To other pages.

January 22, 2014

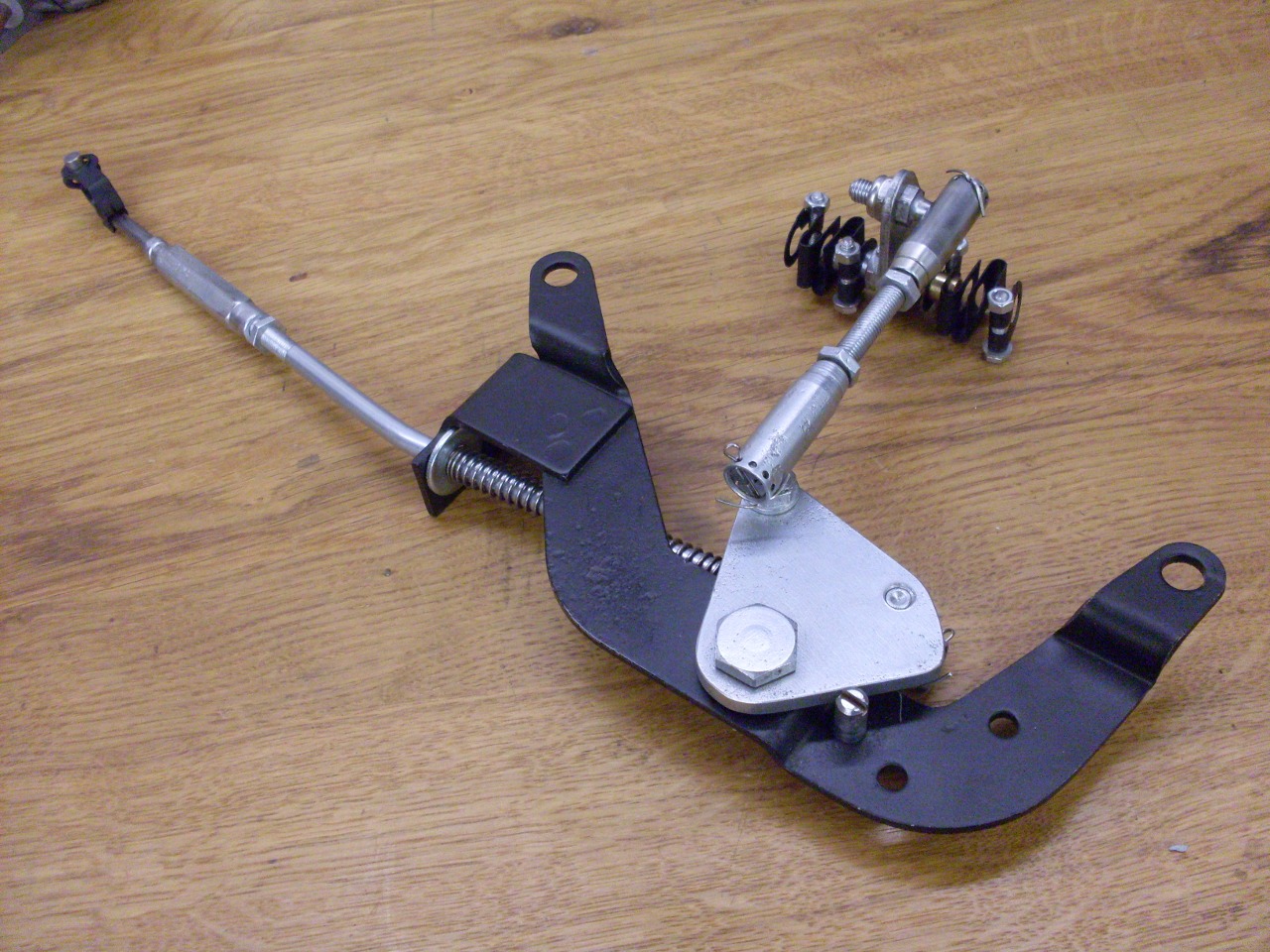

Throttle Linkage

I'm working on the carbs, but while I'm waiting for parts, I took a look at the throttle linkage.

This

linkage basically turns a back and forth motion from the accelerator

shaft arm to an up and down motion that rotates the carb throttle

shafts. There is also provision for spring return, a stop that

limits travel, a lost-motion mechanisnm that assures a

positive throttle rest position, and length adjustments for the various

links. Spring loaded ball swivels are included at various points

in the linkage to give a tight, smooth action. This all sounds

great, but the assembly I took out of the car looked pretty sad.

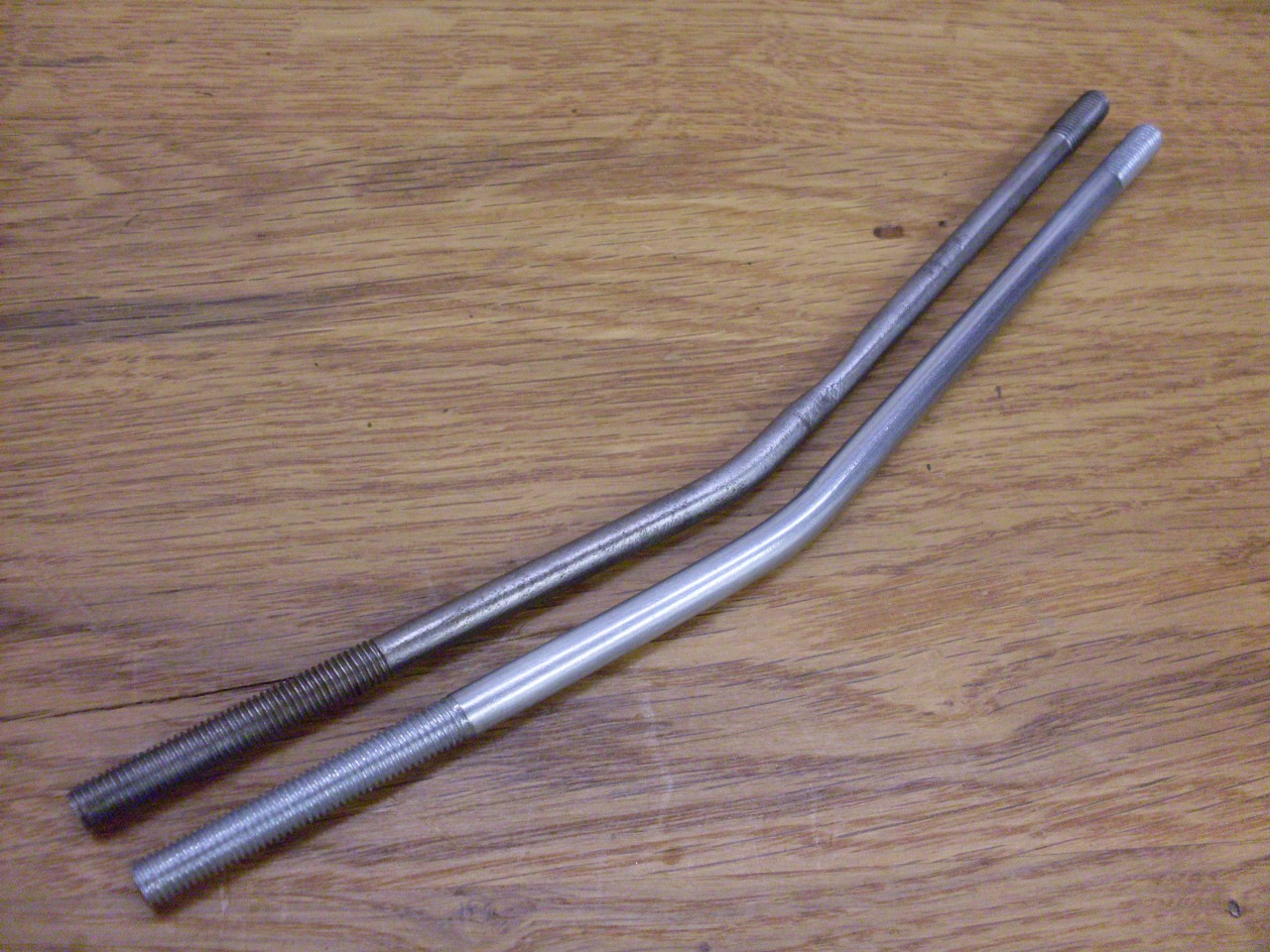

After

a little degreasing and derusting, some of the physical wear becomes

visible. The first pic shows how much the actuating rod was

eaten away by wearing against the bracket (just above the bend in the

upper rod). The lower rod was a new shop built replacement,

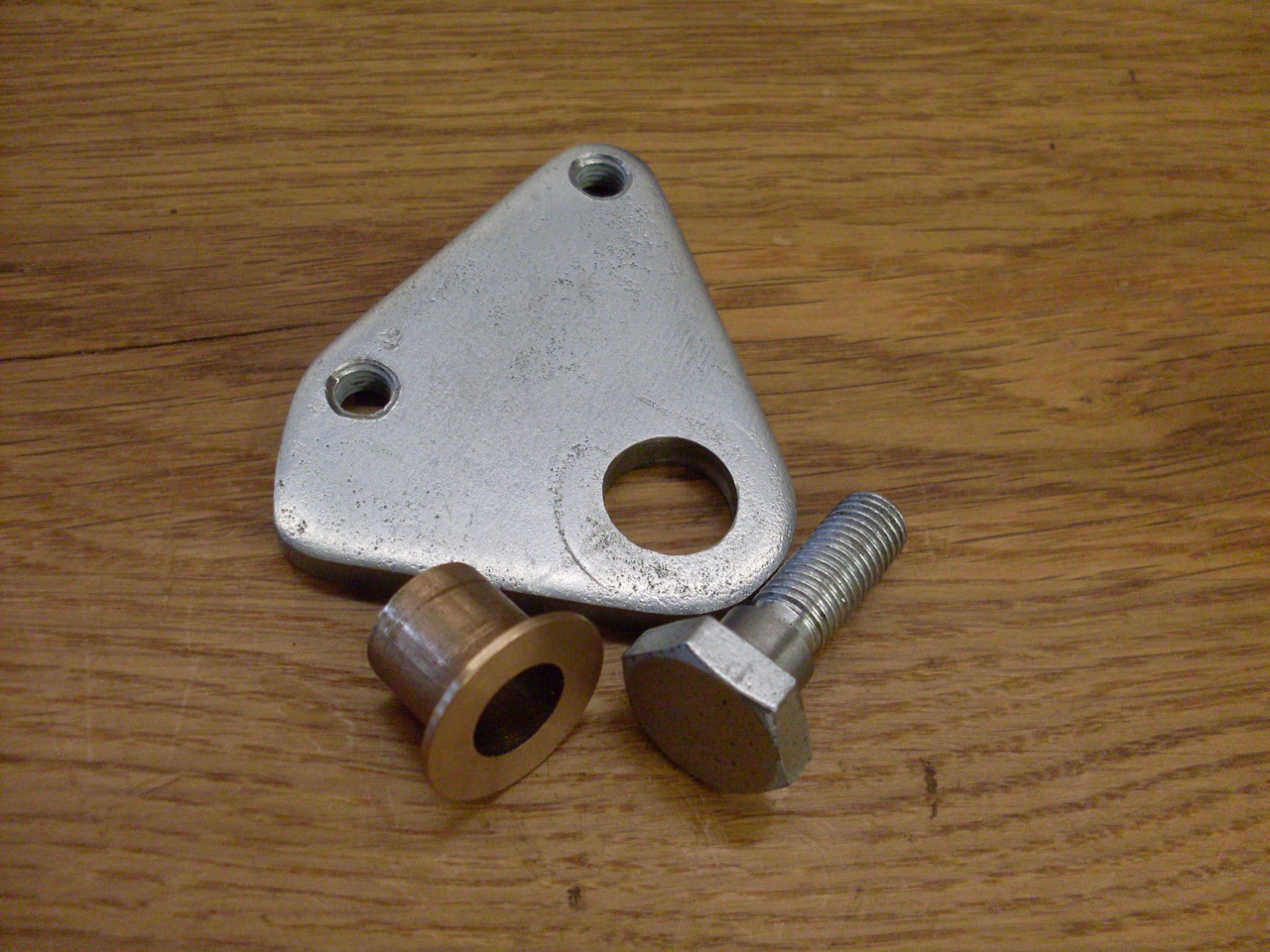

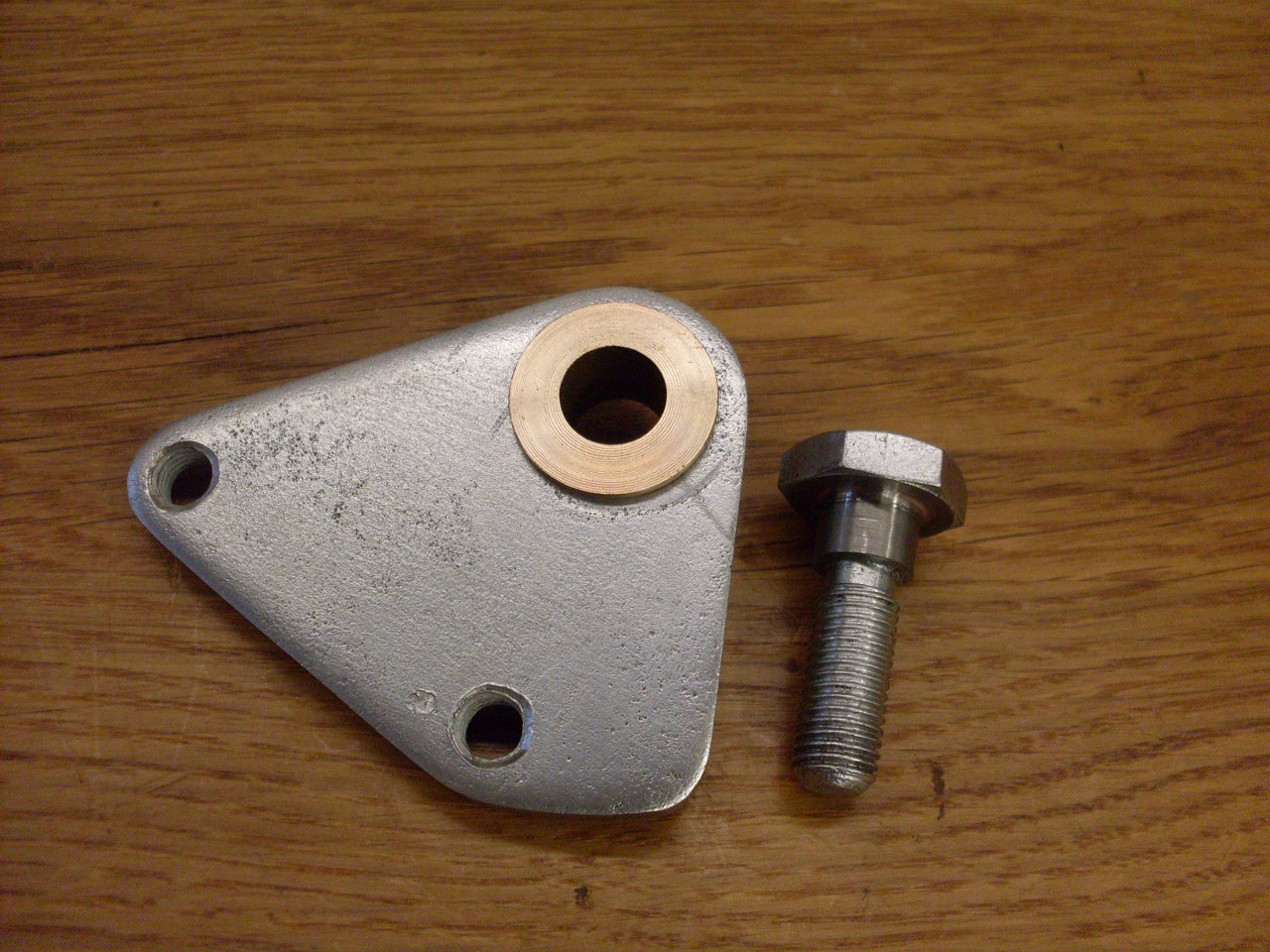

threaded and zinc plated. The bracket didn't fare much better,

with years of throttle movement sawing away at it. The last pic

shows the bracket repaired. Although the rod is threaded 1/4-28,

the original rod itself only measures about 0.218", suggesting the

threads were rolled on, giving the larger diameter. The

replacement rod is a full 1/4 inch, which required the slot in the

bracket to be enlarged a little.

The

considerable rust left pits in some of the parts, but a fairly

heavy zinc plate will protect them from any further damage.

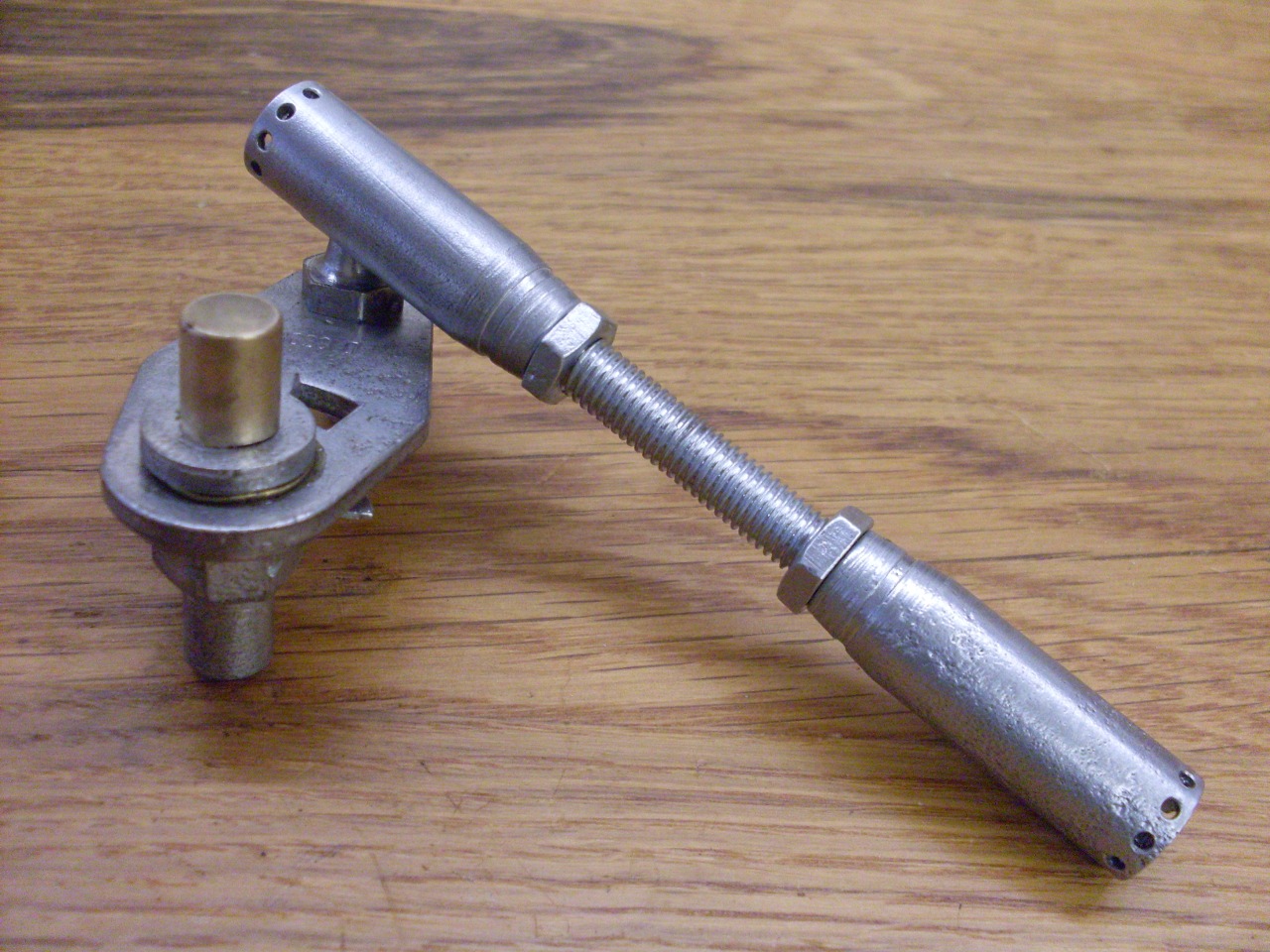

The

bell crank, which translates the motion from one rod to the

other, rotates on a sholder bolt. The fit was sloppy and

floppy, and just cried out for a better bearing arrangement. I

drilled out the bell crank for a flanged Oilite bushing. This

gives a much more satisfying fit to the sholder bolt, and the flange

keeps the crank from rubbing on the bracket.

The

little folded coupling clamps that grip the carb throttle shafts

were just rusty, but a couple of the small bolts were siezed in their

nuts and broke off when I tried to remove them. They look like

maybe 6-32, but are really 4BA threads like a lot of small fasteners on

this car.

The final assembly works way smoother and tighter than how I found it, and maybe even better than original.

Comments to: elhollin1@yahoo.com

To other pages.