To my other TR6 pages.

November 26, 2017

Convertible top

I

was taking stock of the TR6 project a few weeks ago, and realized that

about the only largish subassembly left to do was the convertible top.

So I dragged it out of the shed and up onto a work table.

As

I recall, this is not the original top, but an early 80s replacement.

The top itself was of course pretty much toast. The folding

frame assembly on the other hand was dirty, rusty, and loose, but

appeared to be all present and serviceable.

To

make cleaning and painting easier, I took apart what I could.

Removing the vinyl cover, I could extract the rear bar that

mounts to the body. The frame itself is mostly riveted together,

except for the rear side channels, which can easily be unbolted.

I noted that the front header--the part that mounts to the top of

the windshield frame--seemed loose on its rivets. I wasn't sure

whether this was intentional, to allow a little flex so that the header

could seat. Opinions on some of the forums seem to be split on

this question. At any rate, I didn't think I could do a good job

of cleaning or painting that area with the front header in place, so I

drilled out the beefy rivet.

This made it much easier to do a complete sand blast on the frame.

At

this point, I checked all the pivot points for looseness, and snugged

the floppy ones a little by peening the rivet heads. This helped

a lot to make the frame less rattly and smoother in operation.

I then applied a couple of coats of a two part epoxy primer and a semi gloss black top coat.

The

front header rivets were replaced with a stainless bolt with a lock

nut. In principle, I could slack the lock nut to restore the flex

to the joint, but right now, I heve it cinched down.

The original bolts and spacers got replated, and the nuts and lockwashters got replaced by stainless locknuts.

One

of the replaceable parts on the top assembly is the velcro strips along

the side rails that secure the sides of the top above the side windows.

Kits are available. I bought one. I was disappointed.

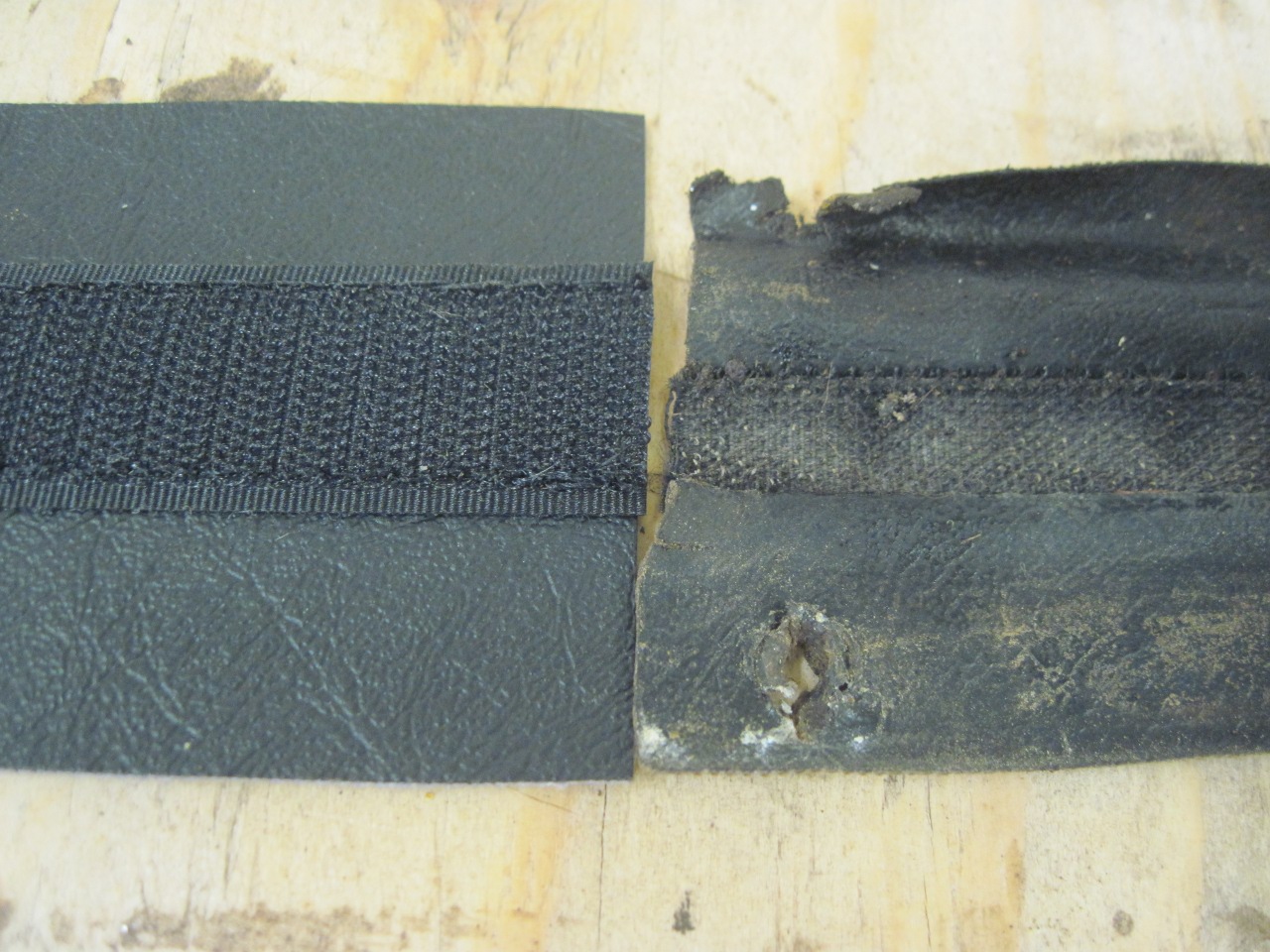

The

original velcro strips were sewn to pieces of vinyl, which were in turn

glued to the frame side rails. The replacement pieces were

constructed the same way, but with gross difference in dimensions.

The velcro strip on the replacement is at least twice as wide as

the original. This makes it much wider than the side of the rail

it attaches to, and would require the velcro to wrap around the edge of

the rail. The velcro is too stiff to do that gracefully.

In

researching the issue, I came across a thread on a forum that discusses

this exact problem. In the last post in the thread, the original

poster reported that he had discussed this with the vendor, and that

the vendor had agreed that the parts were wrong and would fix it

immediately. That thread was over four years old.

Unfortunately,

I had butchered one of my new strips trying to modify it, so I couldn't

return them. It's a $30 lesson that reinforces my bias against

buying replacement parts if it is at all possible to fix the old ones,

or make new ones.

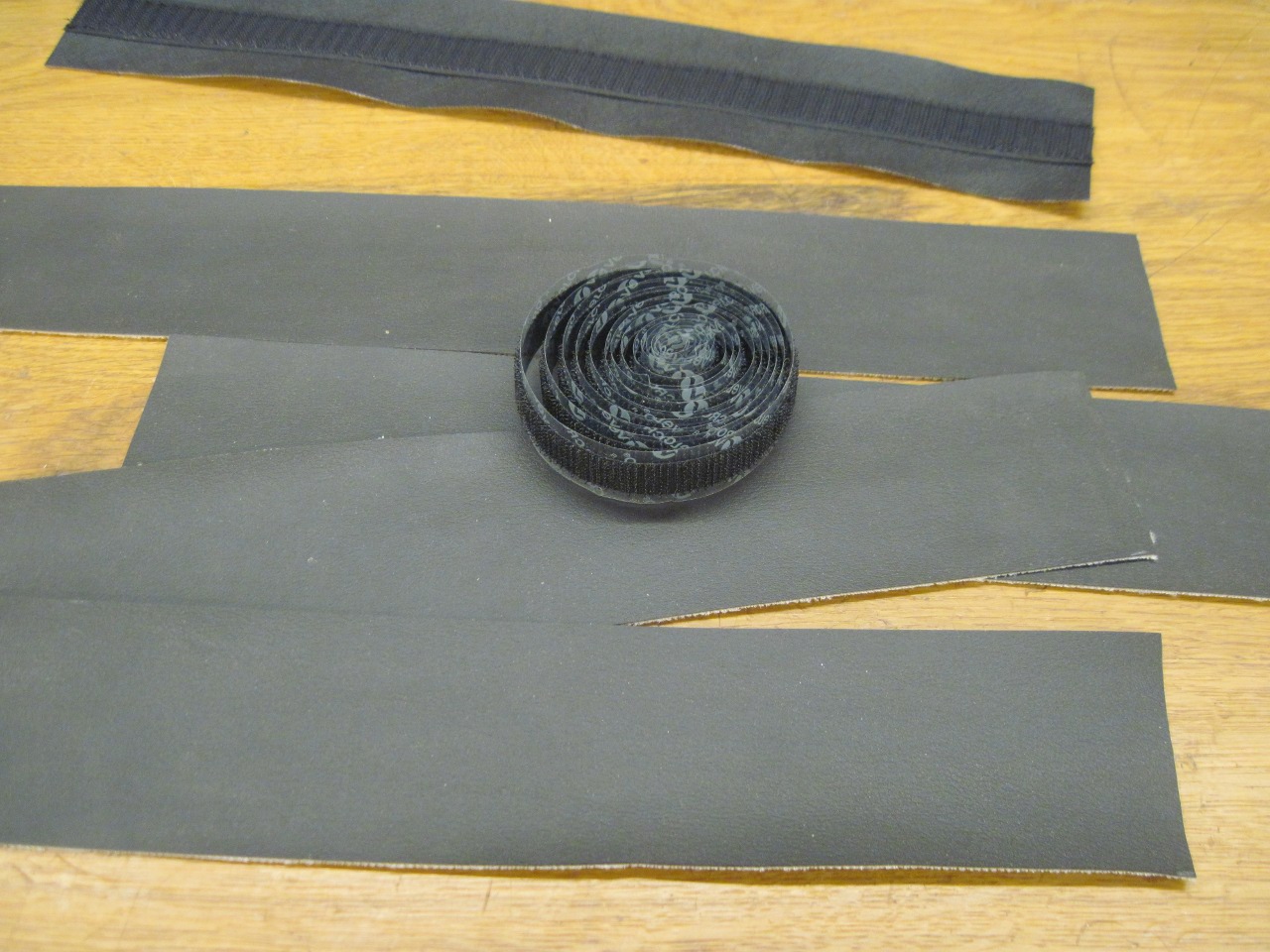

For

less than $10 in materials, I made replacements using 1/2" wide

self-adjesive velcro and some vinyl left over form covering the crash

pads. Whether the adhesive proves up to the task in service, I'll

find out, but during install, it seemed fine.

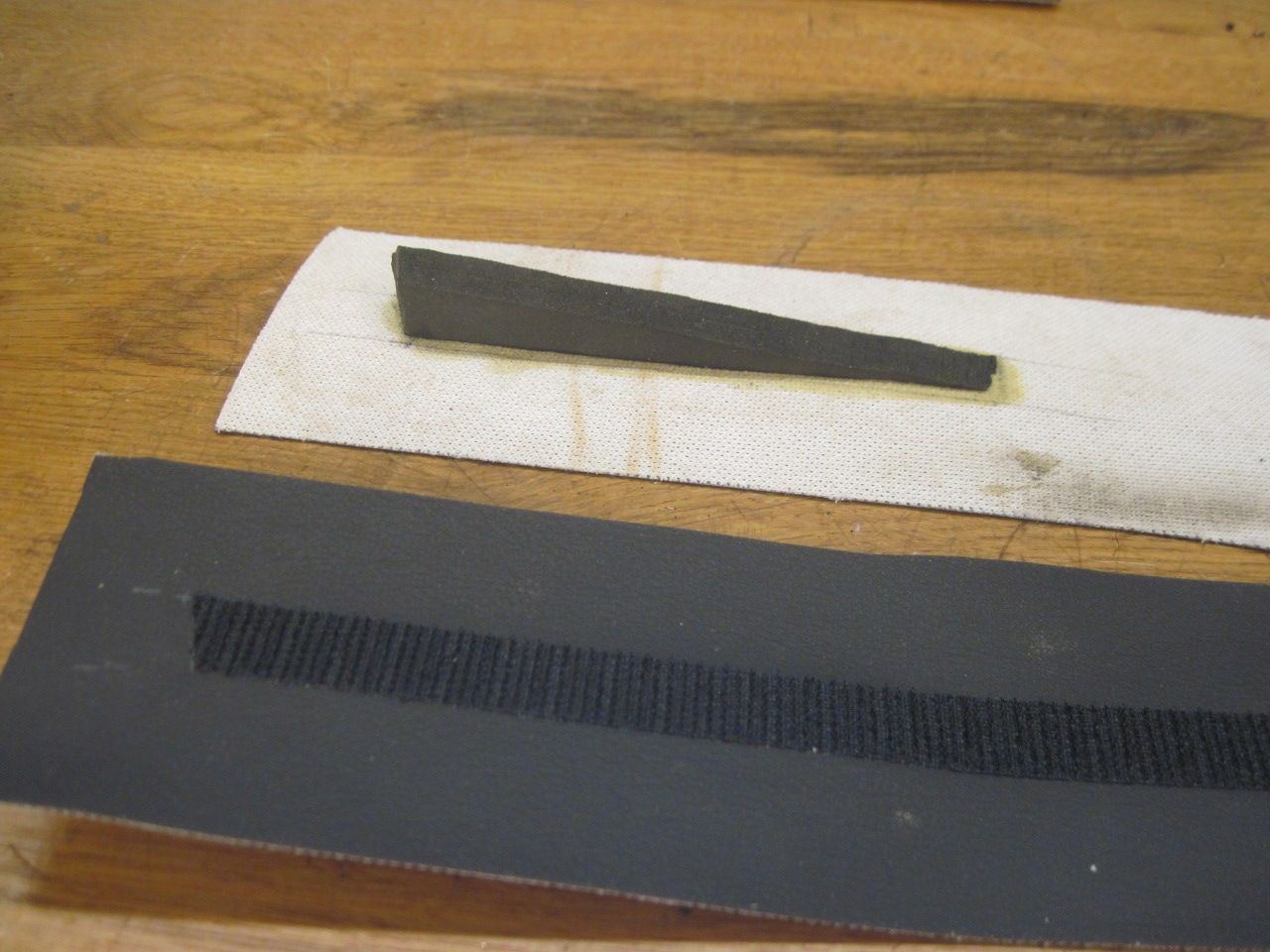

One

other

thing on these velcro/vinyl pieces. A forensic examination

suggested that there were at one time some foam wedges under the vinyl

where it approached the front header. This fills in what would

otherwise be a gap between the end of the header and the rail.

Estimating the dimensions from the remains of the originals, I made a couple of wedges from some pretty stiff foam.

Then applied the velcro to the channels.

I

fixed up and reused the anodized aluminum strips that hold the rubber

window seals. Interestingly, the original screws that hold the

alumium strip to the channel, which look like 8-32, are in fact 3BA.

You never know where this fetish the Brits seem to have

for odd-ball threads will turn up next.

I

figured I should reattach these bumpers before I lost them. They

are apparently NLA. Old rubber sometimes acquires an oxidized

layer that makes the part look bad, but it often comes off easily.

Though a tubular rivet wouold look more original, I had some of

these binder screws that do the job and look sort of cool.

Next up was the webbing. The original pieces were in no condition to be used. Mouse-eaten, probably.

I

came really close to deciding to use webbing left over from my seat

belt rebuild. It is the same size, but I think it stretches less.

In the end, I ordered the proper stuff.

Before

installing the webbing, the top needs to be attached to the rear

header. Since the tonneau snaps hold it in place, I'm not sure it

is necessary to glue it, but I did.

The

snaps required a small mod to my rivet gun. A little spacer that

fits inside the snap. On a whim, powder coated the heads of

the visible rivets black.

Now

back to the webbing. The webs are held in place at the rear

header by a little "keeper" pin that goes in a loop in the end of the

web strap. Since the webbing is supplied without that loop, it

has to be installed. Falling back on some sewing skills gained in

my seat belt rebuild, this was pretty easy.

The

original pins were really rusty. Before I realized that new pins

were supplied in the webbing kit, I made a couple of new ones.

I don't think the supplied pins are plated, but mine are.

The

original rivet plates were pretty rusty, too. In a moment of

weakness, I wimped out and ordered new ones. Powder coated them,

though, just because.

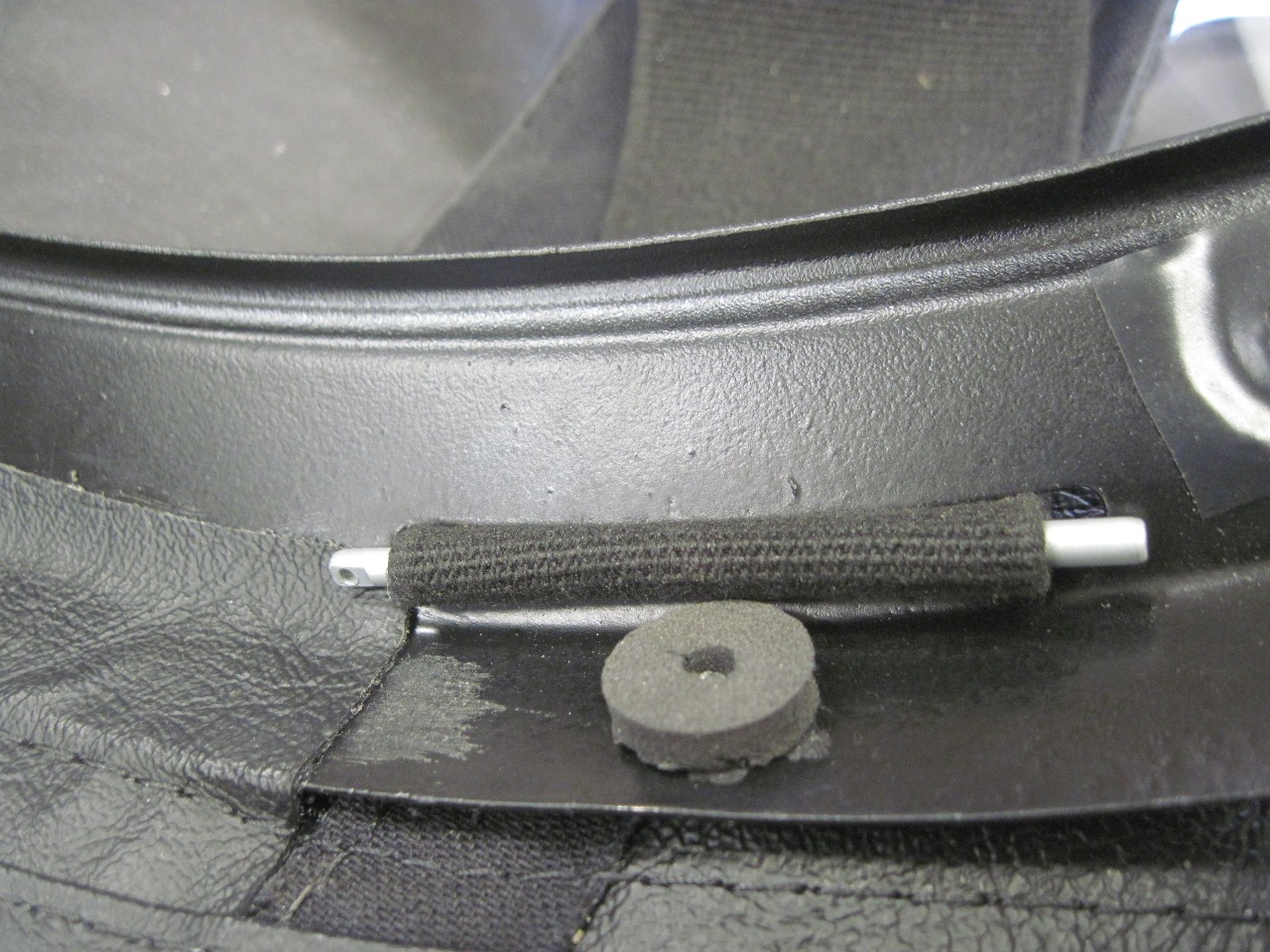

So

now the web straps can be fixed to the rear header. The little

foam donuts are supposed to protect the paint on the body from the snap

rivets, but I think they are too soft to really do that. I ground

down the back of the rivets to the minimum needed to hold.

I

spaced up the front header and pulled the web straps very tight and

marked them. Then fastened them to the front header.

Intermediate bows were adjusted so that they would end up on

seams of the vinyl top, and then were riveted in place.

This

pic is a little blurry, but I used the other half of the velcro from

the side rails, and applied it to the bows where they touch the top

material.

There

is a pair of cam arrangements that hold the front bow tight to the

windshield frame. Mine weren't in bad shape, but were missing the

little wavy spring washers that hopefully help prevent rattles.

Then

it was time to stretch the top. I pulled the top as tight as I

could get it and marked it at the front edge of the front header.

I clamped the top in place, and checked the fit.

After

gluing the top to the front bow and trimming it, I added the channel

for the front seal. The seal itself is a challenge. If the

factory took as long as I did to install that seal, we'd still have

TR6s rolling off the line.

Then,

with the top up, I installed the snaps for the inside flaps that wrap

around the bows. To install the female side of the snaps in

fabric, there is the ubiquitous tool comprised of a form punch and a

plastic anvil. The snap back is placed in the anvil, the

fabric pulled over, and the snap front is pushed on then the

punch is positioned and whacked with a hammer. I have one of

these sets and it works fine, but it looked like it was going to be

sort of awkward to use it inside the car, working basically overhead.

I

imagined a plier-like tool that would do the operation much more easily

in any position. While planning to make one, I happened to see

one identical to what I was thinking. It was cheap, too, so I

bought it.

That tool and the leather punch to make the holes in the vinyl made the snap job a snap.

In

the end, I'm not satisfied with this job yet. To effectively

stretch vinyl, it really needs to be warm, and we are probably all done

with warm here for a while. The vinyl was a little too stiff to

stretch like I wanted. Lights and a hair dryer helped a little,

but what I really need is a warm Summer day. So, I'll table

this job until next Spring/Summer when I'll see what a few

temperature cycles do to the fit. I'm prepared to unglue the

front header and restretch it if that's what it takes. I didn't

even attempt the snaps for the rear side flaps because the vinyl was

just too cold and stiff.

I

liked this project. It makes a noticable difference in the car,

and it looks like progress. The top is one of the more expensive

items on the car, and it made me a little nervous taking punches and

sissors to it.

Comments to Ed at elhollin1@yahoo.com

To my other TR6 pages.