To my other TR6 pages

April 19, 2019

Jack

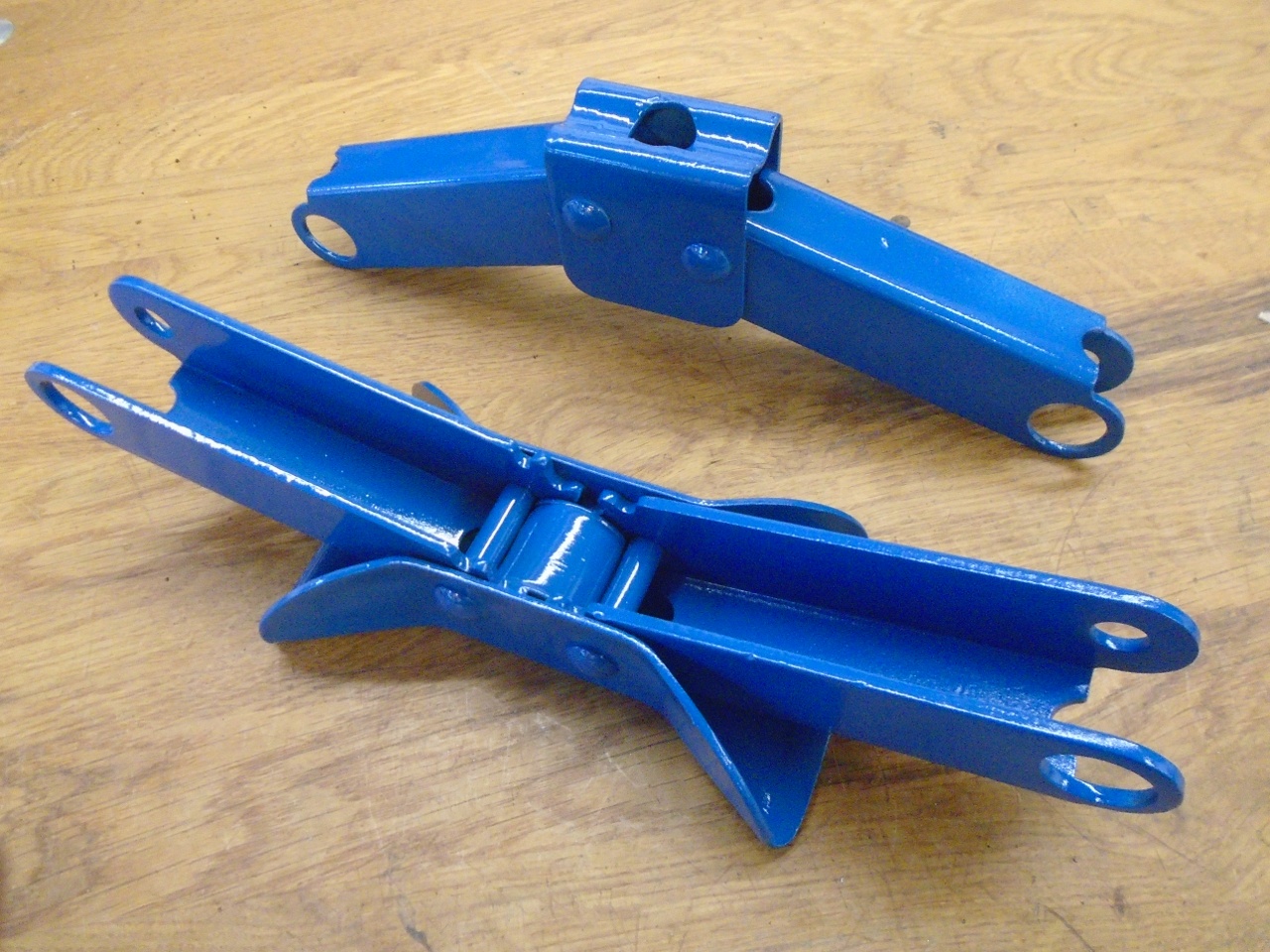

Well about the only thing left in the boxes of original parts for this car was a couple of crusty old jacks.

With

a little research, I determined that the one onthe right above was from

the TR6, the other one probably for the GT6. The TR6 jack was

dirty, rusty, and stiff, and didn't seem to be working right. See

how the lead screw is displaced to one side?

Now,

certainly, many inexpensive aftermarket jacks would be totally adequate

for this application. For originality's sake, used jacks are

available, but would cost between about $80 and $200, based on some

quick research. In keeping with the spirit of the overall

project, though, I had an incentive to try to revive this jack, so

that's what I did.

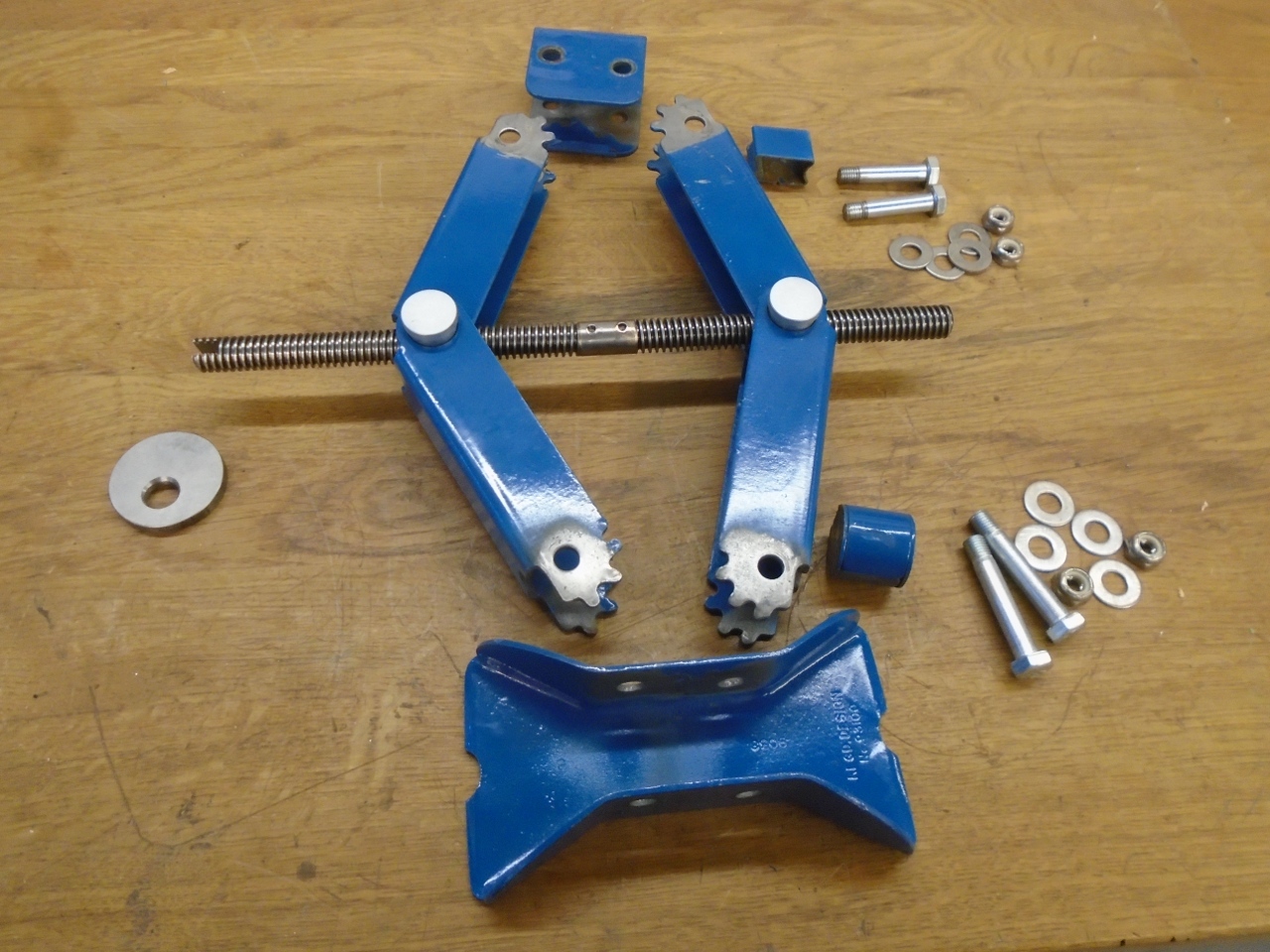

I

traced wonky operation problem to one of the lead screw nuts being

completely stripped. After drilling out the rivet-lile upset

metal on one side of the nuts, the lead screw pulled right out.

To get the lead screw completely free, I had to saw off the drive

washer. Stripped nut is on the left.

The

lead screw had an Acme thread--a squarish thread much stronger than the

more common V-threads, but the threads were still pretty worn. To

pull the jack arms together when the screw is turned, one end of the

screw has right-hand threads, and the other end has left-hand threads,

with right- and left-hand nuts to match. I didn't think it likely

that I'd find a double ended lead screw anywhere, but I thought I could

possibly make one. Turning it on the lathe was a possibility, but

I actually wimped out and bought short lengths of right and left hand

Acme threaded rod. The original screw appeared to be M14 metric,

but I bought 1/2-10 Acme rods. The 1/2 inch rod is slightly

smaller than M14, but it allowed a little more meat on the sides of the

nuts.

Short lengths of the rods were silver brazed to a small coupler piece.

Then

made the nuts to fit the rods. Rather than swaging the nuts in

place like the original, I put a threaded nose on one end.

Then fashioned a new drive washer based on the remnants of the old one.

Meanwhile, the rest of the jack got stripped and painted a color fairly close to the original.

This

is where I realized that the jack would not go together without

separating the jack arms. The only reason I was able to get it

apart in the first place was because one of the nuts was stripped.

Note the cog teeth on the ends of the jack arms. They mesh

with each other to ensure that the arms move in synch. There are

also some distance pieces at the top and bottom joints to make sure

those cogged ends stay aligned. I considered replacing the

original rivets with rivets, but opted for threaded fasteners with lock

nuts. I think this should allow better control over stiffness of

the joints, and even make repair easier if necessary.

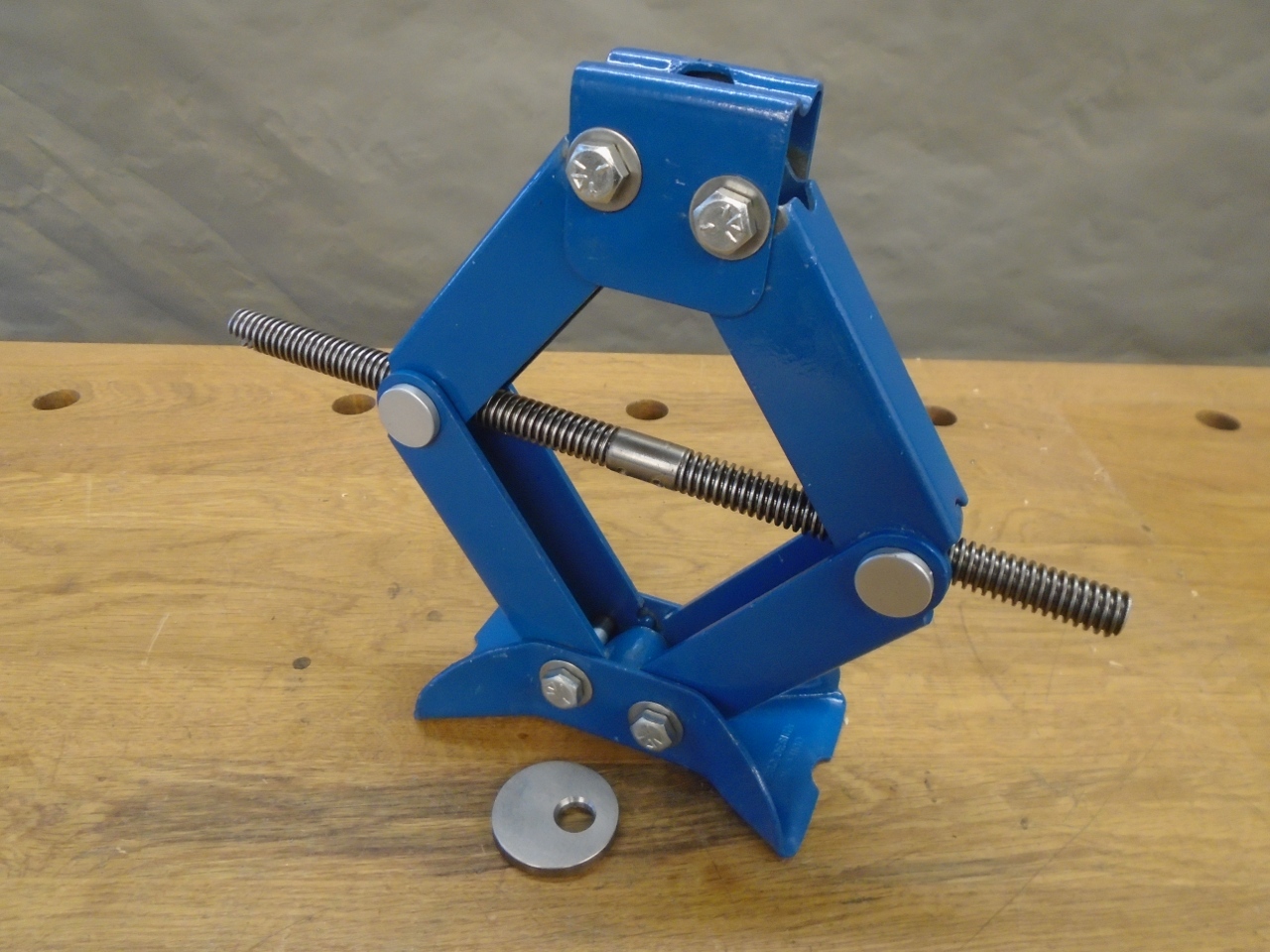

Lastly, the drive washer was silver brazed to the lead screw.

Ready for service.

I

have it on pretty good authority that the jack was originally closed

down on the spare tire wing nut. This does seem to keep it in

place, though I think I'll find a way to put some kind of pad between

the jack and the wheel.

This

was a silly little project, but it kept me busy for a couple of rainy

days. The cost for the Acme rod and taps was less than what I'd

have to pay for a used jack on eBay.

Update, June 30, 2019

I

knew when I did the jack that there must have been some kind of lug

wrench that came with the car from the factory, but I couldn't find it.

Then, while cleaning the garage in preparation for the next

project, I found this. I'm pretty sure it is the original TR6 lug

wrench.

I

took it apart and cleaned up the rust and traces of black paint to

assess the condition. There was a pretty good kink in the main

shaft, probably from someone having to use a cheater bar to remove a

"professionally" installed lug nut.

A few minutes at the hydraulic press got the shaft back in line.

I assume the "A/F" means "Across Flats".

A little high-temp filler to smooth the rust pitting, then some black powder coat got the wrench looking pretty close to new.

I'm

frankly not sure how useful this lug wrench is. The torque arm seems a

litle short to apply much gronk to a tight nut, but I'll keep it in the

car, probably with a short cheater bar.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages