To my other GT6 pages

May 27, 2022

Oil Filter Adapter

Even into the seventies, Triumph cars clung to the archaic oil filter

arrangement that consisted of a replaceable cartridge type filter

element inside a reusable housing bolted to the left side of the

engine. There was a pressure relief valve built into the housing

that would allow oil to bypass the filter if the filter became clogged.

It isn't that these filters were ineffective--they filtered oil just

fine. It's more that they made sort of a mess when changing the

filter element. On a lesser point, they also lacked an

anti-drainback valve that most modern filters have. Without this

valve, oil in the filter could at least partially drain back into the

sump when the engine is shut down, requiring a little time to fill up

again on the next start.

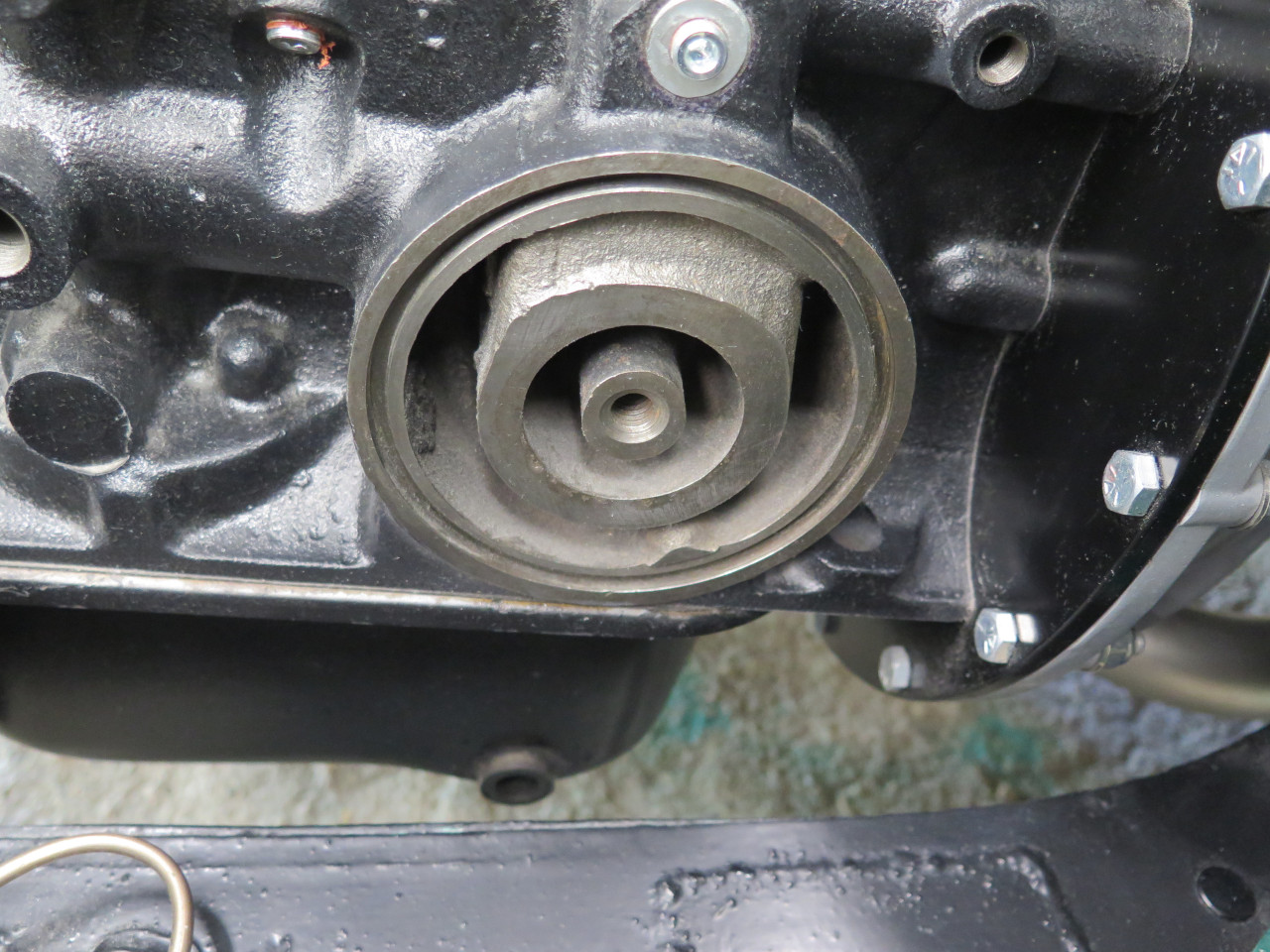

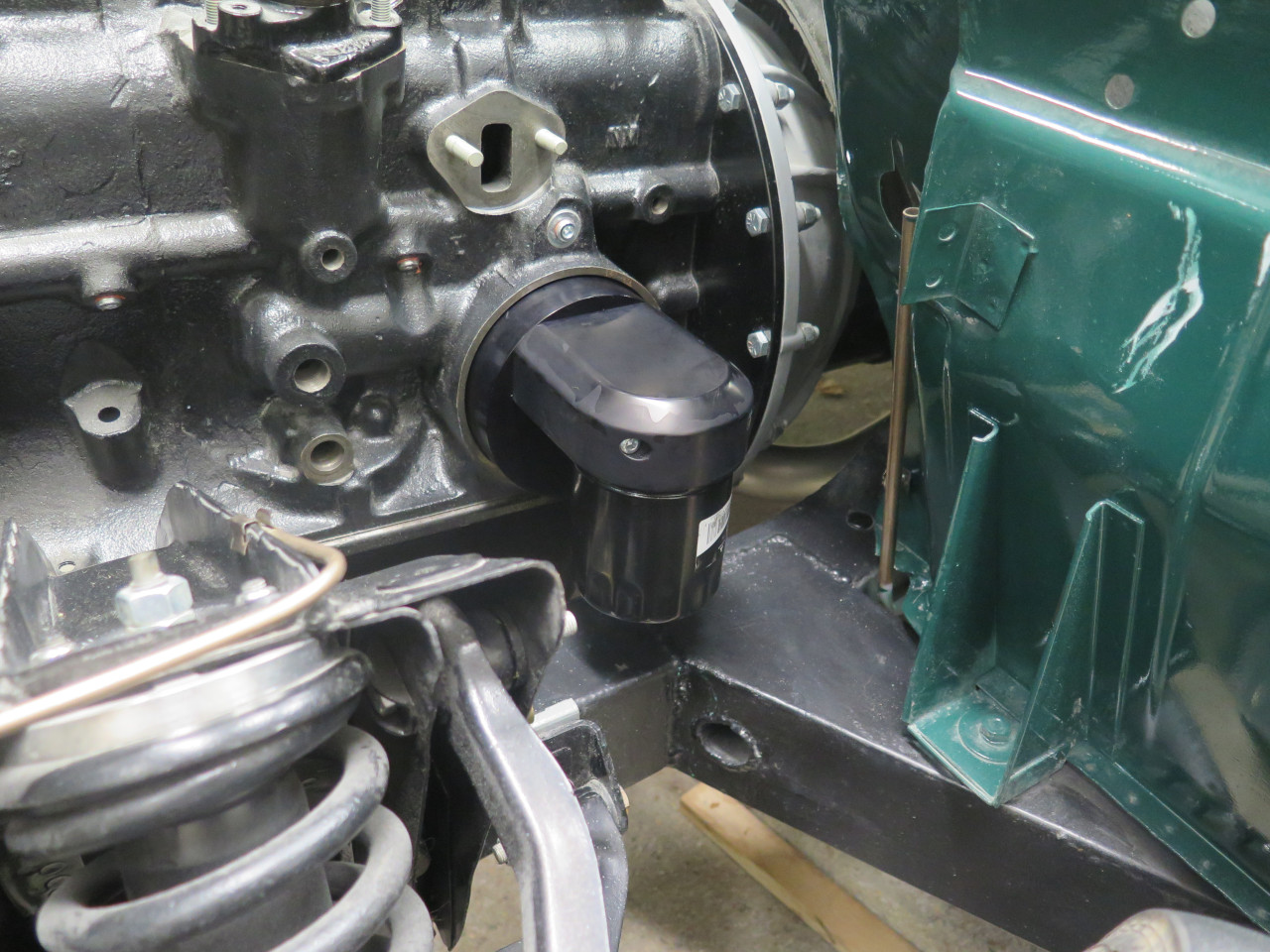

This is the filter housing on my car. Please forgive the Chevy

Orange color. I apparently once thought it was cool. The

flying saucer-shaped thing inside is the relief valve.

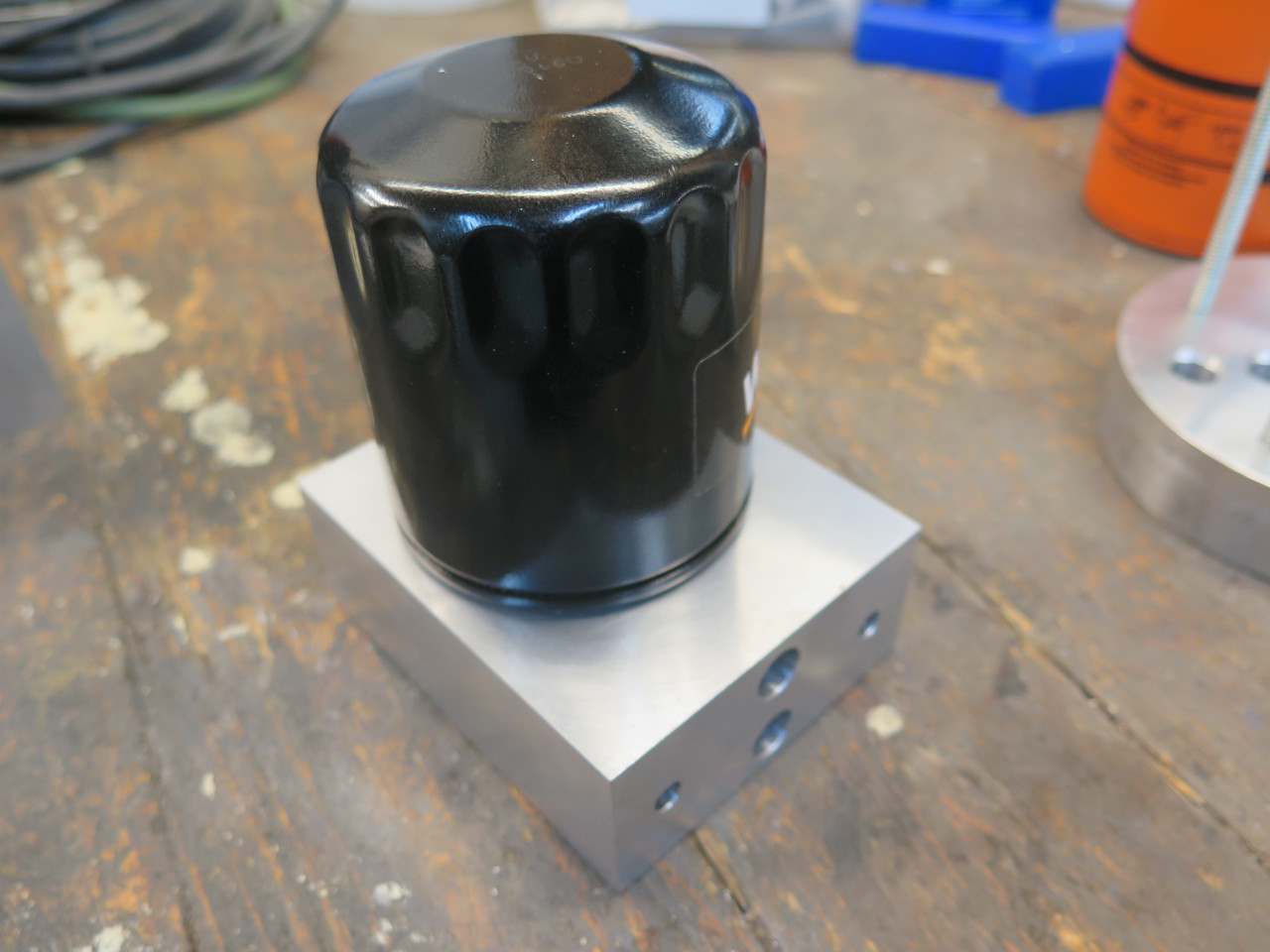

It's a pretty common mod for owners of these cars to install an adapter

to convert the car to use a modern spin-on filter. The idea is to

make changing the filter a simpler and more pleasant job. All of

the adapters I have seen are similar to this one, which I bought online,

along with the recommended filter.

The adapter fits in place of the original filter housing, but the filter

has to be placed at a pronounced angle to clear obstructions in the

area. Even switching to the shortest filter I could find doesn't

help much.

Now, having the oil filter at an angle isn't really the end of the

world, and I know that some modern cars have the filter at an angle, but

I didn't like it. First, it compromises one of the main reasons

to fit a spin-on--not having oil drip all over when you remove the

filter. Second (and just as important to me), it violates my sense

of righteous rectitude. It looked like a general purpose design,

meant to fit a wide range of cars, but none of them very well.

I was ruminating, sitting and staring at the skewed filter when Inner Engineer popped into the garage.

"Wassup?" he asked, probably not really expecting an answer.

"I'm just trying out this spin on filter adapter I bought," I answered anyway.

"Hmm. Why's it all wonky like that?"

"So that's the first thing you noticed, too?"

"Yeah. Looks cockeyed."

"I don't think there are any other choices if I want to go with spin-on."

"Didn't you do something for your TR6?" he asked, looking at me sideways.

"Well, yeah, but it was a lot of work."

"You're retired, Dude. What else do you have to spend your time on?"

I didn't have a good answer.

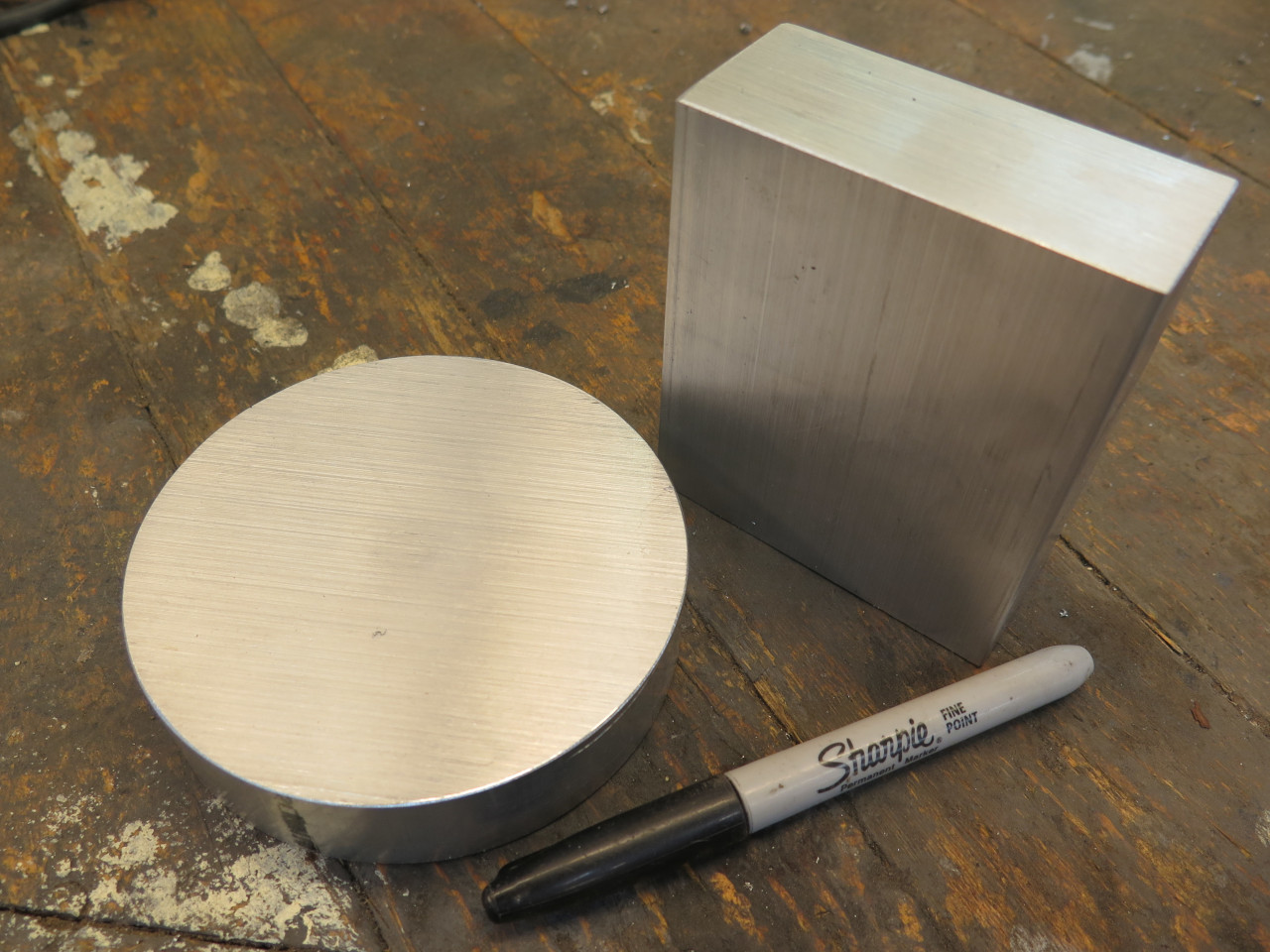

I went online and ordered a couple of chunks of aluminum.

The puck-shaped piece is for the base of the adapter--the part that has

to interface with the engine block. It has to have a lip around

the outer edge that fits in the groove in the block. That groove

is where the big skinny square section O ring seal goes. It also

has to have a seal that bears against that intermediate circular feature

on the block. That seal keeps the dirty incoming and clean

outgoing oil streams separate.

The commercially available adapter has a spring loaded carrier for that

inner seal. My understanding is that this was necessary because

that seal surface on the block varied in depth relative to the outer

sealing surface. The variation was certainly over car years and

models, and maybe even over individual blocks.

Since I was making this adapter just for this particular car, I saw no

need to account for that variation. It was still a sensitive

dimension, though. Ideally, on tightening the adapter to the

block, I wanted the outer seal to touch and compress first, followed by

the inner seal. I took what measurements I could, but to be sure

of the relationship, I 3D printed a little mockup of the base with my

calculated dimensions, then cut a wedge out of it so I could see inside.

With the part's outer rim seal sections just bottomed out in their

groove, the inner seal was still about 0.015" from touching. I

knew from measuring the used outer seal I removed from the block that it

compresses at least 0.025" when the fastening bolt is fully tightened,

which would see the inner seal compressed by about 0.010". Even if

these numbers are a little off, a little oil weeping past the inner

seal wouldn't be a big deal.

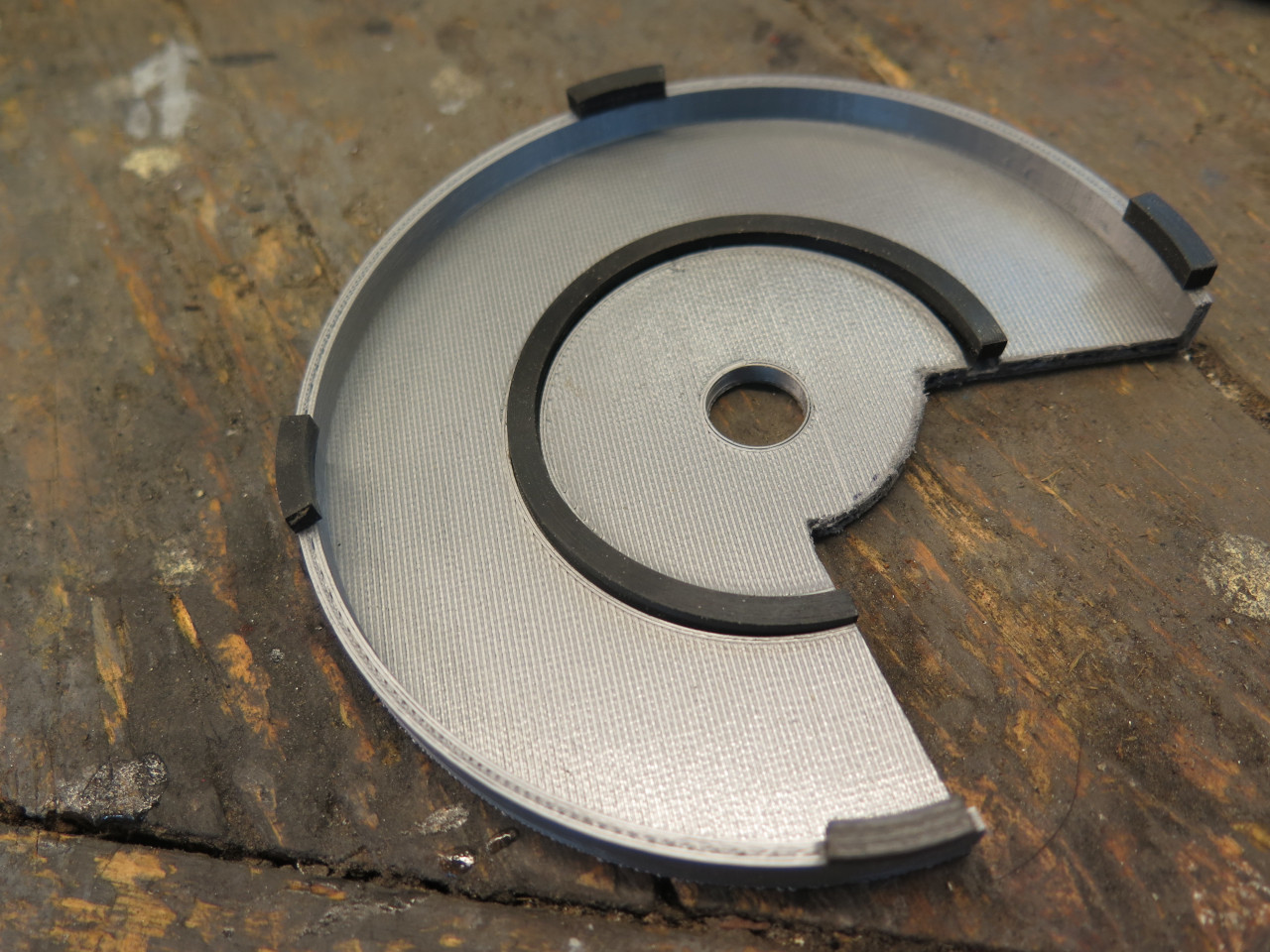

With some comfort in the dimensions, I committed the puck of

aluminum. The inner seal is an industry standard square section

size -227, while the outer seal is whatever is supplied by the

vendors. The fastening bolt also has to be sealed, and that copper

looking thing is an AN900 crush washer, a common aviation part (AN900-7

for the 7/16 ID part).

Now, in order to get the oil from he block side to the other side and

vise versa, there had to be an oil passage on either side of the inner

seal. Each of these passages needed a seal to the part that holds

the filter.

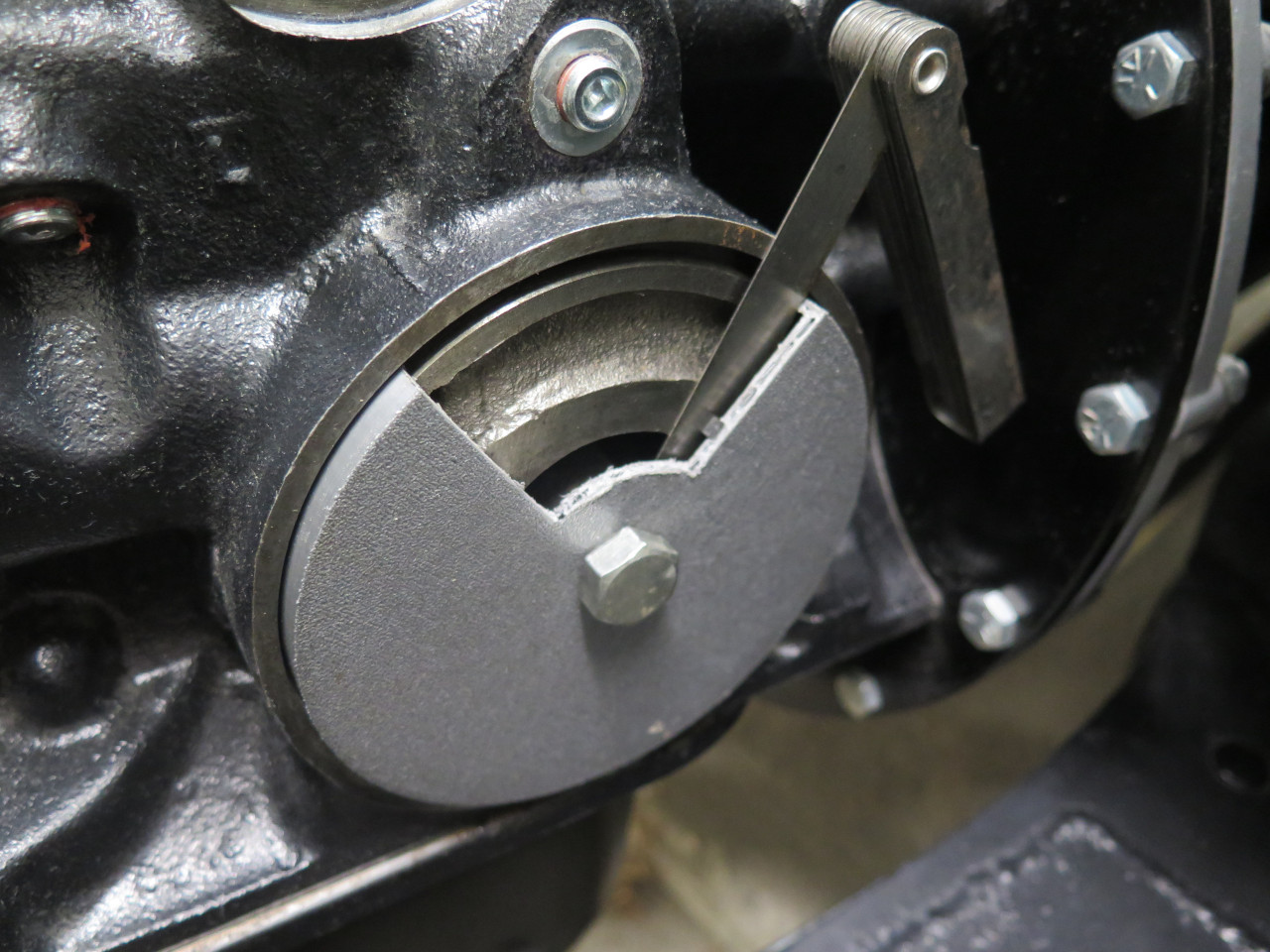

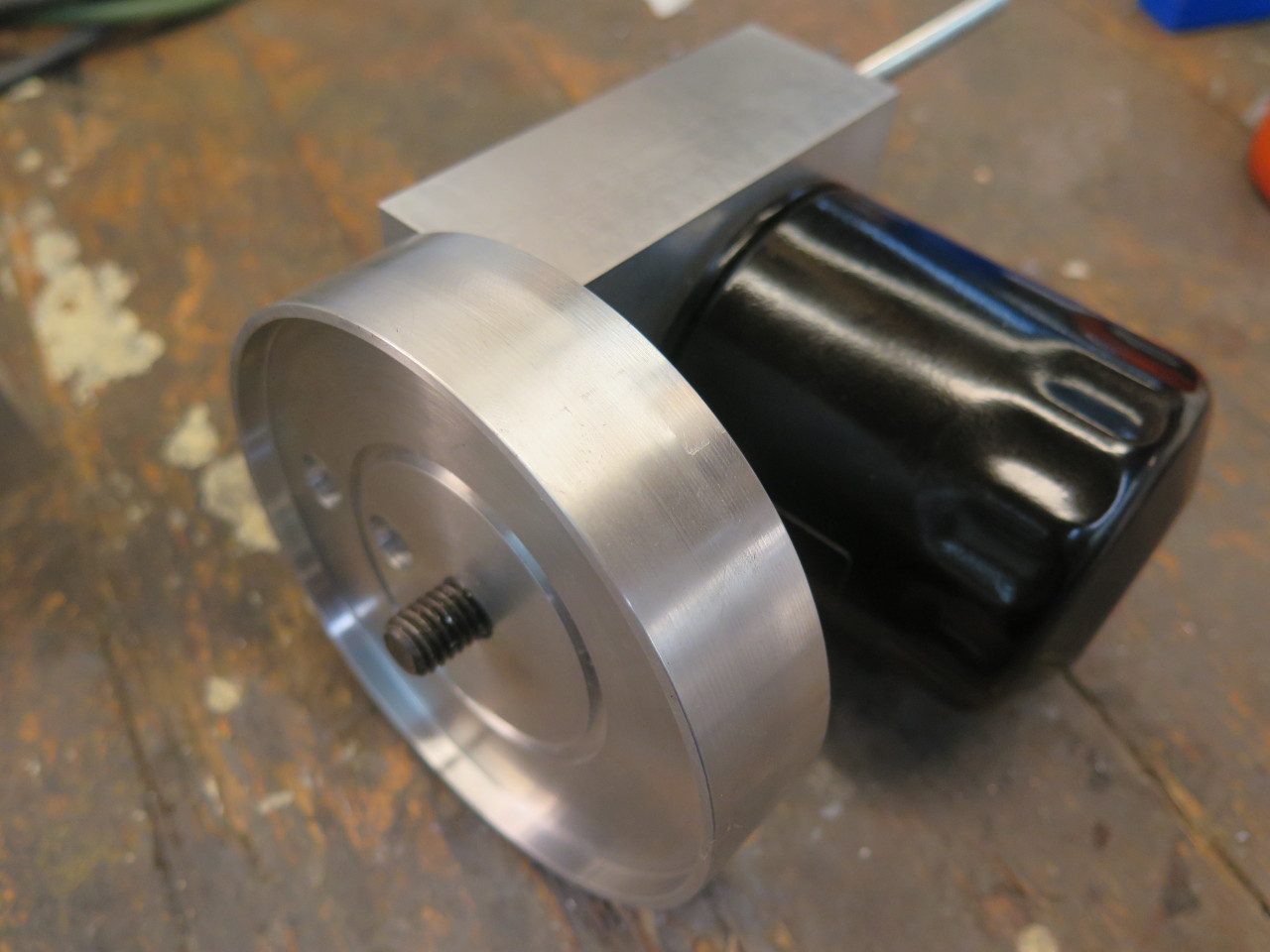

The squarish block became the filter mount. It was drilled and

tapped to receive the filter nipple. There are quite a few possibilities

for this thread, but I chose 3/4-16 as a pretty common one. The

nipple itself was made form a 3/4-16 bolt. Oil passages were also

drilled to match the ones in the base.

Fitting the two parts together, everything matched up OK, but the assembly looked piecemeal and awkward.

Rounding the filter mount to match the filter helped a lot.

A generous chamfer made it even better.

A little polish, and some might even call it attractive.

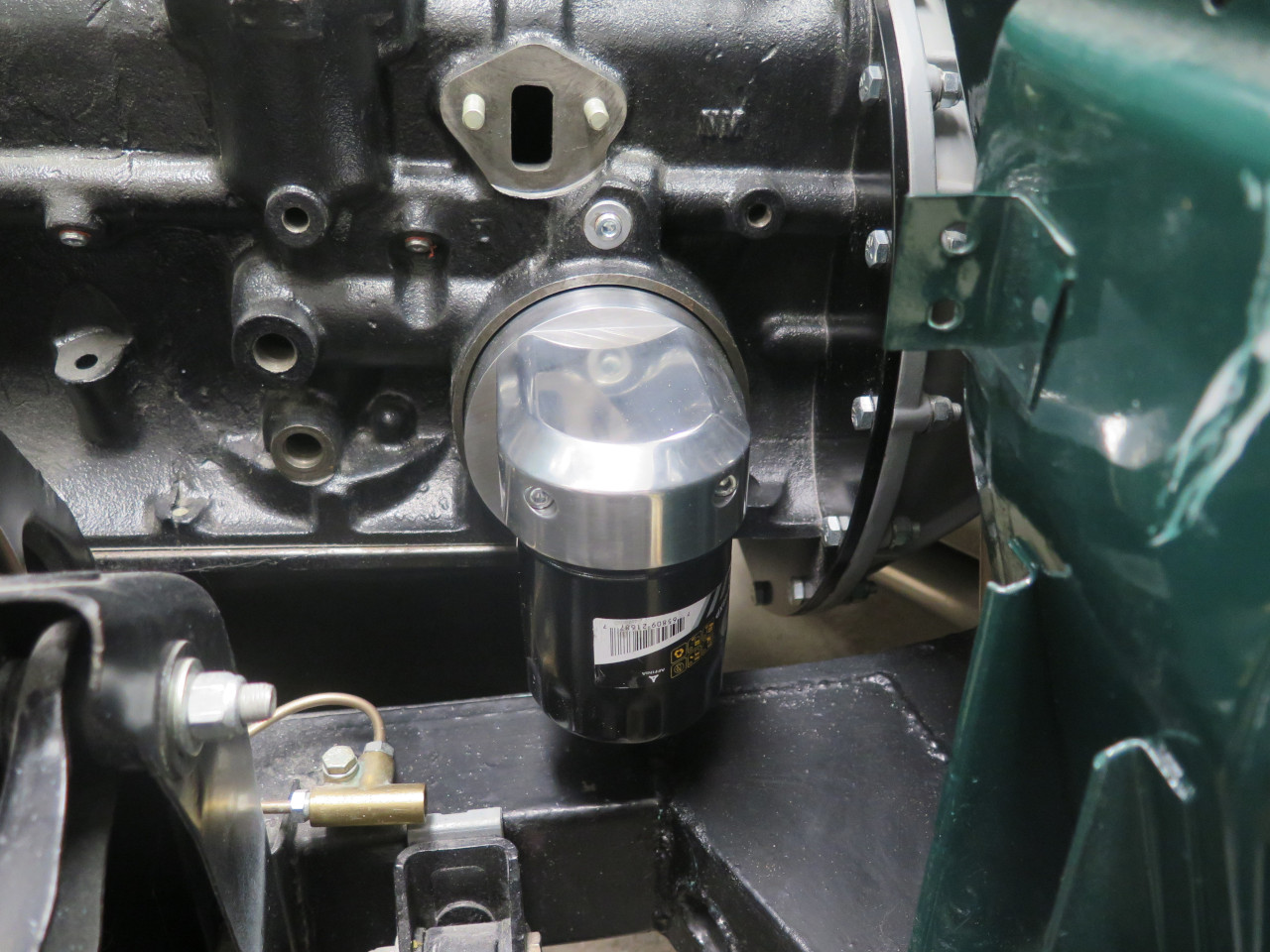

And on the car. Hmmmm, looks a little too blingy to me.

I thought about powder coating the parts, but in the end anodized

them. Red or green anodizing were in contention, but lost out to

boring black.

Since the filter nipple has a hole in its side that has to align with

one of the oil passages, I didn't want it turning. It was

installed with red Locktite, and was staked all around.

Ready to go.

Looks better to my eye.

I did a little research for alternate filters. This is a quite a

bit larger filter that works, but for clearance reasons, I have to use a

hex head fastening bolt instead of the socket head cap screw.

This one was quite a lot of work, especially since it was largely for

aesthetic reasons. It took a few days, and the cost added up to

probably not much less than the commercial adapter (which I also

bought). No regrets, though. It was an enjoyable job.

Update--July, 9, 2022

When I published the above page on a few forums, I got a question about

interference with the steering column. The questioner pointed out

that the reason that the factory GT6 oil filter housing was smaller than

the TR6 housing (at least on LHD cars) was that the GT6 steering column

interfered with the larger housing.

In fact, I had thought about the potential for interference, but in a

maybe over-optimistic eye-ball evaluation, I thought that any

interference would be minor, and I could probably just reshape my

adapter a little to accommodate the column.

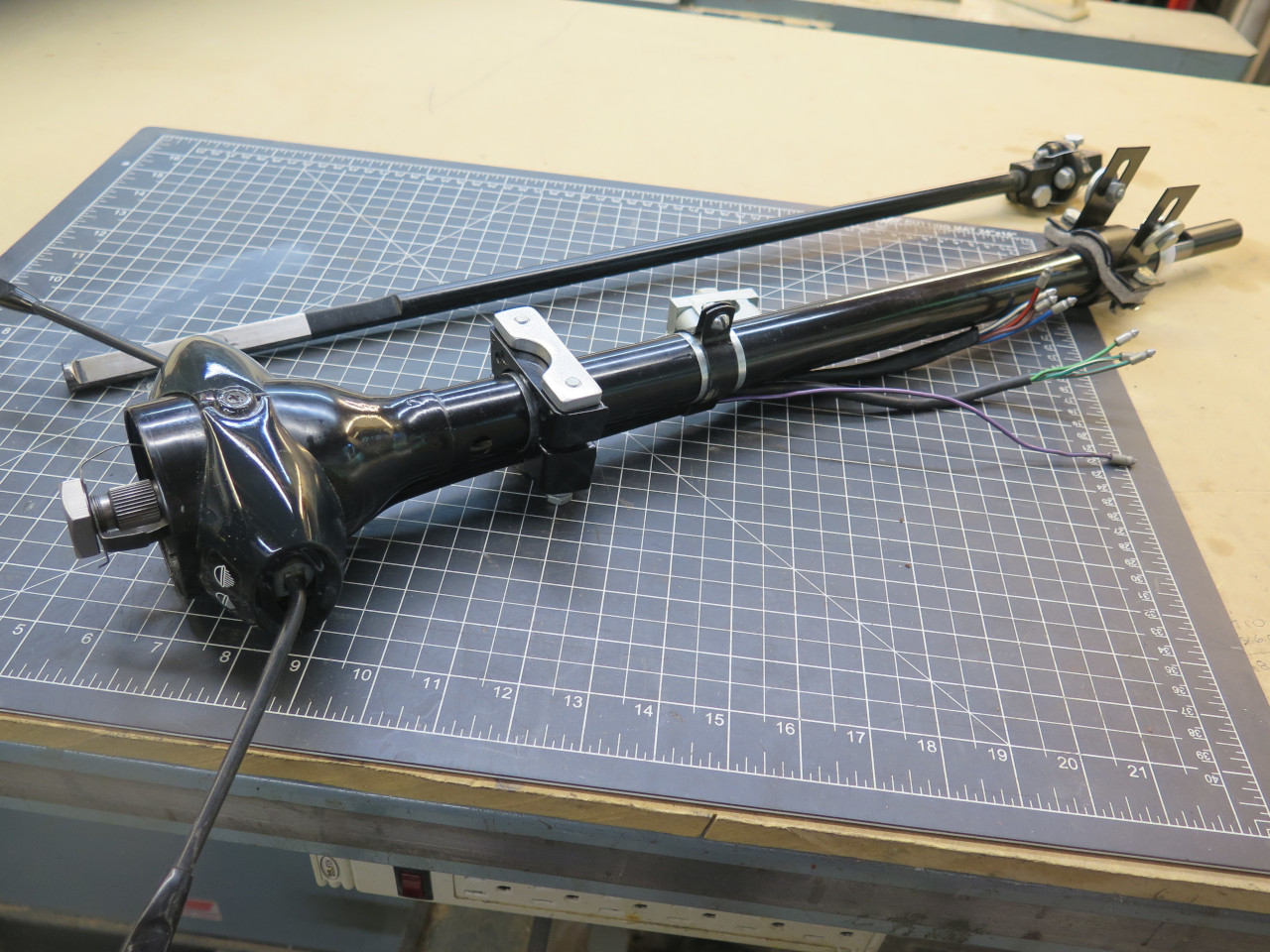

Well, I dug out the re-furbed steering column

a few days ago and installed it. Then I went to install the

filter adapter, and to my horror saw immediately that the interference

was not minor. and that no amount of reshaping the adapter was going to

fix it. In fact, the column would pass directly through the top

oil gallery of the adapter.

It looked like the filter mount part of the adapter needed to be at least 3/4" lower to clear the column.

I slept on it for a couple of nights.

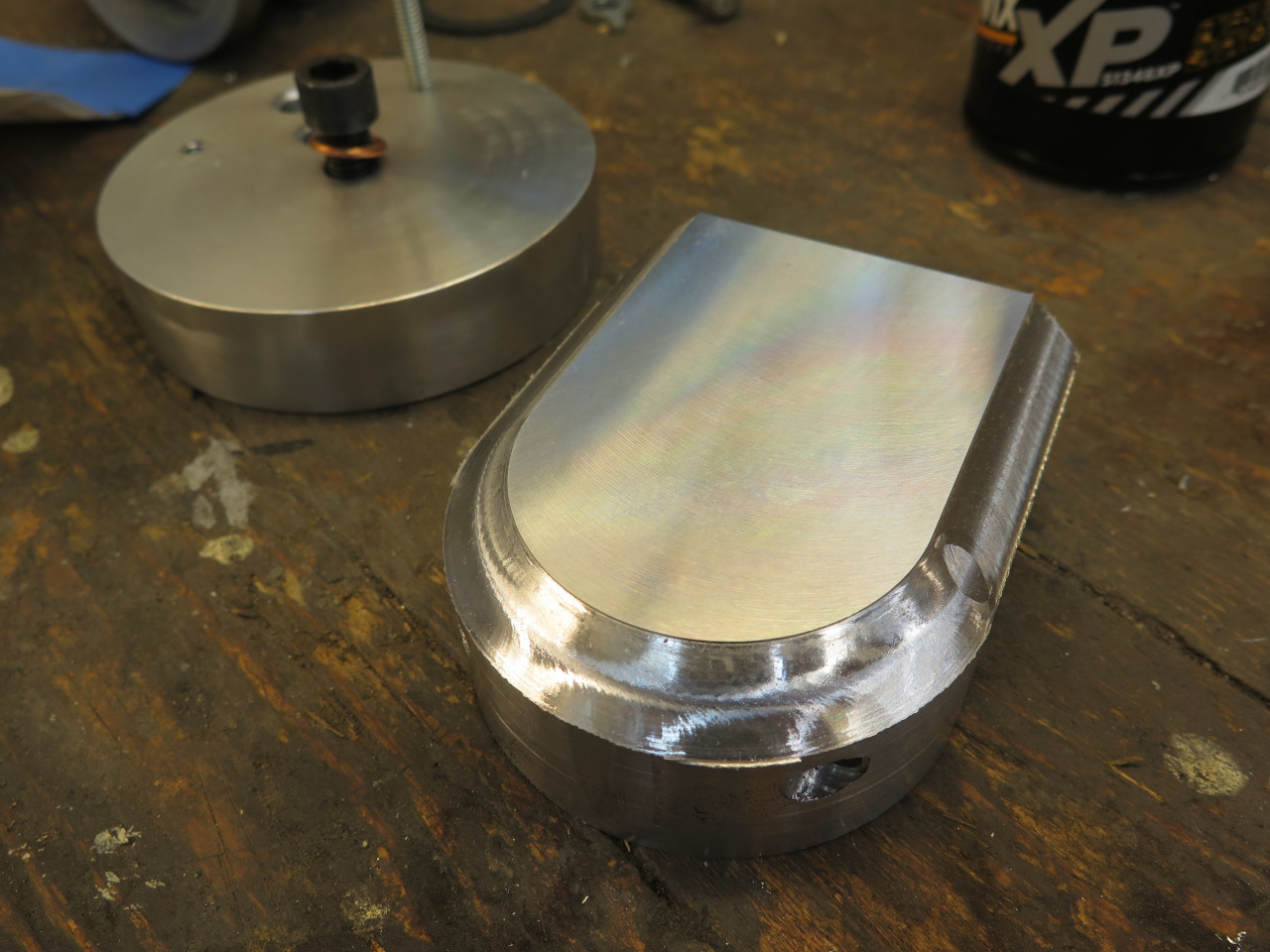

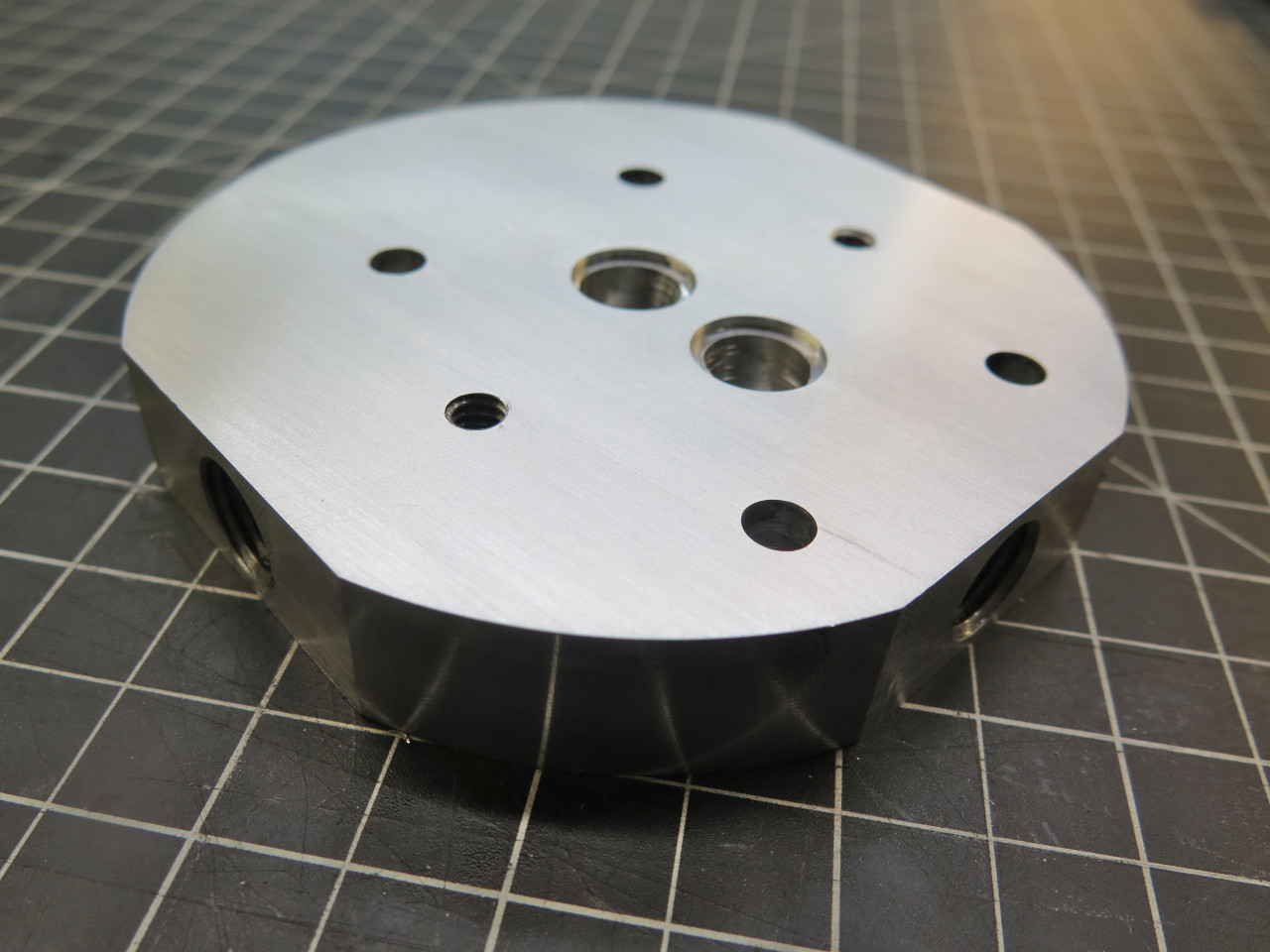

I finally landed on making a transition piece that would go between the

adapter base, which bolts to the engine block, and the part that holds

the filter. The transition would jog the two oil galleries

downward by 3/4". I figured I could do this translation in a piece

about 11/16" thick and still have generous sized galleries.

I started with an aluminum puck similar to the one that became the

adapter base, and drilled the required passages, and some mounting

holes.

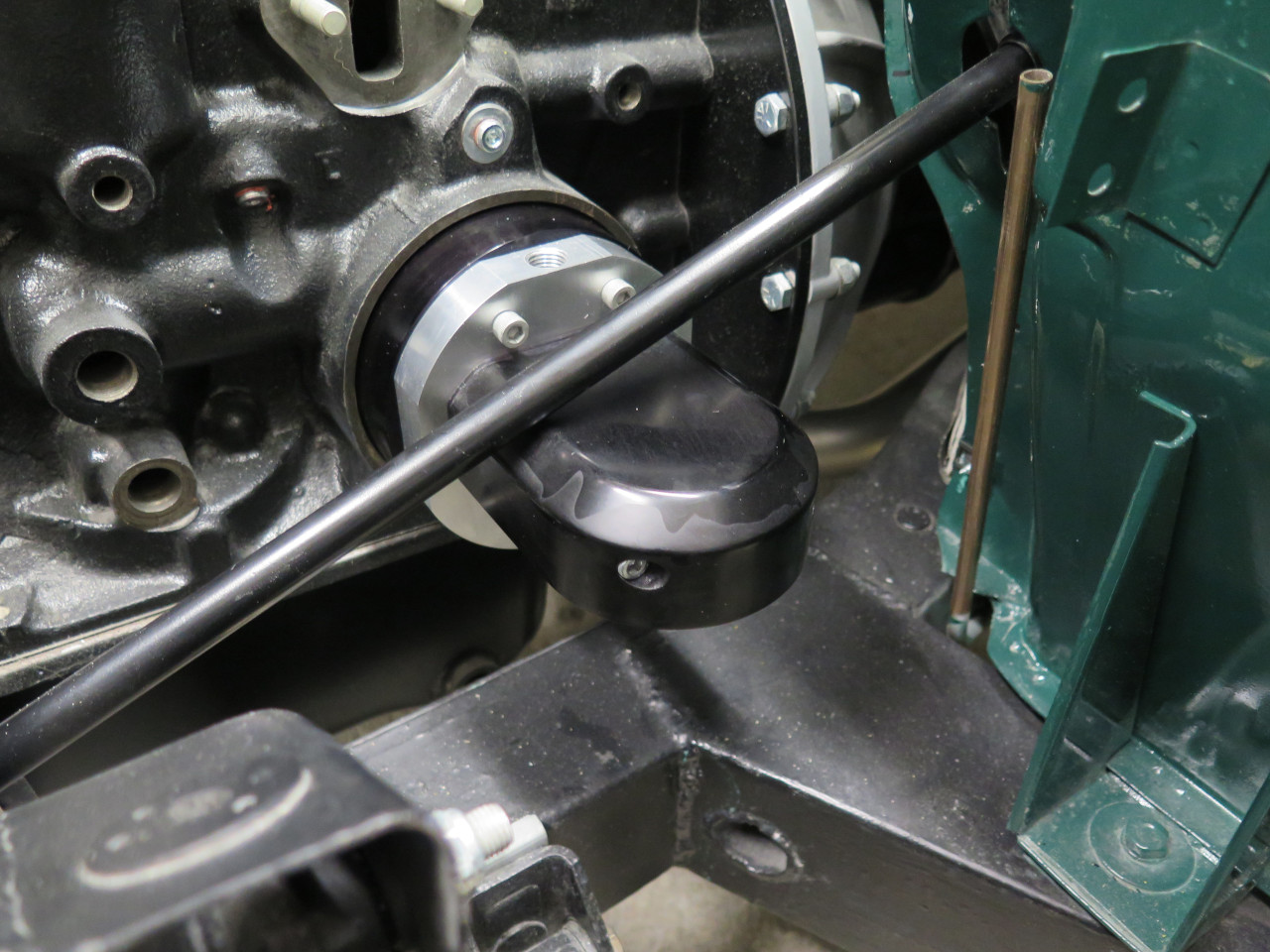

Then attached the filter mount in its new lower position.

Bolting the adapter to the engine, I found that there was no longer any

interference, but that the steering shaft was very close to the filter

mount. I know that the engine can rotate a little on acceleration

or engine braking, so this seemed like an issue.

So, here is where the re-shaping came in. All I had to do was

carve out some of the meat of the adapter near where the steering shaft

ran.

That did the trick.

I knew that the smaller filter could accommodate being shifted down by

3/4", but I wasn't sure about the larger one. Happily, it still

fits, too, but barely. Running the brake line to that T connector

might also rule out the larger filter.

If I had known at the outset that this adapter was going to be so much

work, I'm not sure I would have done it. The resulting piece is

complex. The best part about it is that it's done.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages