To my other GT6

pages

December 25, 2020

Steering Column

The steering column in the GT6 was apparently used across a range

of both small and large chassis Triumph cars. There seem to be

some mounting variants, and later columns have provision for a

steering lock, but the design is mainly the same. My column

was filthy, tired, and sort of loosey-goosey, but it appeared to

be complete.

The column is made up of an outer aluminum housing holding a

telescoping shaft. The telescoping shaft consists of the

outer shaft, which is connected to the steering wheel, and an

inner shaft, which connects to the rack and pinion box. The

two shafts are held in relative position by a friction fitting. I

believe the idea is that in a front end collision, the inner shaft

would slide rearward against the friction, absorbing some of the

impact energy. This is only good for a few inches of travel,

though. After that, it appears that another part of the

energy would be taken by crumpling the thin, soft aluminum

housing. This was Triumph's version of the collapsible

steering column.

The outer column housing carries the column controls--turn

signals, headlight hi/lo beam, and the horn button parts.

Also inside the column housing are a pair of bushes that the shaft

rides in. Judging from the play in my steering wheel, I knew

the bushes were worn. So, out they came. The original

bushes are a steel cylinder inside a rubber jacket. Inside

the steel is a nylon lining , which is the actual bearing

surface. The rubber jacket has a small protrusions that fit

into holes in the column housing. It can be a bit of a wrestling

match to get the resilient bushes to move. Cutting or

drilling away the rubber protrusions seems to help.

In addition to wear of the nylon insert, my shaft showed signs of

wear. I could see it, feel it, and measure it.

New factory type bushes can be bought, and they probably aren't

that expensive. On the other hand, I didn't really see the

advantage of the multi-layered bushes. A simple solid

bushing, made to press fit in the housing should do the job, and

maybe even tighten up the steering a bit by eliminating the

resilient rubber layer. I chose to stick to plastic for the

bearing surface, though. This is a rod of Delrin, an acetal

plastic with good stiffness, good dimensional stability, and high

natural lubricity with steel. The bushes shown are the

originals.

The Delrin bushes were machined for a pretty tight fit in the

housing. The fit was such that I didn't see any need for

locating devices like the nubs on the originals. They are a

nice slip fit on the shaft.

There is some leeway in exactly where the bushes go in the

housing. I took advantage of that and put the bushes a

little farther apart than stock. The main reason I did this

is so the bushes don't ride on the areas worn by the original

bushes, but I think the slightly wider spacing may also improve

the solid feel of the steering wheel. I powder coated the

housing before installing the bushes. I decided to help the

natural lubrication by squirting in a little graphite powder in

and around the bushes. The result is a very nice tight but

smooth rotation of the shaft in the housing.

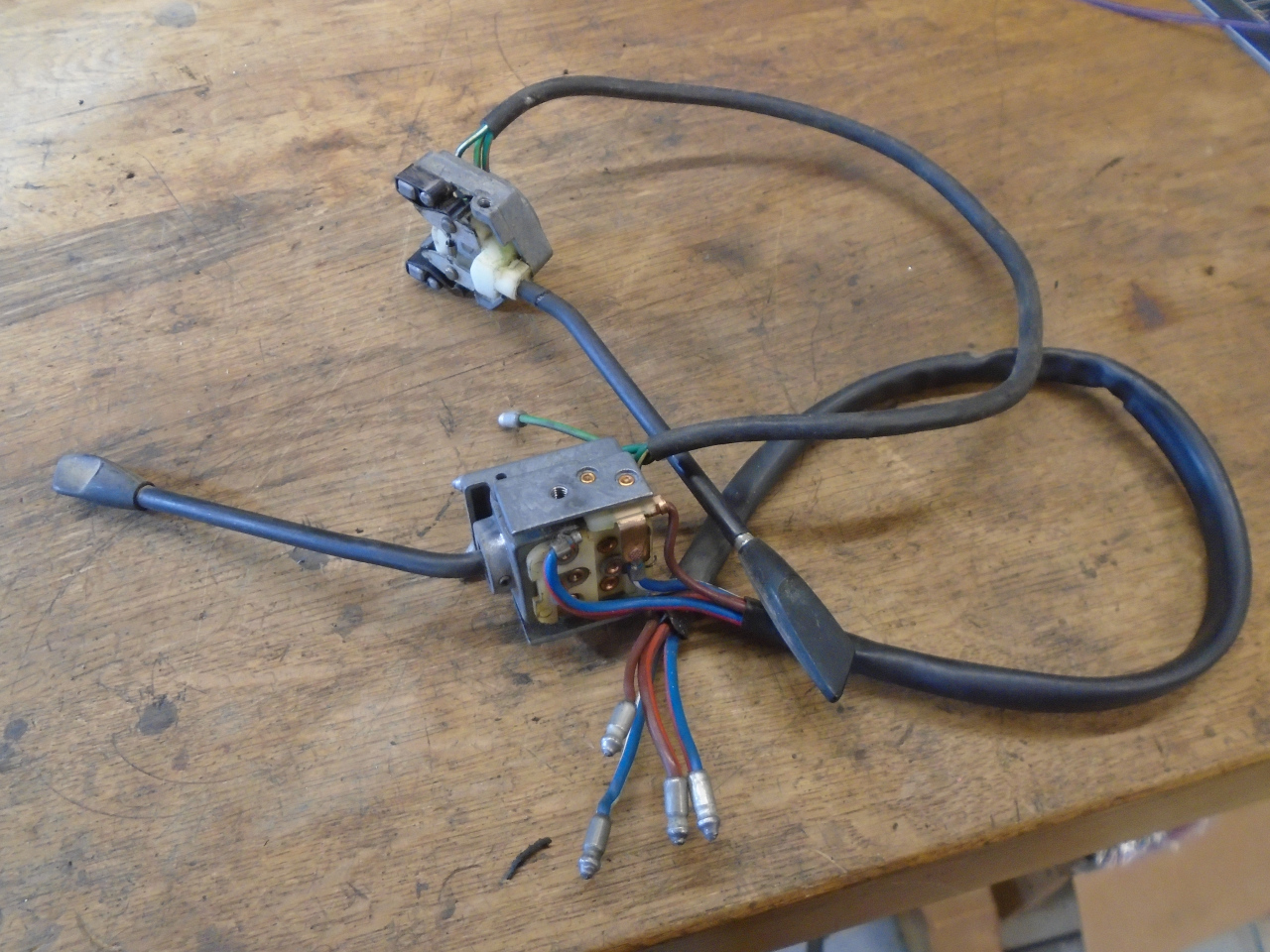

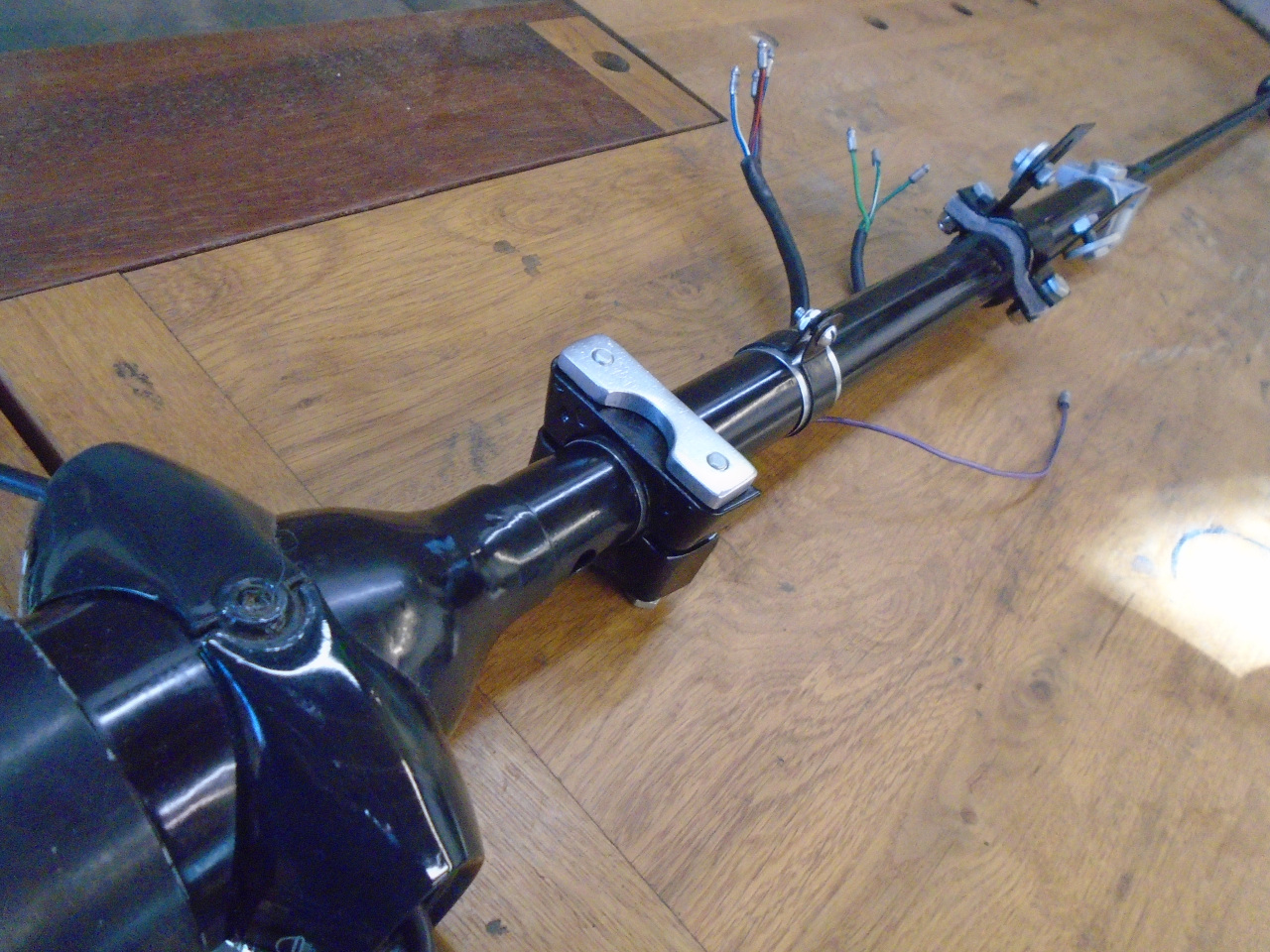

Next out of the tub of steering column parts was the electrical

controls.

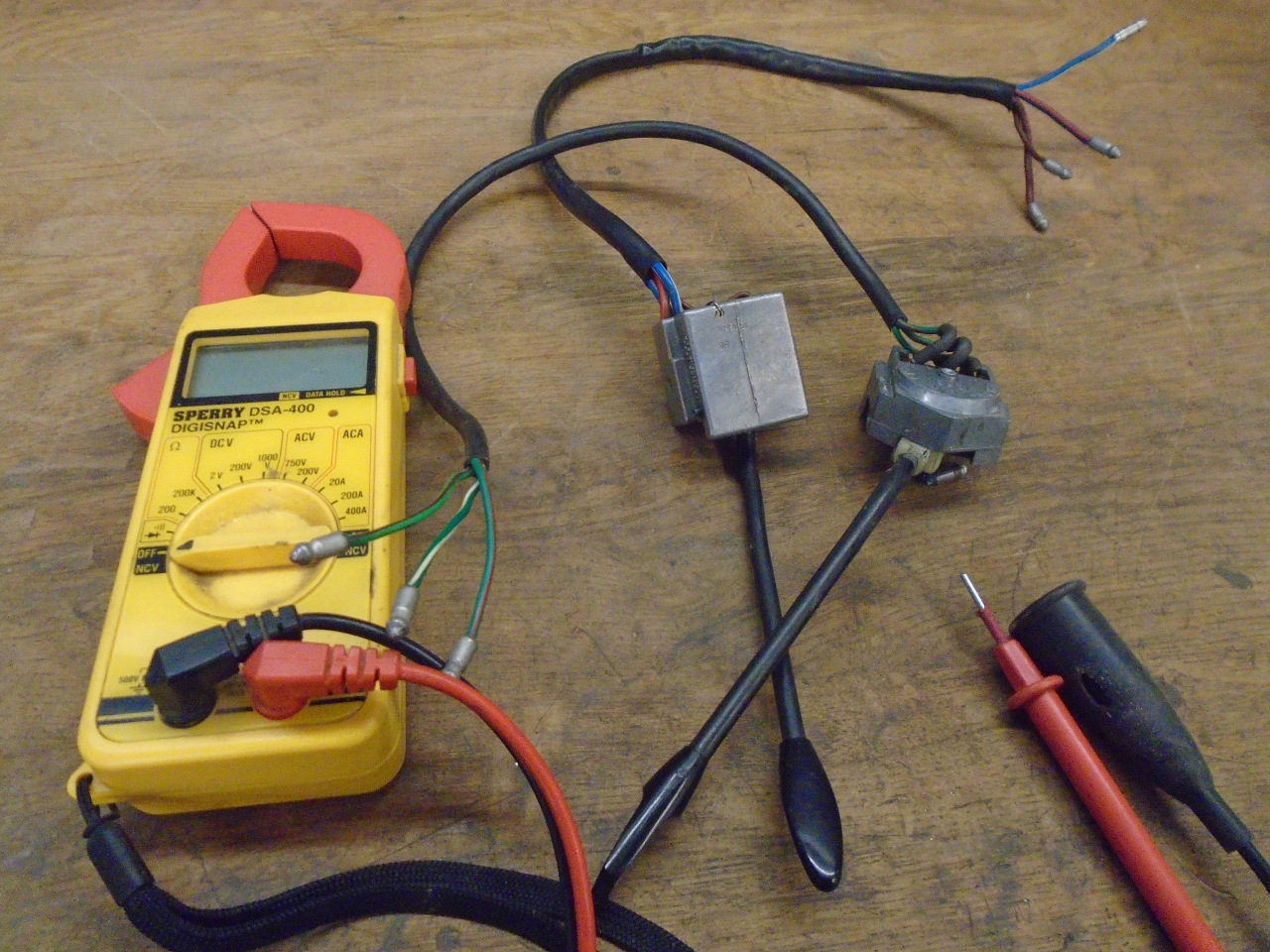

A general cleaning made them look good enough to use, but I wanted

to make sure they worked. All was good except the high beam

circuit. It was frustratingly intermittent, but I couldn't

reproduce it on demand. I thought the problem was at the

bullet terminal end. Replacing the bullet fixed it.

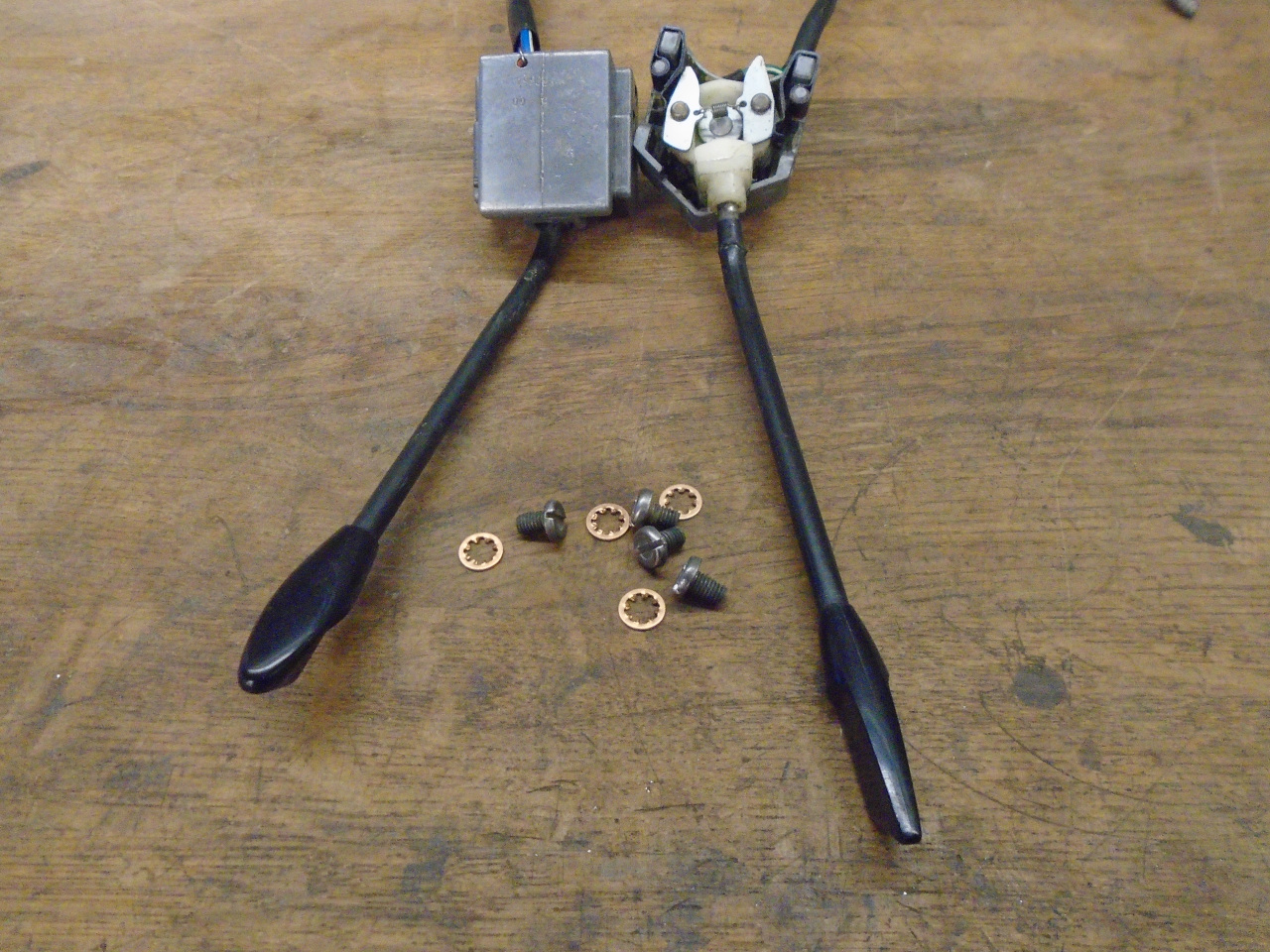

Ready for install. One interesting factoid: the fixing

screws for the controls, which appear to be 8-32 are actually a

rather odd 8-36. Not odd, exactly, since 36 is the standard

UNF pitch for a #8 machine screw, but it's not very common.

I'm sure some well-intentioned folks have jammed an 8-32 in there.

Then I checked the turn signal canceling function. It

depends on this little clip fastened to the upper steering shaft.

Then it was the escutcheons that cover the switches. They

are just plastic shells that improve he esthetics. The one

on the right was just cleaned up with soap and water.

This is probably an example of where I maybe should have left well

enough alone. I thought the white legends on the escutcheons

were a little natty, so I removed them, used some plastic

polishing compound to brighten up the plastic, and applied new

waterslide decals. Frankly, after the work to improve them,

I don't think they look any better, and maybe worse.

Certainly the outline of the decal is more visible than

before. Ah, well. Live and learn.

These little inserts have the threads for the screws that hold the

escutcheons.

The escutcheons were applied...

...and then the horn contact ring goes in so its wire can

join the others. A couple of tabs in the housing bend down

to hold it in.

This little piece is a cover to protect the wires as they come out

of the column housing.

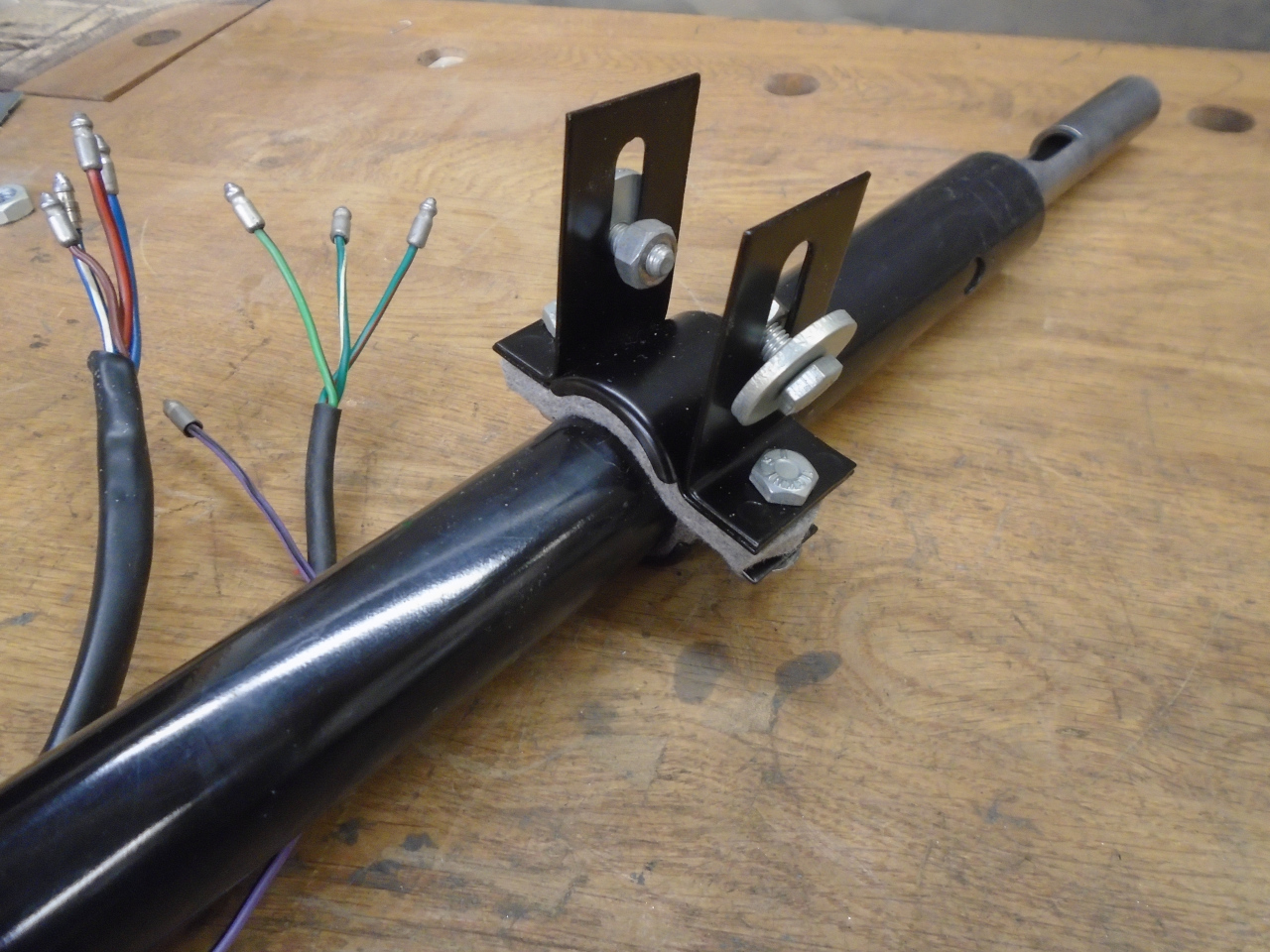

Then it was time for some mounting brackets. The parts at

the top are for the rear mount (closest to the steering wheel),

while the parts at the right are for the frontmost mount. The

black parts are powder coated, the silver parts are stripped and

replated.

The rear mount has a little clip that snaps around the

housing. Since the aluminum of the housing is so soft, it

gouges very easily. I put little bands of galvanized steel

sheet under that clip and under the band for the wire

protector. The bands protect the aluminum.

The front bracket gets new felt strips that gently cradle the

column.

These parts close off the lower end of the column housing.

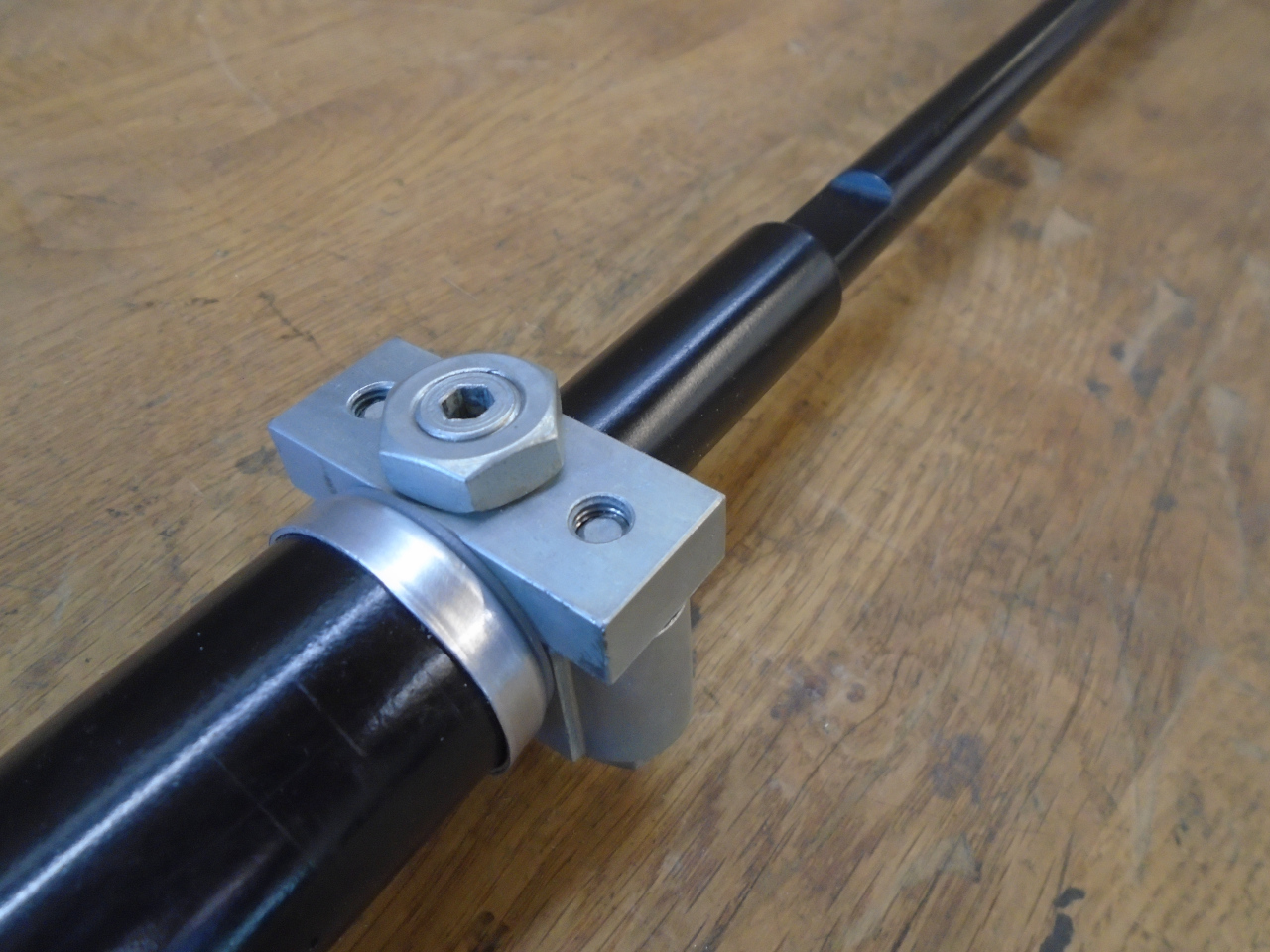

The last thing to do is install the inner (lower) steering shaft.

There is a cutout in the outer shaft that allows the friction

fitting to bear down on a flat on the inner shaft.

I've been holding on to this mystery part for over a year

now. I finally realized where it goes. It's a nut

plate for the rear column bracket.

There were a couple of other items in the steering column

bin. The horn button really goes more with the steering

wheel, which I'm not doing right now, but I cleaned it up anyway.

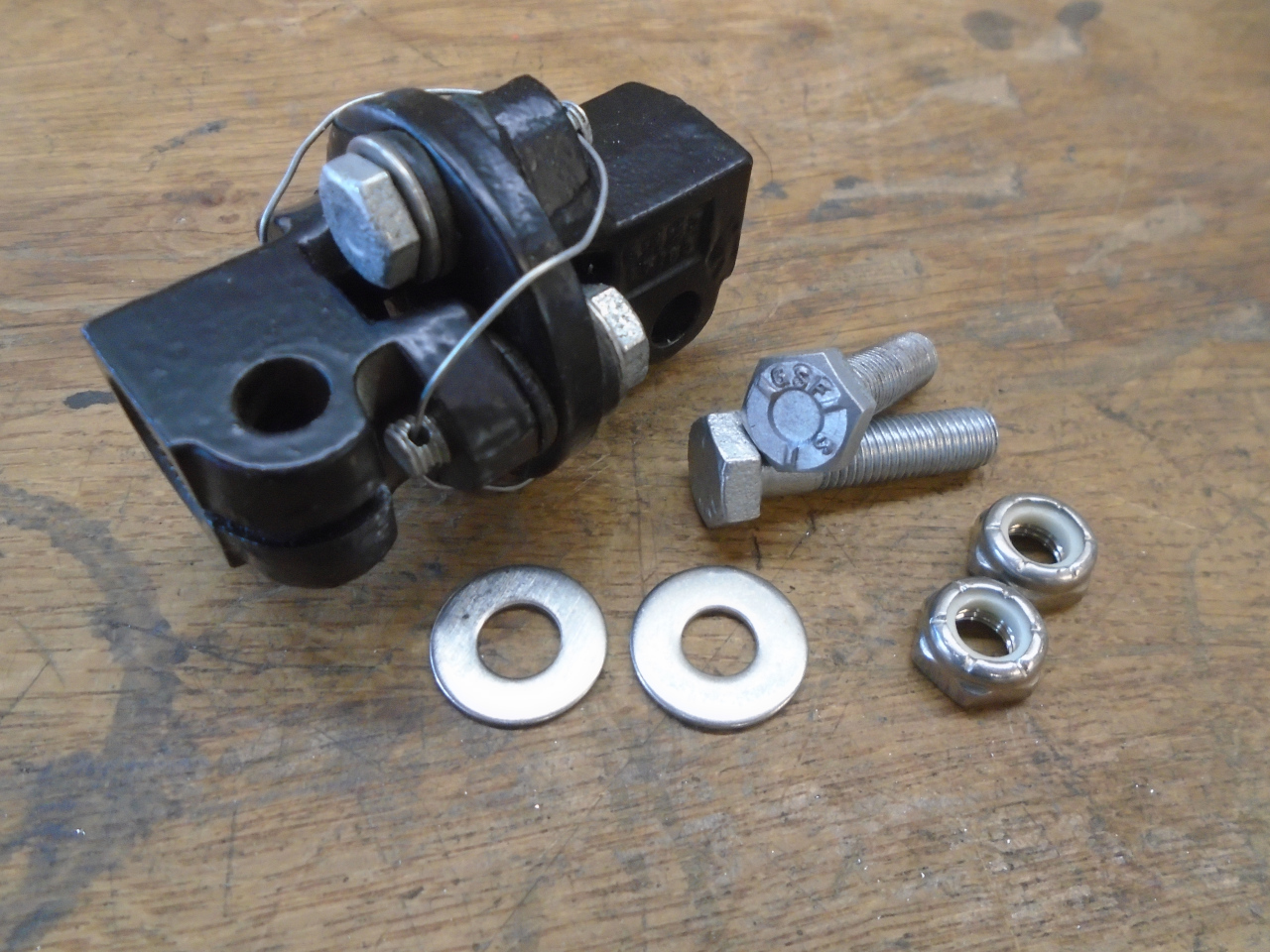

The last piece was the little U joint that goes between the column

and the rack and pinion. I took it apart, cleaned up the rust, and

powder coated or replated the metal parts. The rubber parts

seemed good enough to re-use.

This dude goes on the shelf.

As sometimes happens in these kinds of projects, I had a part left

over. It's a cardboard tube that was found on the lower part

of the column housing. You can see it in the first few pics

above. I can see no earthly purpose for this tube.

After a search, consensus seems to be that it may have been some

kind of install gauge that was just left in place. I'll keep

it for a while in case I'm wrong.

This was an enjoyable project, and was good for a couple of

pleasant days in the nice warm shop. Cost was

minimal--probably under $20, including consumables.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages