To other TR6 Pages

January 5, 2014

Oil Pump

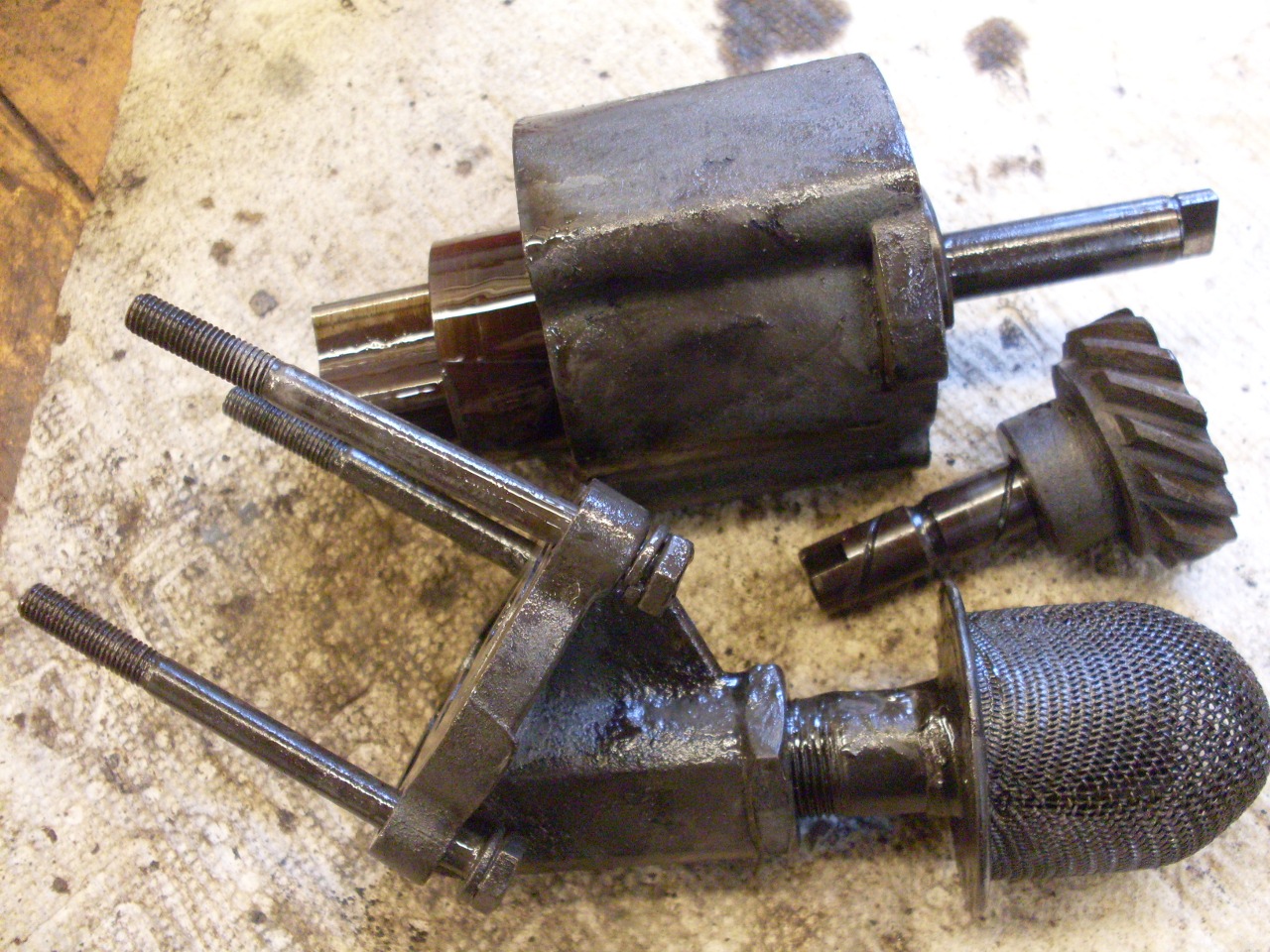

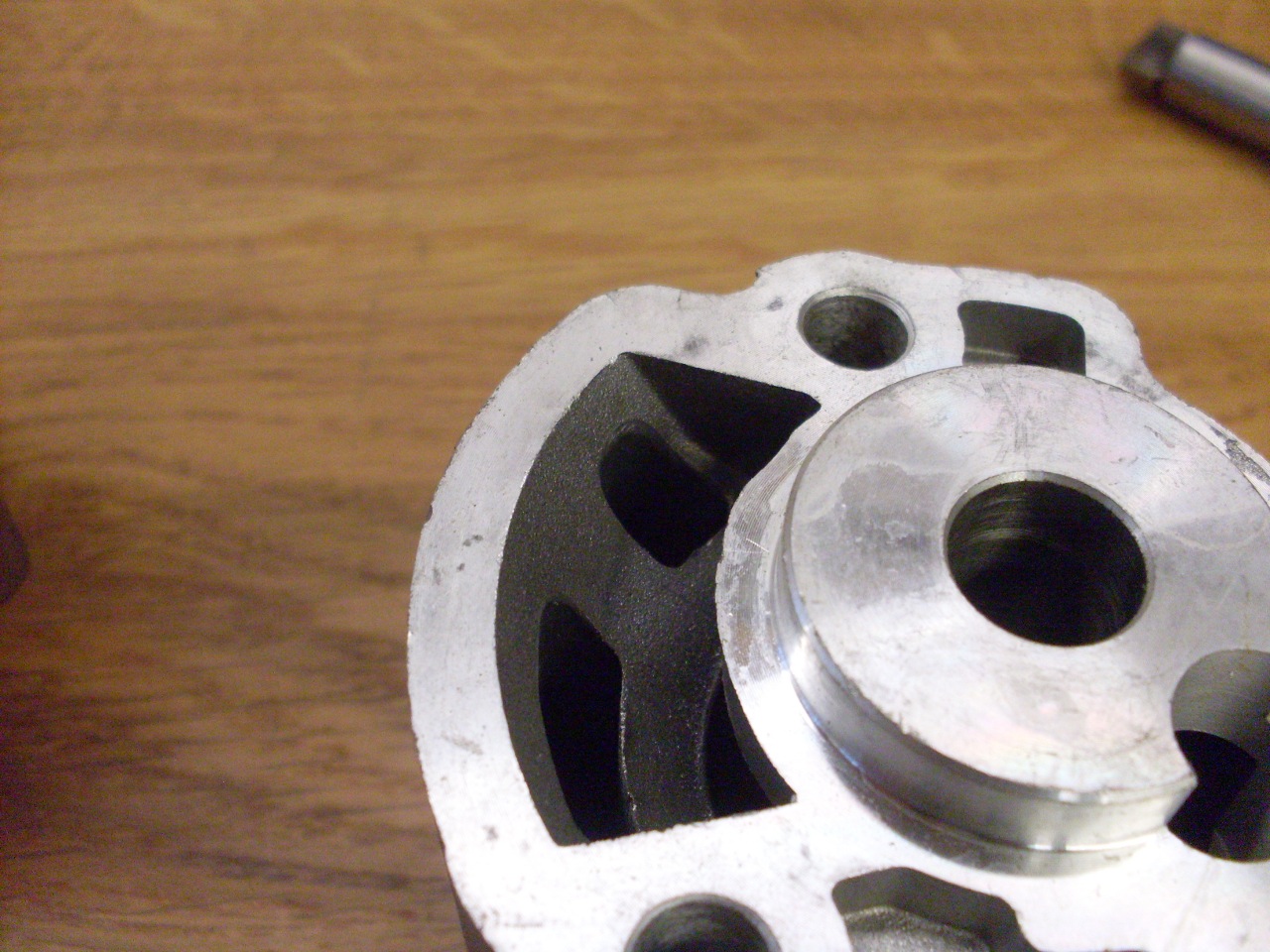

The

TR6 uses a gerotor type positive displacement oil pump that is very

common in automotive applications. A four-lobe inner rotor is

driven from the cam shaft and turns a mating five lobe outer rotor.

The changing volume of the spaces between the rotors creates

suction on one side of the pump and oil pressure on the other.

Because of this, these pumps depend on fairly close fits for

efficient operation. Being bathed in oil, they wear slowly, but

the tight tolerences mean that they do need to be replaced occasionally.

There

are three main specs for this oil piump that gage wear:

lobe-to-lobe clearance between the inner and outer rotors,

clearance between the outer rotor and the pump body, and the clearance

between the ends of the rotors and the pump end cap (which

carries the oil pickup tube). My pump was well out of spec

on the rotor-to rotor clearance. The spec calls for under 0.004"

and mine wes almost 0.012". Due to the tight tolerences, oil

pumps are normally replaced as an assembly, so I ordered one.

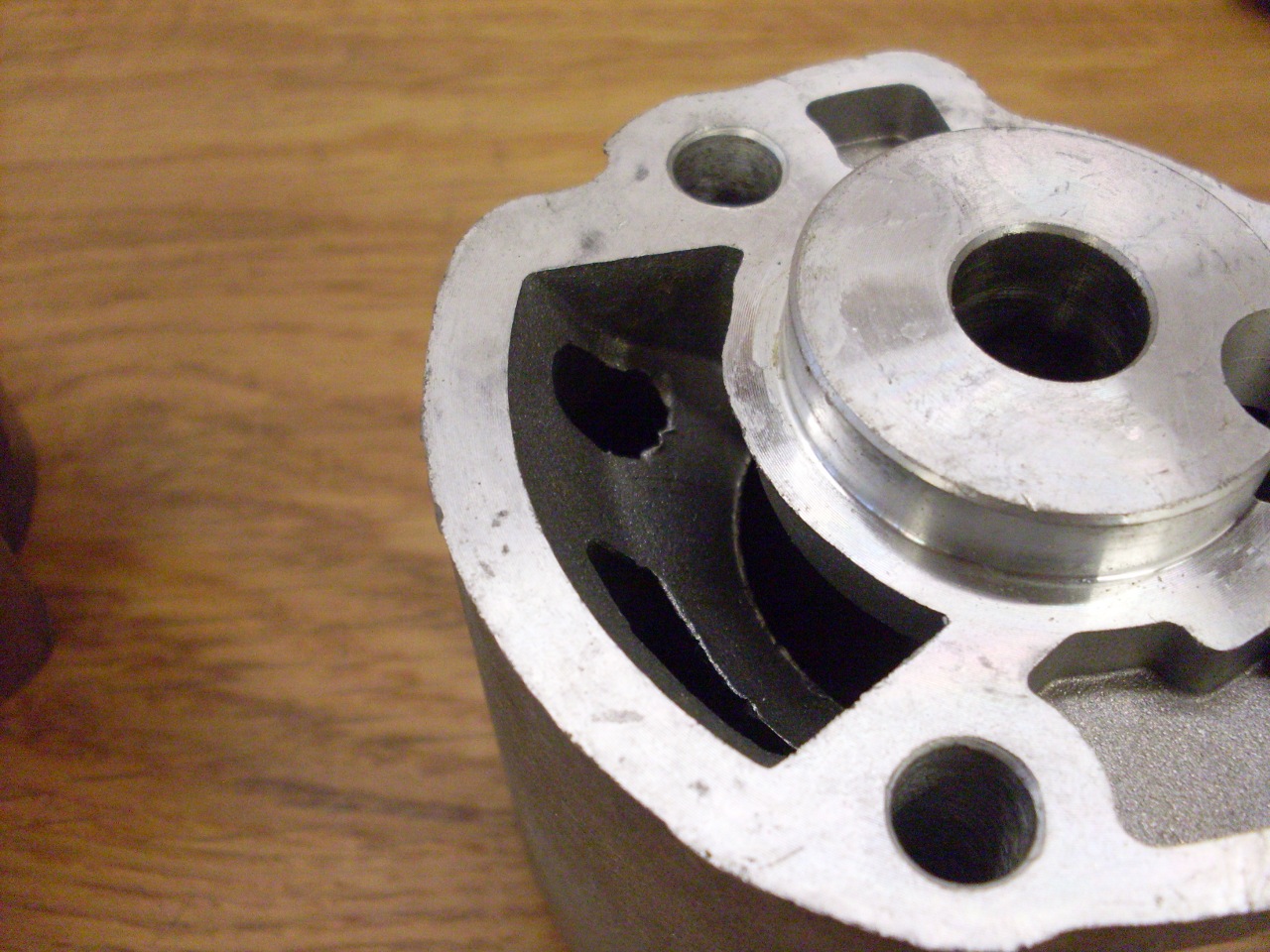

Over

the years, I've developed a bit of a cynical attitude towards

reproduction car parts, and typically don't have very high expectations

for their quality. The replacement oil pump didn't do anything to

change my opinion. While it did measure within spec on all

measurements, there were some other issues that are just irritating.

First, the part was dirty. It looked lile it had

dried up oil on it. Maybe it was a protectant and maybe it

wasn't, but it just looked bad. Many of the machined surfaces

felt like they had burrs at their edges. There were places where

the casting flash was not cleaned up. Just a minute or two with a

small file fixed these things.

Then

there was the pickup tube. The replacement's pickup tube was very

different from the original. It had a much shorter screen and the

pickup tube was longer and threaded less. There is a spec for the

distance between the end of the pump body face and the end of the

pickup screen. Using this measurement on the new pump would put

the actual end of the pickup tube in a much different place than the

original. Is this a problem? I don't know, but it is

irritating--a replacement ought to be a replacement. OK, I

thought, I'll just use the original pickup tube on the new pump.

It was an inspired idea, but unfortunately, the threads on the

new

pump's pickup tube are different from the original.

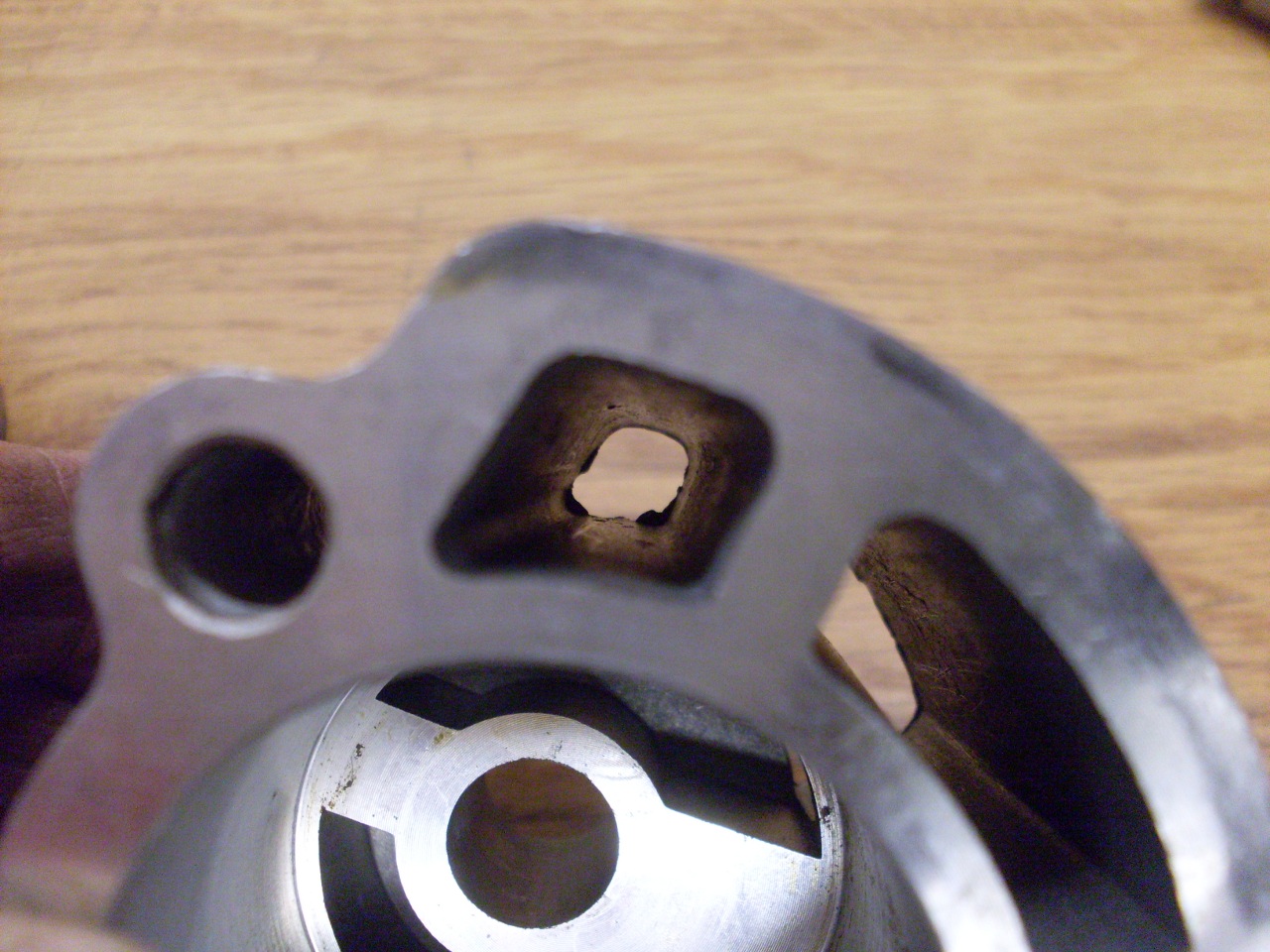

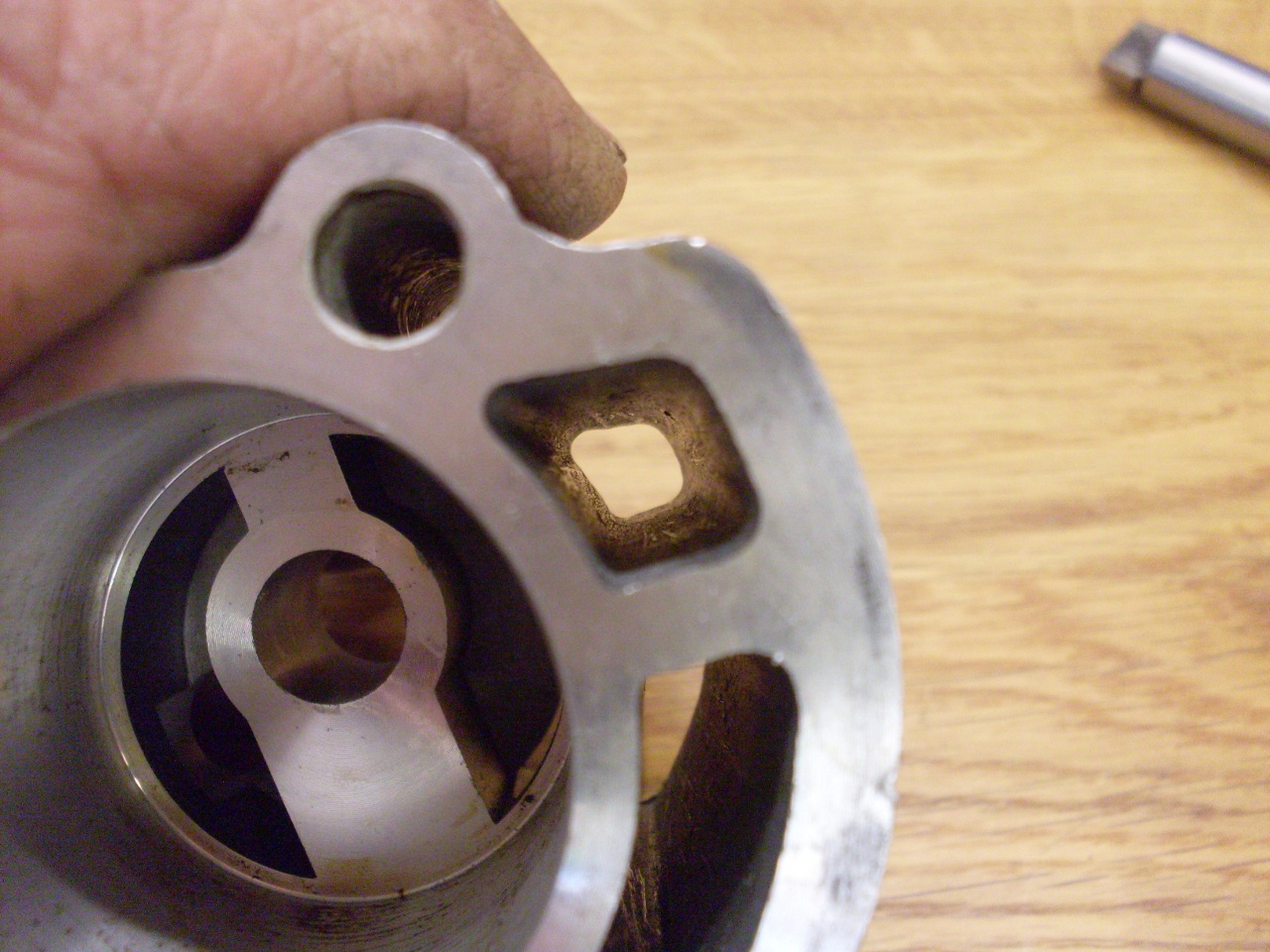

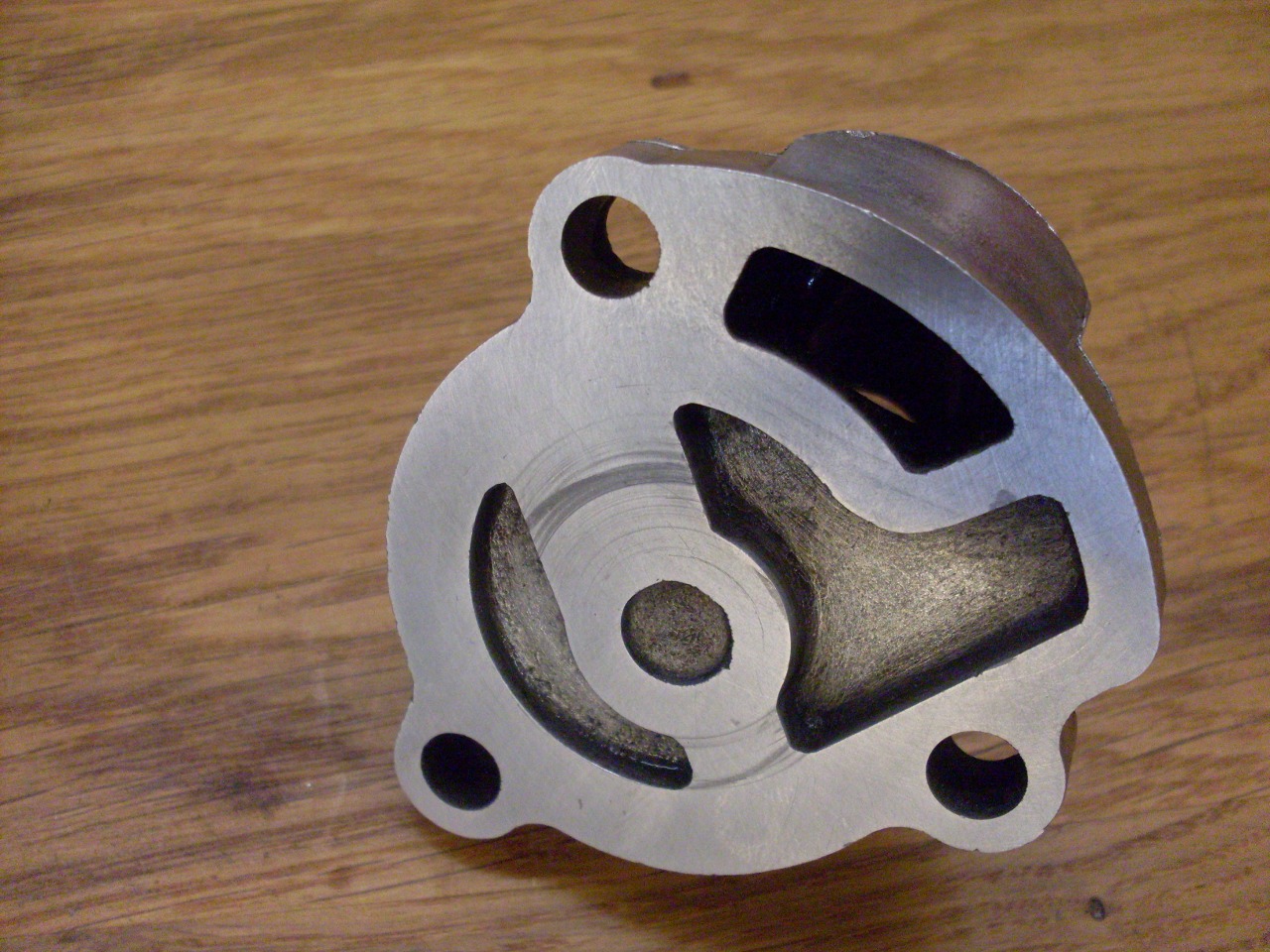

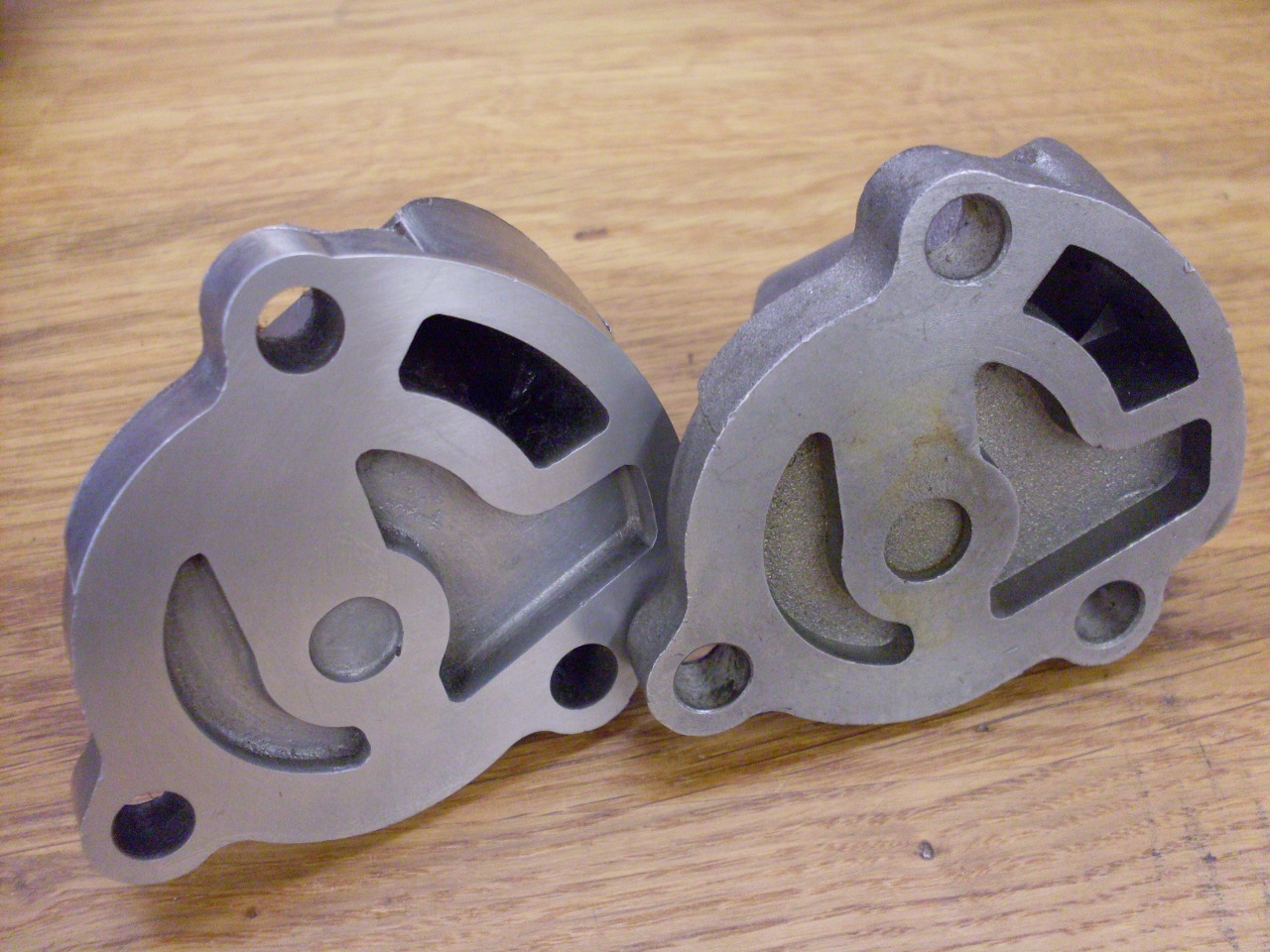

In

the end, I decided to use the original pump's end cap. It had a

little circular scoring, but I was able to linish it out easily on a

surface plate. The 40 year old plate (on the left in the second

picture) looks better than the new one.

One

other difference--the bolts supplied with the replacement pump have a

metric 10 mm head rather than the 7/16" of the original. A trifle

maybe, but with the added assumption that they are of lower quality

than the originals, I'll use the old ones.

The pump as I'll install it--a hybrid of old and new.

Comments to: ehollin1@yahoo.com

To other TR6 Pages