To my other TR6 pages

July 12, 1018

Rear Bumper

Being

of a certain age, the TR6 cars sported pretty conventional chrome

bumpers. By 1974, the US government had instituted crash

worthiness standards on all new cars, and Triumph met these standards

by adding a pair of large rubber shrouded steel protrusions to both the

front and rear bumpers. I've heard a few people say they like the

looks of the rubber protuberances, but most don't, and it is a popular

mod to remove them. A little over half the 40-pound weight of the

original rear bumper assembly is in the added crash protection.

My bumper looked pretty bad, but I dermined that I should at least

clean it up to see what shape it was in.

First,

off with the rubber warts. As is common in disassembling anything

having to do with bumpers or suspension, most of the bolts broke off

rather than coming out peacefully.

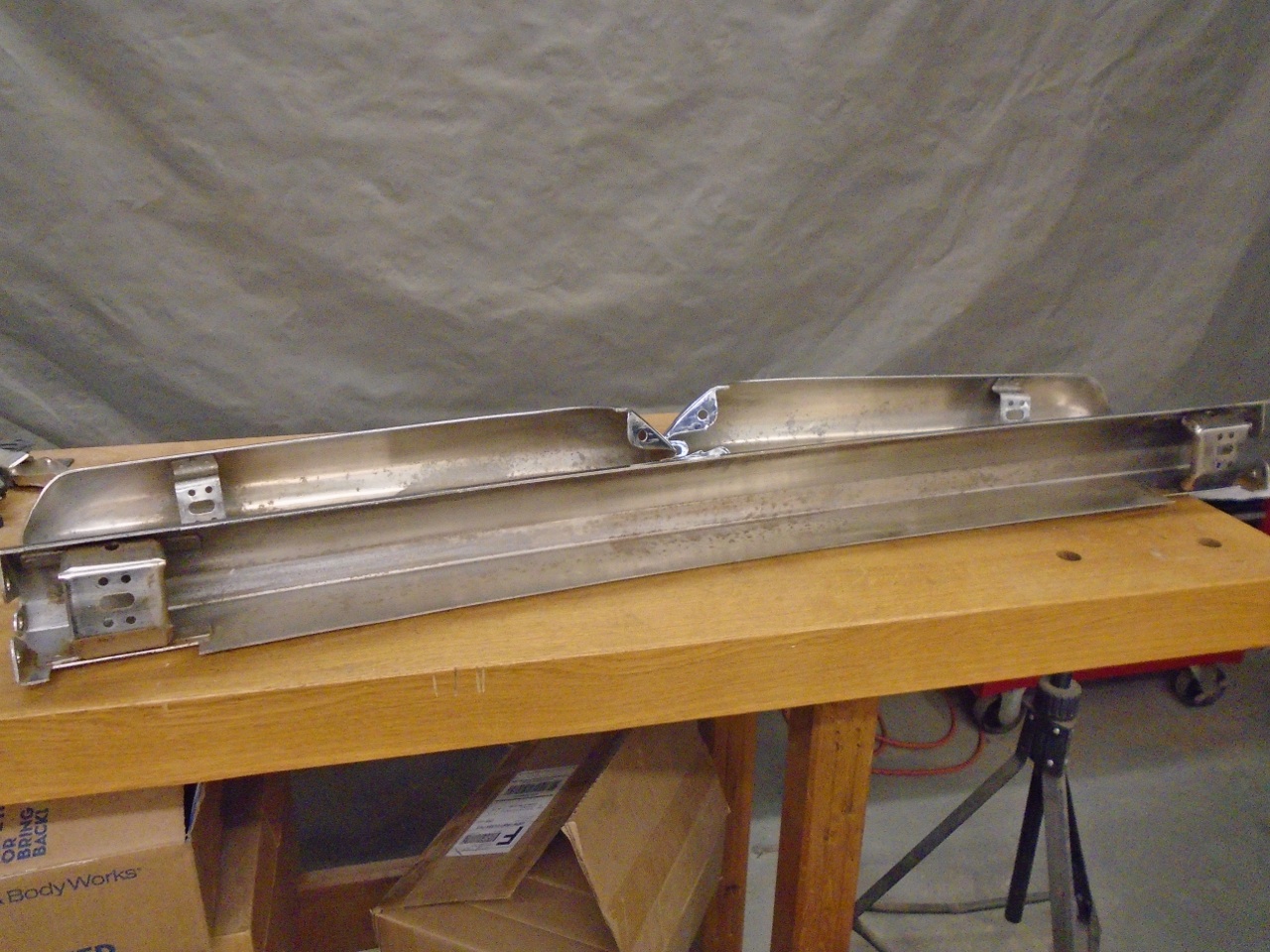

Then

parting the bumper's three component pieces. Again, about half of

the fasteners sacrificed themselves rather than be cooperative.

To

mount the bumper to the car, the bumper has four caged square nuts--two

on the center piece, and on each on the two end pieces. True to

form, three of the mounting bolts had broken off on original

dissassembly, leaving rusted stubs in the captive nuts.

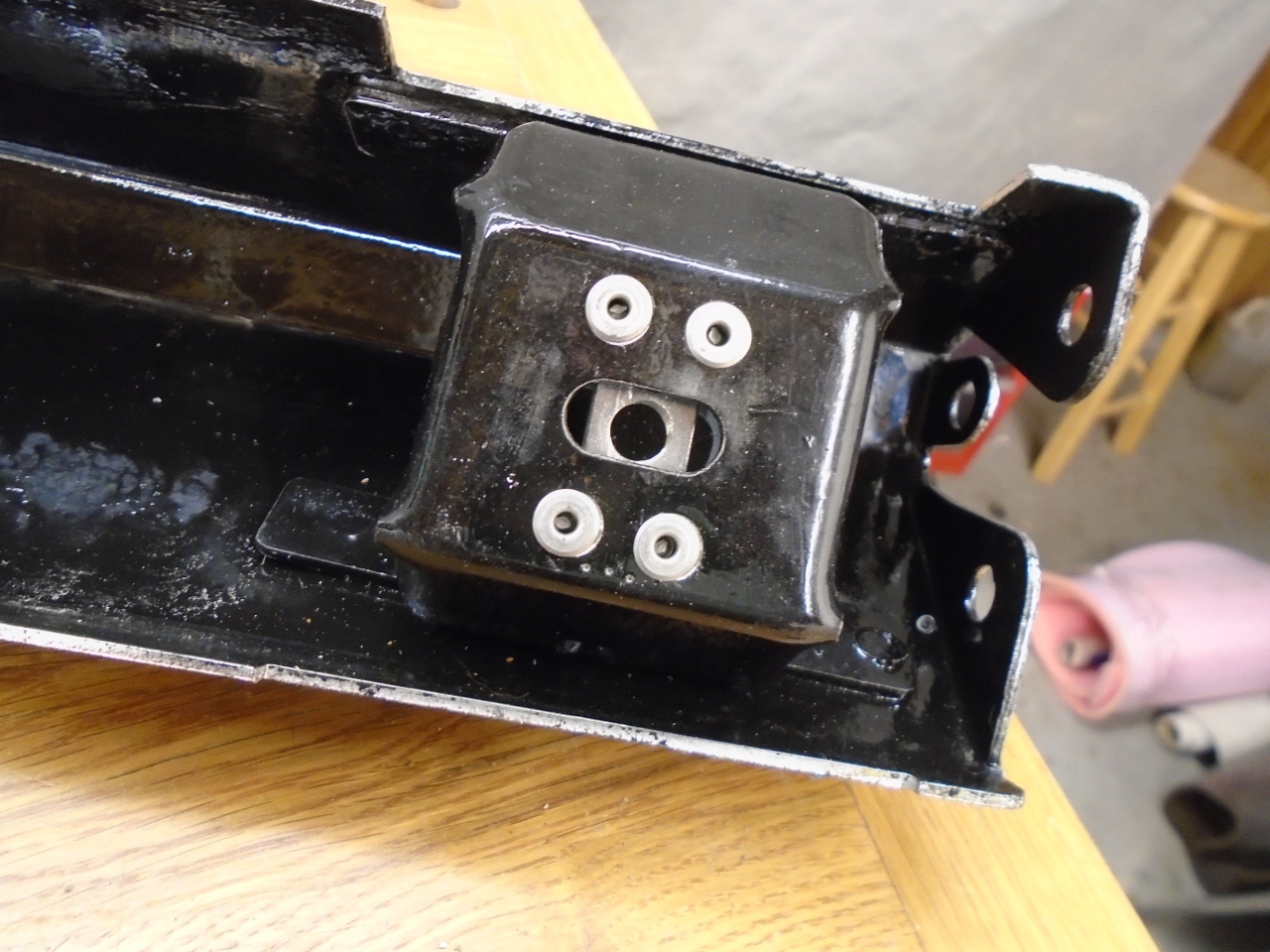

I

made a half-hearted attempt to free the remnants of the bolts, but

mainly just succeeded in mangling the nut cages. In the end, I

just drilled out all the spot welds securing the cages.

While

mulling what to do about bumper fasteners, I turned to the bumpers

themselves. I thought the outside chrome surfaces had a good

chance of looking OK, but the inner surfaces had some patches of rust.

This of course means that the plating is breached, and the

corrosion won't stop on its own.

First,

I wanted to remove all the rust. I normally do this by soaking

the part in phosphoric acid, but I was a little concerned that the acid

may attack the chrome. To be safe, I used my backup method for

sensitive materials, Evaporust. I made this 2-foot long

container, filled it with Evaporust, and lowered the parts into it.

Both side pieces fit in the tank, but the center piece had to be

done one end at a time. The white tube going into the

tank is from an aquarium air pump. The bubbling keeps the

liquid agitated, speeding up the process.

All the rust was removed from the inside, which of course left just bare steel in some areas.

Two

coats of POR15 sealed those surfaces. I would normally prefer to

shoot some epoxy primer on bare steel, but there were some areas on the

bumpers that could really only be reached with a brush. This

favored POR15.

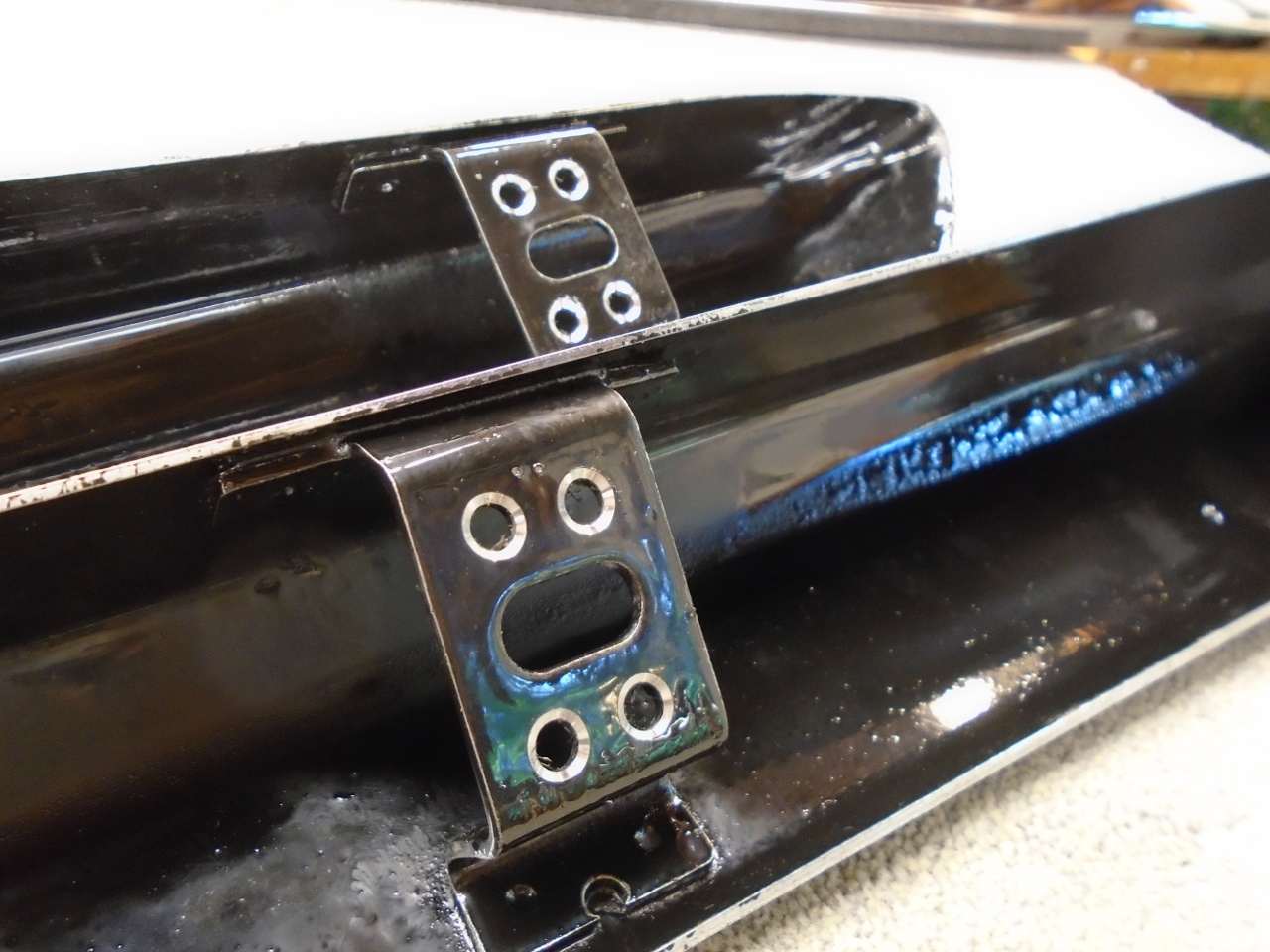

For

the

fasteners, I couldn't think of a better solution than the caged

square nuts, so I made some cages pretty much identical to the

originals, and bought some new stainless square nuts. The cages

were drilled to match the holes left from drilling out the spot welds.

I

got some flat head stainless blind rivets, and countersunk the holes in

the bumper brackets so the rivets would end up more or less flush the

the surface.

Ready to go back together.

New stud plates and rubber gaskets. The anti-sieze is for the benefit of the next restorer.

Let's see if it fits on the car.

But first, some little fiber pads to be nice to the fender and valance paint.

Makes

the car look more finished, I guess, but I almost like it better with

no bumper. Paint it black, maybe? I'll have to think about

it.

No

one standing within five feet of the car will mistake this for a

new or perfect bumper, but then again, perfection isn't one of my

goals.

I like projects like this one where I can make something cruddy look pretty darn good for almost nothing.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages