To my other TR6 pages

December 29, 2018

Wheels & Tires

There

are a number of things that many people consider iconic about the TR6.

The front Grille. The prominent center mounted fuel filler cap.

The blacked out Kammback. I consider the largish red stripe

tires among these things.

Now it's true that the TR6 wasn't

unique in the use of the red stripes, which seem to have first

appeared in the mid 60s on a few American muscle cars. The

US market TR250 had them in 68, followed by the TR6. It

apparently was a move to appeal to American tastes, as was the

larger 185-15 tire size, as opposed to the 165-15 blackwall supplied for sale

elsewhere in the world. We Americans do like our big tires.

My tires were the original Michelin Xs. They still had some tread left, but were pretty hard and cracked in places.

I liked the tires, and even thought I could make them look pretty good, but at 45 years old, they just weren't safe.

But I also had my heart set on red stripe tires.

I

explored a few alternatives. Red stripes can be painted on.

Red stripes can be stuck on. Both of these options really

appealed to my basic DIY instincts. There are also outfits that

apply red stripes to stock modern radial tires, using processes that

make the stripe part of the tire. I struggled with the decision,

but in the end opted to pursue that last option. It is by far the

most expensive, but, due to penny-pinching elsewhere, the budget could

handle it.

So, I ordered myself a little Christmas present. They showed up on the porch one snowy evening.

These

tires are supplied by Diamond Back Tires. Diamond Back offers some choice

on what tire to start with. I chose Michelin Defenders

in size 205R70-15. This is close to the widest tire that will fit

the stock rims and wheel wells. As I said, we Americans like our

big tires.

Notice that, other than a small DOT code, the

outside wall of the tire is completly smooth, with no brand or

other markings. This must be part of the Diamond Back process.

The tires are about 3/4" wider than the already upsized US stock size.

So

the next step was to get the wheels in shape. I really never

considered anything other than the stock wheels. I like them.

I don't always feel that way, though. I'm pretty sure my

GT6 will have some kind of slotted aluminum wheel, while the MGA just

cries for wires.

I took the old wheels to a shop to have the

tires dismounted. I'm glad I did that since, even with their

fancy tire machine, they had a hell of a time getting the tires off the

rims. 45 years in place will do that.

I had done a quick

and dirty cosmetic paint job on four of my five rims some time ago, so

they actually look decievingly good in some of the pictures above.

This one shows a truer picture of the condition they were in.

They

were worse in the inside. The original tires were tube type, so

there was no real water seal at the valve stem. This led to a lot

of rust in those areas.

A fortuitous break in the winter weather let me set up the blaster outside to clean up the wheels.

Then a couple of coats of a nice epoxy primer...

...followed by some silver on the part that will show.

I

was concerned about the rust pitting around the valve stem holes and

the bead flanges, so I opted to use a commercial bead seal product in

those areas.

Well,

at this point, I was anxious to mount the tires on the rims. Then

I realized it was late afternoon of Christmas eve, and I doubted that

any tire shops would be open. Not wanting to wait, I decided to

try to mount the tires myself. How hard could it be? It's

just a matter of shoving that big metal thing into the hole in the big

rubber thing. Never mind that the hole in the big rubber thing is

quite a bit smaller than the big metal thing.

Well,

it was a bit of a wrestling match to start with, but I pretty quickly

learned a few tricks, and the last tire only took a few minutes.

With the money I saved mounting the tires myself, I went out and bought this tire balancer.

This

is a static balancer. It is dirt simple, works by gravity alone,

and clearly shows which side of the wheel/tire is heavy. Weights

added to the light side will bring the center of gravity of the

assembly onto the spin axis, which is where you want it.

Static

balancing was the only kind of balancing done to wheels until a few

decades ago with the advent of dynamic, or "spin" balancing. Spin

balancing does what static balancing does, but also can indicate

differences in mass on either side of the center plane of the

tire/wheel. These masses can impose a rotating bending torque on

the wheel spindle that will be superimposed on the bending torque due

to the weight of the car. There are apparently those who dispute

some of the advantages of dynamic balincing. I've read a paper or

two on it, but don't feel competent enough on the subject to have a

worthwhile opinion.

So what I'll do is statically balance the

tires, and then run them. If I sense any vibration that could be

due to tires, I'll have the dynamic balance done.

The balancer

can easily resolve down to the 1/4 ounce weights I'm using.

The wheel/tires took between 2.25 and 3.75 ounces of weight.

This is in line with the lead rim weights I removed from the

wheels. I used stick-on weights on the inside, where they won't

show.

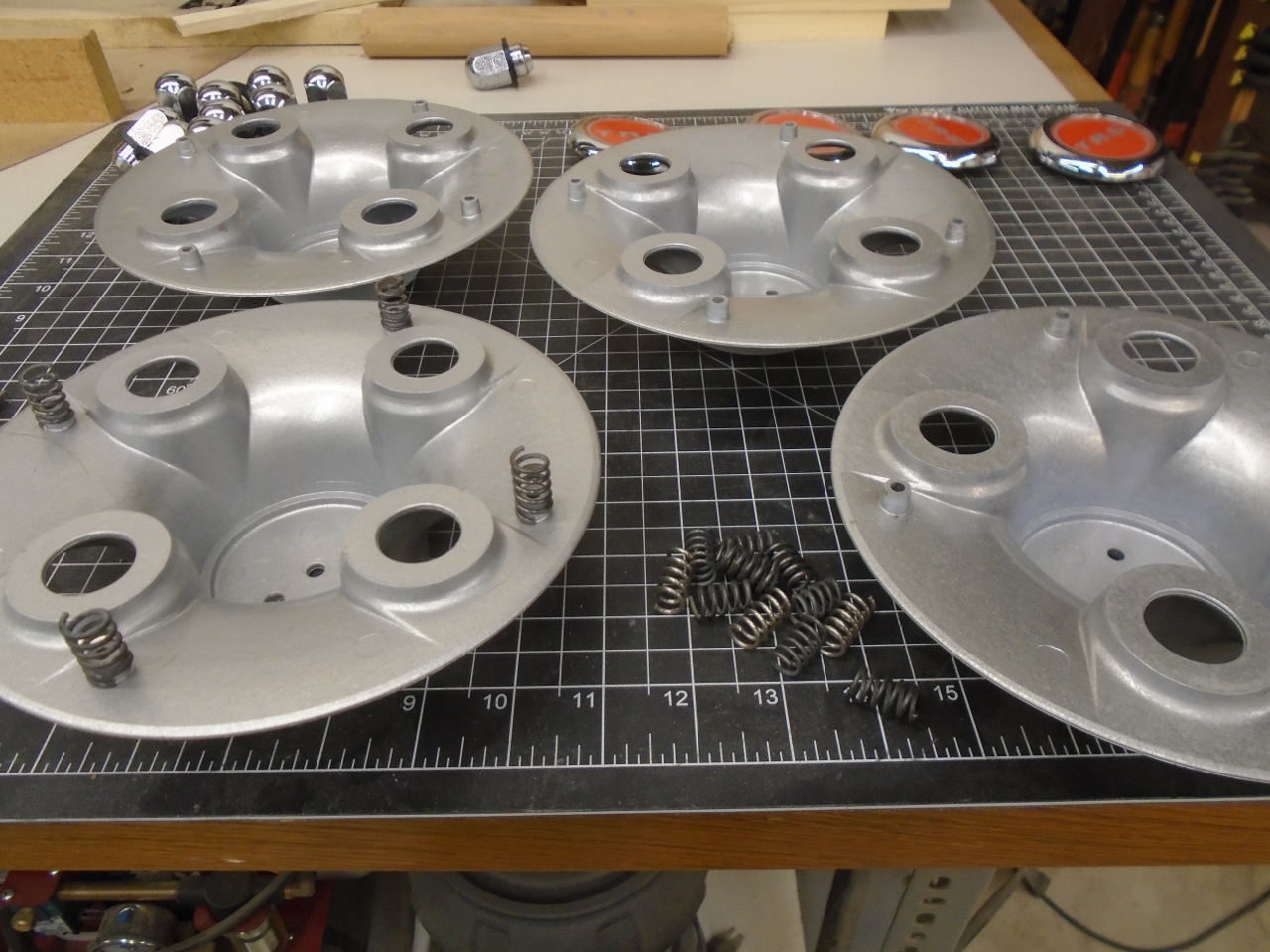

In parallel with the tire work, I was playing with the plastic hub caps. They started out looking pretty sorry.

Stripped

of their logo badges, I could see that they were painted plastic.

The paint on one of the caps was damaged, likely from brake fluid

from some past leaking wheel cylinder.

I

wanted to strip the rest of the paint off of that cap. I tested

my very macho methylene chloride based stripper, and as I suspected, it

attacked the plastic about as fast as the paint. I tried my

wimpier citrus based stripper. The paint ignored it.

So what to

do? I'm a little embarassed that I didn't think of it sooner, but

the answer is obvious--brake fluid! The look of the crinkled

paint is sadly familiar.

The other caps were OK, so just scuffed them up and painted them all with the silver color.

The little medallions were in OK shape, but I cleaned them up and put on new red stick-on logos.

Had to buy a couple of new springs for the backsides.

New locknuts to replace the original nuts and lockwashers..

And put the hubcaps together.

My

chrome lugnuts were all present and cleaned up pretty well. I had

to replace a couple of the plastic inserts that had gone yummy.

The

car had been up on the lift for nearly a month waiting for its new

shoes. At that point, I had everything I needed to mount the

tires.

The

last detail on the wheels was the aluminum trim rings. In my

mind, I had written these off long ago. I could see beneath all

of the road grime that they all had bad cases of curb rash. A

couple of them had this kind of damage nearly half way around the rim.

Original

style replacement rings are not available, and being made of soft

aluminum and mounted in a very vulnerable location, not many

decent survivors exist. There are apparently some rings from a

more modern American car that will fit, but they have a different

profile and, being made of polished stainless, the color is

different and they are more "chromey" than the originals, so to

me at least, they don't look quite right.

I figured I didn't have much to lose by seeing what I could do with the rings I had.

In

playing around with the damaged areas, I found that the aluminum

was very soft, and in fact by using a hard polished metal rod and

quite a bit of pressure, I could sort of move the displaced metal back

into place. It was a tedious and imperfect process, but I was

encouraged. Using that process along with some small files and

sandpaper, I eventually decided I could probably make the rings

presentable enopugh to use. There were a few places where there

was just too much metal missing to fully repair it. These

places I now just call "character".

This

process necessarily removes the anodized protective coating on the

metal. In fact, I had to remove the anodizing on the entire

exposed surface of the ring to get a consistent finish. This

changes the sheen a little. It is now more of a brushed aluminum

look, and the color is slightly different. Though certainly not perfect, I think I can live with these

trim rings.

The

trim rings are held on by a friction fit betweem the wheel rim and

these spring steel fingers around the backside of the ring. These

were pretty rusty, so I cleaned them up as well as I could.

I

wanted to paint the springs to keep them from rusting so badly, but to

save masking time, I just painted the entire backside of the ring.

At

some point, I would have liked to re-anodize the rings. The

problem is that the steel retaining springs would not survive the

strong acid anodizing bath, and I didn't see a good way to remove them.

But leaving the rings bare would have them gradually get dull and

even corrode. The best solutioin I could think of was just to

clearcoat them. Not nearly as good as anodizing, but better than

nothing.

The

trim rings are not perfect, and there are defects that don't really

show in the pictures, but I honestly never thought they would come out

this good.

This

was an expensive project. The tires are among the most expensive

items on the car, but I'm pretty satisfied at how they turned out.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages