To my other GT6

pages

February 1, 2021

Dashboard

Many of the British sports cars of the 50s into the 70s had a few

things that contributed to their mystique. The small, nimble

size, for one. The distinctive sound. The utilitarian,

almost spartan interiors. And the dashboards--mostly simple

and flat, with plain toggle or rocker switches and basic round

gauges reminiscent of an aircraft cockpit. About the only

nod to any kind of luxury or indulgence was the real woodgrain

dash that many models sported. Never mind the questionable

judgement that would put wood in a roadster, the makers bragged

about it in many of their glossy ads of the day.

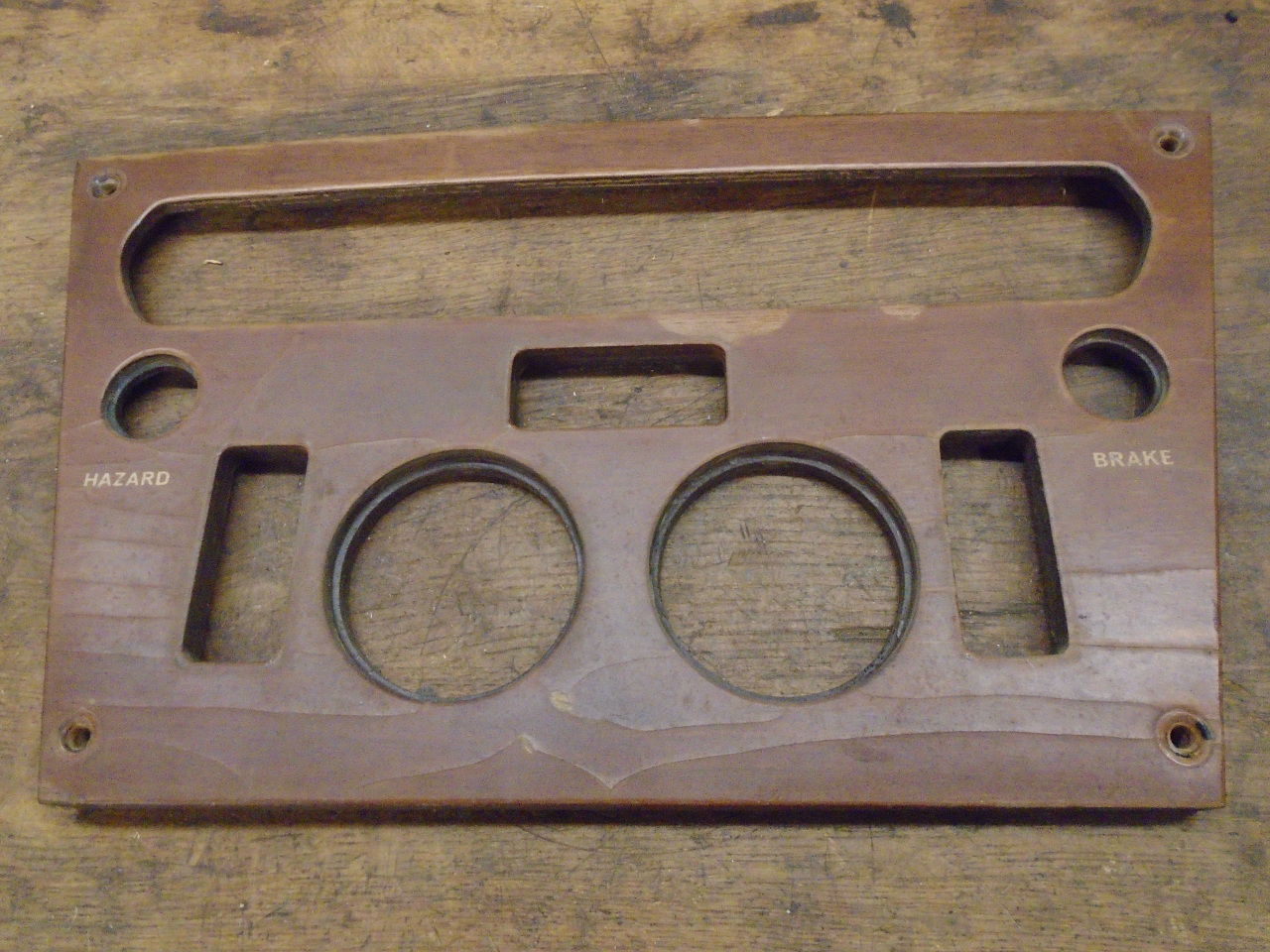

The GT6 was not a roadster, so the genuine walnut veneered

dashboard actually made sense. The dash was in three

sections: The driver's side had the tach and speedometer, the

center part had fuel and temp gauges, the heater controls, and a

few switches and indicators, and the passenger side over the

"glove shelf" had just an air vent.

After removing everything from the dash, I could see that while

the backing plywood and the veneer were in pretty good shape, the

finish was not. It was cracked everywhere, and missing is

spots.

Now, while I'm mostly in the camp of originality on issues of

appearance, I'm not rabid about it, and make notable

exceptions. For me, the GT6 dashboard had a lot of potential

for improvement. First, it only had the two small gauges,

while many cousin and sibling cars (e.g. TR6) had the full

complement of four. Second, it seemed to me that the

switches and indicators on the dash were sort of haphazardly

placed. Third, though I do like walnut in general, I thought

it a little too sedate and boring in this application.

So, after some thought about the amount of work involved, I

resolved to re-create the dashboard, and since the changes would

be fairly major, especially to the center panel of the dash, I

thought starting from scratch was the smartest way to go.

This preserves the original dash panels for some future owner who

might not fully appreciate my taste.

I had actually been thinking about this even before I started on

the GT6, and I had some ideas. I've always loved the

dashboards in the Jaguar E-types. Maybe the rectilinear,

no-nonsense, logical layout of the gauges and switches appeals to

my inner Engineer, but it speaks to me. So I became intent

on building something sort of Jaguar-esque.

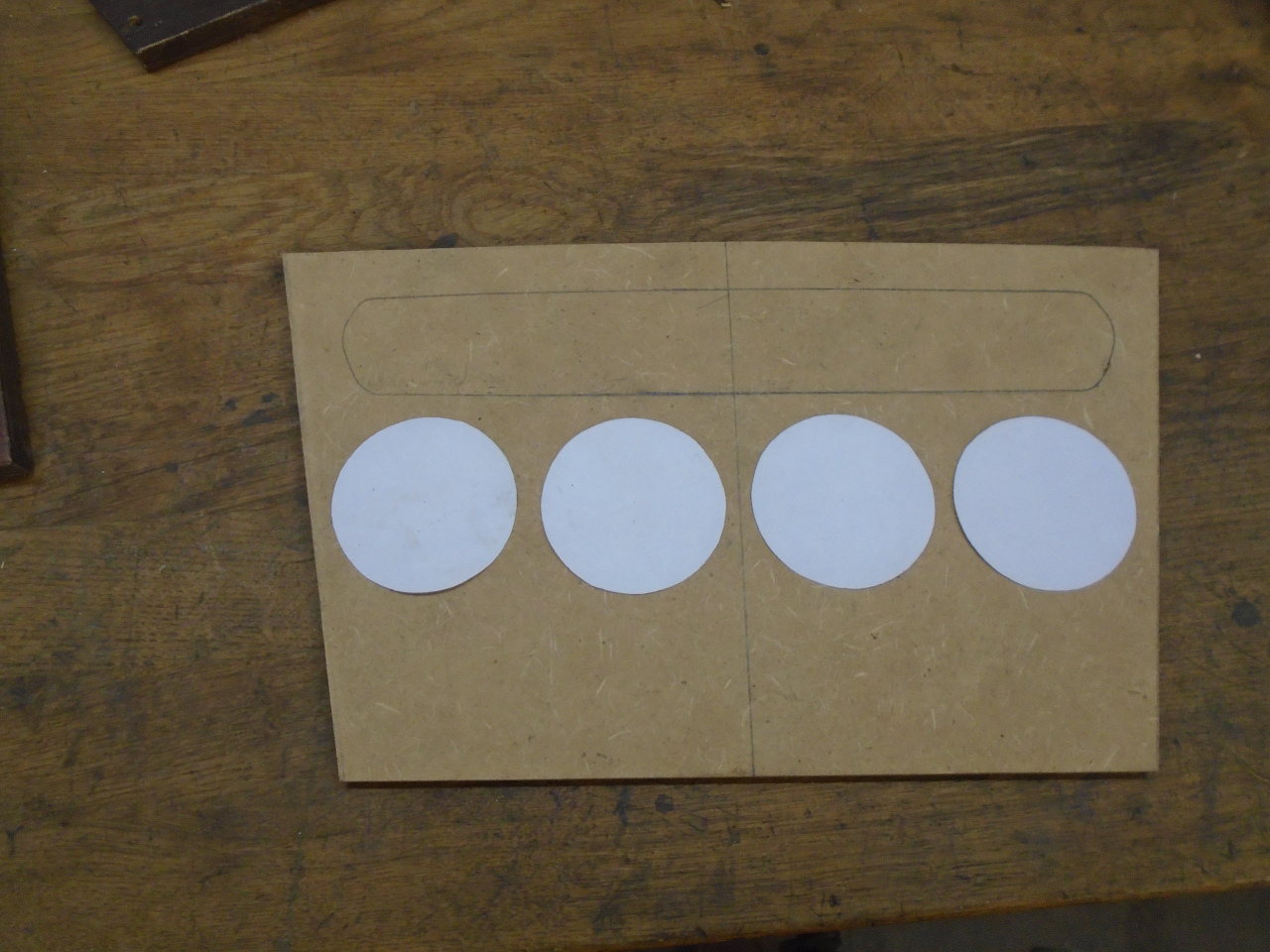

Only the center panel had major changes, so for that piece, I

started with a piece of 1/4" hardboard as a template, shaped to

match the outline of the center panel. The original panel

seemed to be a little short in height compare to its

neighbors. I hope this wasn't intentional, because I made

the template a little taller.

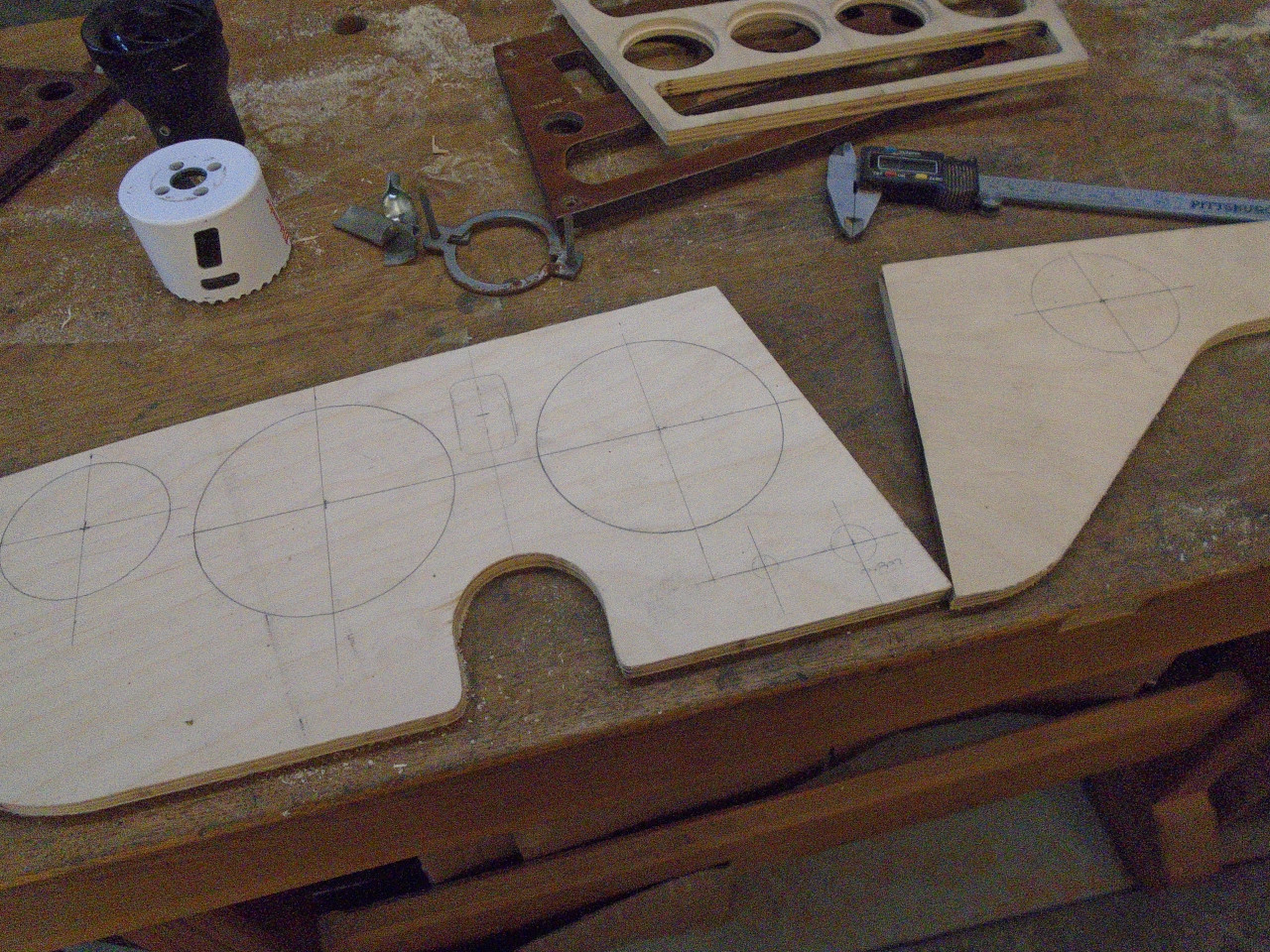

I cut out circles to represent the gauges. I was hoping they

would fit in a straight line. They did. Barely.

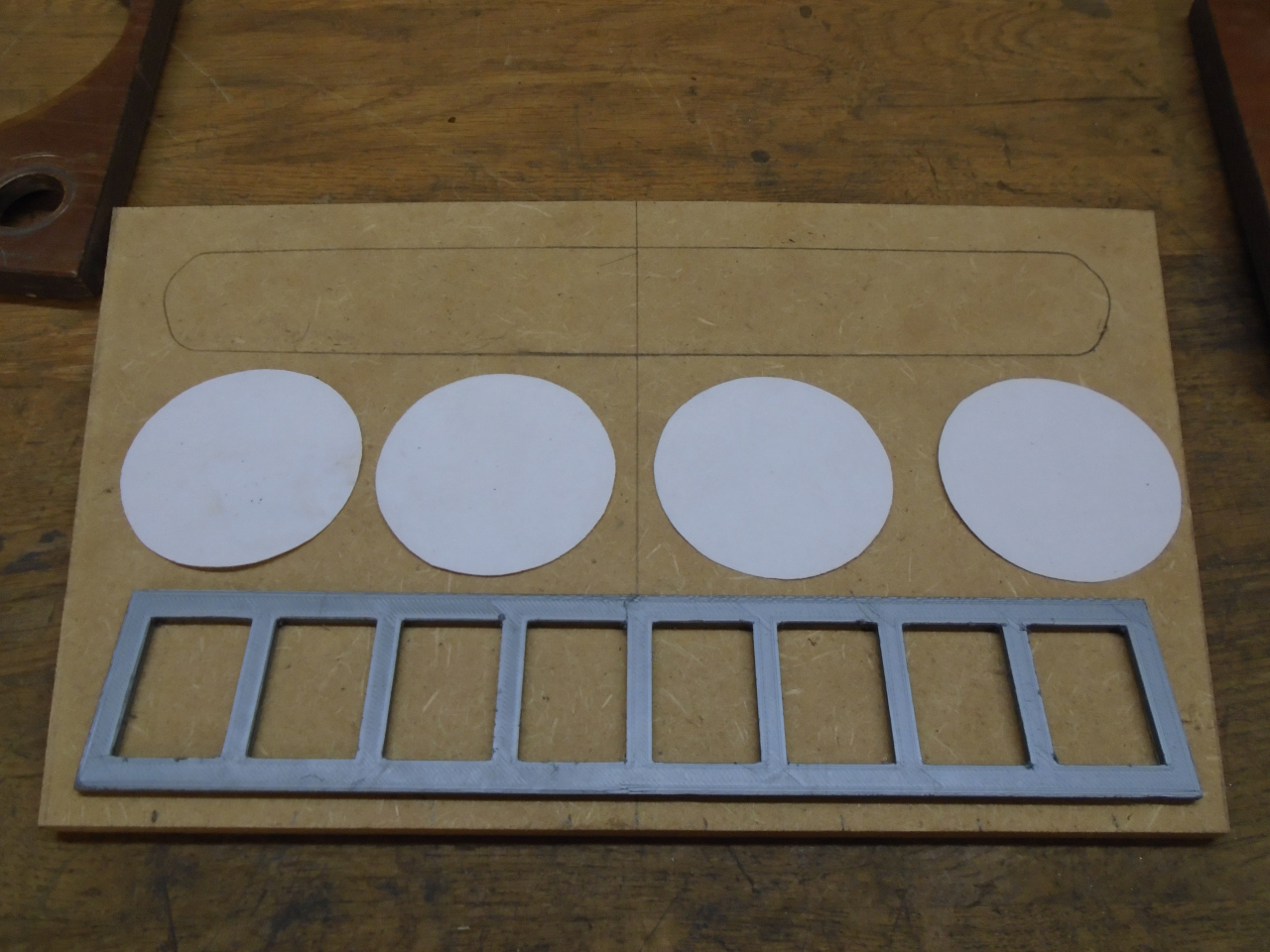

Then switches. Jaguar used both toggles and rockers,

depending on the year. I preferred the look of rockers, but

the limited real estate I had to work with had me doubting that I

could find rockers short enough. Then I happened on a post

on one of the forums from a guy named Dirk from Belgium. He

showed a pic of his dash, and it was almost exactly what I

wanted. He turned me on to a UK company that makes

automotive accessories, including a lot of electrical ones.

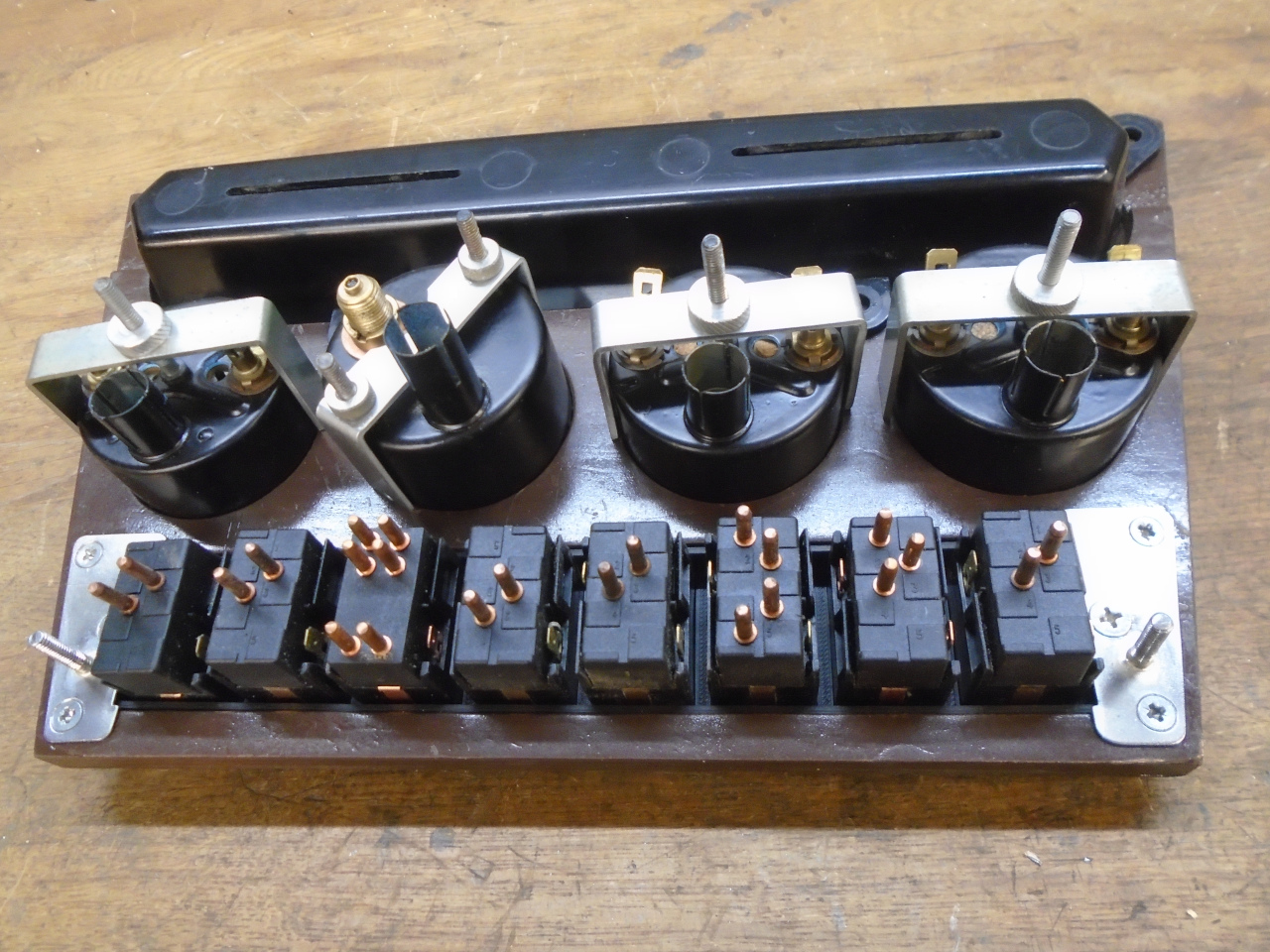

I ordered a bunch of rocker switches.

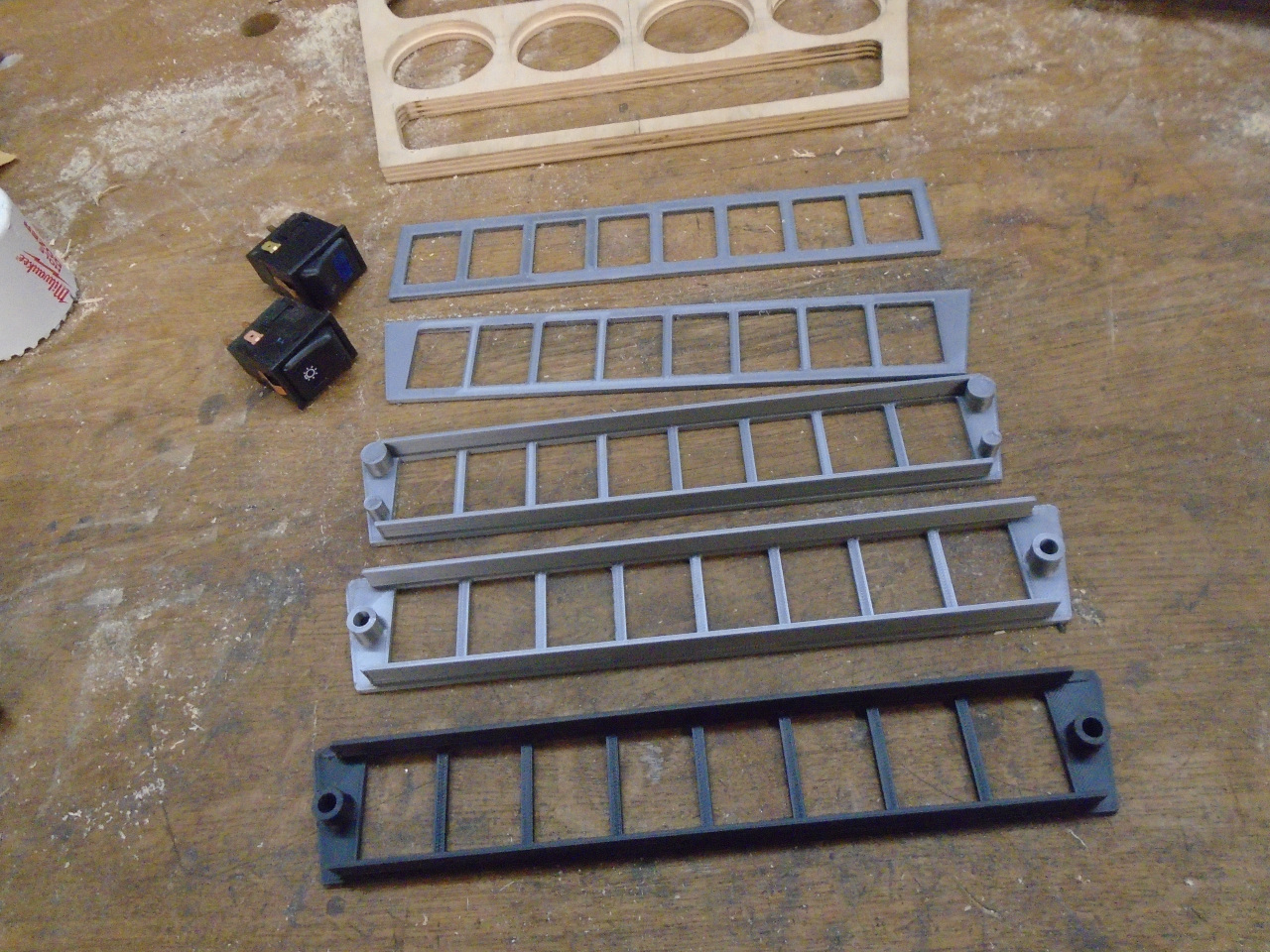

I didn't really relish the thought of cutting all of those

rectangular holes in the template or the final dash, so I cheated

a little and 3D printed a plastic carrier that would hold all of

the switches.

The heater control cutout was traced from the original panel, and

the gauge holes cut with a hole saw.

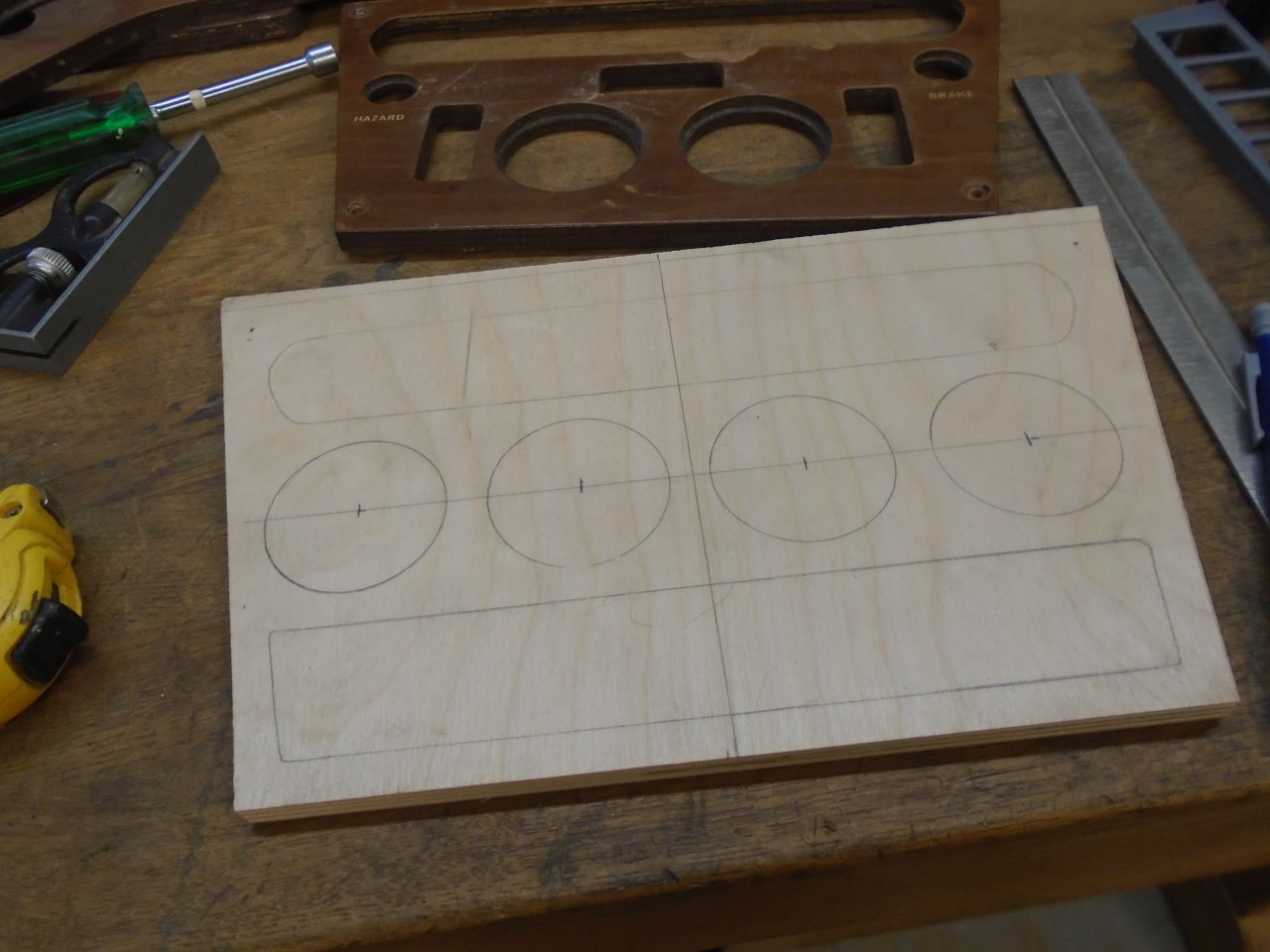

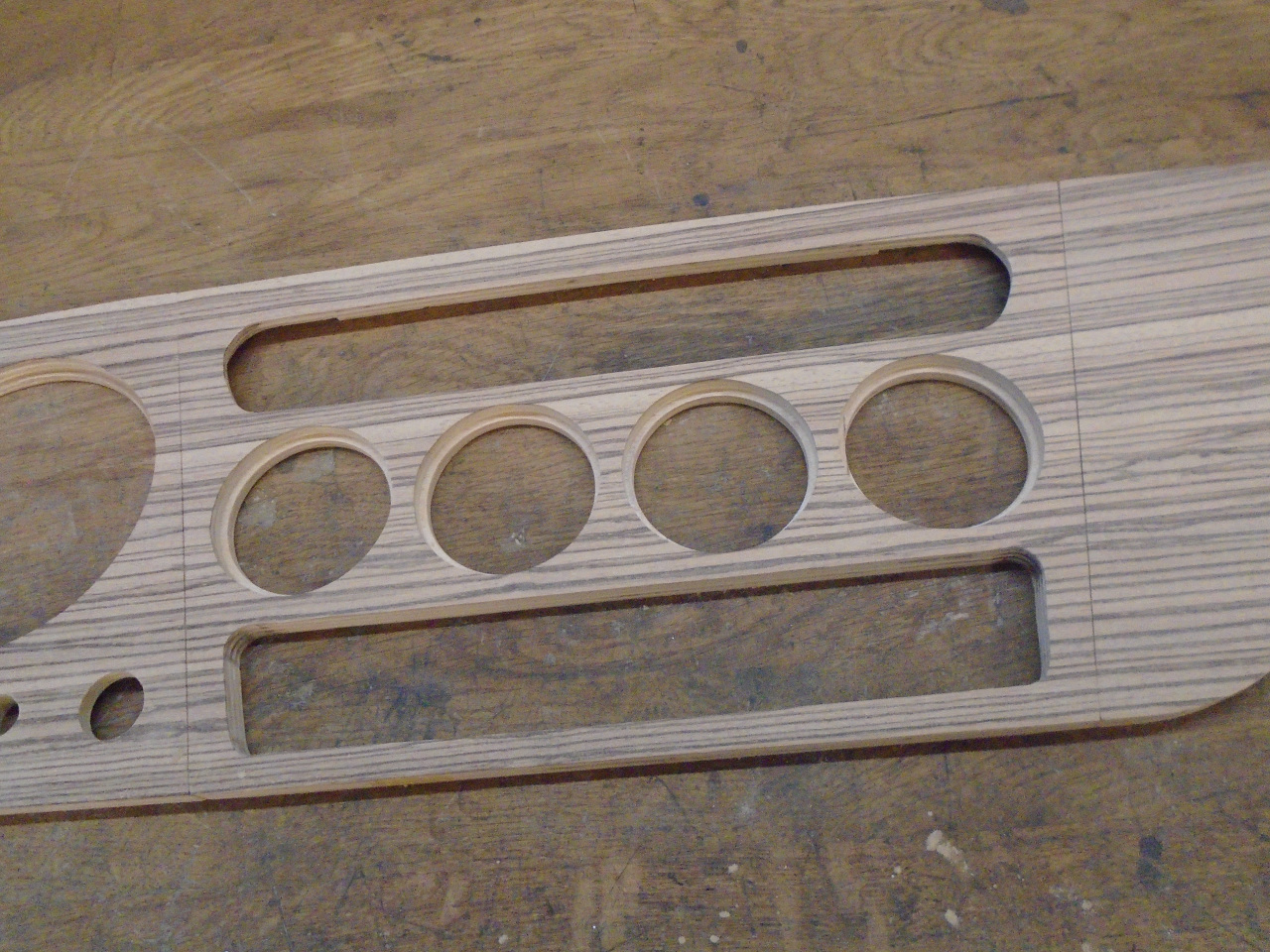

When the template seemed to be right, it was time to transfer it

to the actual dash material. This is a sheet of Baltic Birch

plywood. It's a premium all-hardwood product that comes

primarily from Russia or Finland. It is 3/8" thick, has

seven birch plies, and appears to be very similar to what the

original dash used.

The gauges actually are set into a counterbore in the dash

panel. This might have been a 60s US safety requirement, but

I liked the look so I took the trouble to do it that way.

Openings for the heater controls and the switch module were rough

cut and then trimmed with a router. The camera perspective

is kind of funny in some of these pics. It males the panel

look rectangular, but it is really a trapezoid.

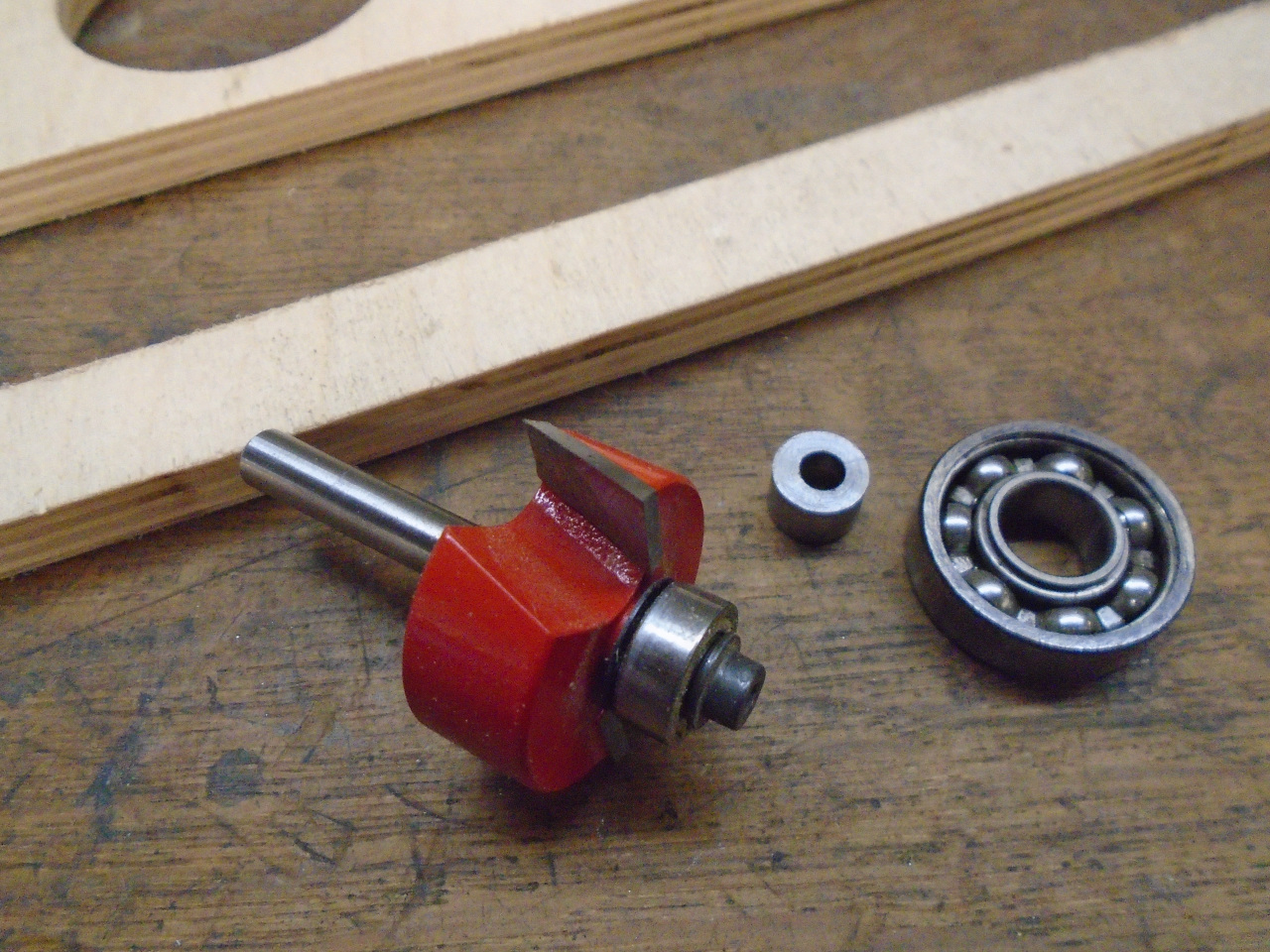

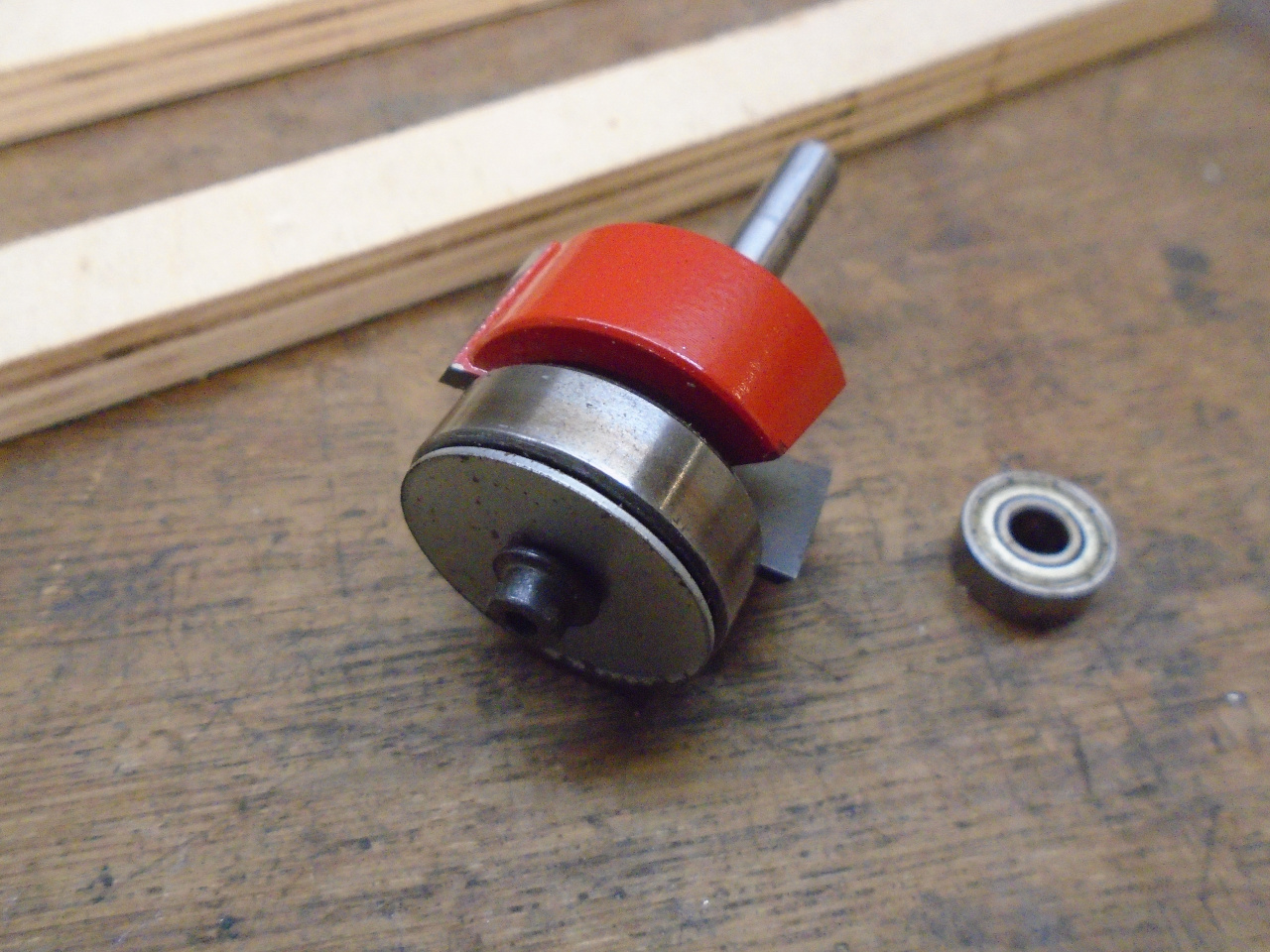

The recess for the plastic heater control plinth took a little

creative assembly of the router bit after finding the right sized

guide bearing.

The plinth was still dirty in these pics.

Everything seemed to fit OK.

I went through a series of iterations on the switch carrier.

The final one is black ABS. It was printed face down, so the

surface is really smooth, and I don't plan to do anything else to

it.

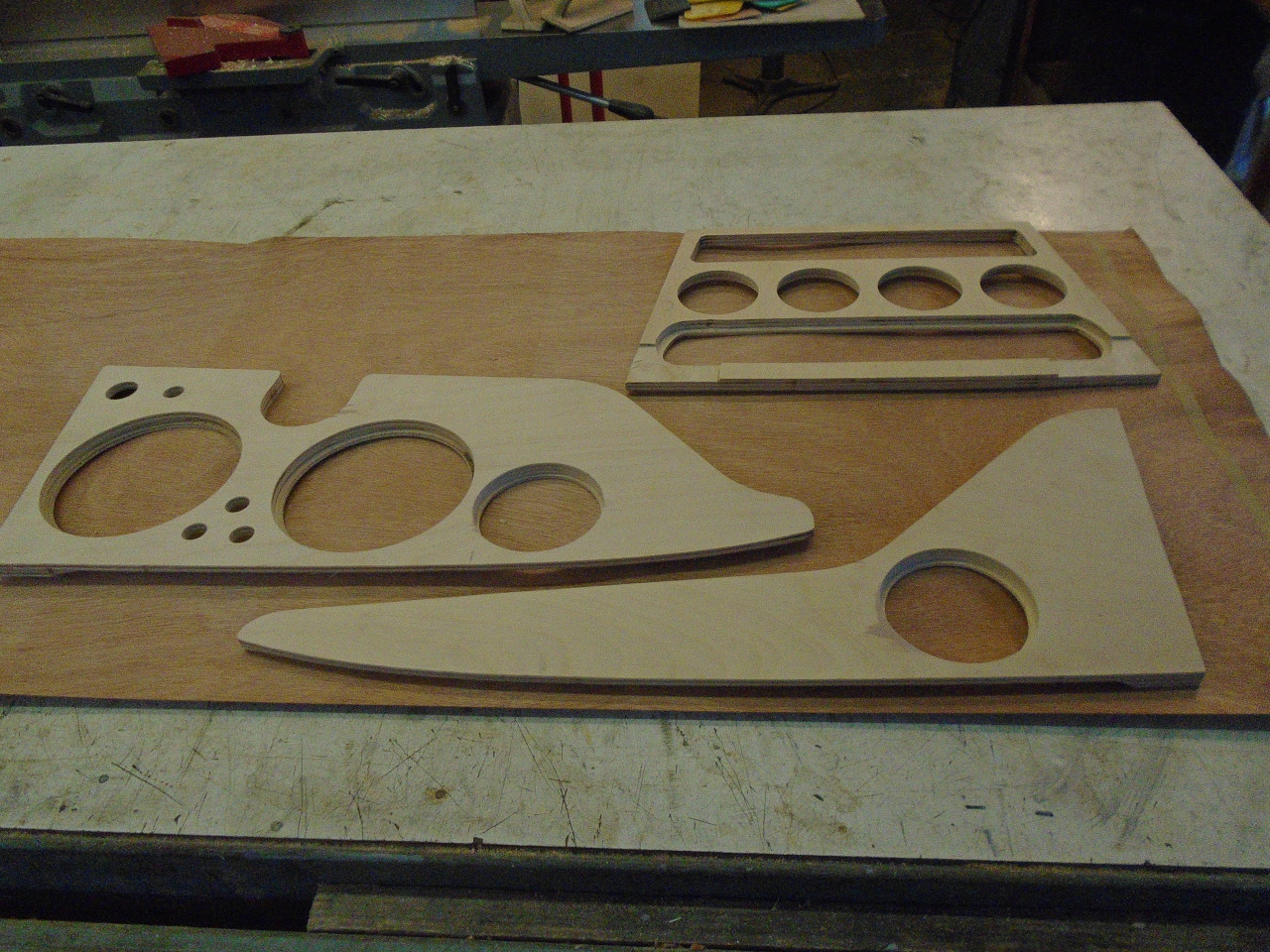

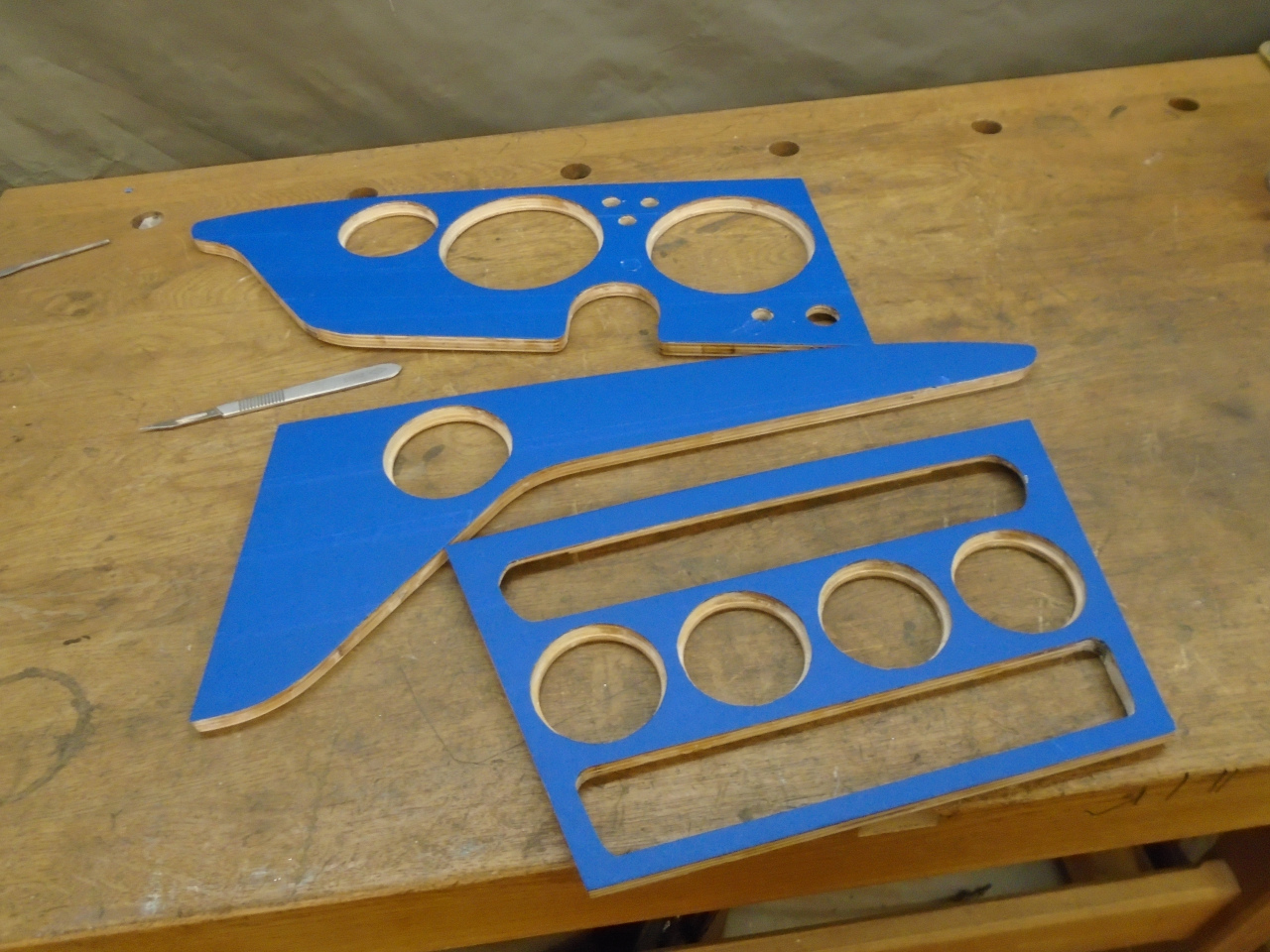

I just used the original panels as templates for the other parts

of the dash.

The passenger side panel was pretty simple--just one lipped hole.

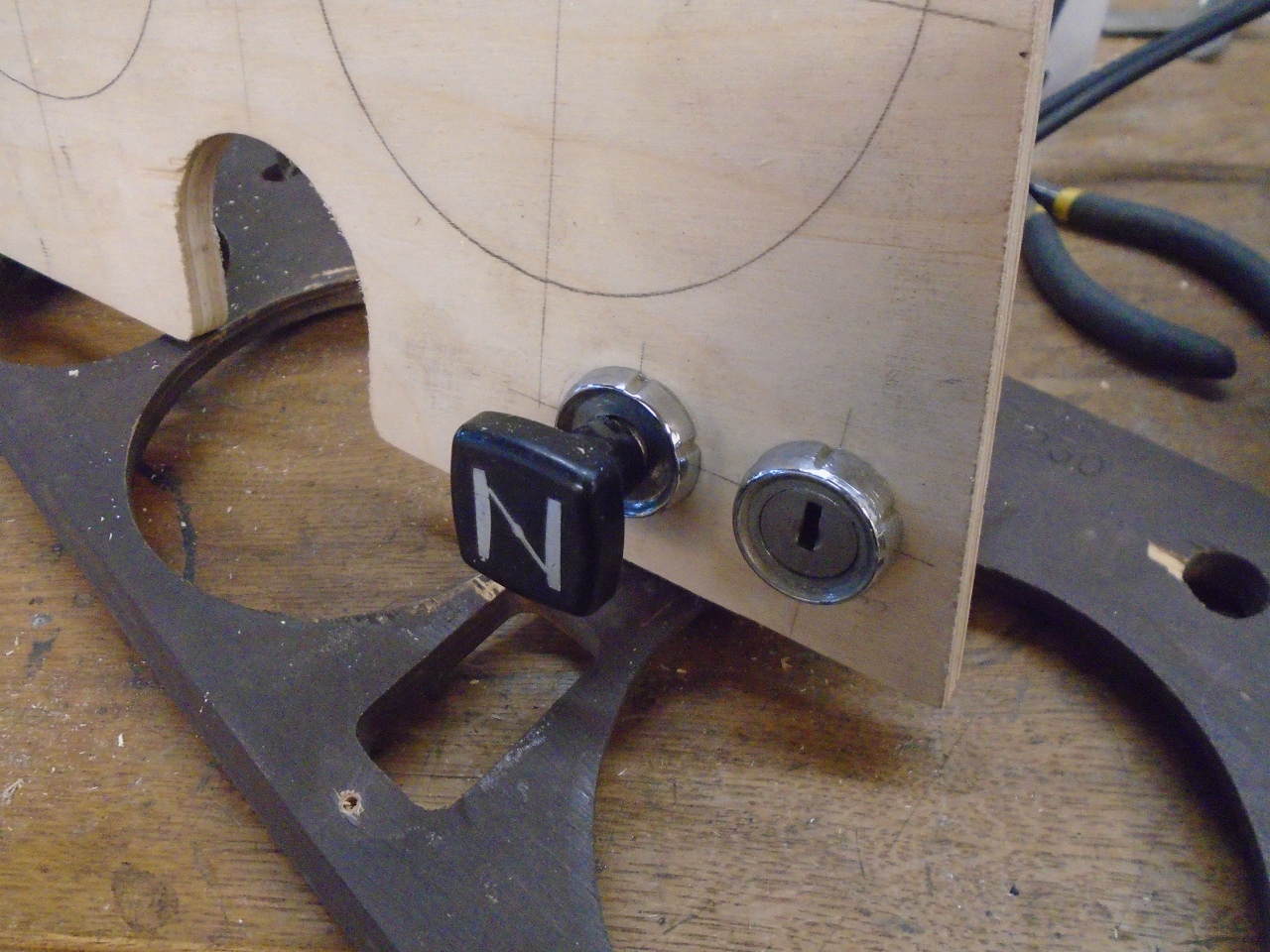

The driver's side panel was almost identical to the stock

one. Ignition switch, choke, tach, speedo, and air vent all

in stock locations.

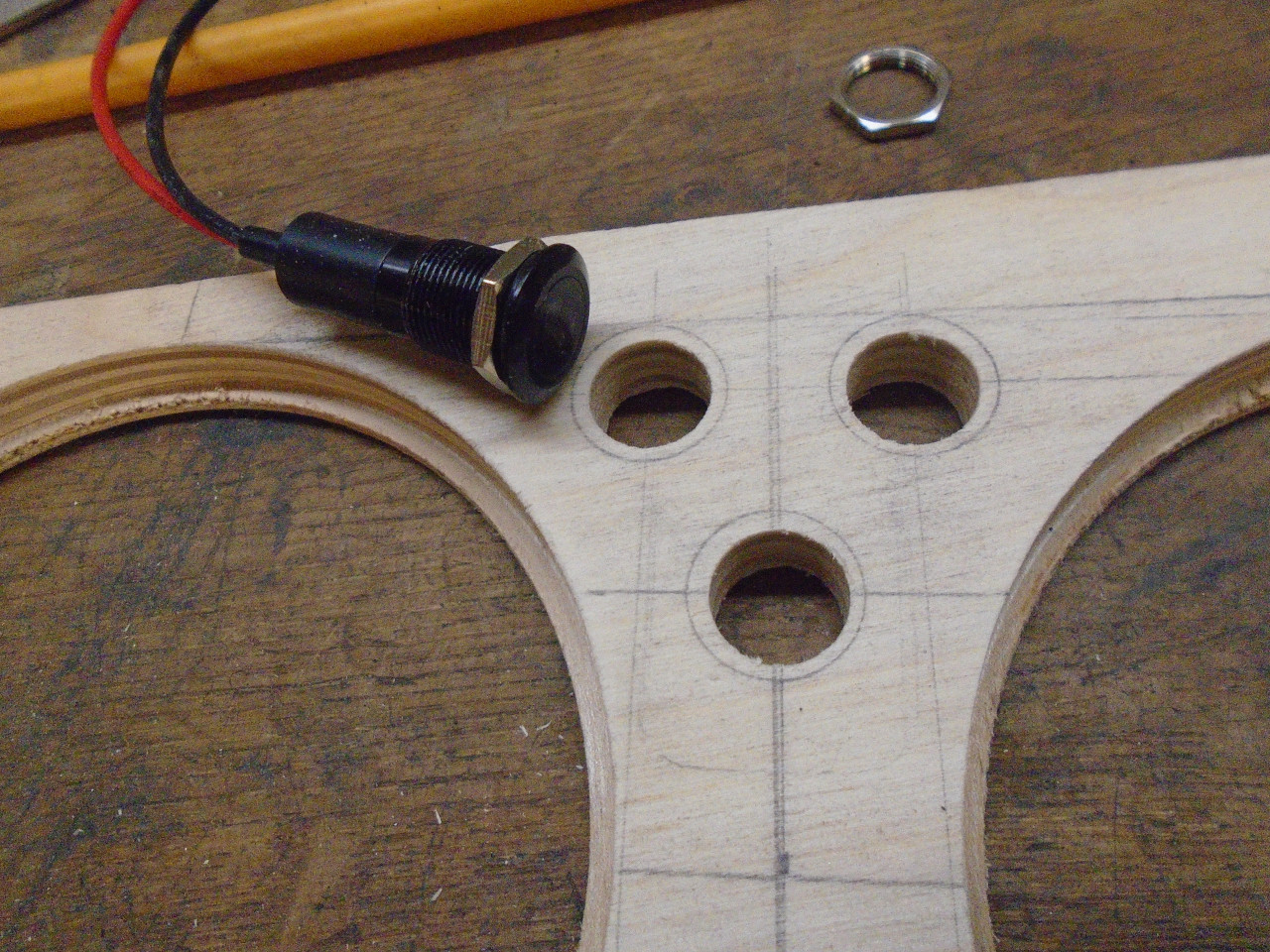

The only departure from stock on the drivers side was between the

tach and speedo. There was previously a hazard switch there,

but I moved that function to the switch bank in the center

panel. In place of it, I put in three indicator lights: one

for the PDWA brake fail, one for a hand brake warning, and one for

turn signal indicator (since you can never see the wimpy one on

the tach face in daylight).

With everything now fitting, it was time to think about

veneer. I went through this process once already with the dash on my TR6.

I considered a lot of wood species. I considered, but

discounted burl veneers as beautiful, but too formal for this

application. In the end, I came back to one of my favorite

woods--Zebrano, or Zebrawood. It was what I used on the TR6,

and I liked the look. And, I still had some on hand!

It will be sort of a common personal connection between the two

cars. So, Zebrano it was.

First, a little prep work. All of the panels were sanded,

and there was a little repair work here and there to fix grain

tear-out near the cut edges. I just used Bondo.

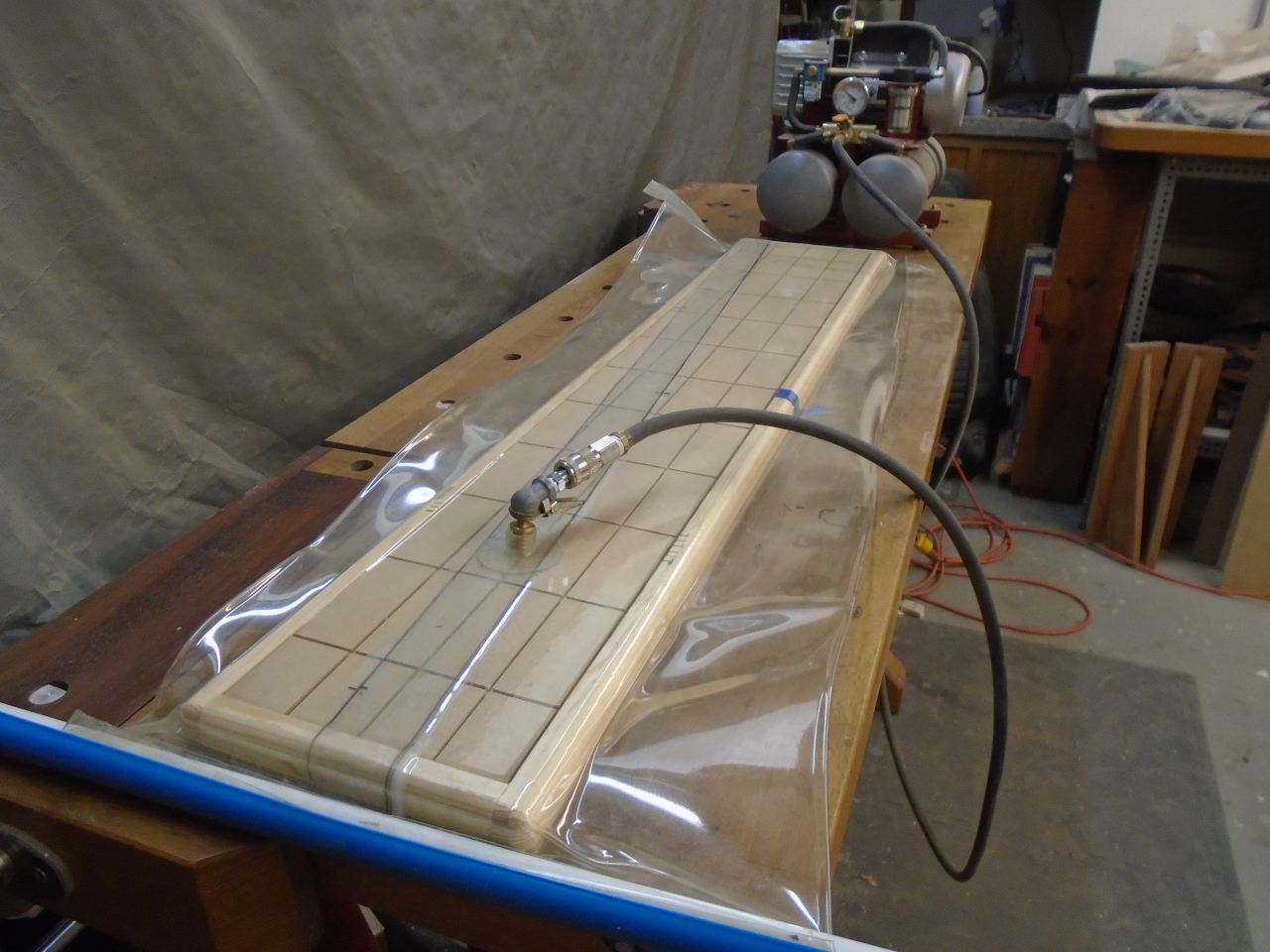

I use a vacuum bag for veneering, so I built this shallow tray to

hold the dash and the pressure board.

It is pretty common practice in veneering to apply a veneer to the

backside of the piece as well as the front. Called a balance

veneer, the idea is that it keeps the plies balanced so that

warping is less likely. On smaller or well constrained

panels like these, I don't think a balance veneer is strictly

necessary, but I decided to apply one anyway. For one thing, it

would bring the final thickness of the veneered panels to just

about exactly what the originals were.

Balance veneers are usually a cheaper or lower grade veneer than

the finish side veneer. This is a species called

Okoume. It comes from Africa, has a grain like mahogany, but

a pink color like cherry. It's pretty inexpensive and often

used as a balance veneer.

So, I spread glue on the panels, set on the veneer pieces, put on

the pressure board, and slid the assembly into the vacuum

bag. The bag is made from heavy clear vinyl--the same

material used to make rear windows for LBC convertible tops.

The vacuum pump is something I built a few years ago, and it is

overkill for this application. A simpler pump would do as

well, and I've heard of folks having success with a shop vac, or

even one of those vacuum bagging devices for food storage.

After an hour or so, the pieces came out for trimming.

Then it was time for the main event. I taped across the

joints between the panels on the backside to keep them properly

aligned so that the grain of the Zebrawood would be continuous

across the joints. I did leave a little gap in the joints so

I could get a scalpel in there to separate them. The veneer

sheet I had was just barely as wide as the dash

panels. This made me nervous, so I taped a narrow strip of

veneer to one edge so that alignment wouldn't be quite so

critical. Edge joining veneer like this is pretty

common. The cutout pieces are in the tray so that the

pressure board is supported in the empty areas.

After clamping, it was trimming time. I used a sharp

scalpel, trying really hard not to get blood on the veneer.

The grain aligned nicely.

By the way, I know some will ask. This is the glue I used.

Then on to the finish. Choosing a finish coating can be

confusing. I've been a wood worker for many years, and have

used most of the common offerings at the big box stores.

Most of them have worked OK. But for a dashboard, which is

essentially an outdoor application for all but the most pampered

cars, I wanted something top notch. On the TR6 dash (which

is even more outdoors than for a GT car) my research led me to

true marine varnishes (not necessarily ones that have thee word

"marine", or "spar" in their name). I chose one that is

popular with the wooden boat crowd. It comes from Holland, I

believe.

The instructions recommend at least seven coats for non-tropical

use. I applied nine coats over about a two week

period. The can says to wait 24 hours between coats, but for

me in my chilly shop, 36 to 48 was more like it. Then after

the last coat, a full week before hand rubbing. I rubbed the

finish to a pretty high gloss, then backed it off to a little more

of a semi-gloss.

After the finishing, here were assorted bits and brackets to

fit. They were all stripped and replated.

Then, to re-create the brown color on the backside and on the

circumferences of the holes, I masked off the varnished areas.

Finally, it was time for assembly. One little detail on the

switch panel was to install these little threaded inserts.

They are heated with a soldering iron so that they melt themselves

into the holes in those bosses.

One little oops realization I had while fitting the switches was

that there was now not room for the lower two mounting screws for

the center panel. I worked around this crisis by making

these little gizmos. They screw to the lower corners of the

panel, and provide a place to screw the switch panel to, and also

have studs to take the place of the original lower mounting

screws. I just hope access to the backside for getting nuts

on the studs isn't a problem.

The new center panel. I have new bezels on the way for the

right two gauges, so they will match the two originals. The

different font on the new gauges still bothers me a little.

The passengers panel.

Drivers panel.

The whole enchilada. I didn't notice that the left air vent

wasn't installed. The panels are sort of propped in

approximate position.

This was a bit of a marathon project. I think I've been

working on it for a couple of months. The result seems OK,

and I can't wait to see it in the car. Cost was probably a

couple of hundred dollars for the switches and the additional

gauges.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages