To other TR6 pages.

January 11, 2014

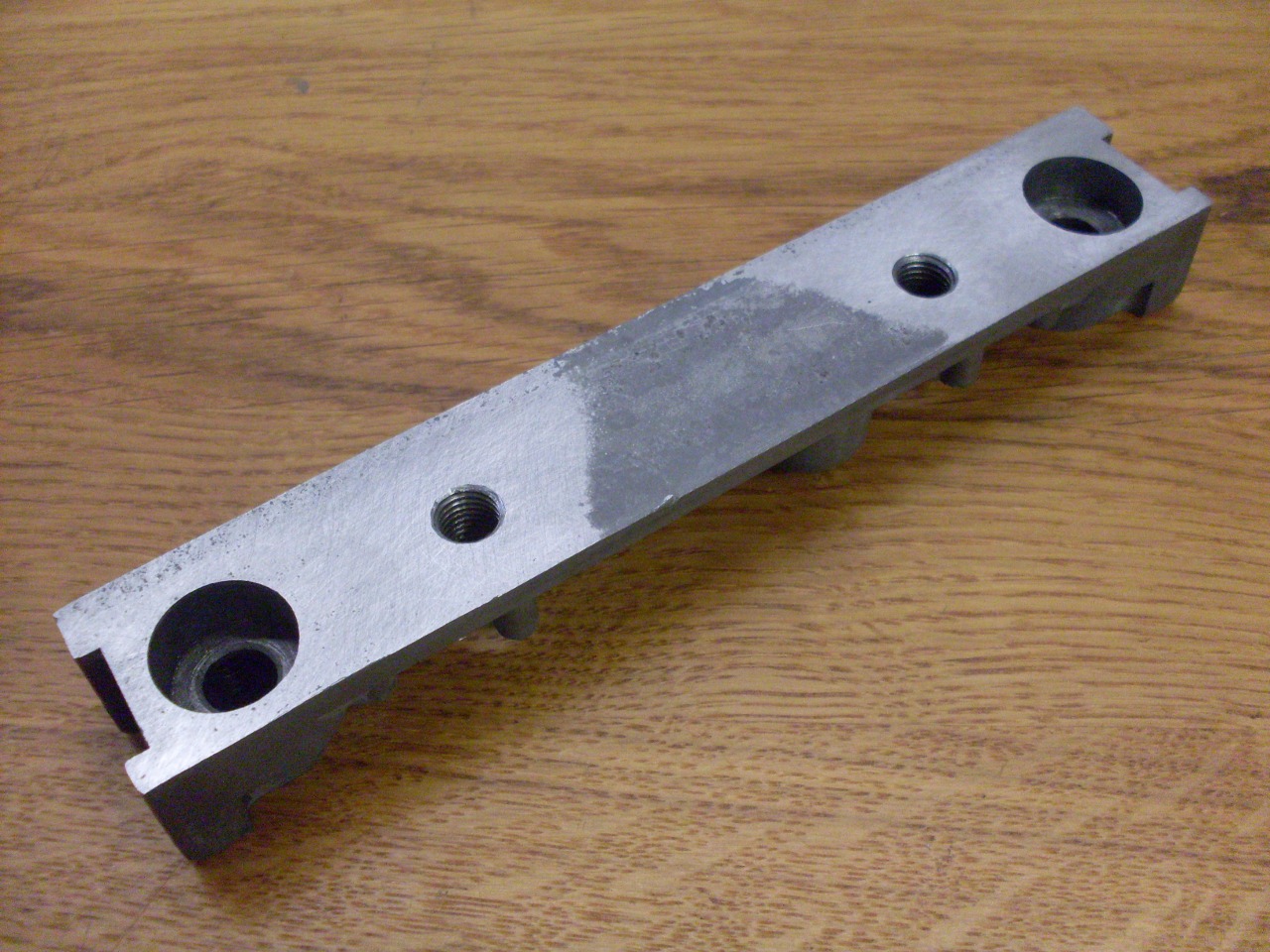

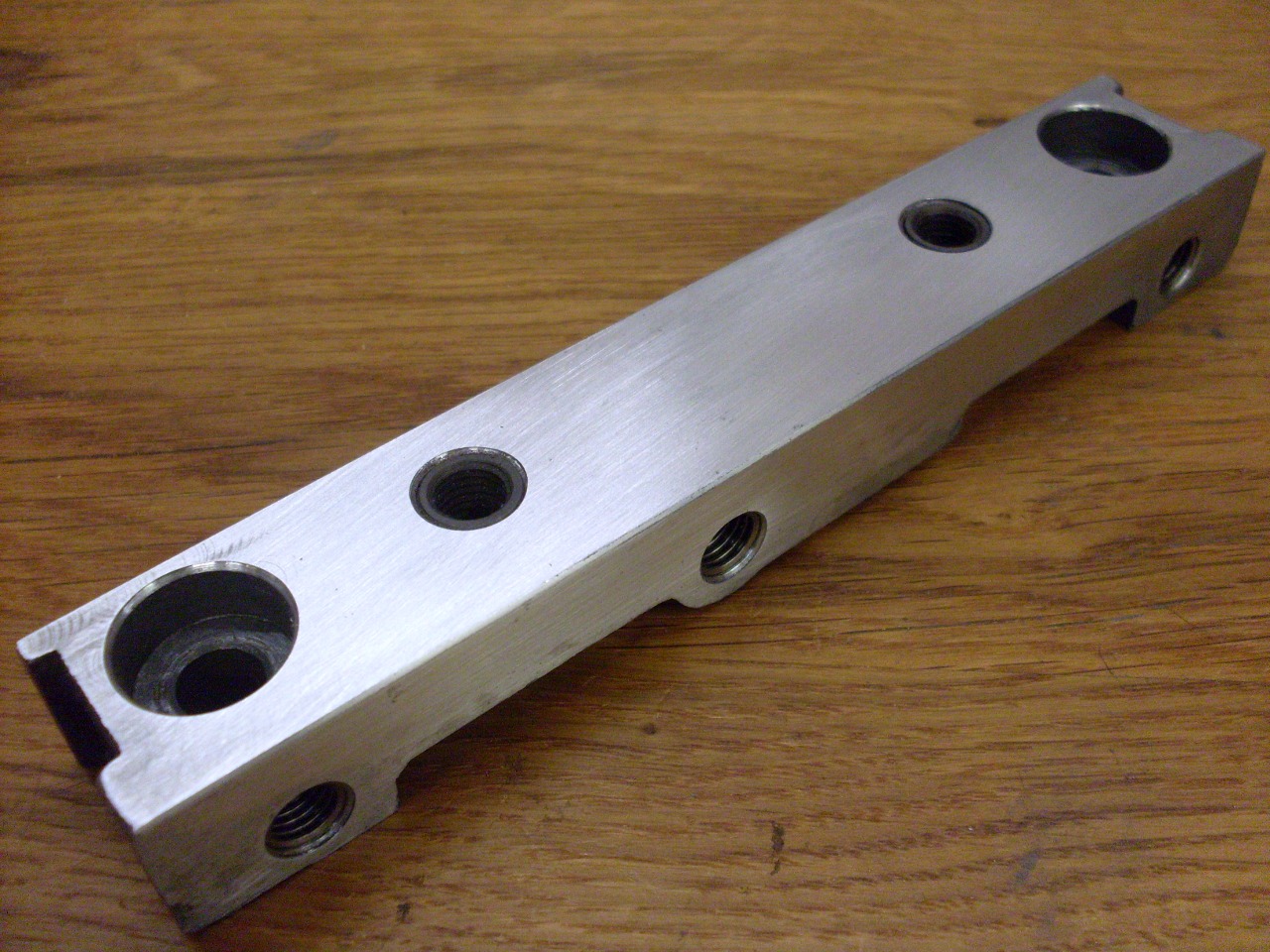

Front Sealing Block

[Click the pictures for a larger view]

The

TR6 engine has a so-called "front sealing block" at the front of the

engine block that closes the perimeter of the crank case and completes

the sealing surfaces for the oil pan and the front plate. It

is a simple item, but is wrought with issues, mostly having to do with

oil leaks. First, the joints between the ends of the sealing

block and the crankcase skirts presents an interesting sealing problem.

Because of the end clearance necessary to allow insertion of the

sealing block, the end seals must be of a resilient material that

can be compressed on installation and can maintain sealing pressure for

long periods of time. Triumph's quaint solution to this is to use

little pieces of wood that are forced into slots in the ends of the

sealing block after it is in place. Though this seems at first to

be a primitive throwback solution, I'm not so sure it isn't a brilliant

approach. Some kinds of wood under compression are known to be

very good fluid seals in applications like barrels or casks.

Gland seals of cork or other soft woods are still common.

Beyond

the sealing issues, the sealing block is made of a non ferrous

metal--some have said aluminum, but it feels more like some version of

Zamac to me. The common belief is that the threaded holes for the

front plate and oil pan fasteners are prone to stripping. The

holes are tapped with a fine thread (5/16-24), and aren't very deep, so

this could be true, especially with a little over-enthusiastic

torquing.

The

threads on my sealing block

were fine, but not wanting to tempt fate, and trusting all the

anecdotal evidence, I decided to take measures to protect against

stripping. There are a few sellers that offer a replacement

"upgrade" sealing block made of steel to mitigate the stripping

potential, but I considered these to be expensive over-kill.

There are other ways to provide strong thereads in soft

materials, so I decided to improve my original block. Besides,

the outer edge of the sealing block is exposed to the elements, and a

bare steel block would start rusting immediately.

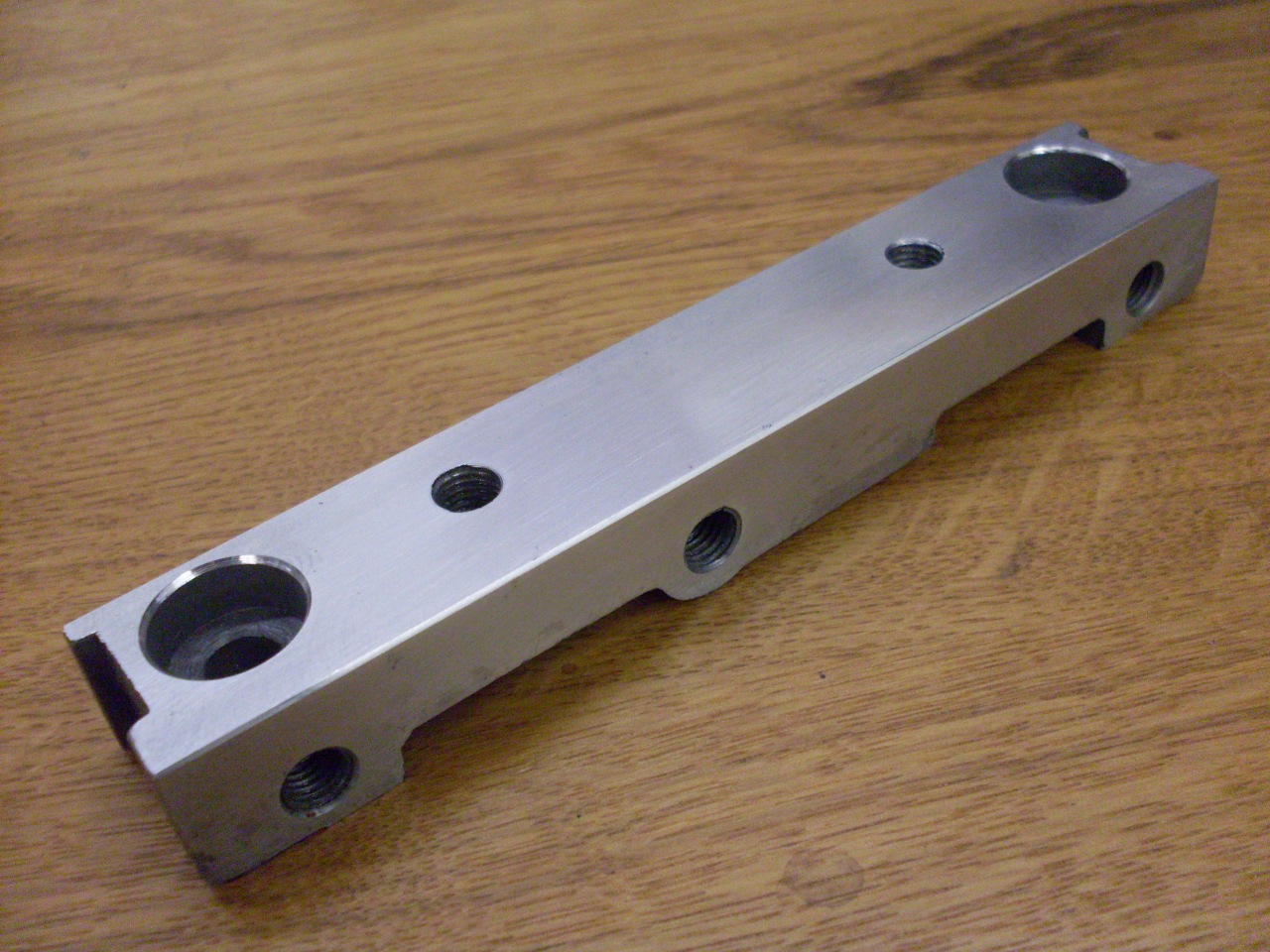

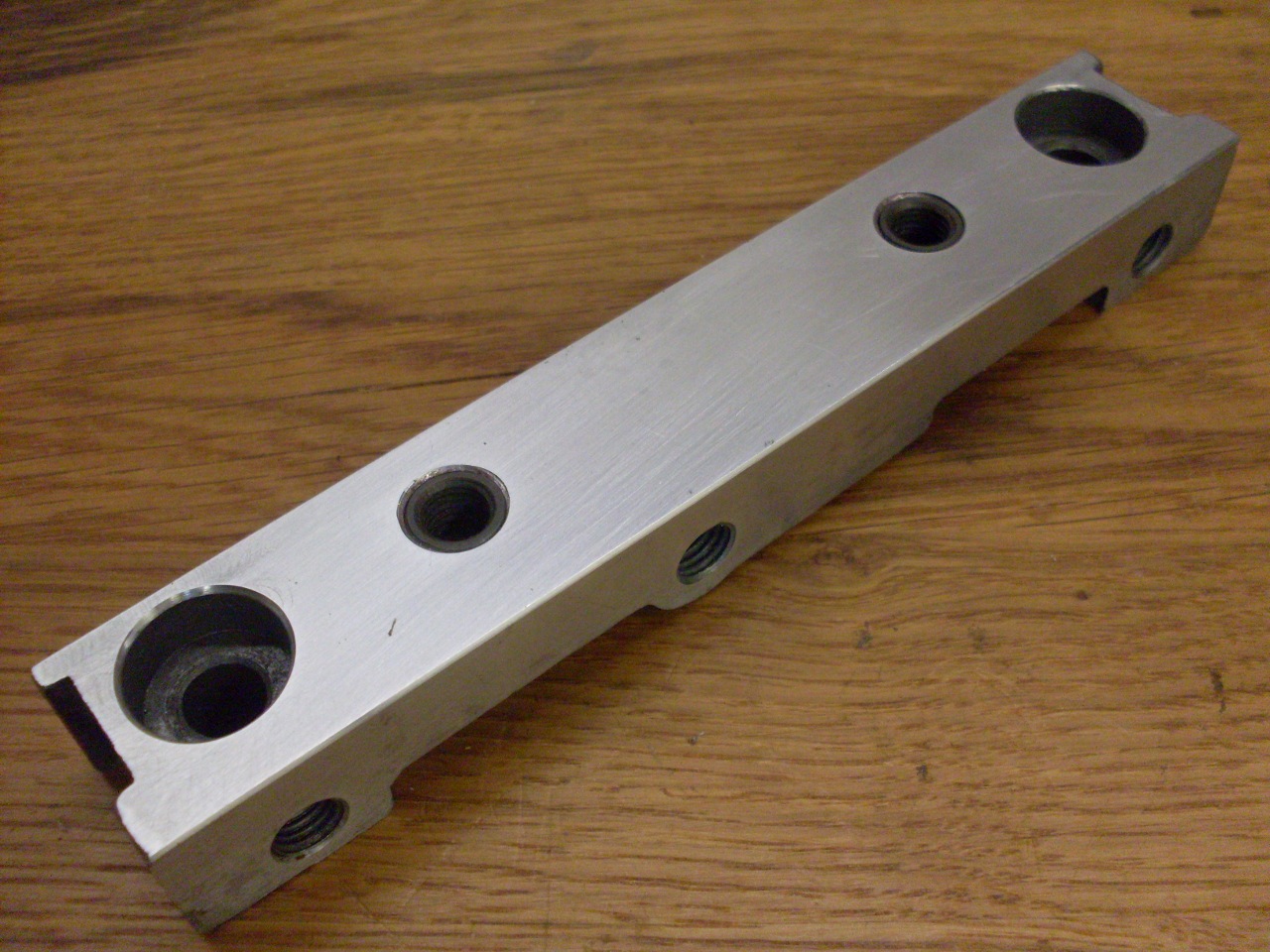

I

noticed that with gaskets installed, my sealing block stood a little

proud of the crank case skirt. As I was skimming the surface

down, I found that the block also had about a 0.015" dip in the middle.

While this really isn't a serious problem, I was glad to find

that when I got the block cut down to be flush with the skirt, the dip

was gone.

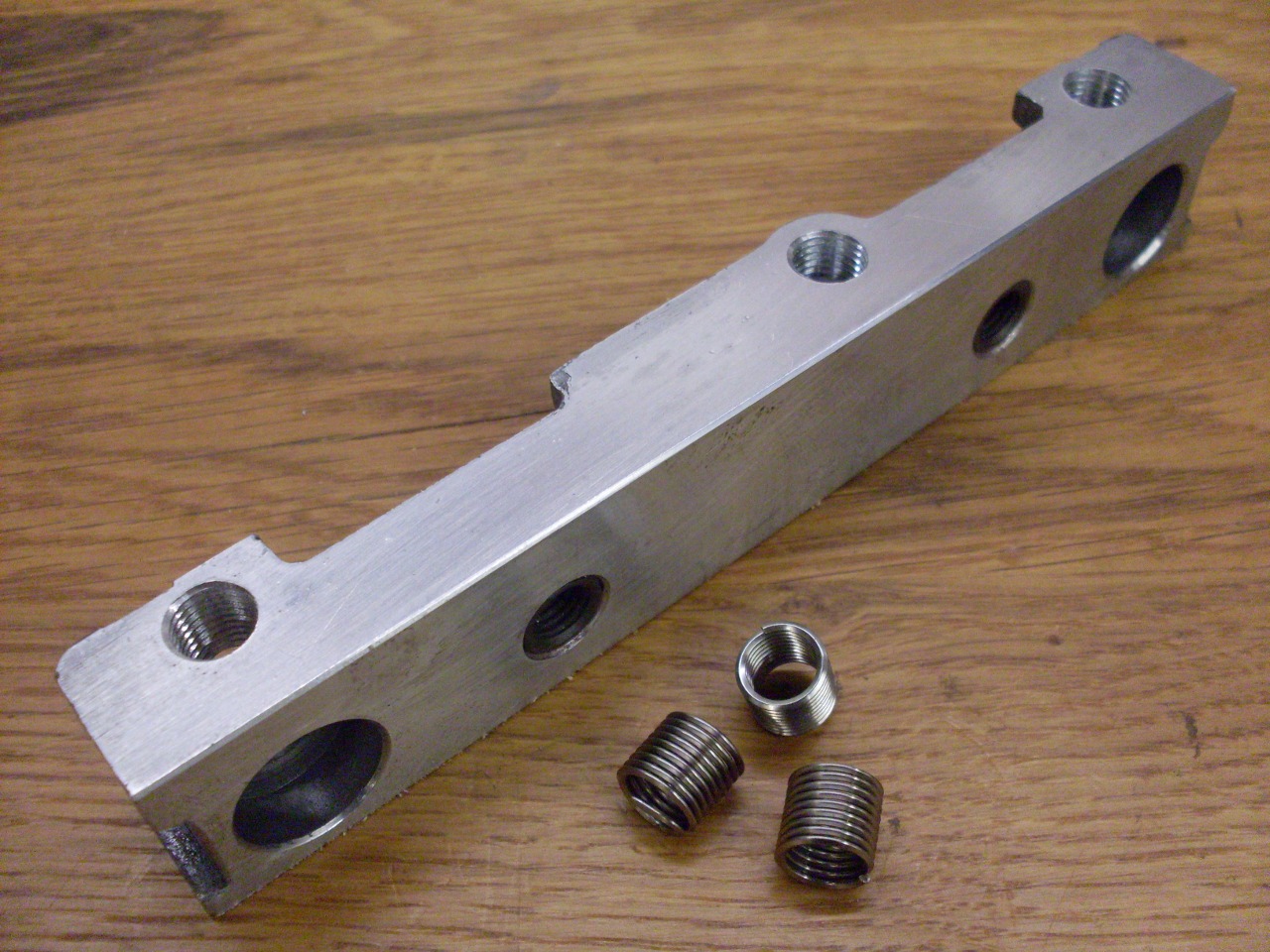

The

easiest way to provide strong threads in a soft material is

to use a thread insert. These are "EZ LOK" brand inserts, but there are

others. The process is simple: drill an oversized hole

(Letter X in this case), tap the hole to the OD thread of the insert

(7/16-14), and screw in the insert. The inserts have a thread

locking compound on the OD threads that activates when the insert is

installed.

I

had planned to use the inserts on all of the threaded holes, but it

looked like a couple of the holes on the front side of the block

were a little close to the edge for my comfort. In the case of

these holes, I used Helicoil type inserts, which need a smaller hole.

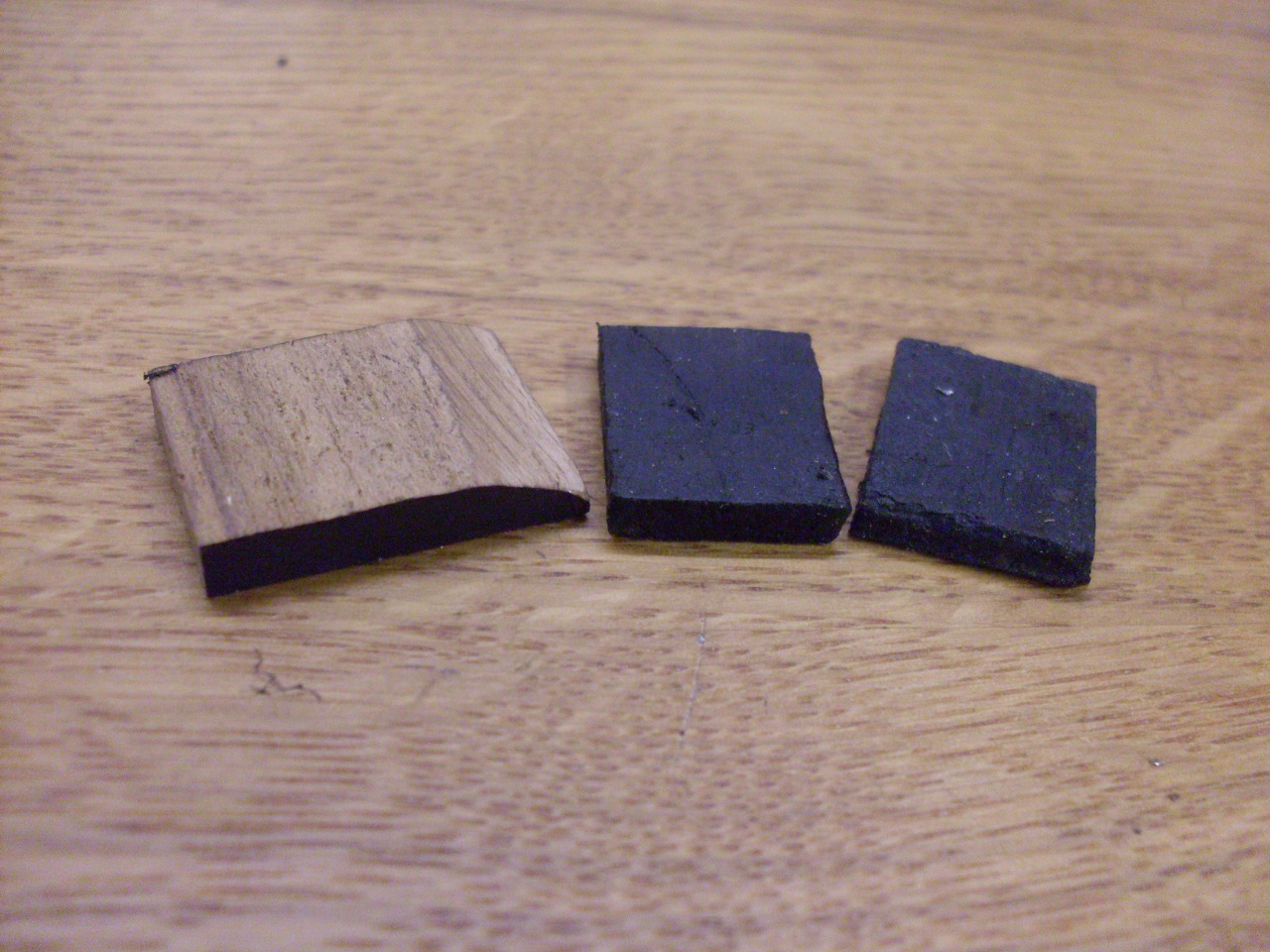

With

the threads taken care of, I started looking at hte wood sealing

blocks. The originals were oil soaked and compressed, so it was

hard to tell anything about them. I had ordered a new one (it was

an oversight--I meant to order two), but it didn't seem to bear much

resemblance to the originals. It was way too big, and had a large

taper on one side. Rather than trying to sort it out with the

supplier, it seemed easier to just make my own. I know a little

something about woodworking, and the new block appeared to be a

hardwood, possibly walnut or butternut (judging from color and grain,

but it's really hard to make a good determination from such a small

piece). I had some walnut around, but finally opted to use white

oak. White oak has a closed cell structure that makes it

essentially liquid tight. I cut a strip of the right width and

thickness, and I'll cut the seals from it when I install the sealing

block.

Finally,

a word about the paper gaskets. In the same lapse of sanity as

for the wood block, I only ordered one of them. I opted to just

make the other one from 0.031" gasket material, using the old originals

as a pattern. When I did that, I saw that my home made gasket was

actually a better fit than the store bought one, so I made a second

one. My ordering goof ended up saving me a little money. My

hand-crafted gaskets in the middle, 40-year old used original on the

right, new store-bought on the left:

The

sealing block looks like it will be a good fit in the block, and I have

a pretty high confidence in the threaded holes. This was

accomplished for about half of what some are asking for the steel

reproduction block.

To other TR6 pages.

Comments to: elhollin1@yahoo.com