To my other MGA pages

June 7, 2025

Heater

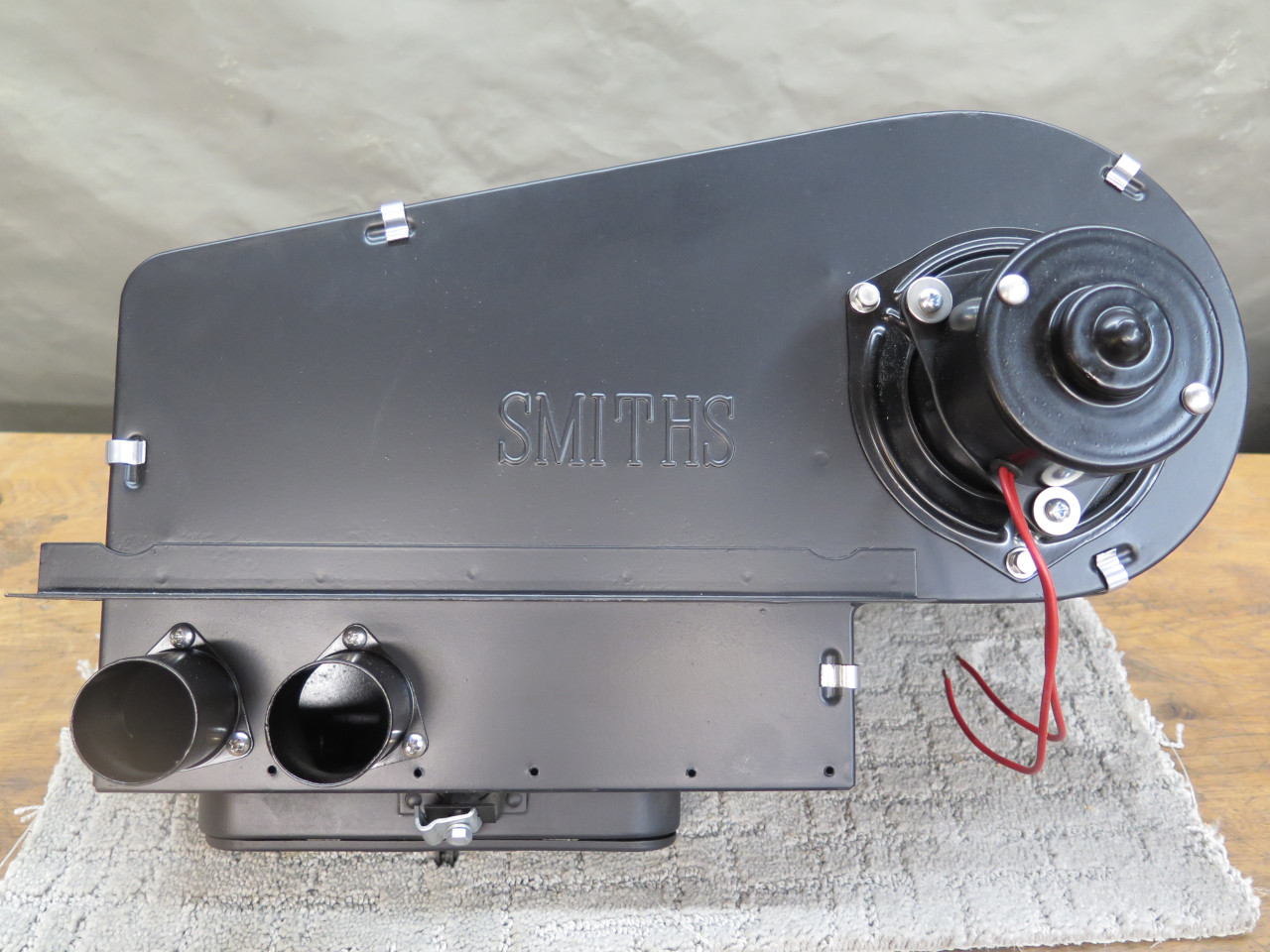

The cabin heater was actually an optional accessory on MGA cars, but in many markets, it was essentially standard.

It is of a pretty standard design consisting of a radiator core fed from

the engine cooling system, and a blower motor driving a squirrel cage

fan. Unlike many cars of the day and since, it lived in the engine

compartment, and not behind the dashboard.

To jump ahead to the blower motor, where most of the drama was, click here--> Blower Motor.

I had painted the heater unit back in my 70s restoration, so it was now dirty, but not all that bad in appearance.

It had apparently been serving as living quarters for generations of small rodents though.

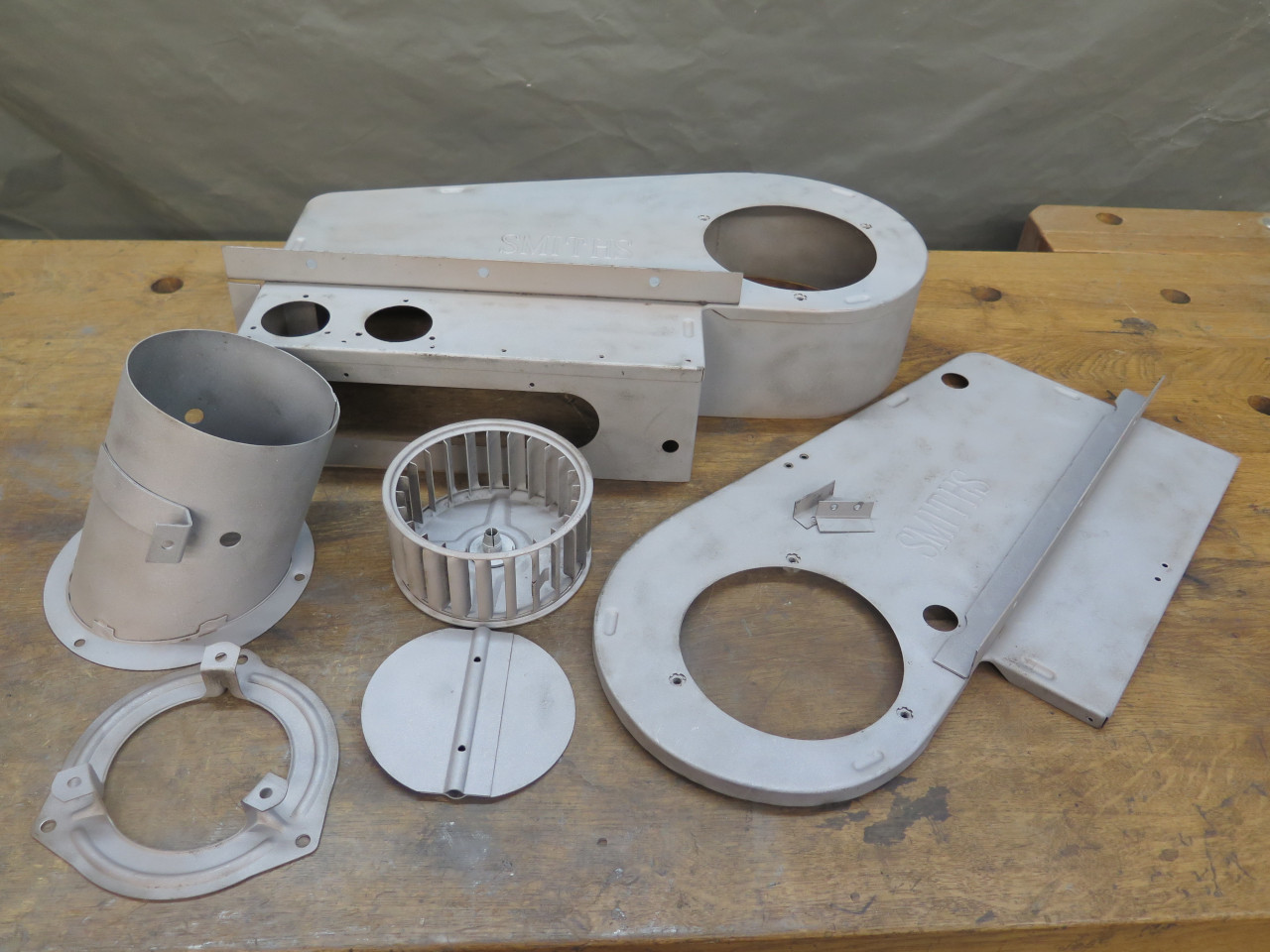

I separated it into its major components.

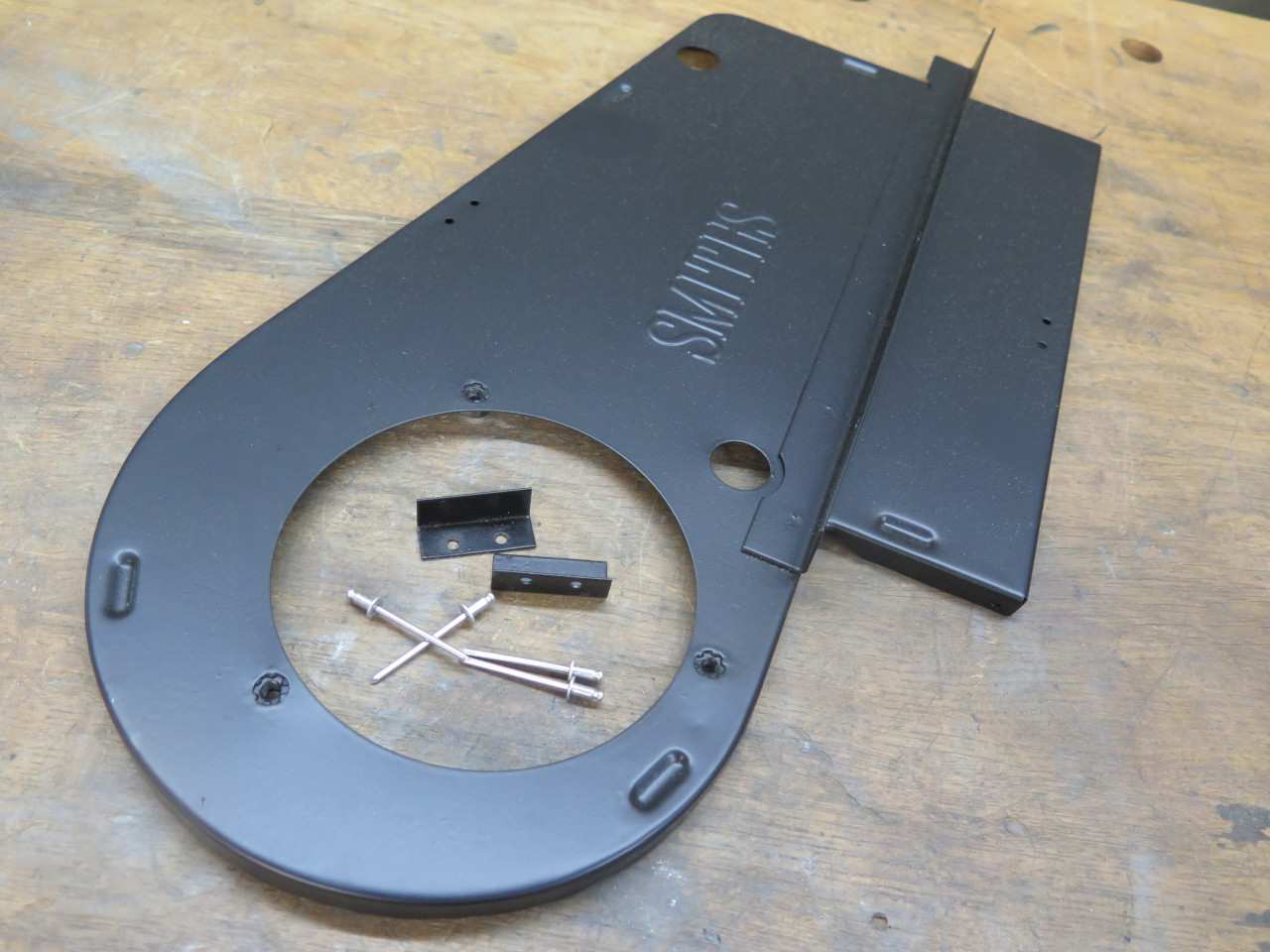

In preparation for blasting, I removed these little guide tabs from the front cover.

Blasted all the sheet metal parts.

Before I started to reassemble anything, I had to know if the heater

core was good enough to use. I removed the resilient sealing

strips on the broad sides.

One end appeared to be bulged out. I don't know if this is normal, but it was certainly a cause for concern.

I flushed the core with hot water for a while. It ran clear almost

from the beginning. I then filled it with a phosphoric acid

solution to see if it would loosen any accretions inside. It did

produce a minor amount of dark scaly stuff, but not much.

As a gross test of integrity, I attached a hand air pump to one port, and a pressure gauge to the other.

It appeared to hold pressure OK, but the real decider would be the bubble test.

So, in to by shop sink under a few inches of water.

The cooling system pressure spec for early MGAs, including mine, is

apparently 4 PSI, and for later ones, 7 psi. I tested the core to

10 PSI. The pressure held steady, and there were no bubbles.

So, with an apparently serviceable core, I did a little more cosmetic cleanup.

The sealing strips make sure that air has to go through the core fins,

and can't go around it. I used a firm felt material that matched

the dimensions of the originals.

The core mounts on the heater's cover plate. It got fresh paint, and new grommets for the core ports.

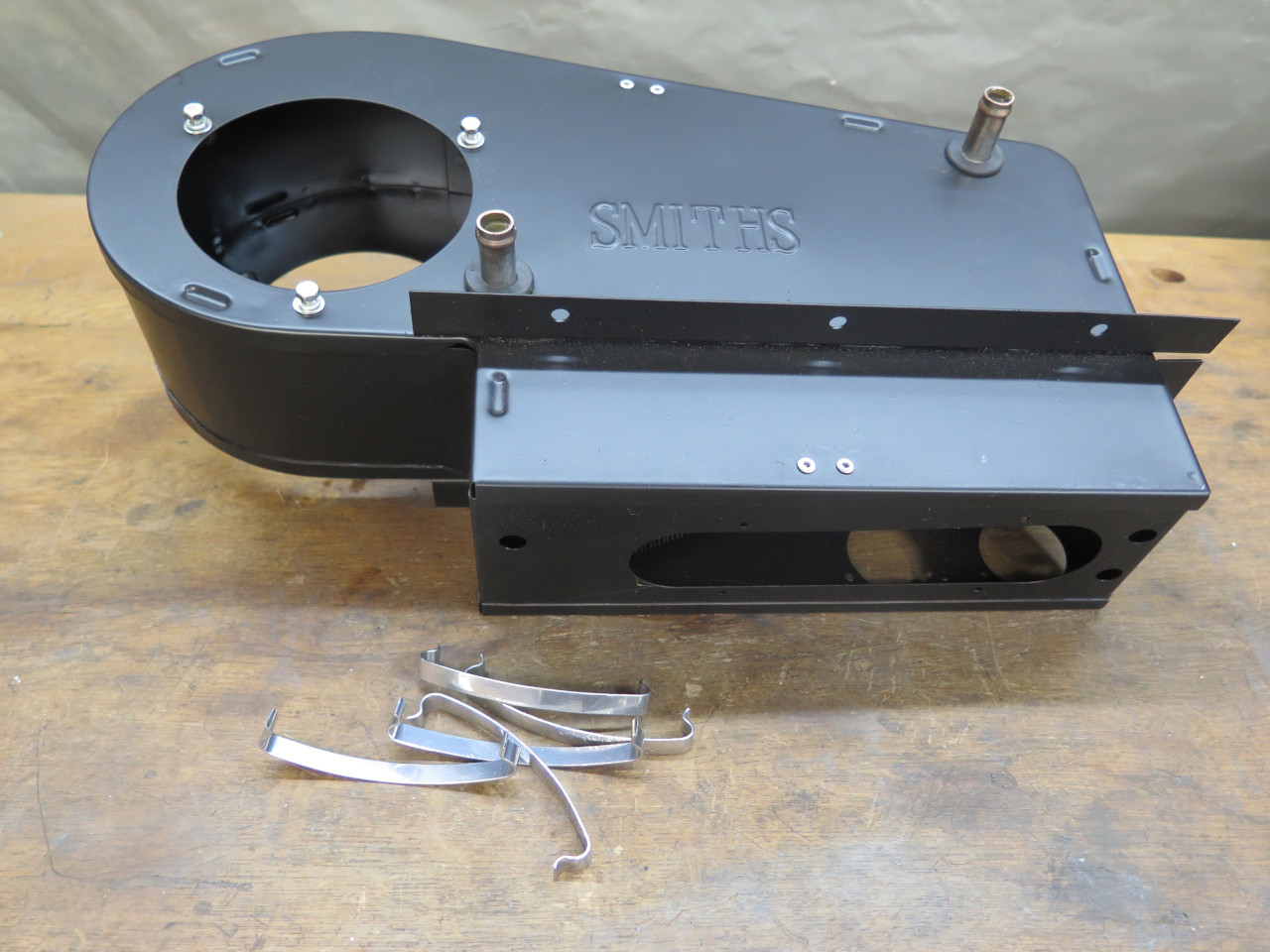

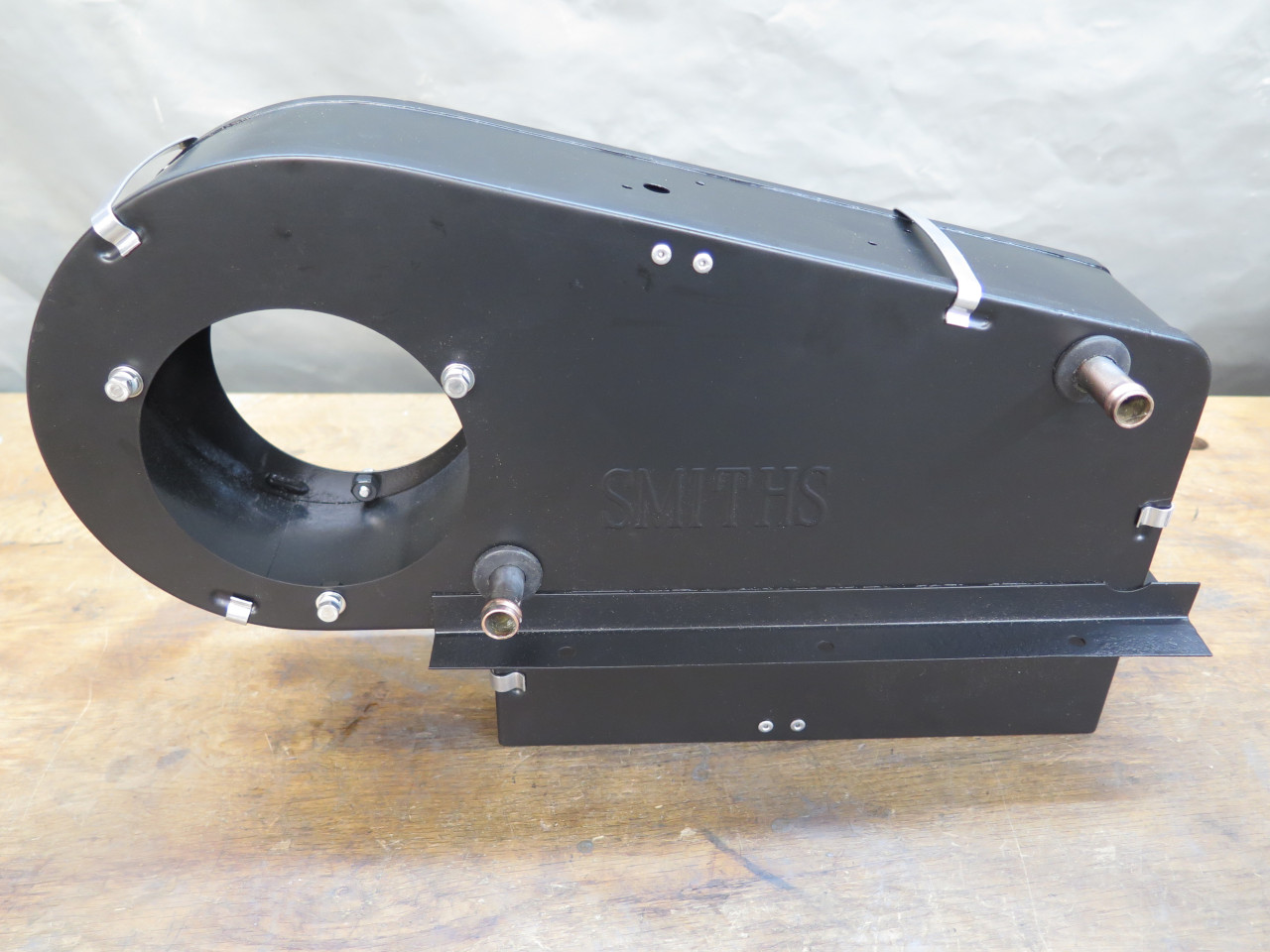

The heater's main body has some flanges that locate the core. Felt gets put on them, too.

Then the two pieces capture the core.

The main body and the cover are held together by five spring

clips. I would normally replate pieces of this size, but spring

steel can be problematic. It can be susceptible to hydrogen

embrittlement without special post processing. In this case, I

opted to just blast the parts and powder coat them silver.

The heater's main body...

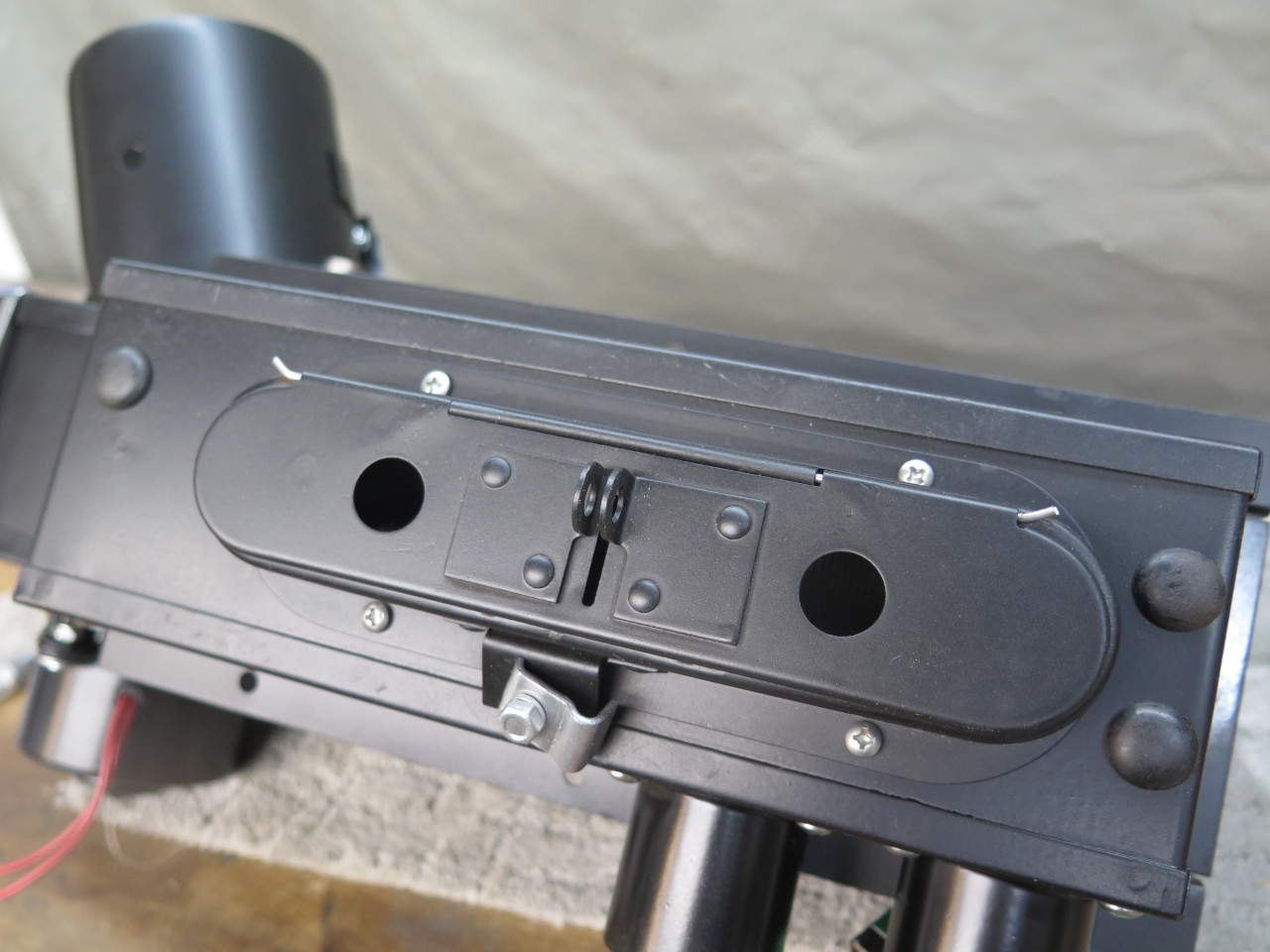

The next assembly I looked at was the little air door at the bottom o

the heater. When the door is open, air is released into the foot

wells. When closed, air is forced into the defroster ports.

Te door was essentially seized. Forcing it was flexing the hinge

part of the door. I was afraid it would break the hinge.

Over time and with copious amounts of penetrating oil and encouragement,

I got the door to move, but it was still very tight. I decided to

try to remove the hinge pin. It wasn't easy.

After blasting and powder coating, ti got a brand new straight stainless steel hinge pin. The door works effortlessly now.

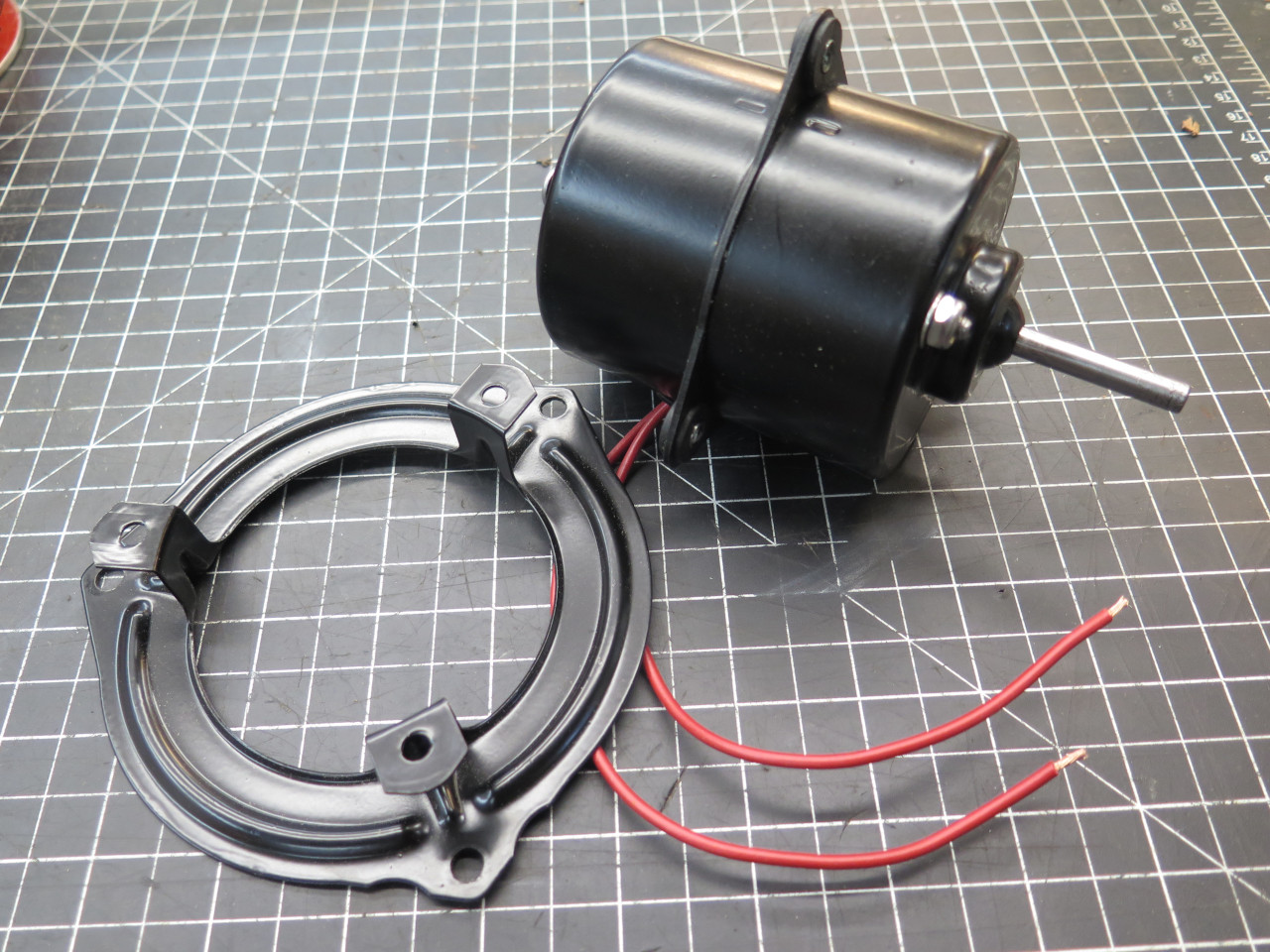

Then I came to the blower. I broke it down to just the motor.

I hooked it up to a 12 volt power supply. It ran, but sounded like

nails in a coffee can, with a hint of squawking. So, apart it

came.

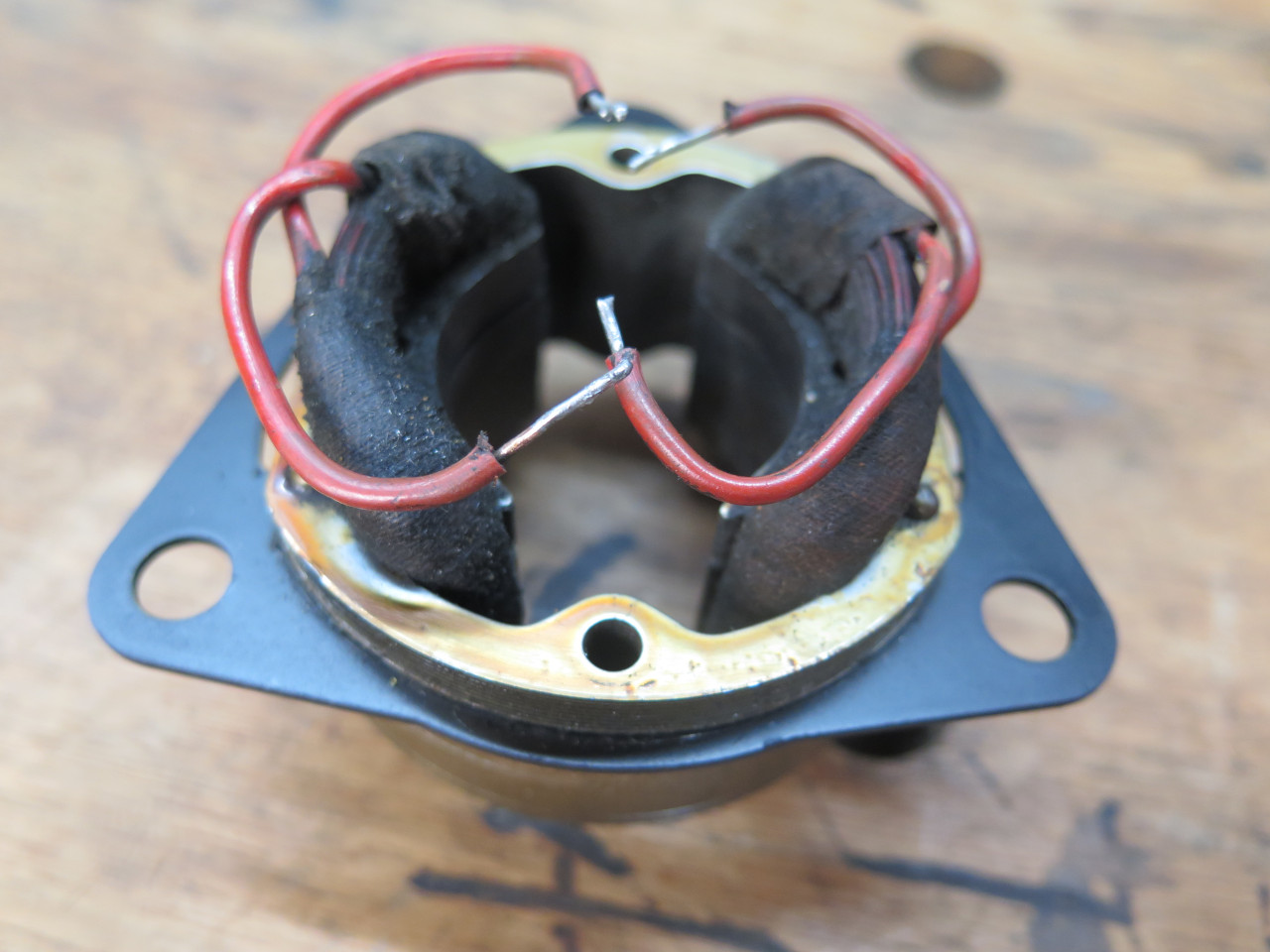

I discovered that this is a series wound universal motor. All of the windings looked OK, with no evidence of overheating.

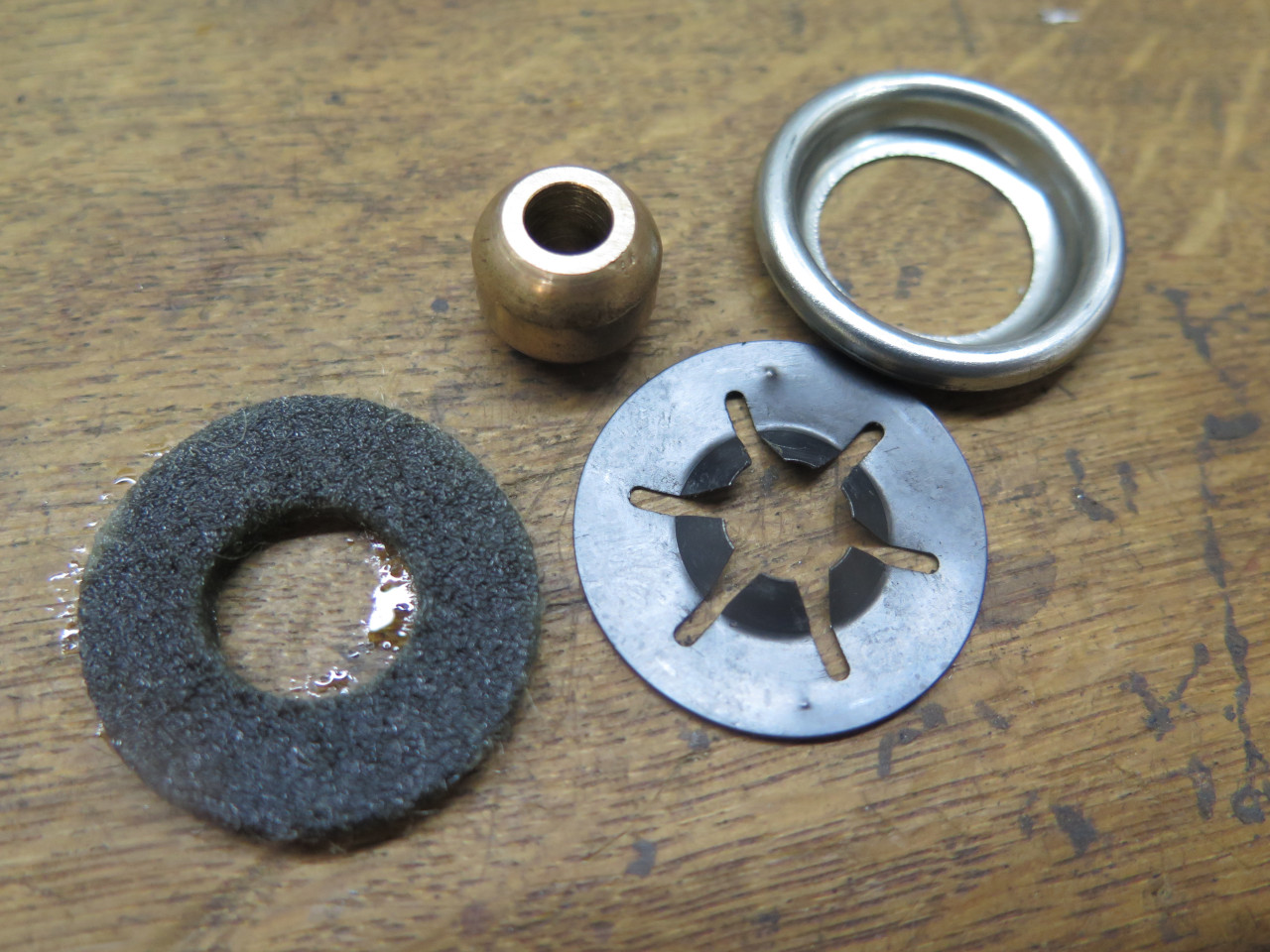

The noise problem seemed to be that the bushings at each end of the

motor housing were worn, and allowed quite a bit of play. These

are self-aligning bushings, consisting of a spherical sintered bronze

bush held by a fingered spring such that it can rotate a small amount in

any direction. I figured I didn't have much to lose, so I knocked

one of them out. There is also a felt pat that holds a reservoir

of oil, and a retainer ring that keeps everything in place.

Now, I suppose that somewhere I might be able to buy these spherical bushings, but a half-hearted search turned up nothing.

But I had another idea. I ordered some ordinary sintered bronze

bushes with an ID if 1/4" (that's the armature shaft diameter), and

5/16" OD.

Then drilled and reamed the spherical bushes to 5/16". The

straight bushes were a firm press fit into the spherical ones.

Then just trimmed to length. They were then a much better fit on

the armature shaft.

Sintered bushings are made by compressing powdered metal into a solid

shape, but leaving some small space between the metal granules.

That space, which could amount to 15% or so of the bushing's volume,

serves as a reservoir for oil. The porosity allows oil to travel

through the bulk of the bushing.

To make sure the bushing starts out with as much oil as possible, and

maybe to clean out some of the nearly 70 year old oil from the original

bushing, I did a vacuum treatment on the bushings. By subjecting

it to a fairly deep vacuum, any air in the pores of the metal will

expand and be expelled. If it's done in an oil bath, the exiting

air will be visible as bubbles. Then, when the vacuum is released,

atmospheric air pressure will force oil into the pores.

Initially, there was general foaming of the oil, but this was probably

mostly just air dissolved in the oil. Later, the bubbling slowed

down and became localized over the bushings. A plume of darker oil

formed around the bushes, presumably ancient oil from the 50s.

I wish I had thought to weigh the bushes before and after the treatment.

Before re-installing the bushings, I cleaned up the two halves of the

motor housing, including welding up the holes I drilled to pop the

bushings out. Then a nice powder coat.

I soaked the felt pads with fresh oil, dropped everything into the housings, and pressed in the retainer ring.

The armature is now a nice smooth slip fit in the bushing.

At some point in this process, I had cleaned up the commutator, though it wasn't that bad.

The commutator end housing was similar, but it also had an insulating

disc glued in, since the brush plate is in pretty close proximity.

I used so called "fish paper", which is designed for use around

electrical parts.

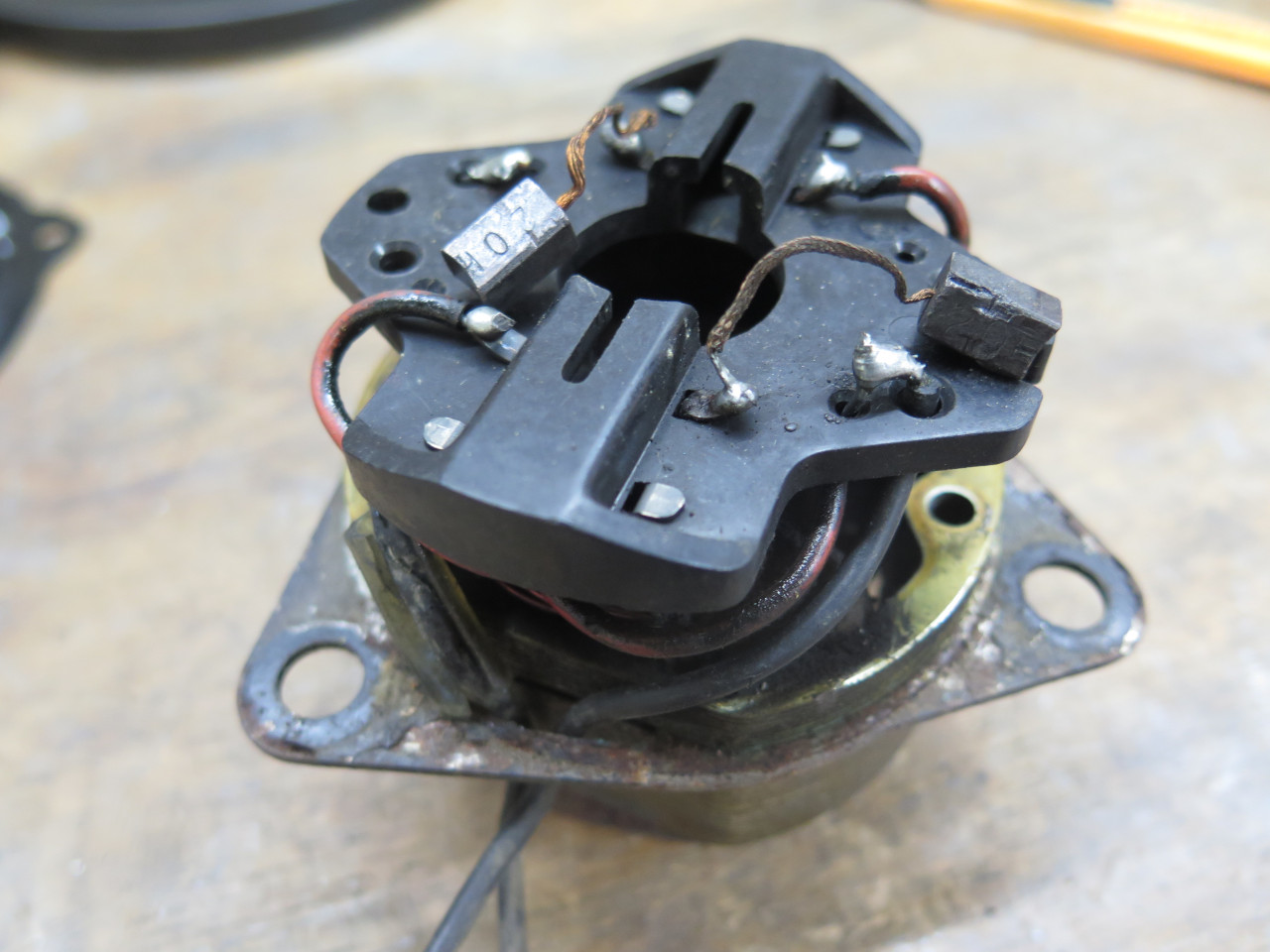

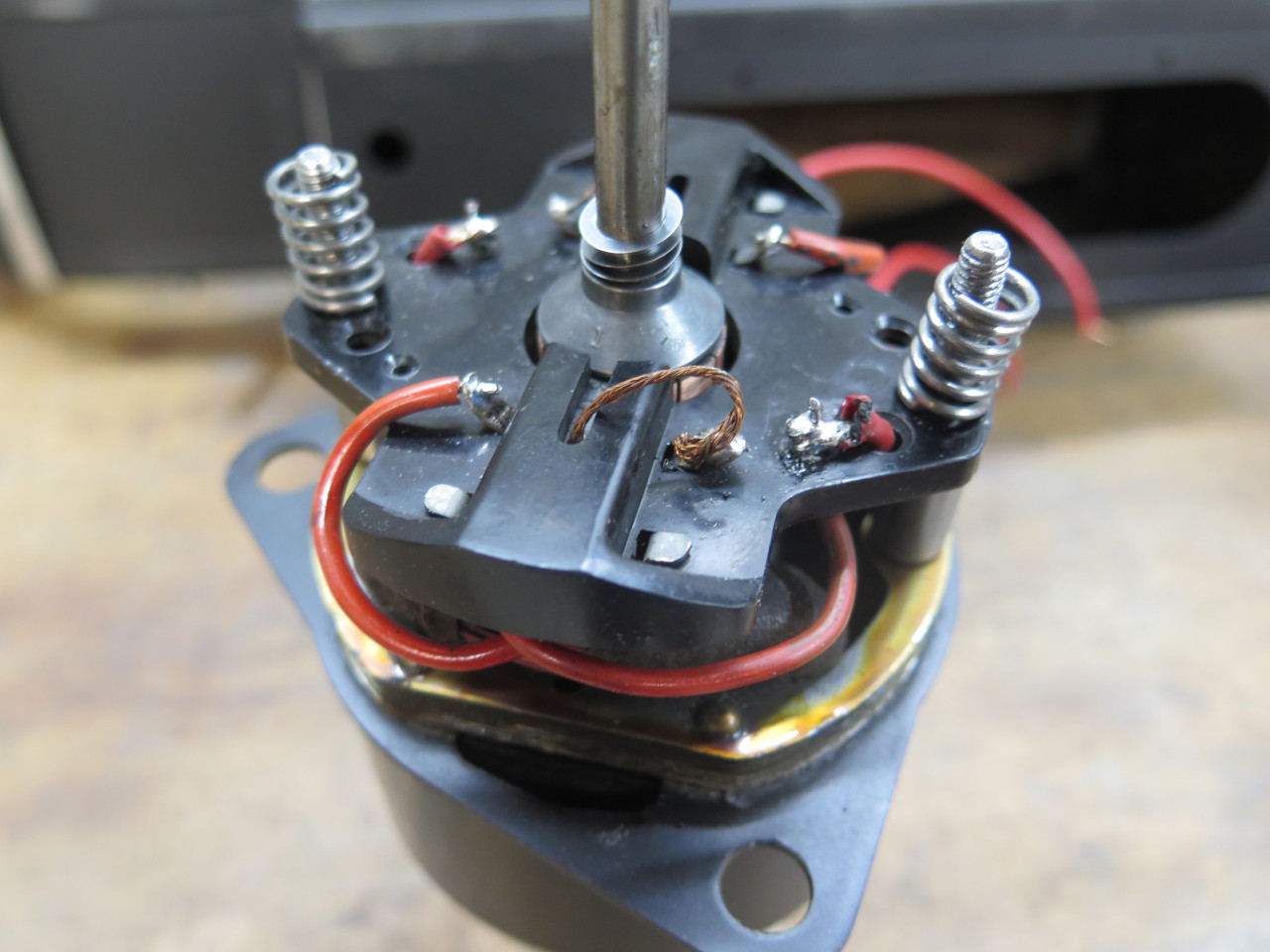

Then it was time for the brush plate. The brushes are carried by a

Bakelite piece that is held by the housing screws. I wanted to

clean and paint that triangular mounting bracket that is captured in the

stator core, and this would be way easier without the brush

plate. Unsoldering four connections allow it to come free.

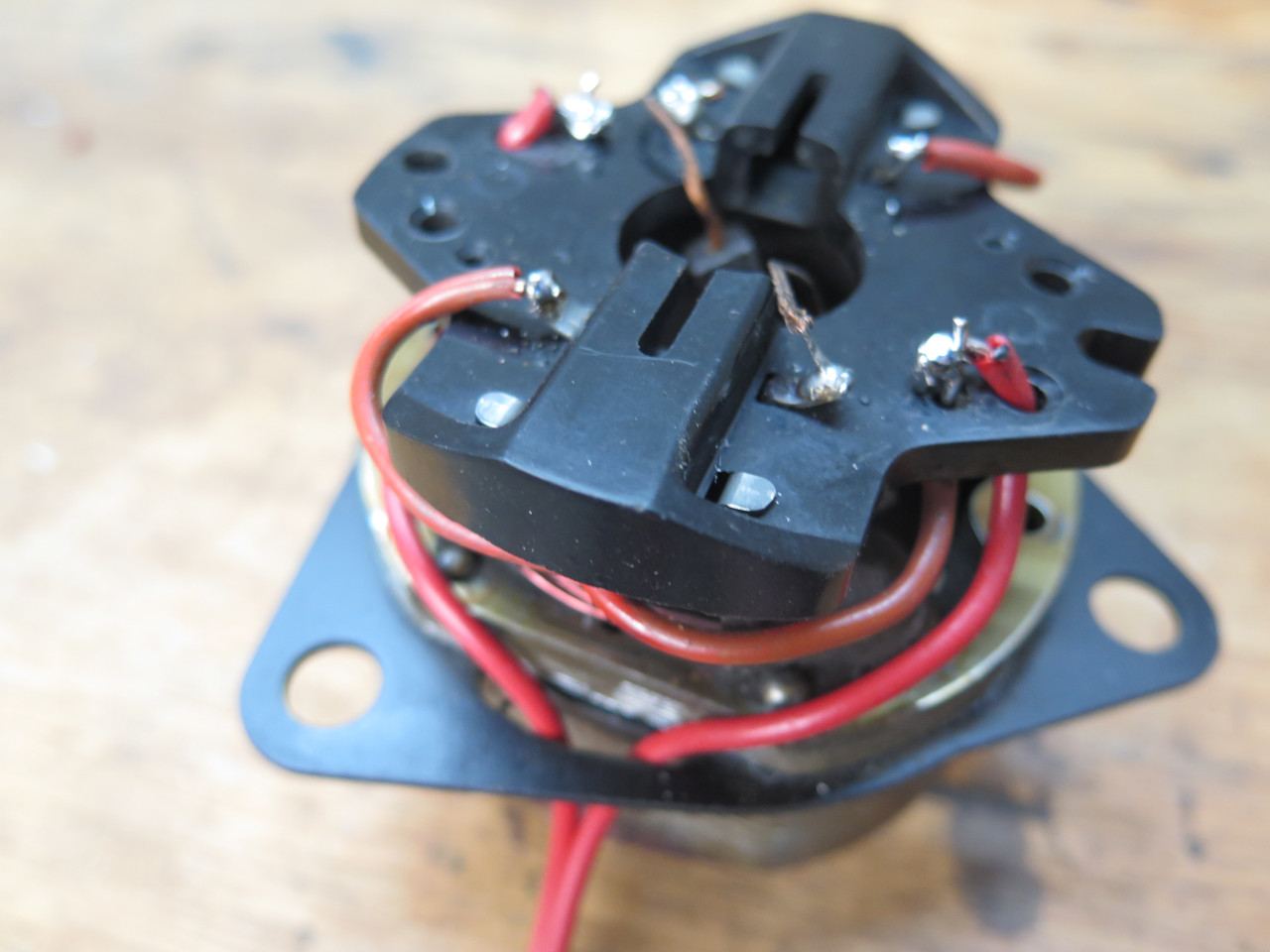

After painting, I cleaned up the wires a little, and resoldered the

plate, also took the opportunity to change the lead wire color to red

from the original black. Black wires suggest ground connections,

and another color seemed more appropriate to me. The motor is not

polarity sensitive, so the wires can be the same color. The

external leads go through this little dual grommet, which was still fit

for use.

At this point, I did a dry run of the armature in the two cases, and

confirmed smooth rotation with no play, but this was mainly to measure

end float. It came out to be about 0.025". I don't know what

the spec would be for this, but 0.025 seemed like a lot, and I thought

it could have been contributing to the noisy operation.

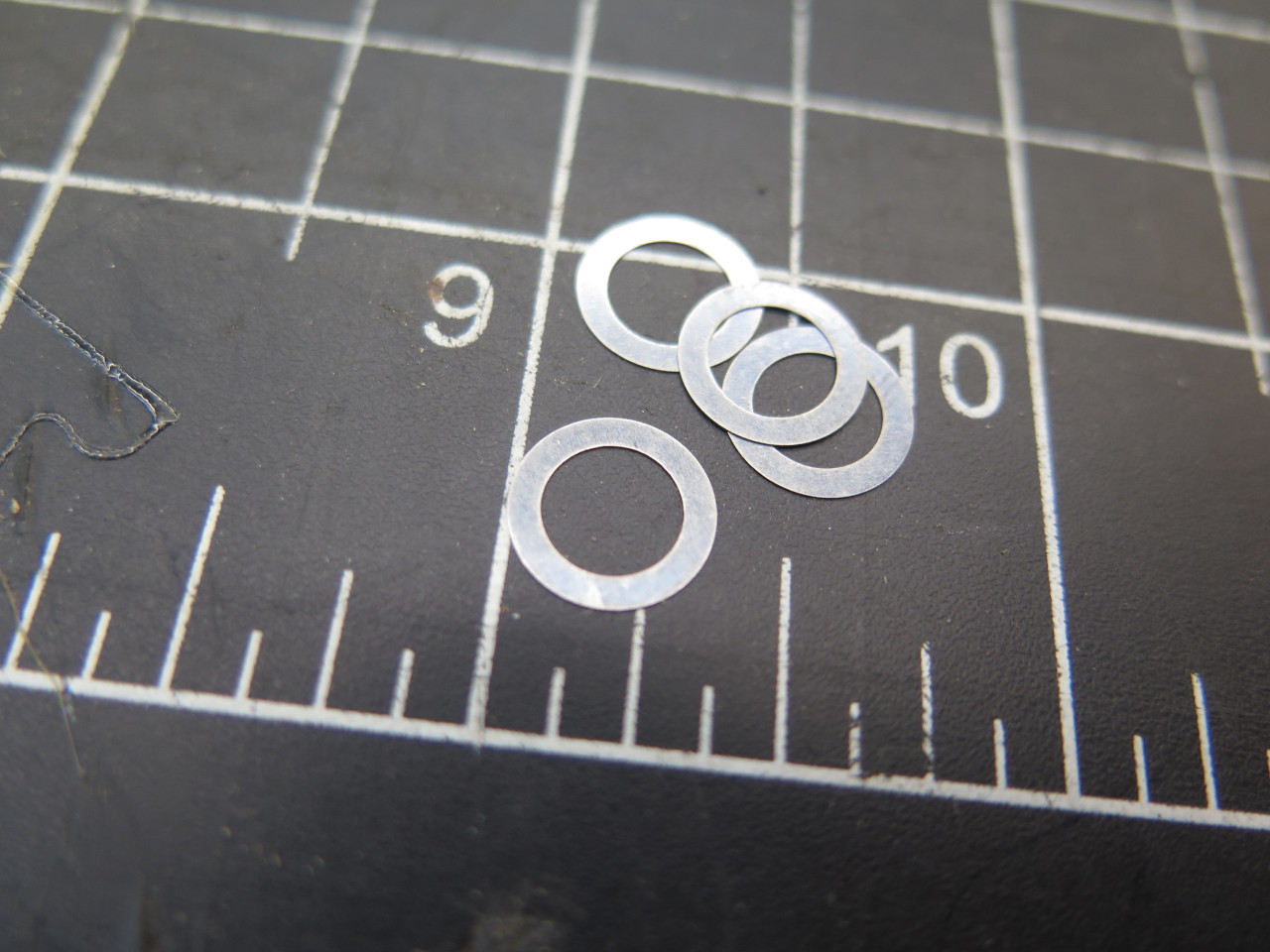

End float is set by small shims on the armature spindle. I'm not

sure how many were supposed to be there, but I only found one. I

got some 0.005" shims, and put four of them on the armature

spindle. That reduced play to around 0.005", which seemed OK.

Then it was show time. I assembled the motor, set up the power

supply to 14 volts, hooked it up, and threw the switch. The motor

started instantly, ran for half a second, and stopped suddenly,

seized. It wasn't fully seized--I could turn it through part of a

rotation, and it would catch and refuse to go any further.

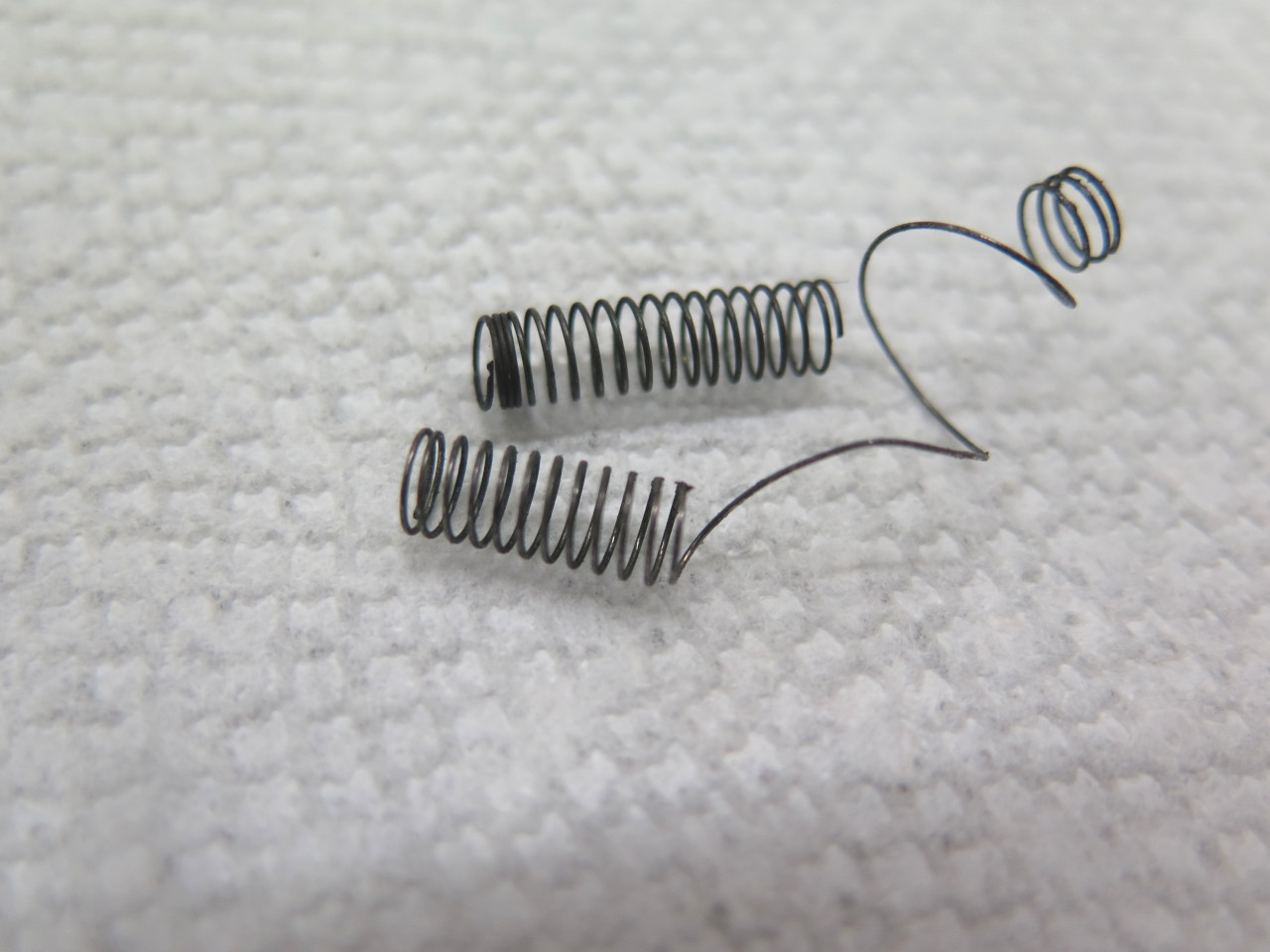

Here was the problem. I had apparently botched installing one of

the brush springs. It must have been hanging down below the brush

plate instead of being fully in the brush cavity. Something

snagged it.

I pawed through my "tub o' springs" and found a few candidates.

Nothing was a particularly close match. But fortunately, my local

ACE Hardware came through for me. A pretty close match, and

exactly twice too long. I cut it in half and installed the halves,

more carefully this time.

Another trip to the power supply, and this time I was thrilled to hear a very smooth and quiet motor.

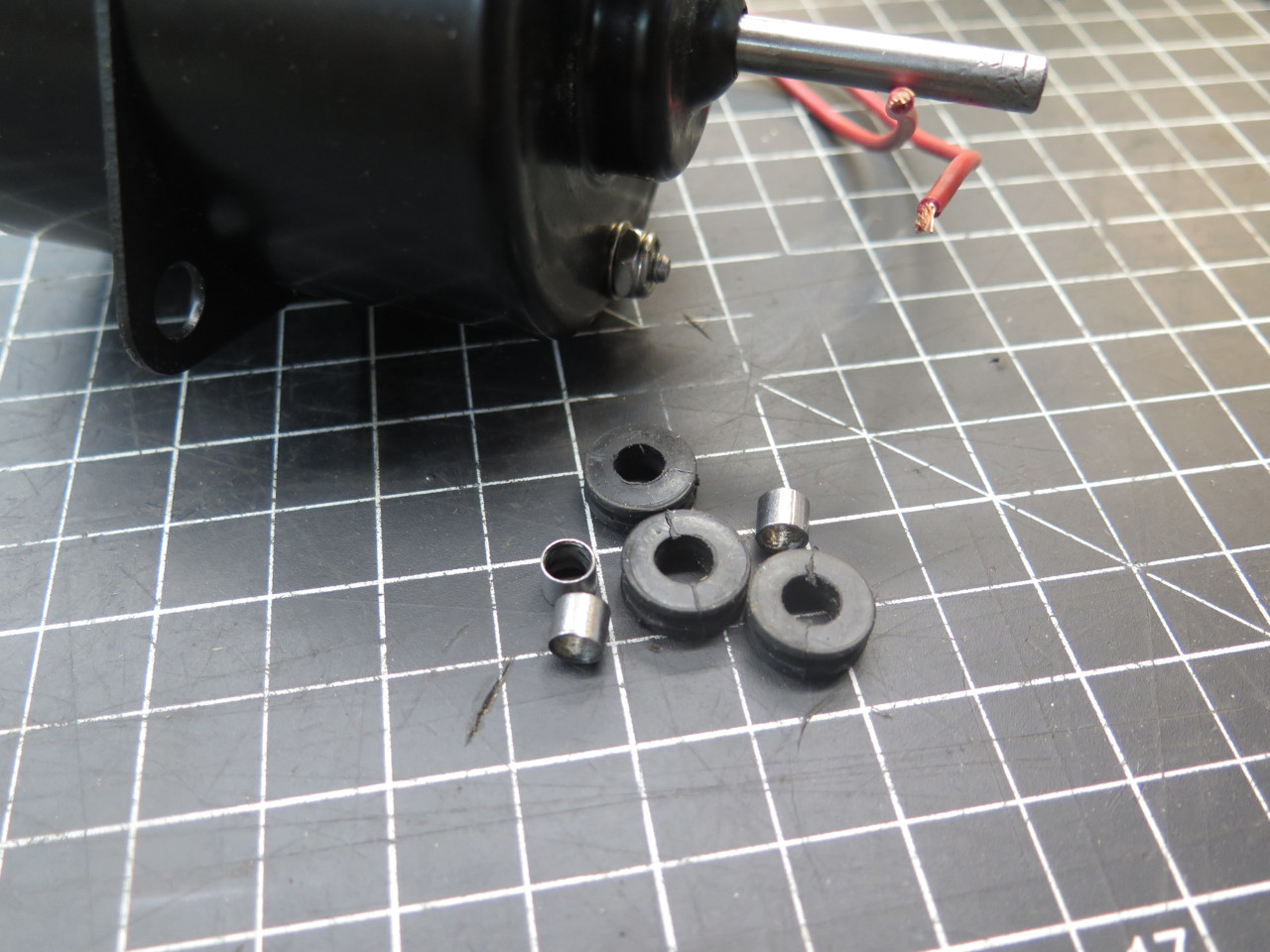

These little grommets serve as a resilient vibration damping mount for the motor. They were good enough to re-use.

Next was the mounting bracket, and the squirrel cage.

Major components, ready to be co-mingled.

Added the little defrost spigots.

And some little plugs. Not sure what those holes would have been

for. Also replated the little control cable housing clamps.

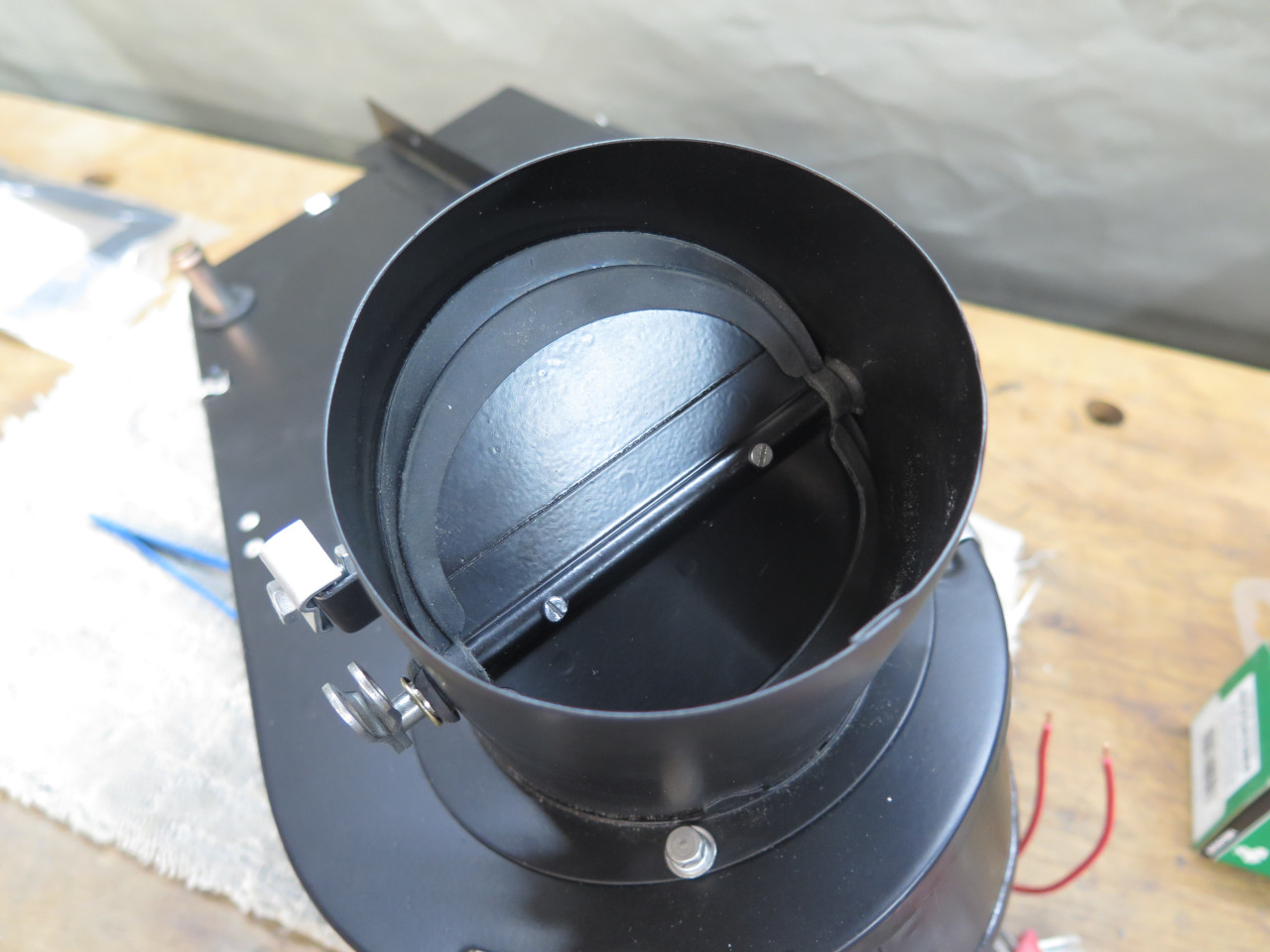

This left just a couple of final details. One was the butterfly

valve in the air inlet. It modulates the amount of outside air

entering the heater. It has a molded rubber seal around it's

perimeter which is still available.

Lastly, a little cosmetic nicety. The little metal ID and caution

plates on the top of my heater were long gone, but reproductions are

available. The number plate proved to be a so-so replica, mainly

in that the bordered fields for the stamped numbers were quite a bit

narrower than the originals. This meant that the original 1/8"

stamped characters would not fit in the space. I opted to move to

the next smaller size, which is 1/16" They fit fine, but look a

little small.

This was a pretty finicky project with some drama thrown in. It

seems like a lot of work for something I'm not sure I'll use much.

I think materials came to less than $50.

Comments to Ed at elhollin1@yahoo.com

To my other MGA pages