To my other GT6

pages

March 20, 2021

Hand Brake Lever

I am prone to forget to release the parking brake before

driving. I don't think I've ever caused any major damage by

doing this, but it certainly isn't good for the brakes. On

my more modern cars, I rely on warning lights or audio to tell me

when I've spaced off the brake. I believe some later

Triumphs did have a warning light on the dash, but this GT6 had no

such amenity. Since I'd had the forethought to include a

Parking Brake warning light on the fancy new dash,

I had to follow through and provide a sensor to go with the light.

On the GT6 and related cars of the era, it was common for the

parking brake to be actuated by a hand lever next to the driver's

seat. Pulling up onthe lever pulls a cable that in turn

applies the rear brakes. The lever includes a spring loaded

pawl/ratchet arrangement such that the lever holds position when

pulled up tight. A button on the end of the lever disengages

the pawl to release the brake. The lever provides a

mechanical advantage of about 4.5:1.

My lever was cruddy...

...but it came apart pretty easily.

My plan was to install a snap action switch (often called a

"microswitch", but that's actually a brand name) on the lever that

signals when the lever has left it's fully down, released

position. My first thought was a mercury switch that detects

tilt. As I thought about the effects of the grade where the

car is parked, and G forces while driving, I decided a more

conventional mechanical switch might be better.

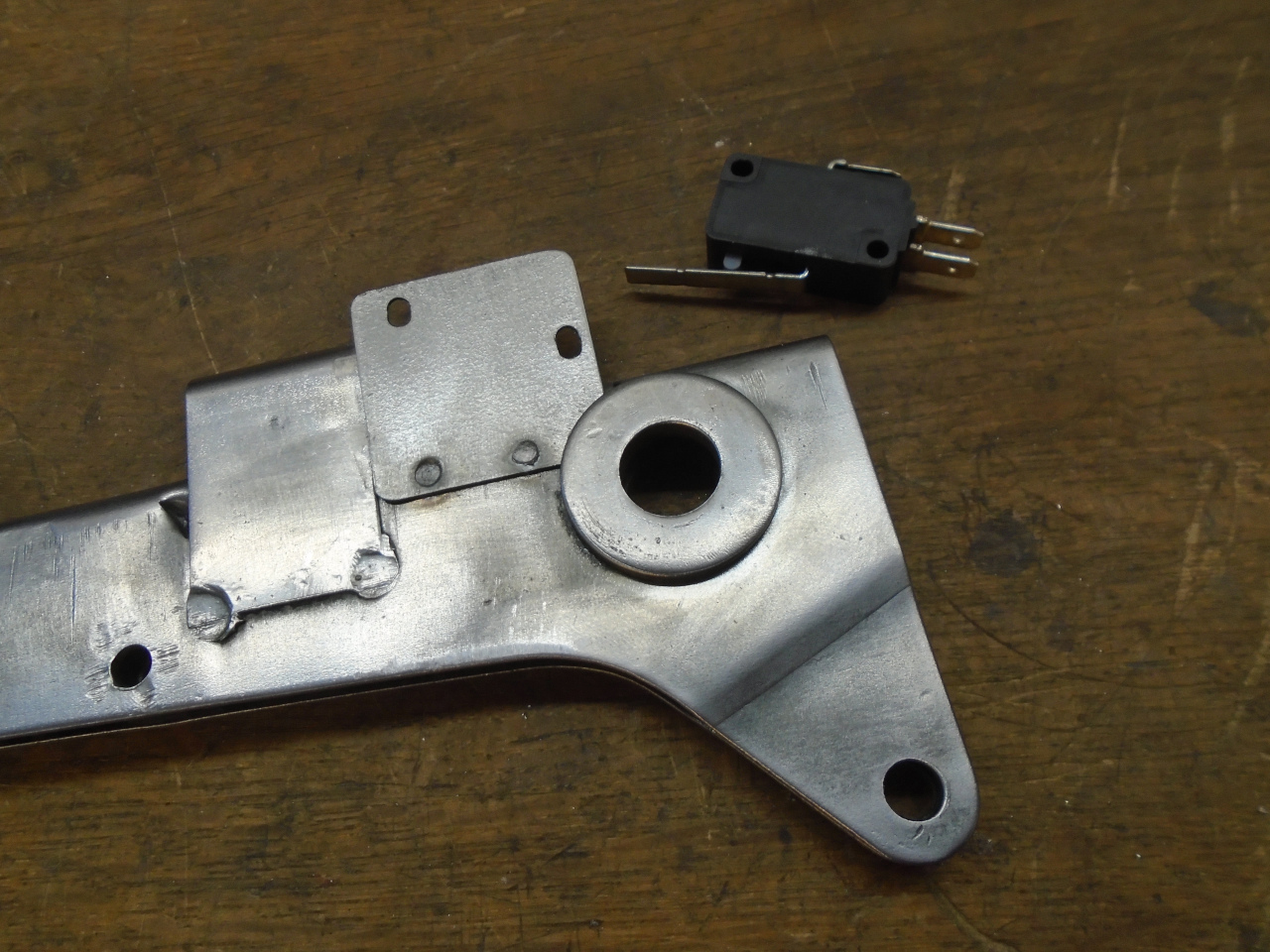

There didn't appear to be a natural place to put the switch, so I

had to do a couple of tweaks. There is a slot on the top

spine of the lever that the toothed ratchet segment pokes through

when the brake is released. I thought I could somehow

activate the switch with the ratchet. I extended the slot to

provide better access to the top of the ratchet.

But even then, the ratchet was too far down in the hole for the

switch to reach. I decided to add a little nub to the

ratchet to poke up through the slot. The thickness of the

ratchet was about 0.160" (likely 4 mm, actually). I found a

big washer very close to the same thickness.

I cut a contour to match where it would be joined to the ratchet,

and left it long elsewhere to help with holding and

clamping. The ratchet material is very hard, so I

tried to limit the heat from welding to preserve the temper.

Then trimmed to shape.

Then I had something to work with.

The switch would be located on the spine of the lever, with its

actuator over the new slot. A little plate would be attached

to the side of the lever to mount the switch.

I thought spot welding was the cleanest way to attach the switch

mounting plate, but the double wall of the lever wouldn't permit

that. At least not until I drilled a couple of holes on the

opposite side for spot welder electrode access.

Then mounted the switch.

The switch/ratchet seemed to work OK, so I powder coated the lever

body.

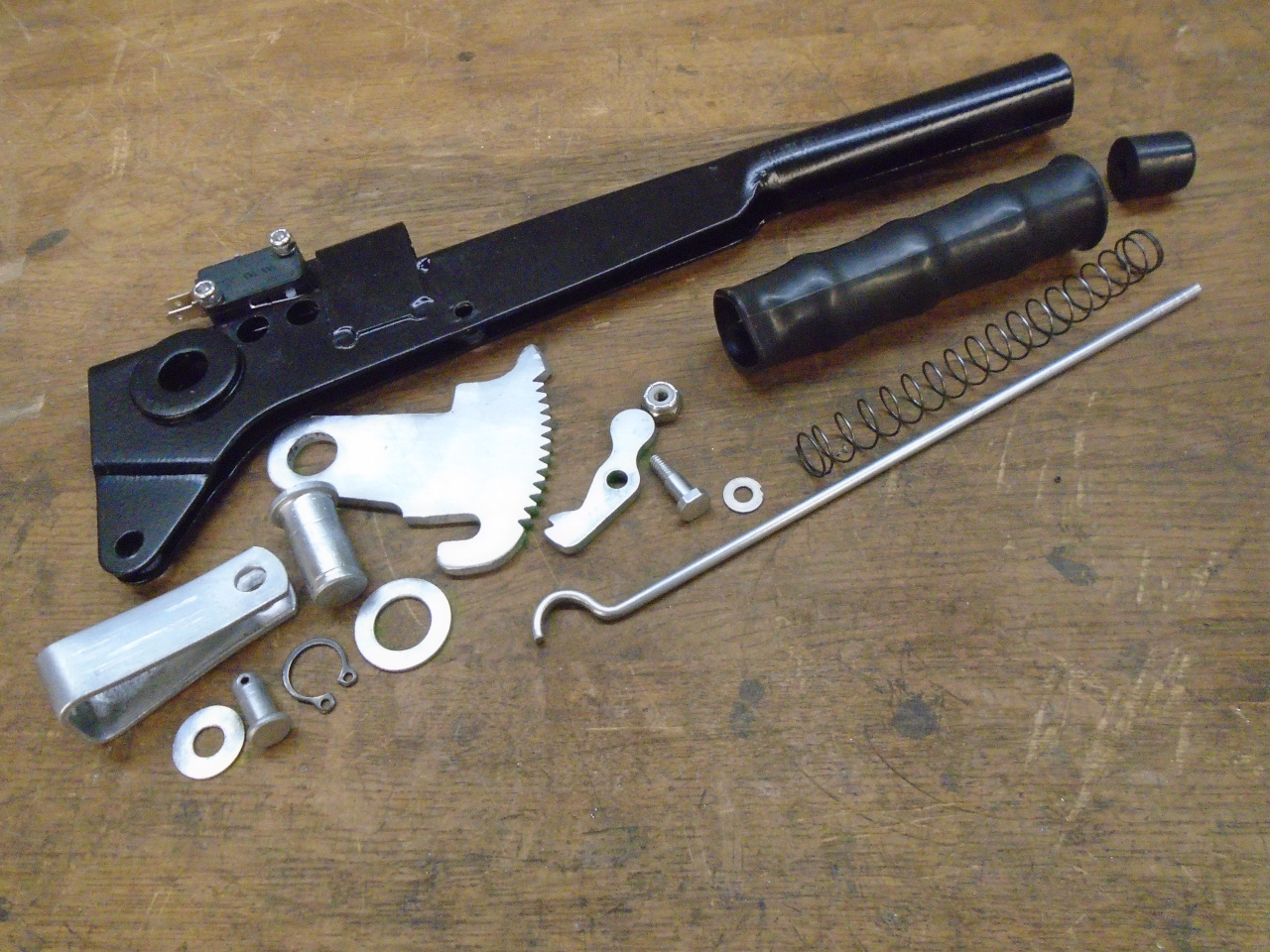

Before reassembly, the pawl assembly needed some attention.

The pawl was originally held in place by a simple pin (on the

right in the picture) that was apparently just peened on both

sides to keep it in place. Instead, I used a shoulder

bolt. Since the hole in the pawl is an odd size (well, odd

on this side of the pond--I think it was 5 mm), and the pawl is

too hard to drill easily, I just made the shoulder bolt to fit.

Gathered up all the cleaned up parts...

...and slapped her together.

This was one of those quick, silly little tasks that might only

take a few hours of actual time, but adds something worthwhile to

the overall project. Cost was a few bucks for the switch,

plus some consumables.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages