To my other TR6 pages

April 21, 2019

Odds & Ends II

So, the weather here on the prairie is getting better, and I'm really itching to get this car on the road soon.

I

started by trying to get a finer tune on the carbs. The car

started, ran, and sounded fine with the initial carb settings I made

when I rebuilt them, but I thought maybe I could tweak them some.

I started by synchronizing the throttles, which allegedly

equalizes the flow through the two carbs.. Many people do this by

ear with a plastic tube in the carb throats. I chose to use

machinery to do it. I used a Unisyn, which is placed over the

mouth of a carb, and indicates the flow into the carb by a ball

floating in a clear tube. This pretty easily allows the linkage

to be adjusted so that both carbs flow the same amount of air, at least

at idle.

For

setting the mixture, I had a few things I wanted to try. But

first, I needed my needle adjustment tool, which of course was AWOL.

This would stop me in my tracks, so I was forced to improvise.

I remembered what the tool looked like, and I could take all the

necessary measurements from the carbs, so this was the home-made result.

One

well known technique to set carb mixture is to slightly lift the air

valve and note how the engine speed changes. This didn't really

work for me, and I've read that it really only works reliably for a

stock engine.

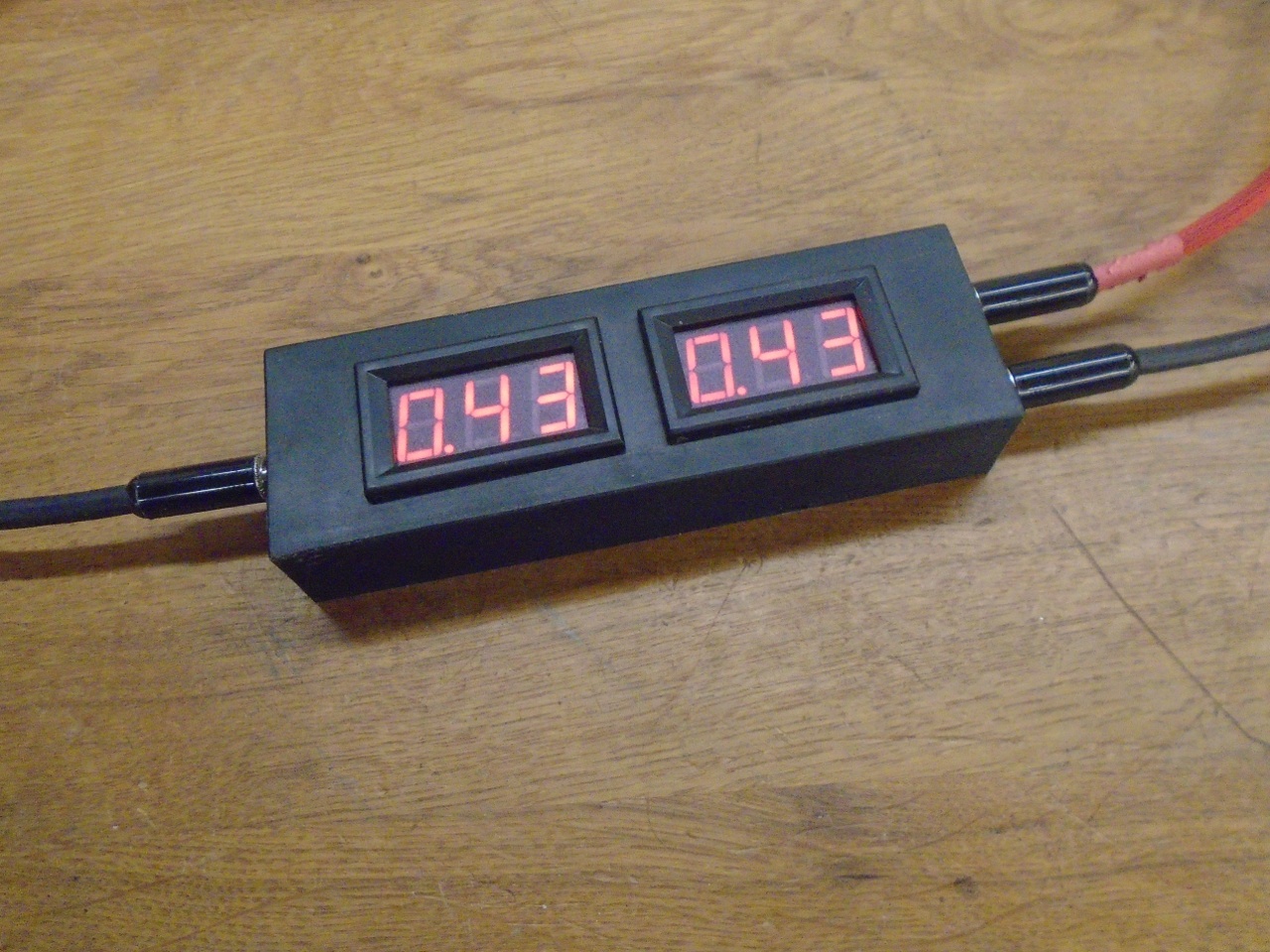

The

next thing I tried was reading my oxygen sensor outputs. The

voltage produced by an oxygen sensor is an indication of air/fuel

ratio. I didn't have a true A/F readout, but since I knew pretty

well what output voltage coresponded to what A/F ratio, I just made up

a little dual voltage readout to the show the voltage from each of the

two sensors.

For

this, too, I had a hard time getting consistent reaults. Since my

oxygen sensors were handled a lot during the mockup and fabrication of

the bungs in the exhaust downpipe, I suspect one of them may be

damaged. I may pursue this more in the future.

In

the end, I decided that since the engine seemed to be running so well

at the initial setting, that I would just leave it there for now, and

read the plugs after a little mileage.

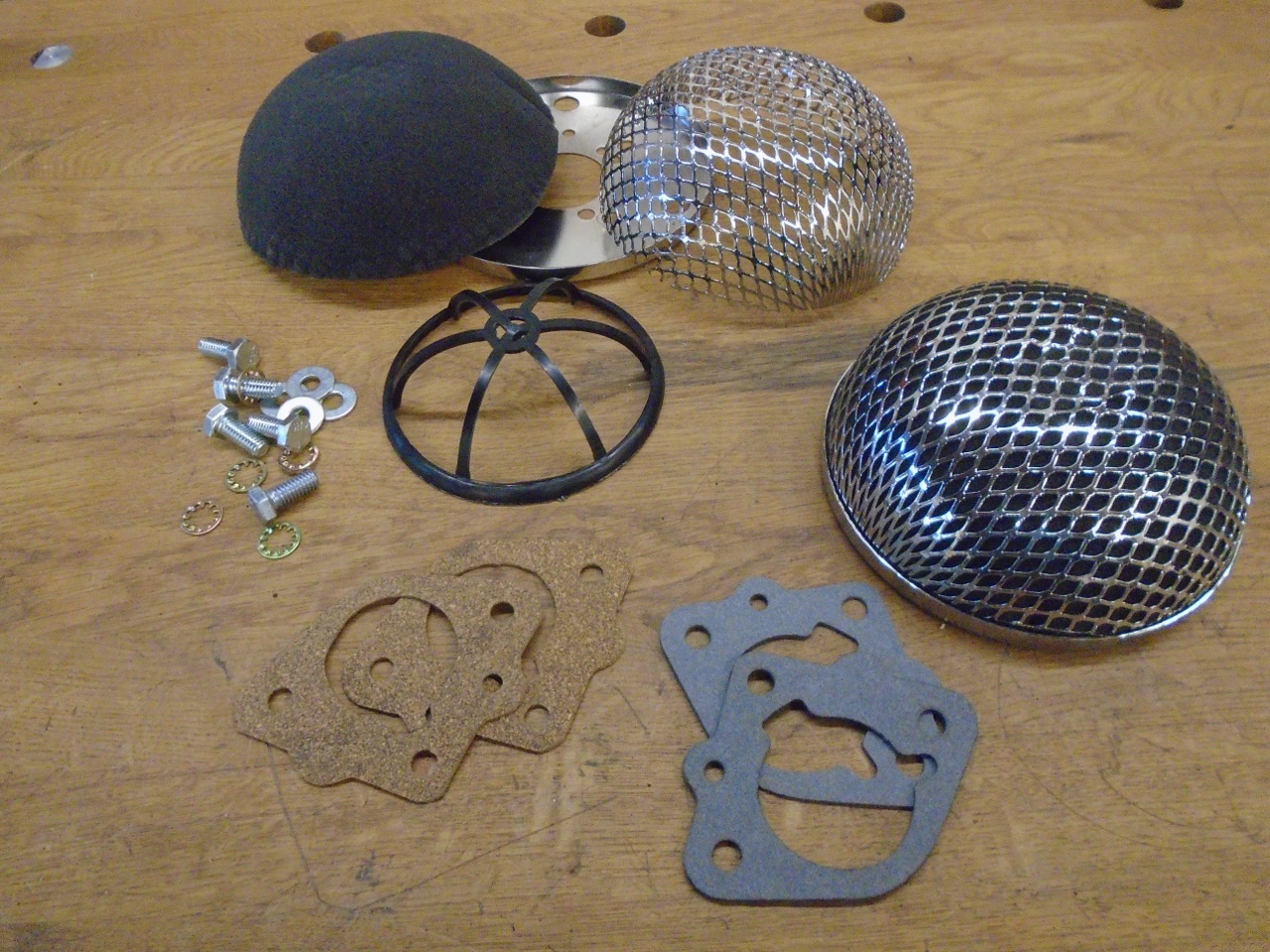

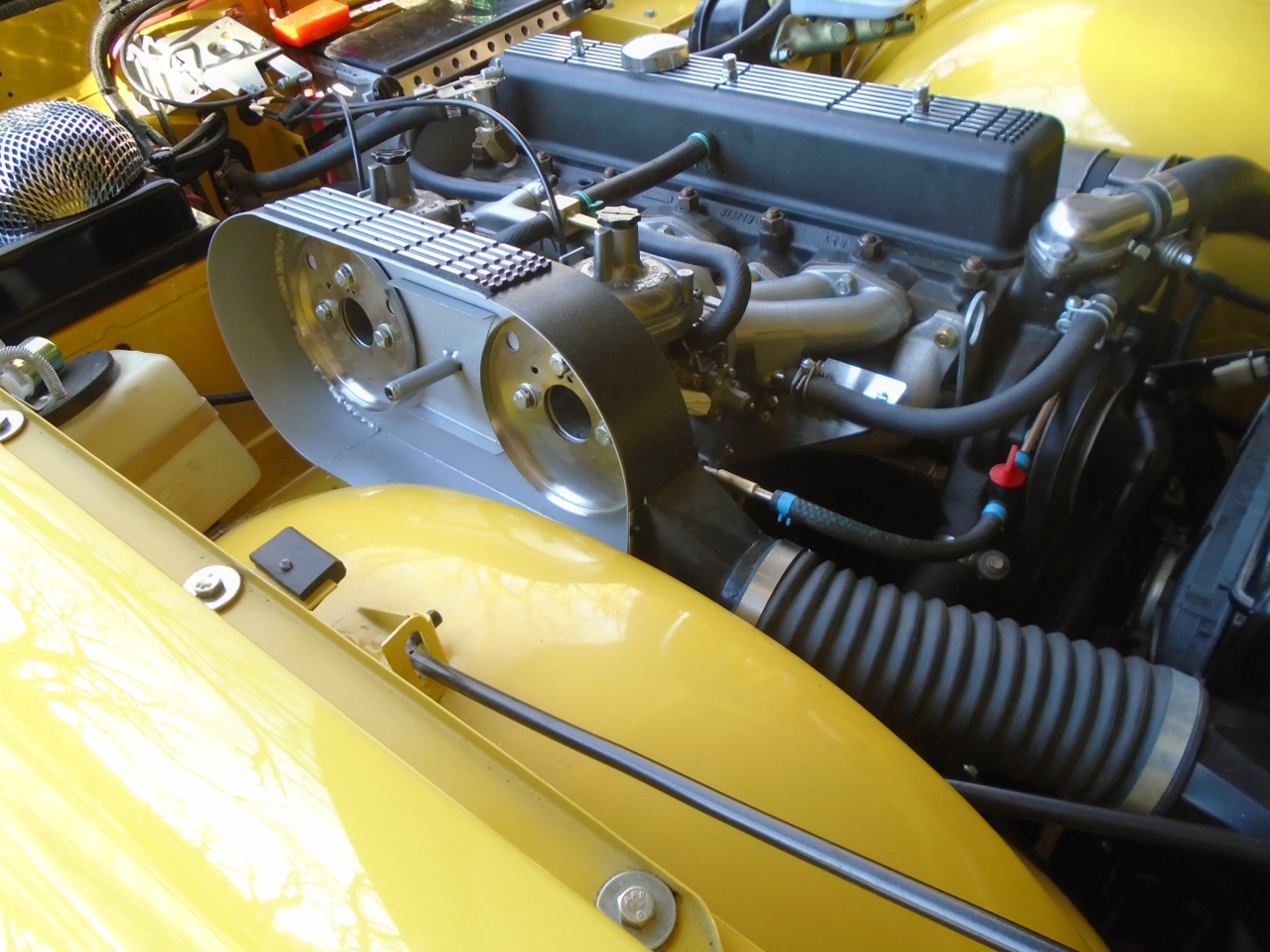

At this point, I could button up my trick air box.

I dug out the Ramflo filters I bought. Each filter consists

of a base plate, a dome-shaped foam filter element with a plastic

support that fits inside, and an expanded metal cover. This

arrangement takes two pairs of gaskets, so one pair in the picture is

home made.

The

base plate fasteners go through the air box and into threaded holes in

the carb flange. Considering where these fasteners are, safety

wire seemed like a good idea.

Then

buttoned everything up. The Ramflo foam elements can be run with

or without oiling them. I chose to run them dry.

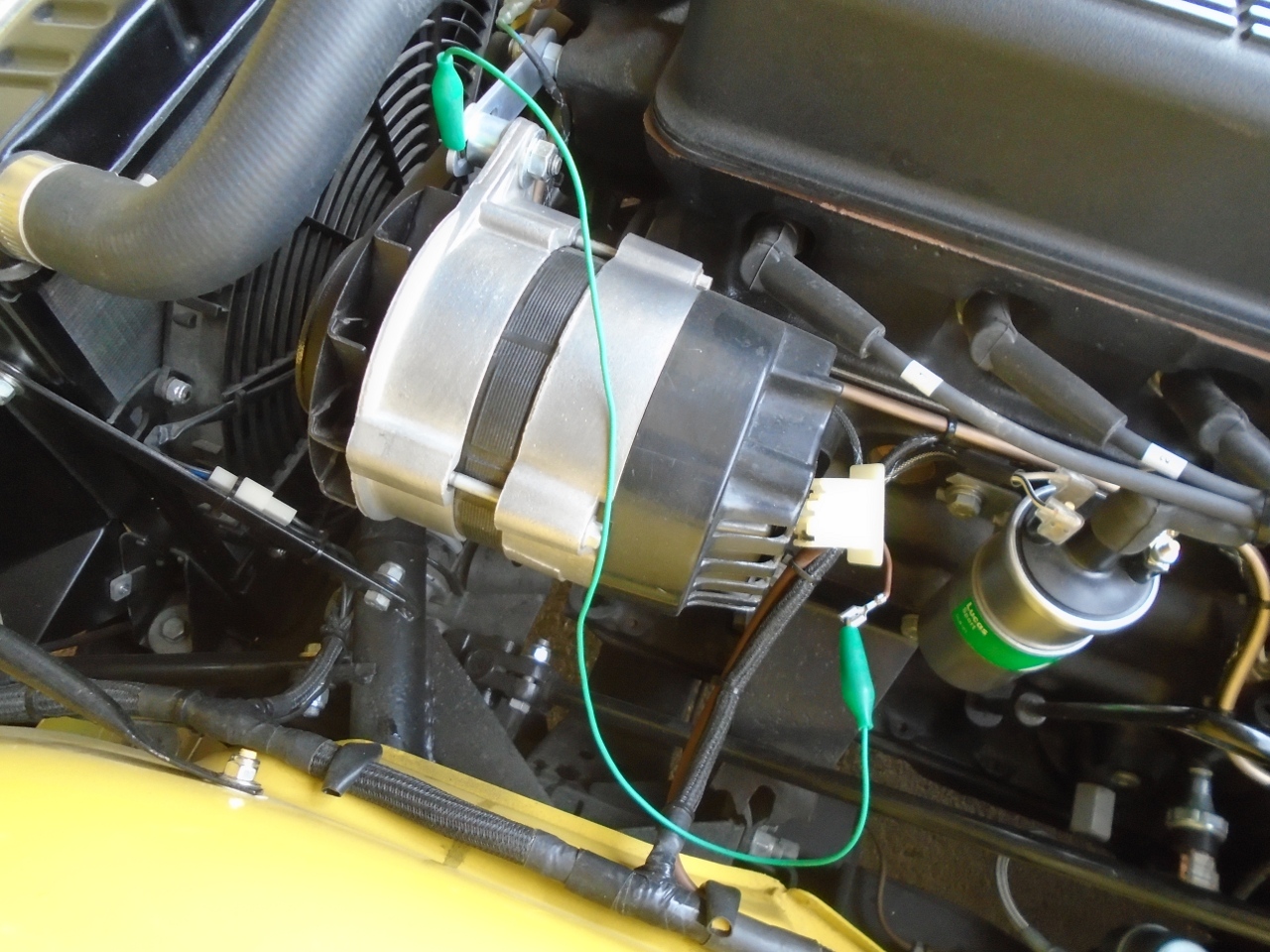

One

last thing--during all of this tuning, I noticed that my voltmeter

seemed to be reading a little lower than I expected. With the

engine running, the system voltage should be at around 14 volts or

more, but it was reading only 12 or so. I had calibrated the

voltmeter, so I trusted it. This implies that the alternator

wasn't working. During some investigation, I also discovered that

the ignition light (which is really more of an alternator light) was

not coming on when the key was in the ignition position, with the

engine not running.

Now,

the ignition light is important becase it provides current to the field

winding of the alternator to help "bootstrap" the alternator until it

can provide its own field current. When the light is on, that

indicates that current is flowing to the field winding through the

light. So, my problem could conceivably be with the ignition

light circuit. To test this, I just pulled the ignition light

wire out of the alternator plug and grounded it. With the key on,

the light lit. This showed that the light circuit was OK, and the

problem was with the alternator, almost certainly in its internal

regulator.

To

save time, I ordered a new 18ACR alternator, and a regulator module.

The alternator came in first. The new unit was advertised as

having 60 amp capacity, while my original was only 40.

When the regulator comes in, I'll install it in the original alternator, which will become the spare.

One

other last thing. Also during the tuning, the electric fan would

occasionally cycle, as I would expect it to. When I didn't hear

if for a while, I checked and found its 20 amp fuse blown.

The fan's specs say it draws around 13 amps, but there is

probably a surge well over that when it starts. I'll replace the

fuse with a 25 amp and monitor it for a while. I have a light on the dash to tell me when the fan is running.

There are a number of other things on the punch list for the car, but I now consider it roadworthy.

That's all for now. I'm going for a ride.

To my other TR6 pages