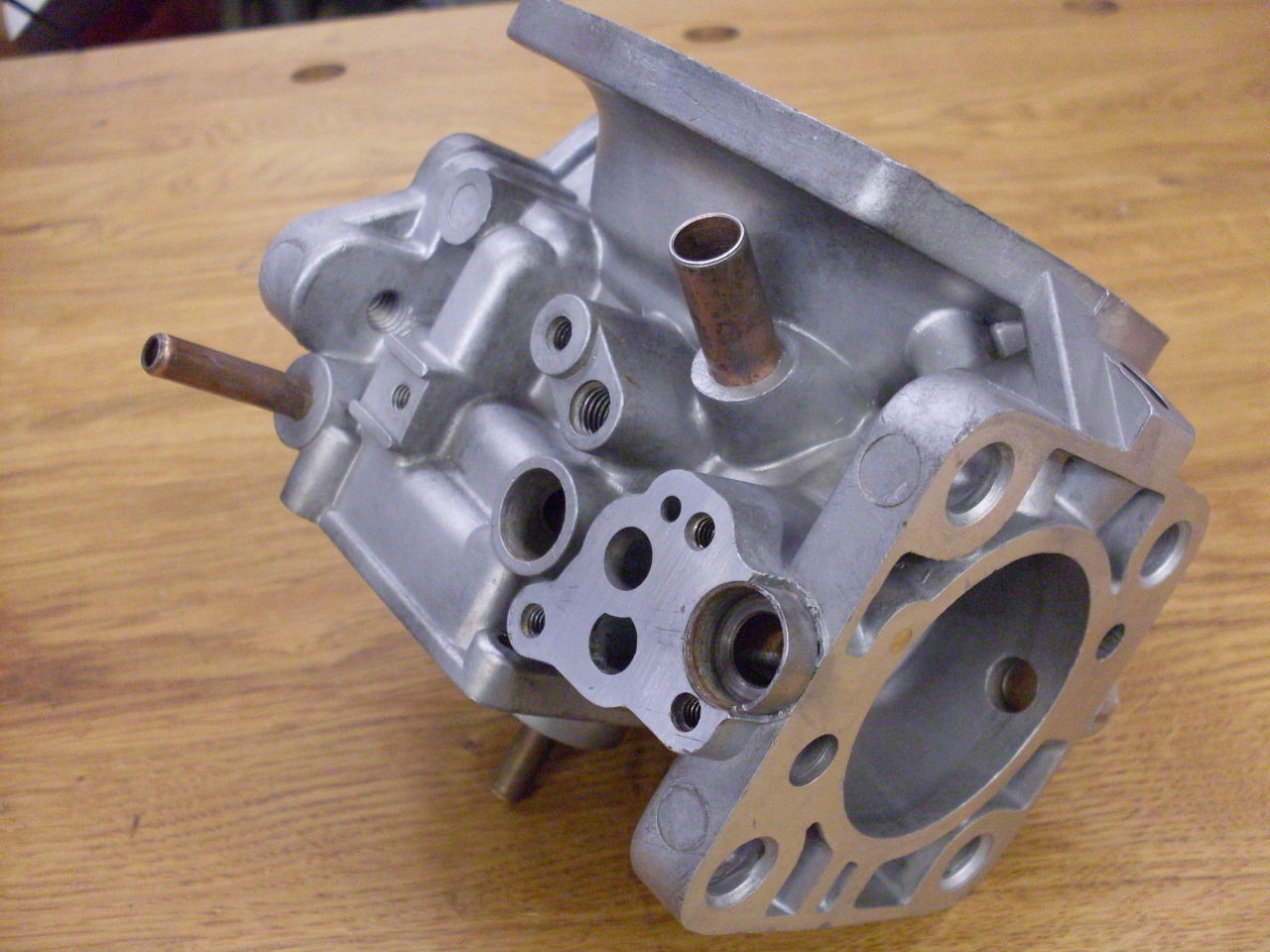

The body casting itself cleans up pretty easily, but being pot metal, its surface finish degrades over time.

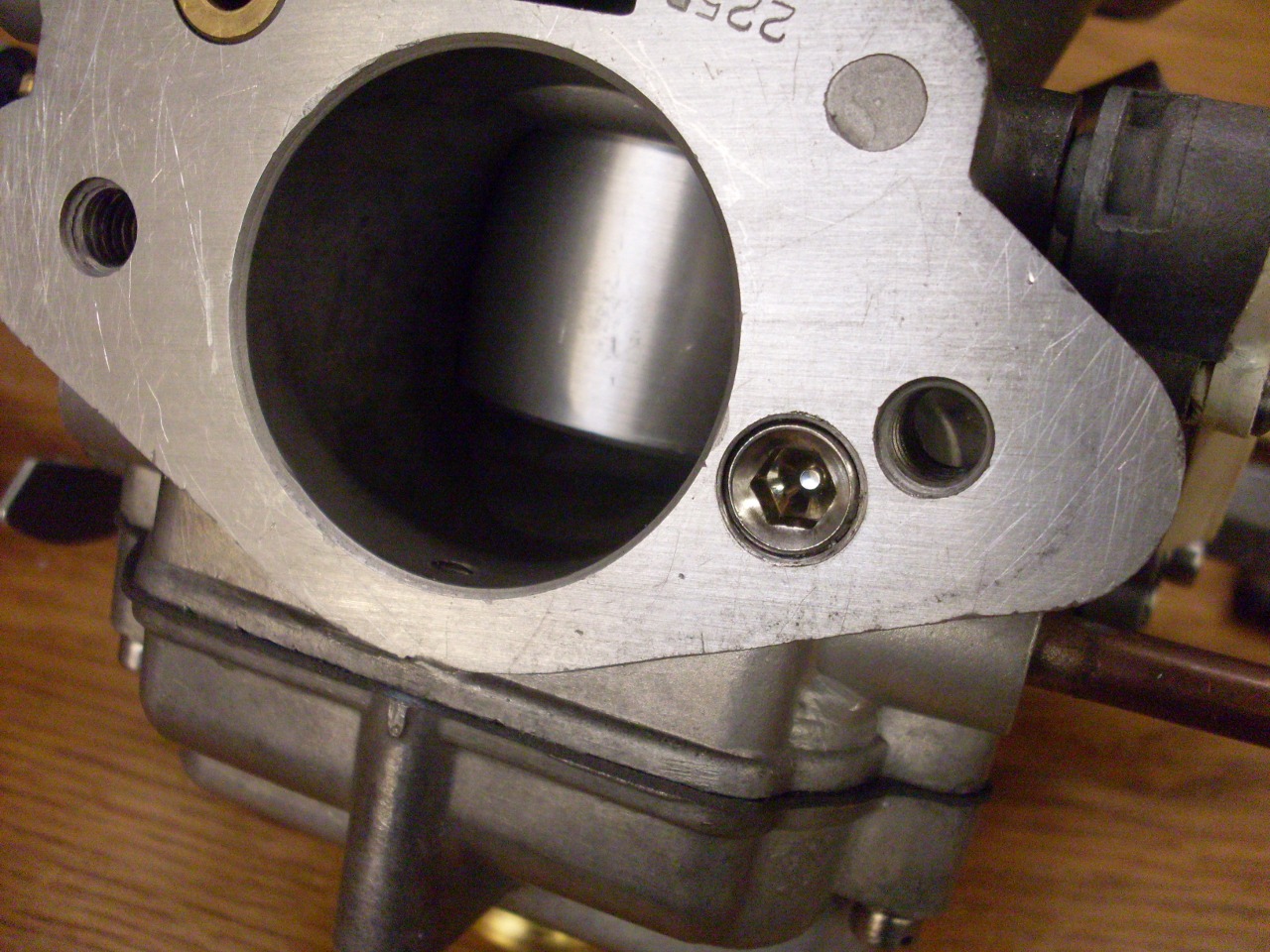

I bought carb rebuild kits, which included new throttle shaft seals.

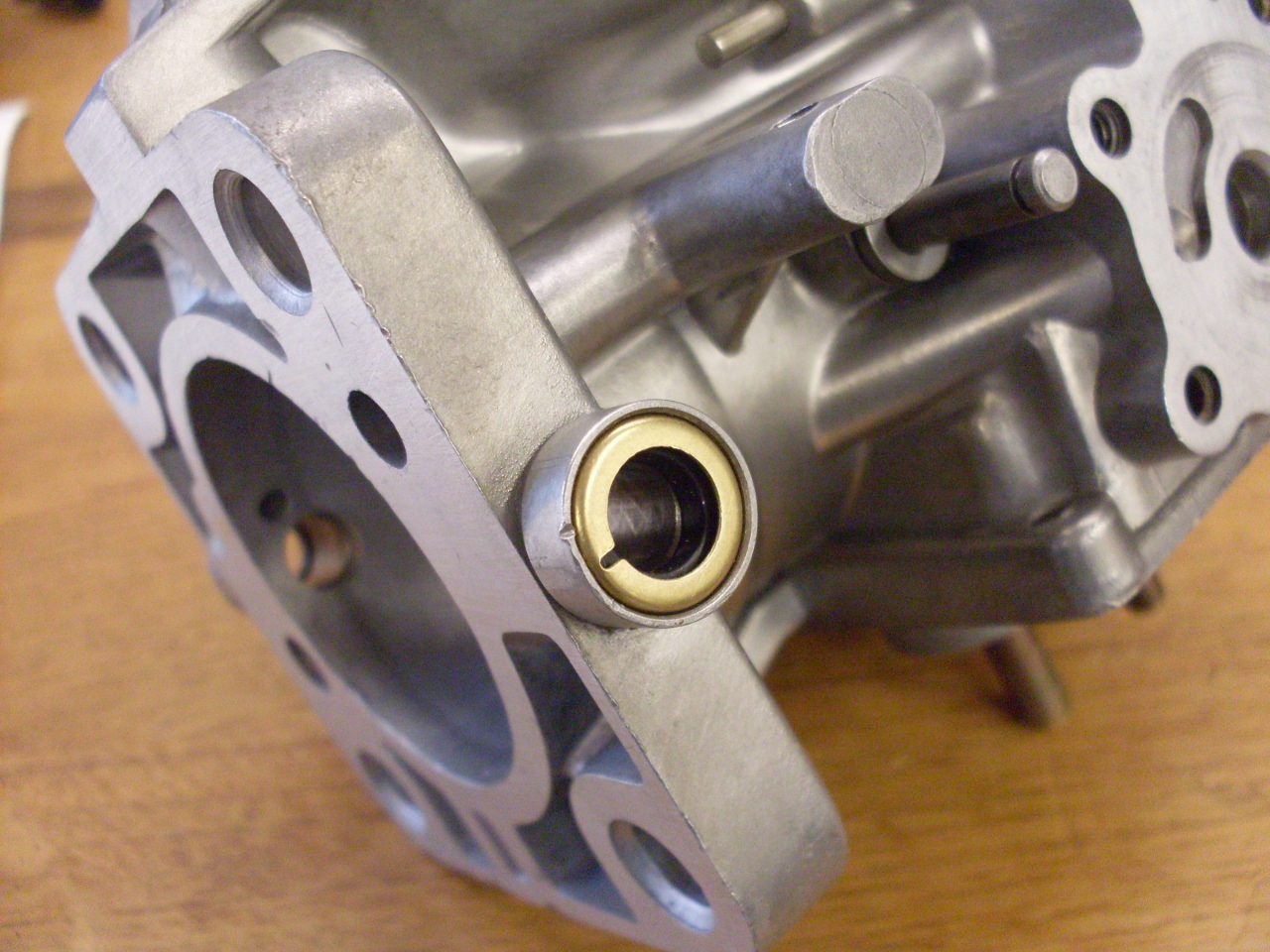

One

O ring that is sometimes missed is the one on the needle adjuster.

Mine was hard and brittle, and broke when I removed it. It

probably wasn't sealing very well.

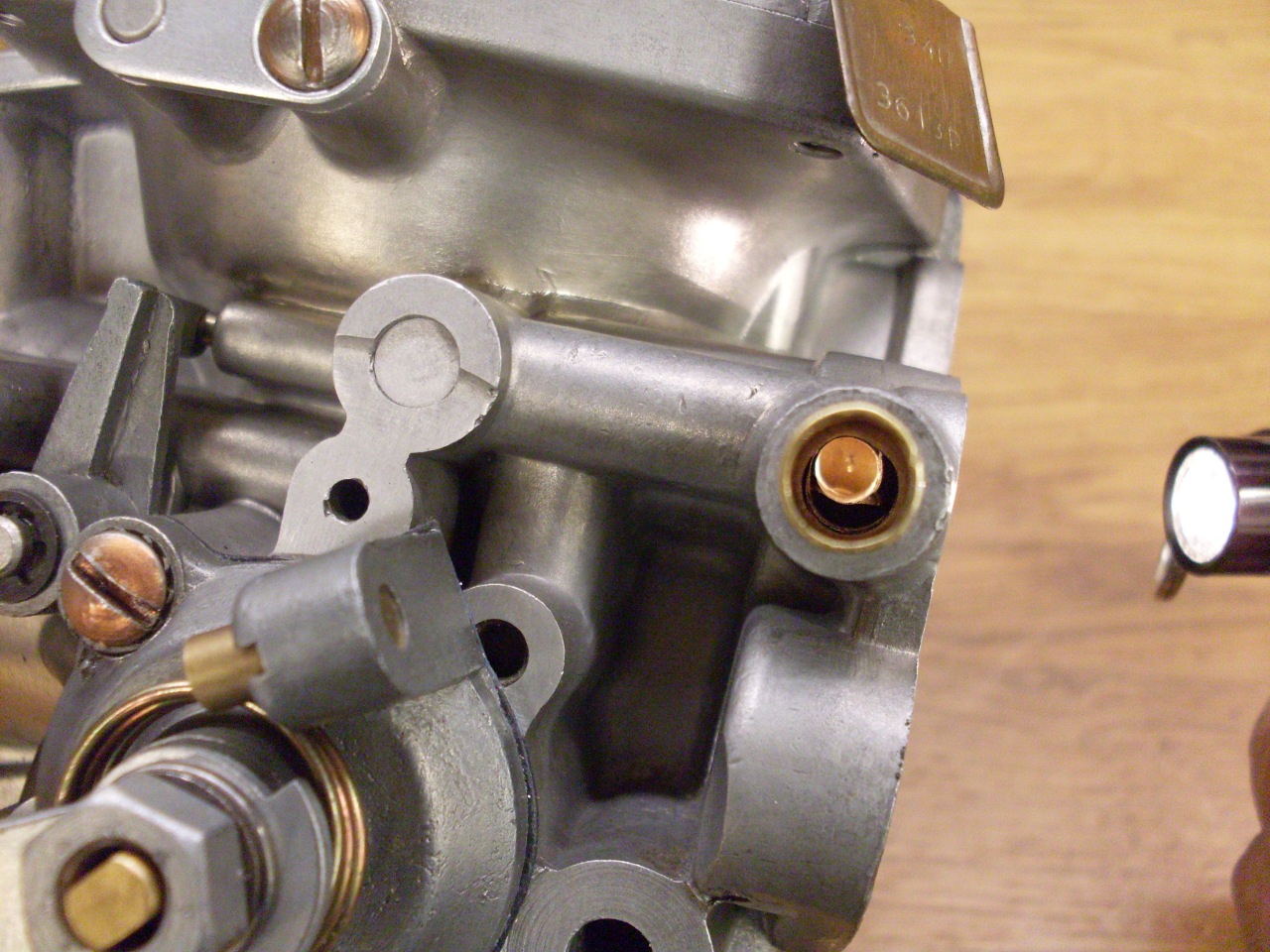

At

the suggestion of some helpful people on TR6 forums, I reused the

original float bowl needle valve after checking that it was working.

Apparently the quality of aftermarket valves is suspect these

days. I have the ones that came in the kits if I need them.

Also set the float height to spec.

Top end gets a new diaphragm.

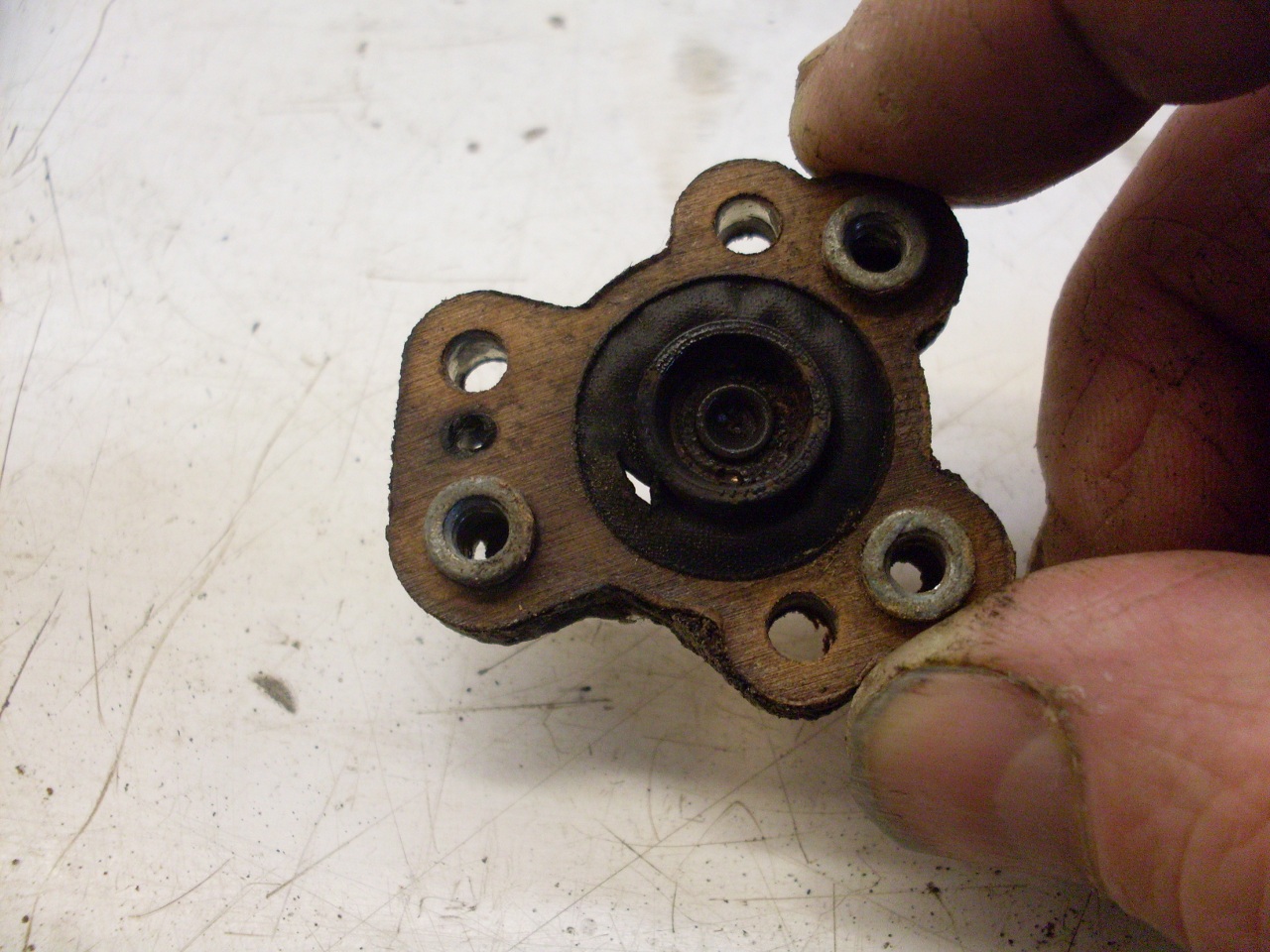

Here

is one of the emission "add-ons". It is a bypass valve that opens

at high manifold vacuum and passes mixture from the mixing chamber

around the throttle plate, effectively limiting the depression in the

manifold. Some of the parts for the bypass valve, including

the diaphragm (shown perforated in the second pic) were not

included in the kits I bought. They up the cost of the rebuild considerably.

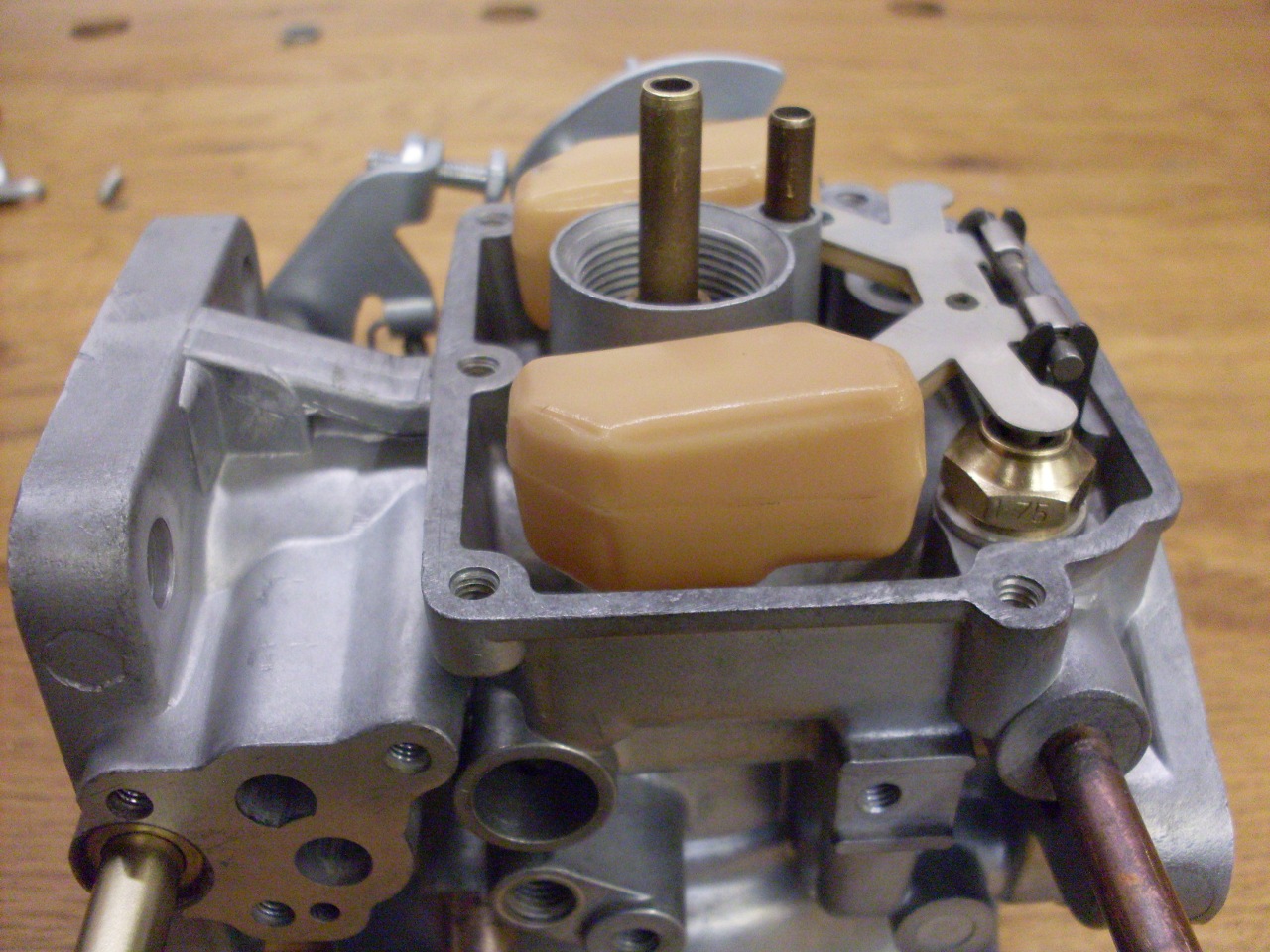

The

temperature compensators are another emission goodie. They pass

air around the air valve at higher temperatures, leaning the mixture.

There isn't very good factory guidance on adjusting these, but

some pretty innovative and knowledgeable enthusiasts have suggested

that they should begin to open at about 115°F and be fully open at

140°F, but that the exact temperatures are less important than

that the two compensators open in unison. The method for setting

them is simple, but a bit of a hassle.

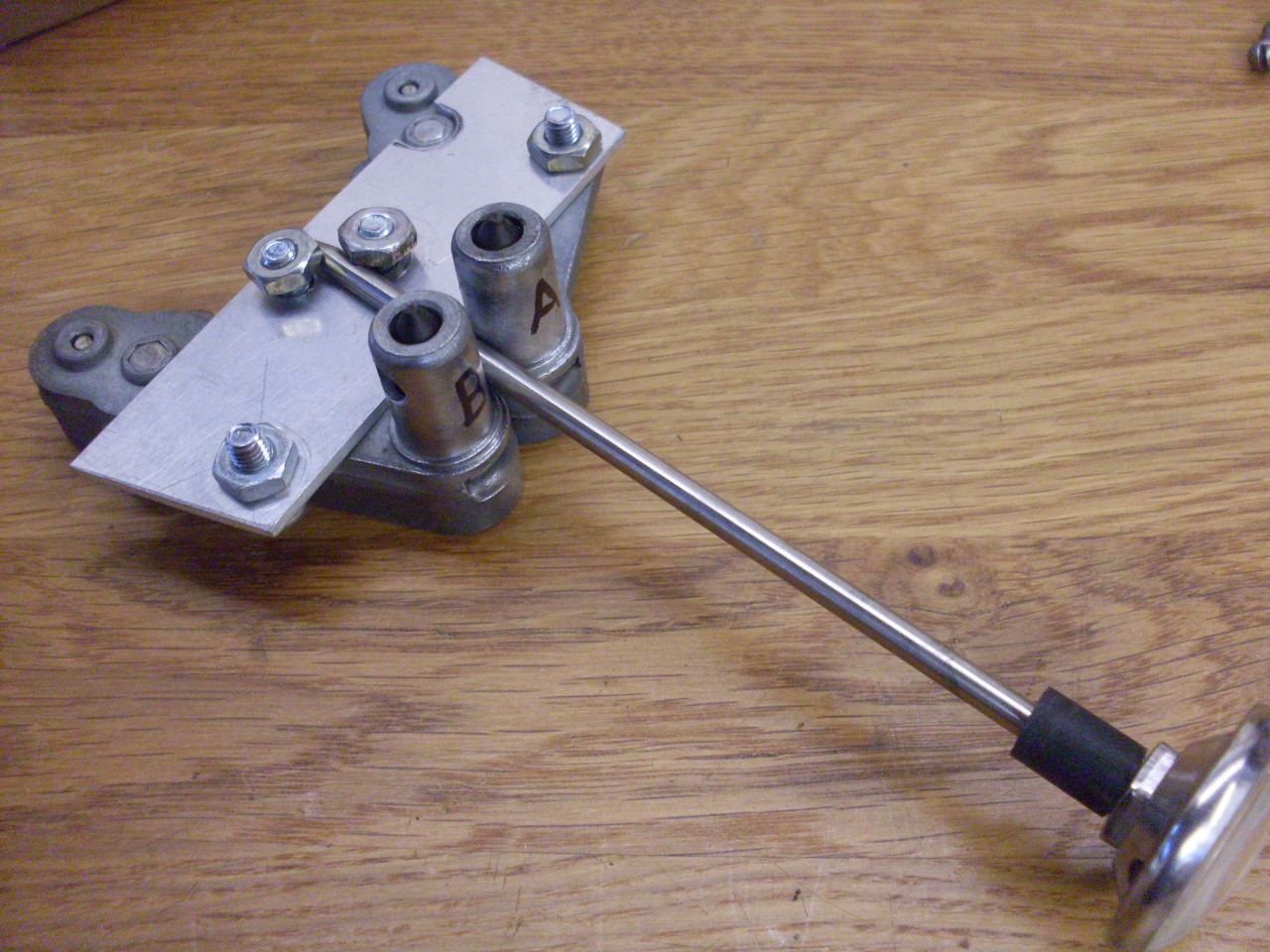

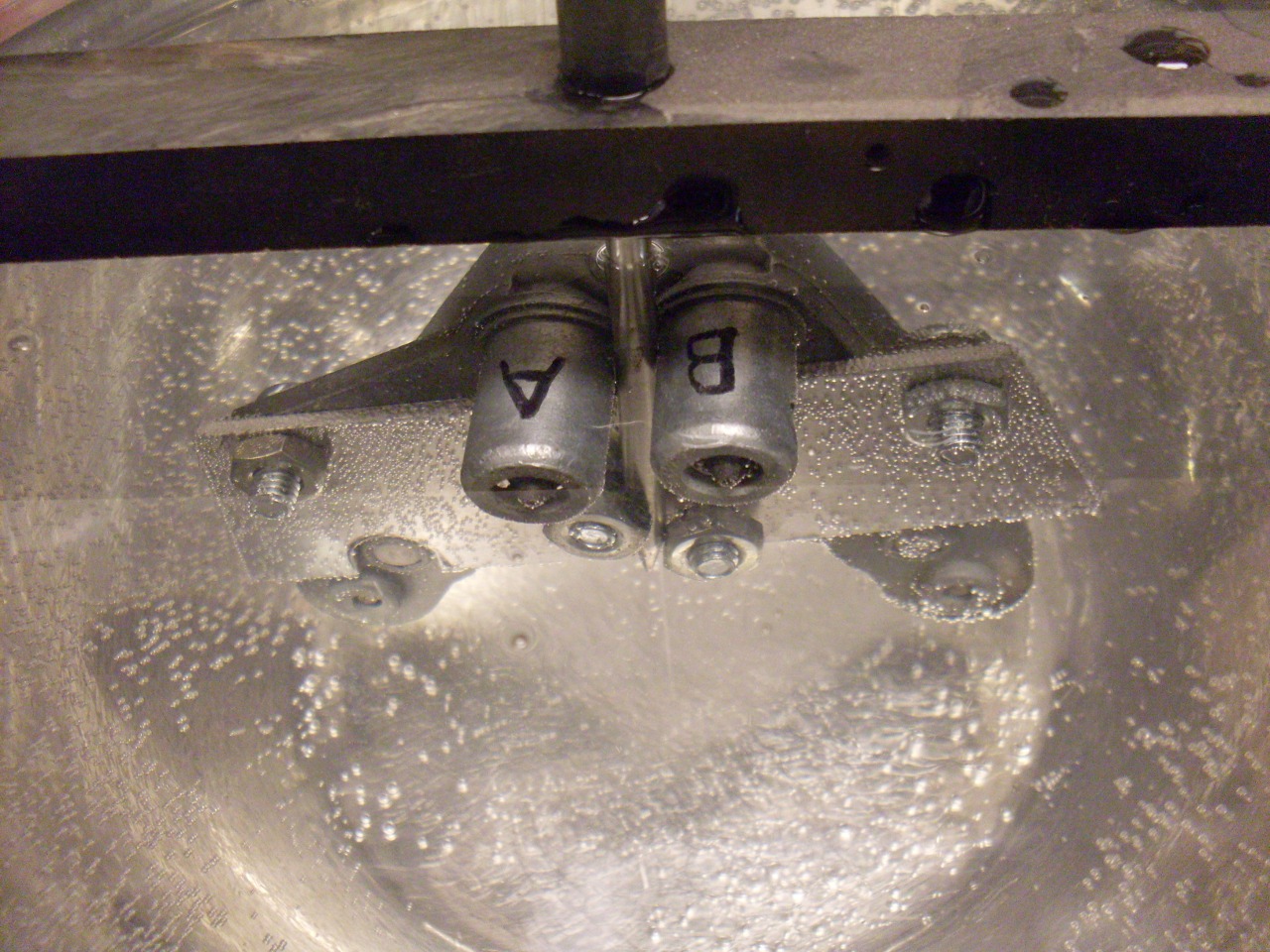

I made an aluminum plate

that would hold both compensators and a thermometer such that I could

easily see the position of the air plugs. The whole contraption

was lowered into a pot of water on a hot plate. After several

iterations of raising the temp and adjusting, I had the compensators

tracking together over the suggested range.

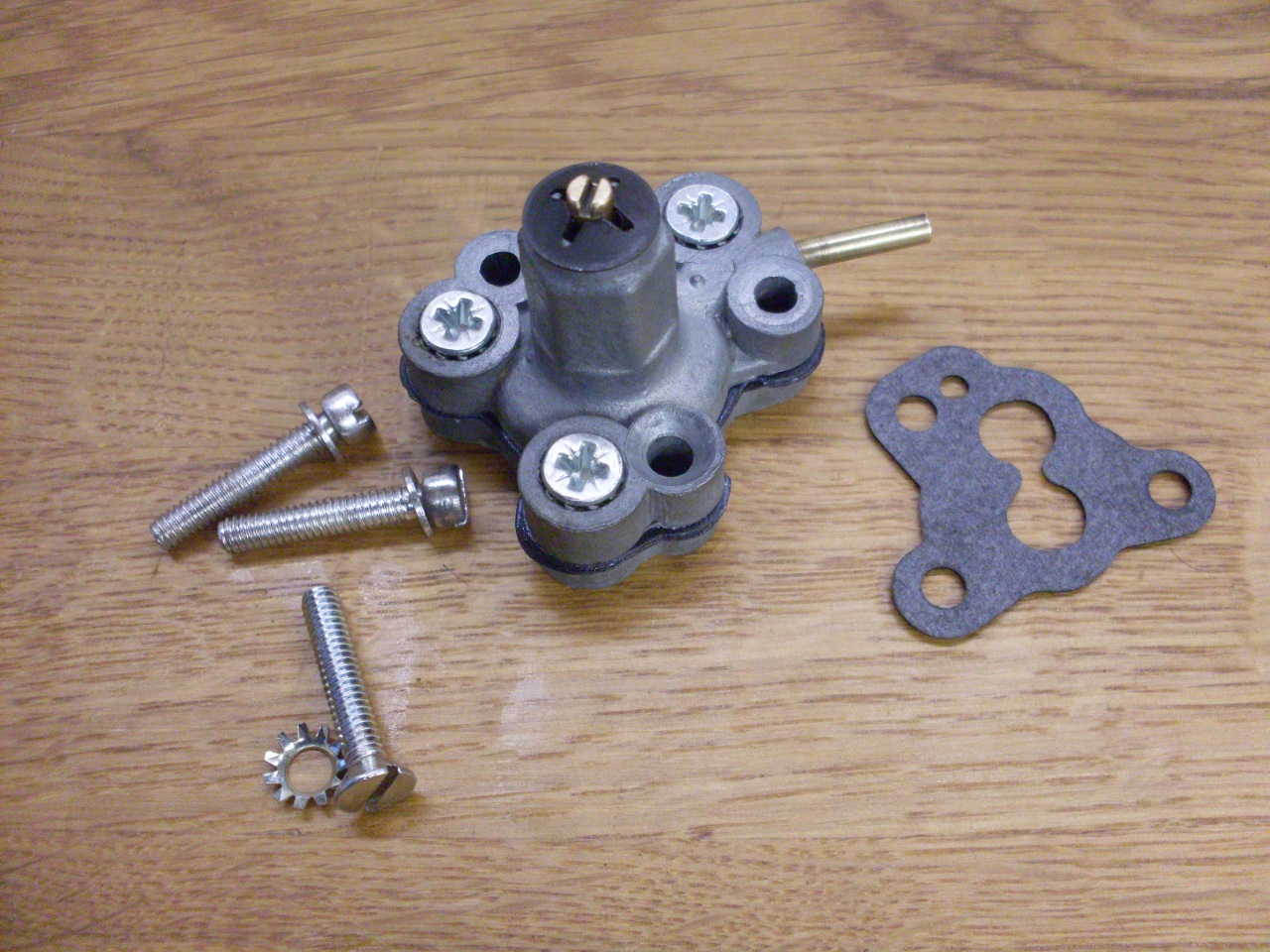

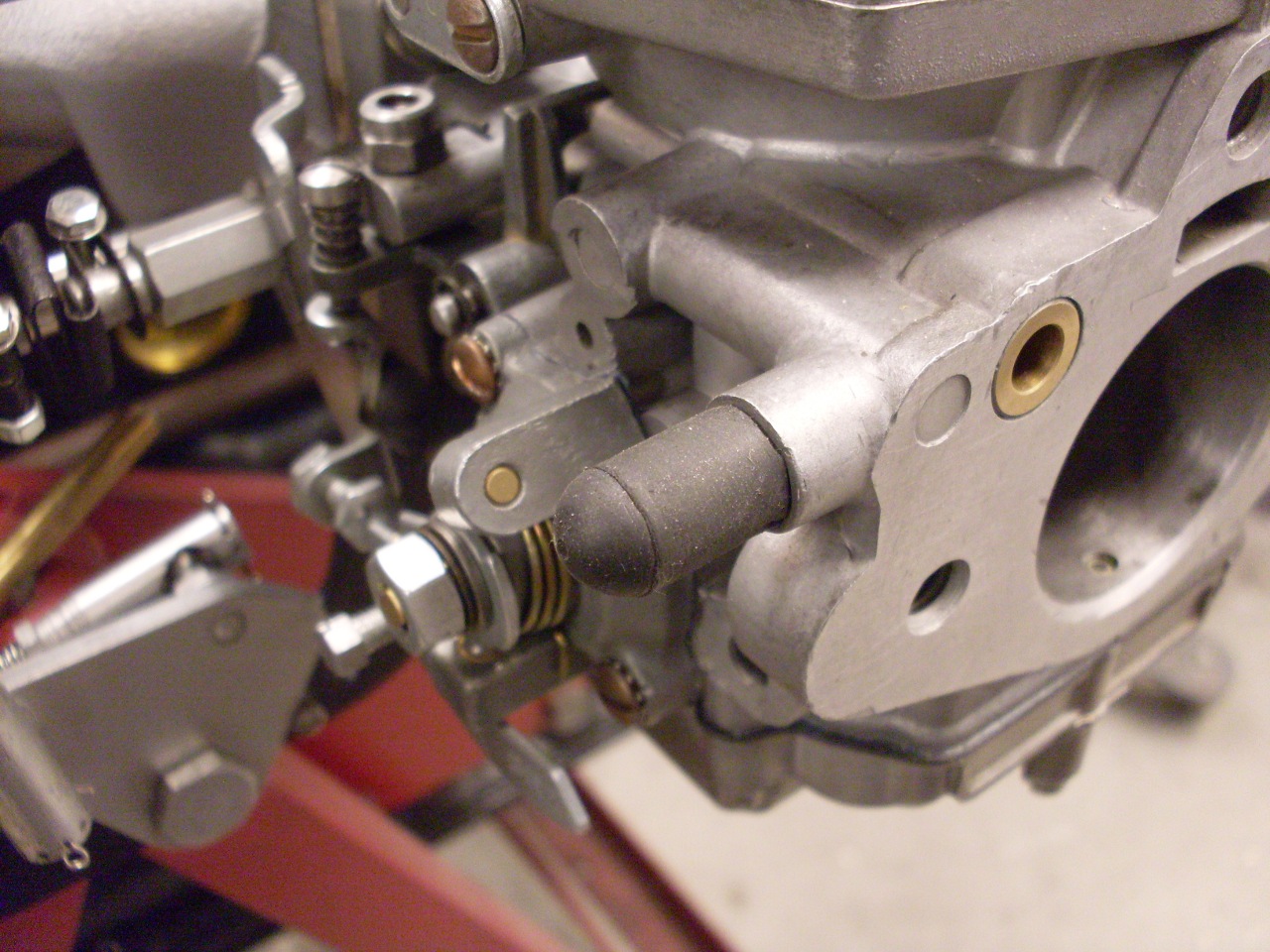

The next

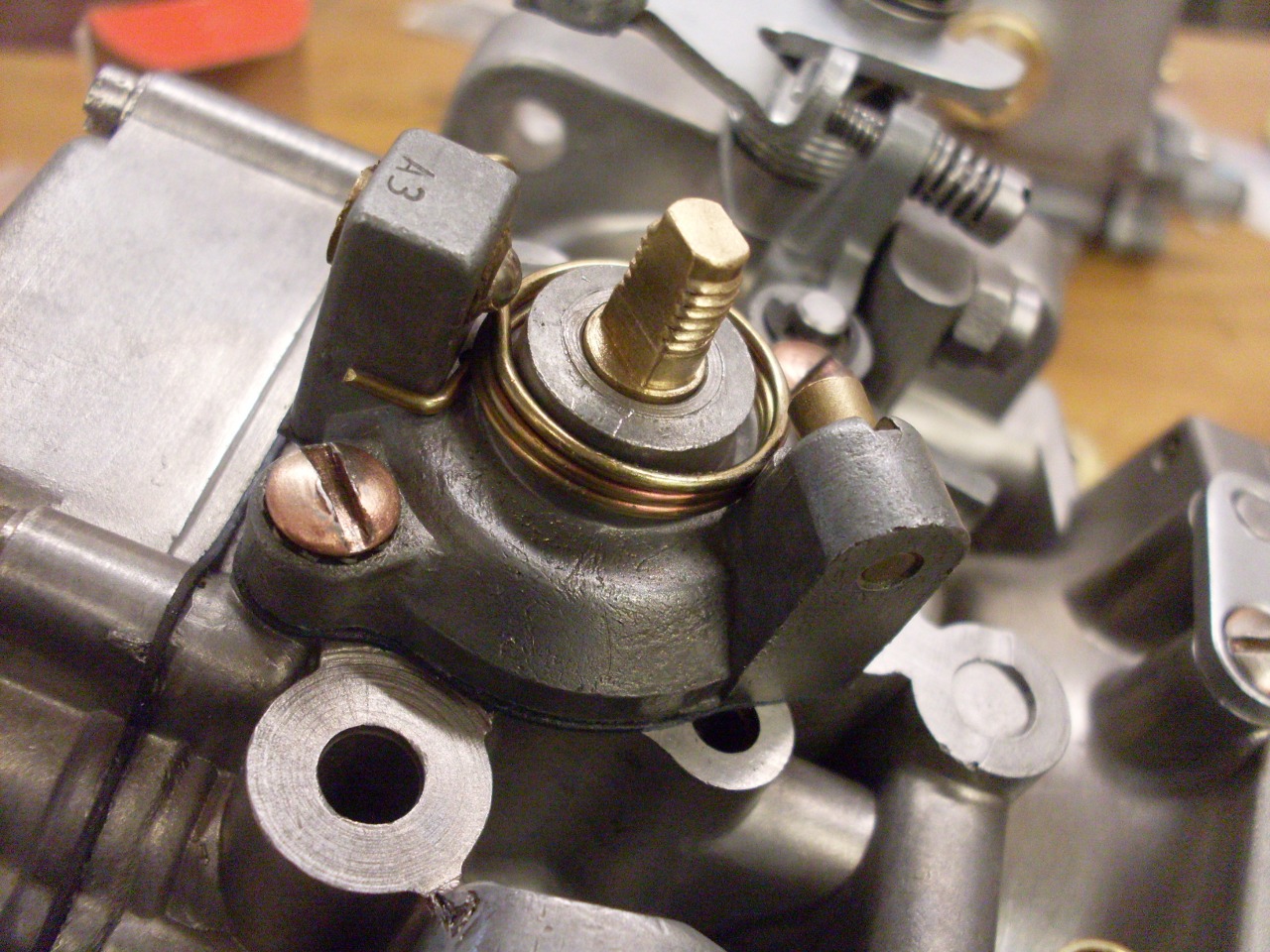

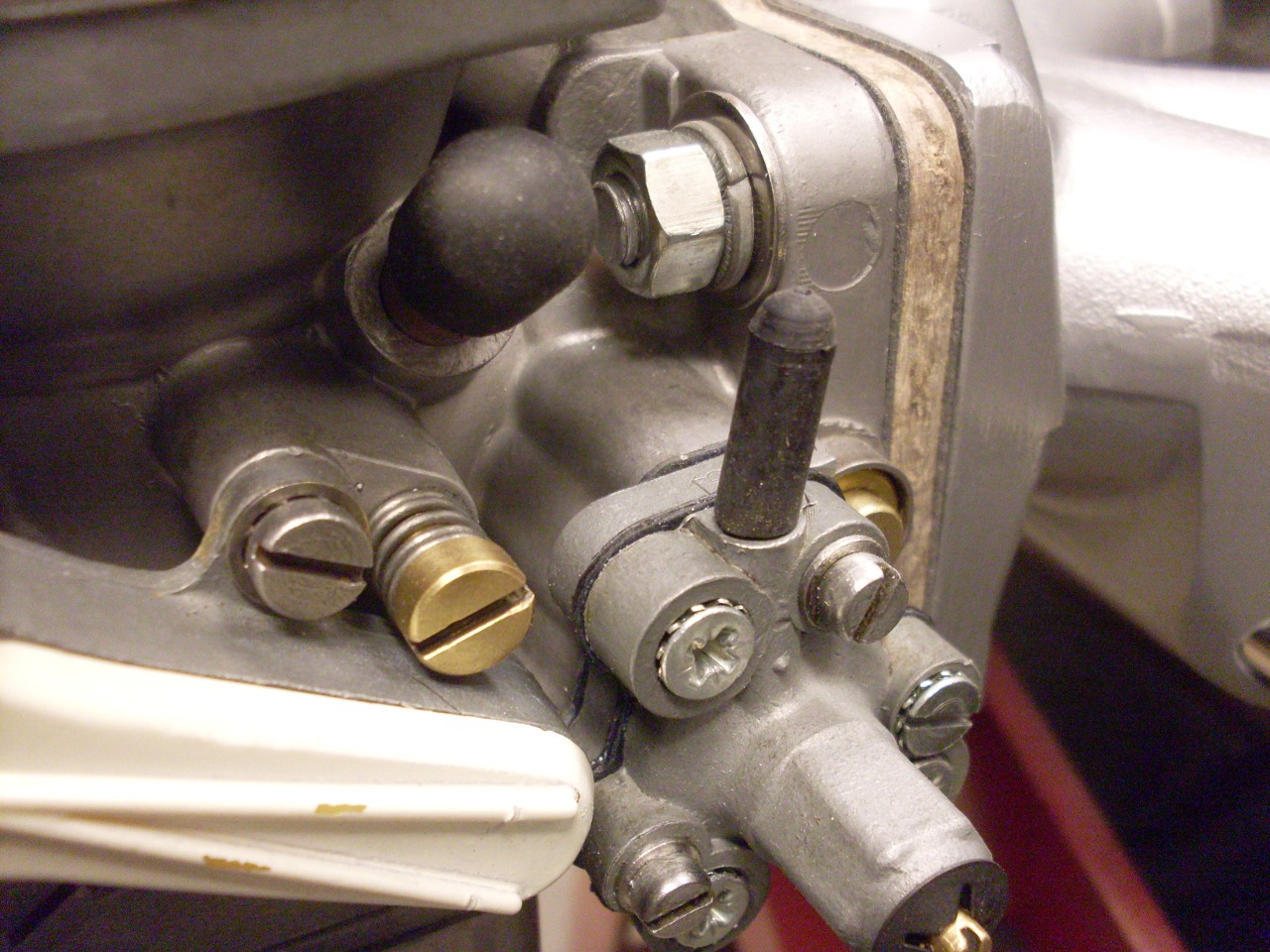

little attachment is not emission related--it is the cold start valve,

which when manually opened, adds fuel to the mixture, richening it.

It does what a choke does. The little valve on the arm at

the upper left in the first pic is an EGR vacuum dump. I'm not

using EGR, so that valve won't make the cut on reassembly.

One

other mod on the cold start valve is to add a return spring as found on

earlier cars. By '74, the "choke" control used a cable with a

solid core, so it could both pull and push the cold start arm.

These cables are very troublesome (I remember problems with

mine), and many owners

replace them with ones with a flexible stranded core that can only

pull. Thus the spring return. There is a detent ball was

supposed to give an indication of half choke that was interfering with

spring action on one of the carbs, so I had to back it away from

contact. The other detent ball was already out of touch.

All the various cams and links and such were pretty badly rusted, so they got fresh zinc.

The EGR vacuum port was plugged.

I was working on one carb at a time. The transformation was pretty striking.

Now

that all systems were brought back to operational condition, I disabled

some of them. My logic is that before the era of emissions

controls, the carbs did fine without these contrivances, and turning

them off will make the carbs simpler and more reliable. On the

other hand, it is conceivable that I may decide that one or more of

these functions is necessary after all. For this reason, I

resolved to defeat the devices only in a totally reversible

way.

First, to defeat the temperature compensators, I threaded

and plugged the compensator's air source in the inlet flange.

This also shuts off air to the bleed screw, which is no great

loss since it really takes special equipment to set it any way.

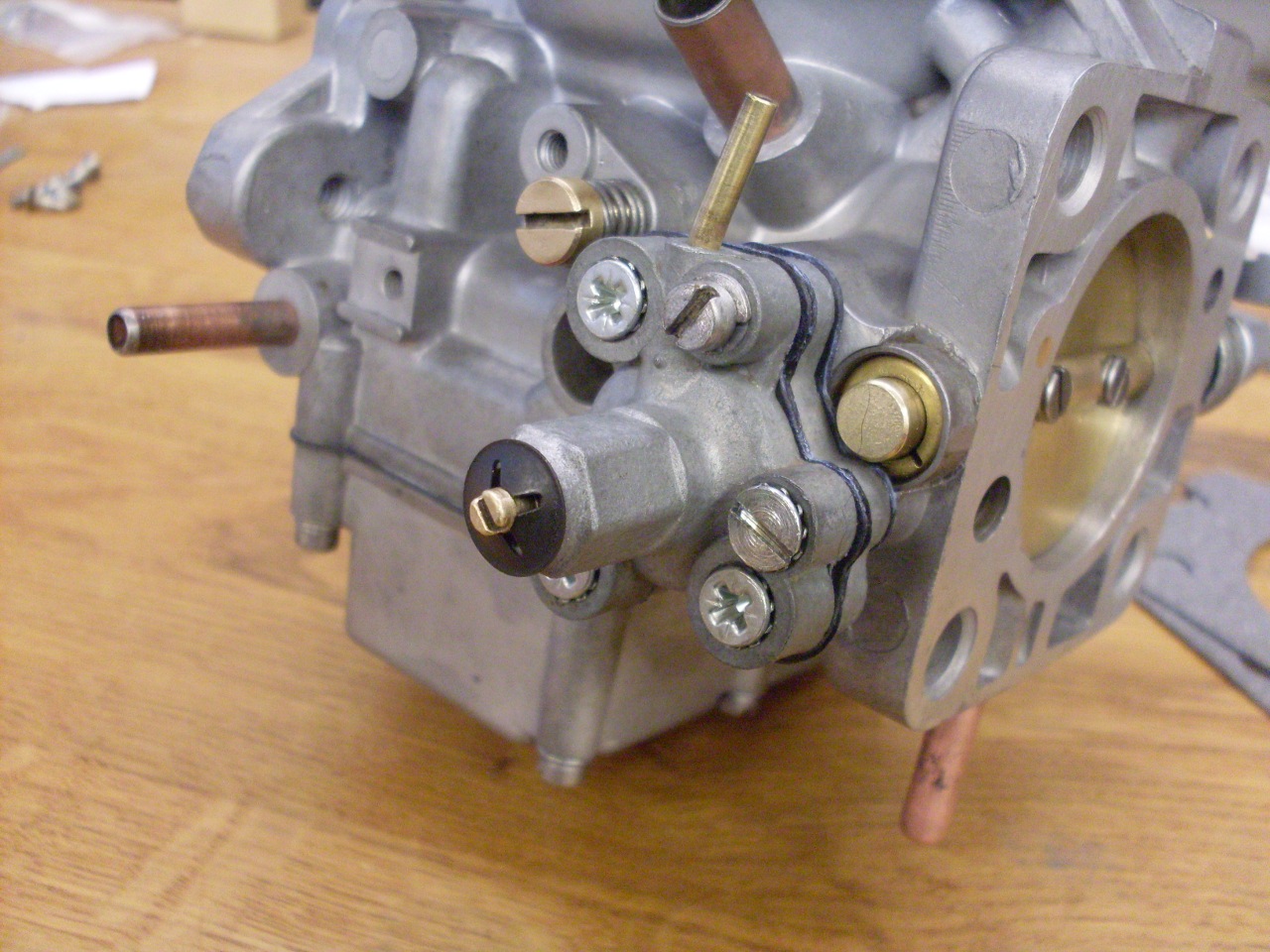

For

the bypass valve, I originally thought just eliminating its vacuum

signal would be enough. However, it looks like at least on these

carbs, that there is also an internal passage that opens just on the manifold side of the throttle plate. I'll defeat the

bypass using the adjuster screw to keep the valve closed.

The

last piece of emission trickery on these carbs is the bowl vent.

When the throttle is cosed, a valve switches the float bowl vent

from a passage leading to the air cleaner to an external tube that was

connected by a hose to the carbon canister and anti run-on valve.

Since I don't plan to run either of these wonderful devices, I

needed to deal with the external bowl vent. It can't be

simply capped, since that would shut off the vent at idle. I

could leave it open, but that would seem to invite unsavory things into

the float bowl.

In the end, I simply drilled a 3/16 hole

between the external vent passage and the passage to the air cleaner.

I did it by drilling down throught the external vent tube.

This way, I can cap the external tube, and the bowl still vents

to the air cleaner at closed throttle. Since the new drilling passed through the

side of the brass bush in the air cleaner port, to reverse the

mod, I would just pull out the bush, rotate it 180 degrees, and push it

back in.

I found little rubber caps to neatly close off the unused ports.

The carbs will now go on the shelf while I tend to the rest of the car.

Comments to: elhollin1@yahoo.com

To my other TR6 pages