To my other GT6 pages

August 17, 2019

Steering Rack & Pinion

I

think just about all Triumph cars of this era sported rack and pinion

steering. This kind of steering provides very responsive control

with good feedback from the road to the steering wheel.

My

steering sassembly was rusty, dirty and greasy, but it seemed to be

working OK. I decided to take it apart and at least refresh the

50 year old lubrication. I also found a few small things I could

improve.

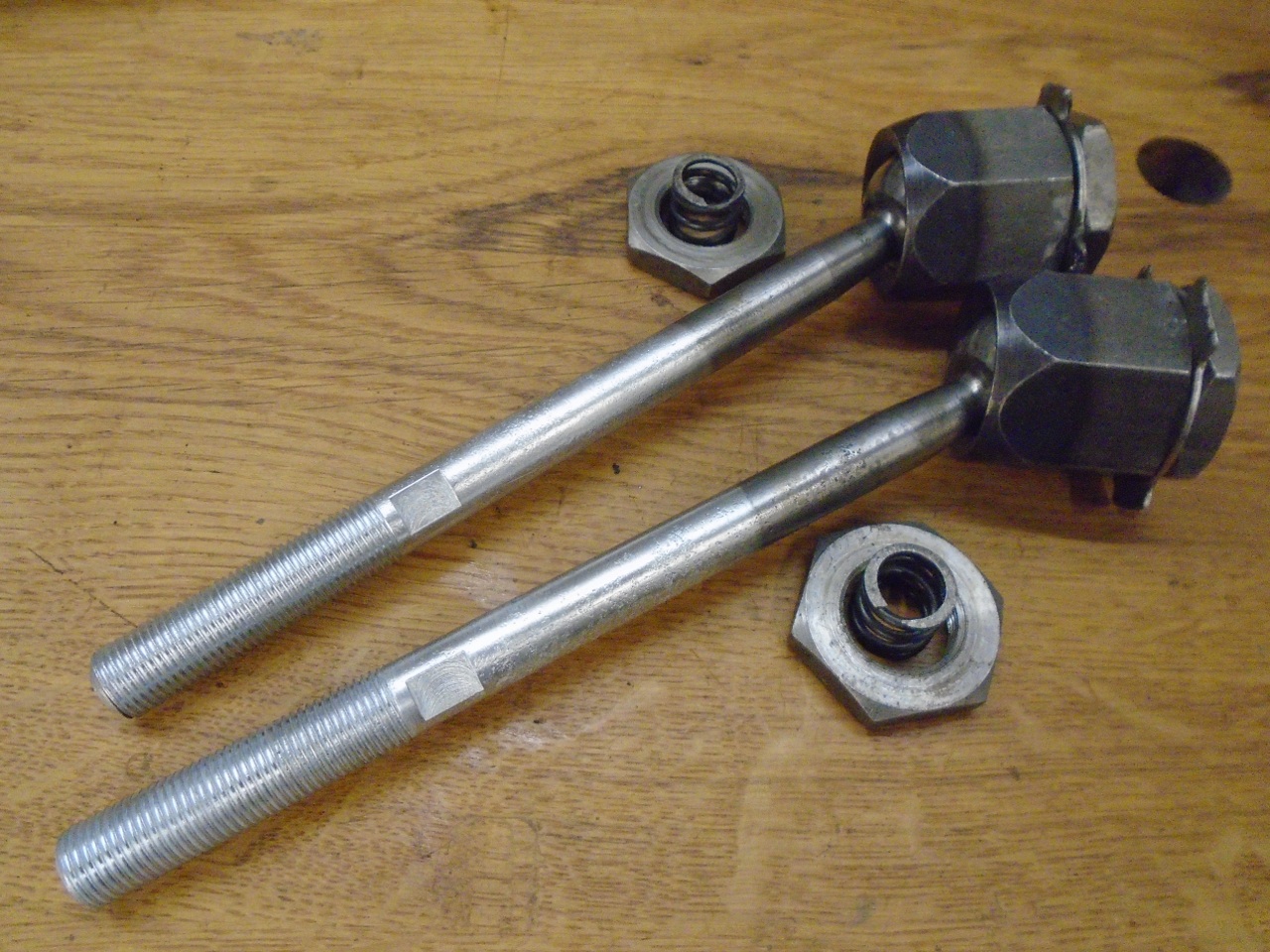

Under

the tired bellows boots are the inner ball joints for the tie rods.

I was actually happy to find a lot of grease in there. It

means that the joint had not lost lubrication.

Here is one place where

I made what I consider a small improvement. When adjusting toe-in

on thece cars, the tie rod ends have to be screwed in or out on the tie

rod. The problem is, if the threads are a little tight in the rod

end, turning it just rotates the tie rod. The usual remedy is a

pair of Vice Grips on the tie rod. I was looking for something a

little more civilized than Vice Grips. I had seen tie rods

somewhere that had flats milled into them so a wrench could hold them.

So that's what I did. Milled flats for a 3/8" wrench.

Also zinc plated the parts of the rods that are exposed to the elements.

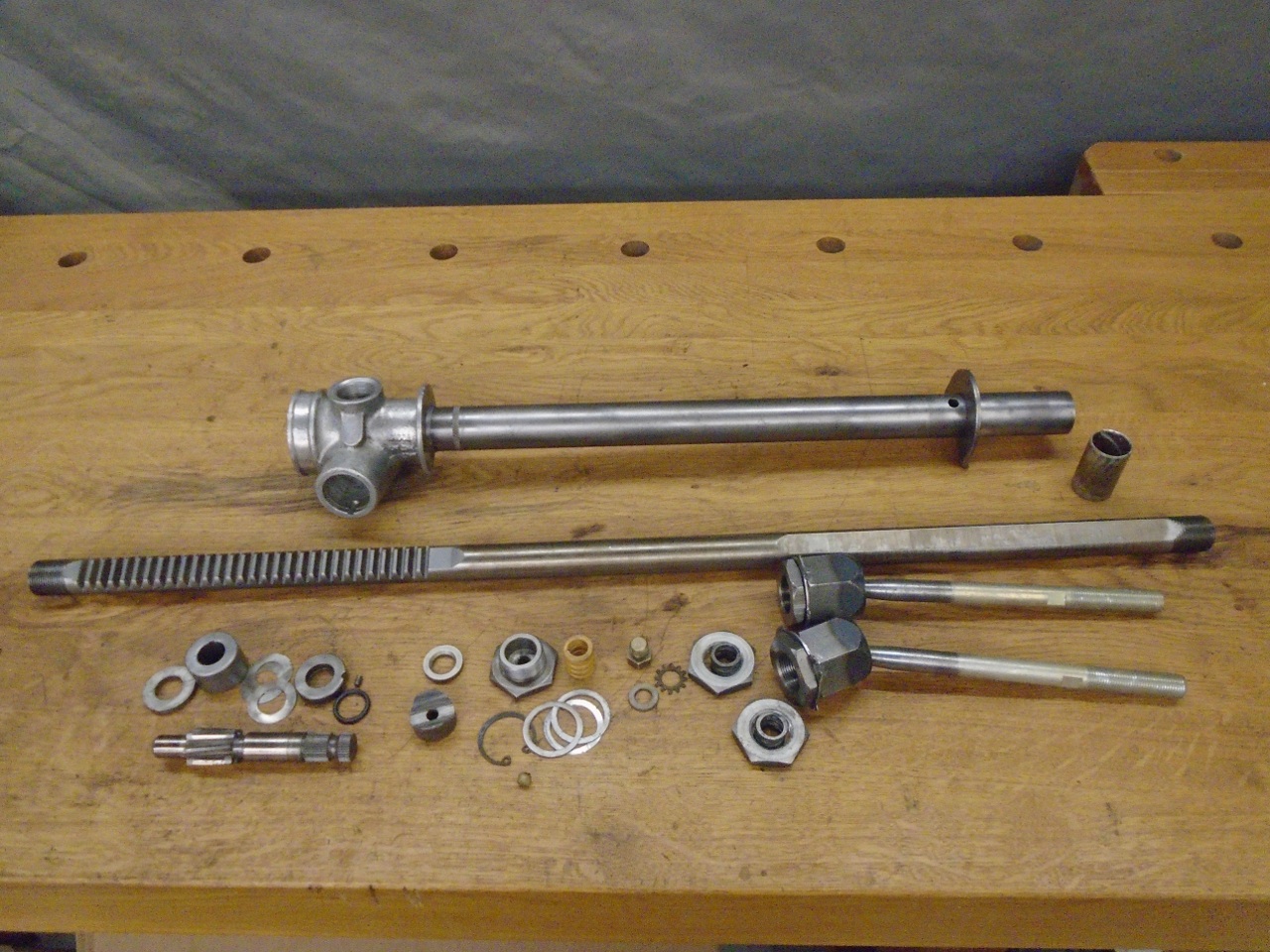

Then cleaned up the rest of the parts for a good inspection.

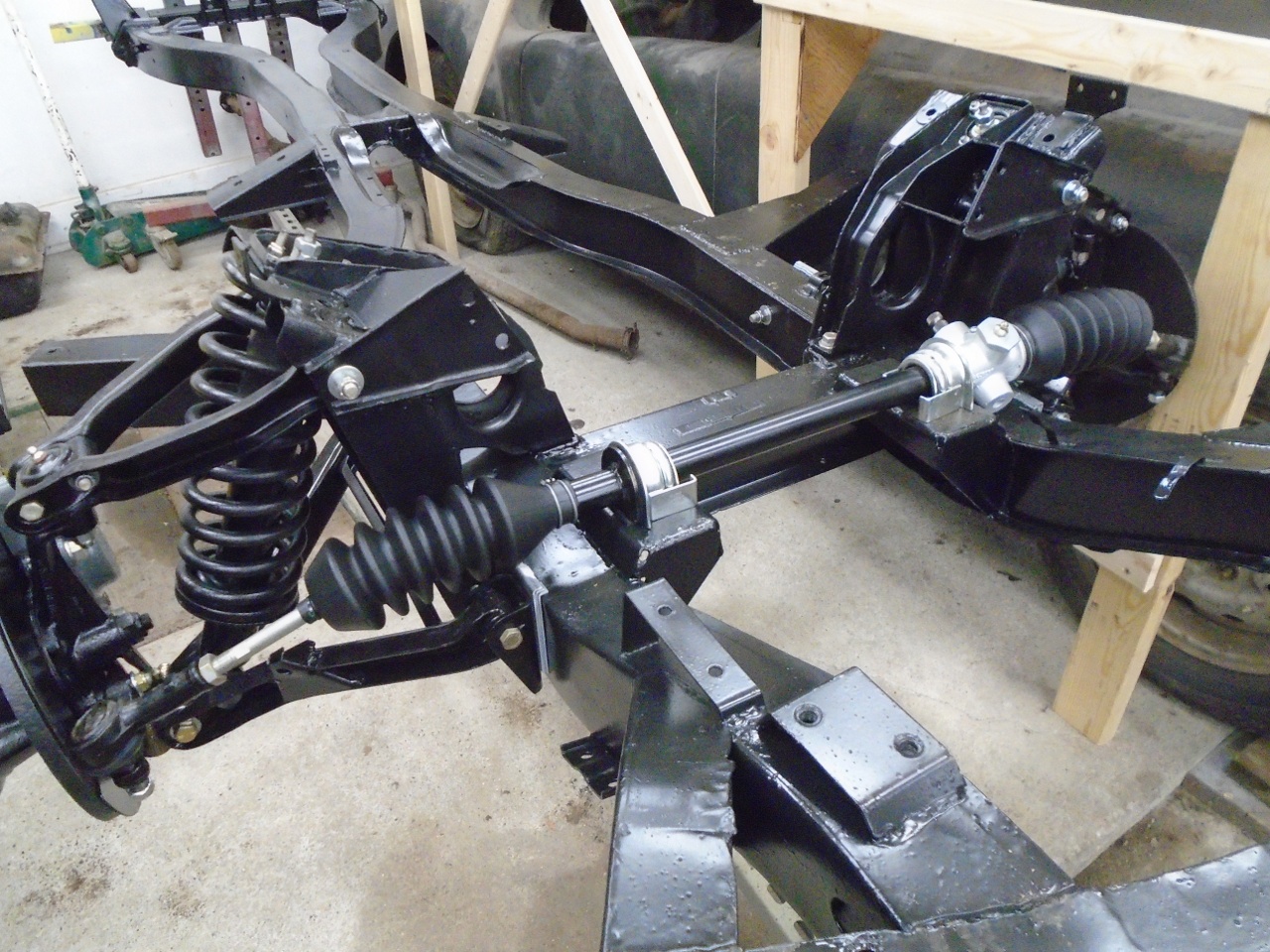

Powder

coated the steel rack tube. I bought a new end bush, but the

original was a better fit on the rack, so I put it back in.

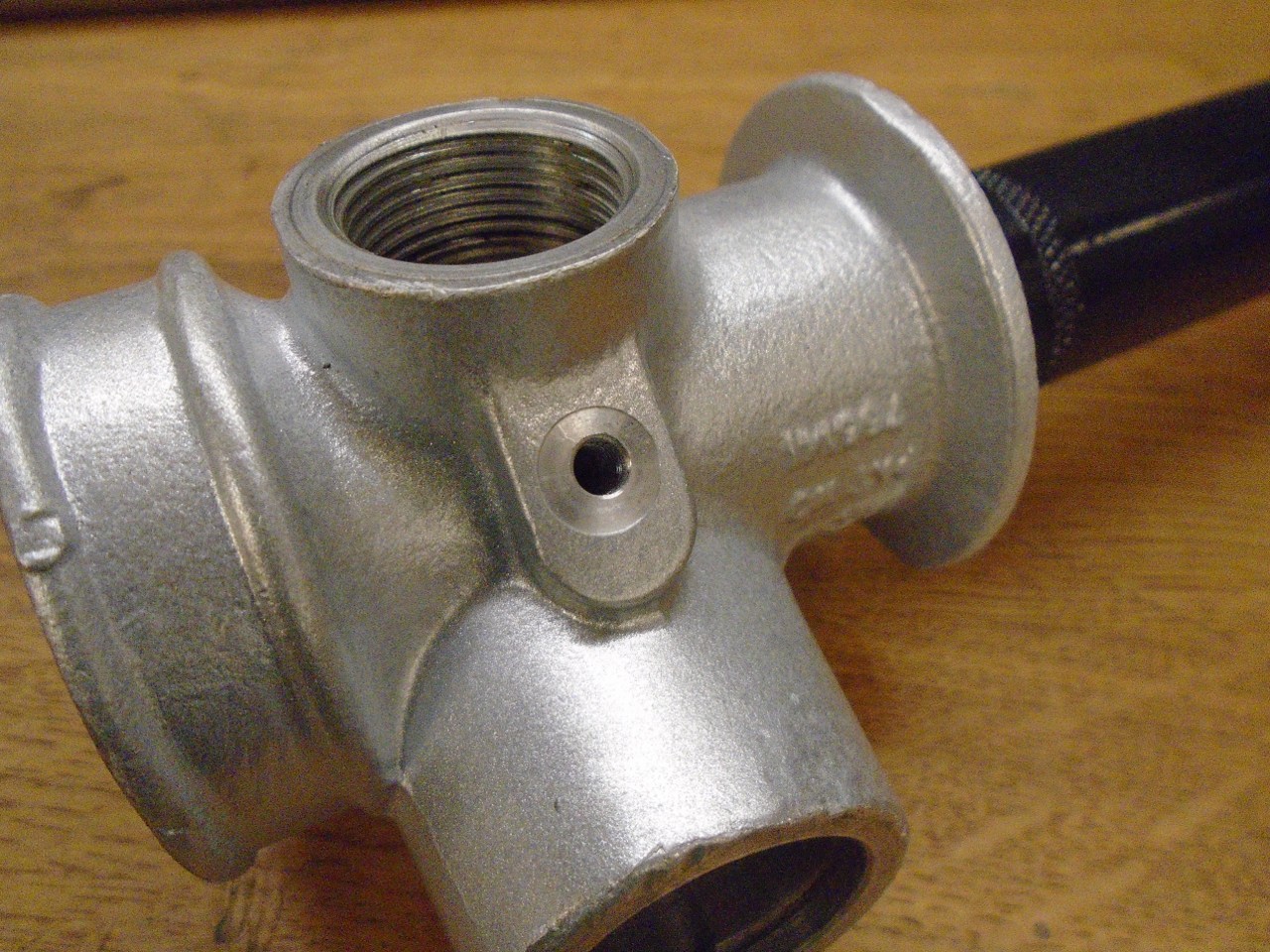

I remembered

how Triumph liked to ground the horn switch--with a wire terminal under

a plug in the rack lube hole. Factory instructions for greasing

the rack were to remove the plug, replace it with a grease zerk, pump

some grease, and then remove the zerk and replace the plug and ground

wire. That has always seemed a little more convoluted than

necessary to me. I found a nice place for an explicit ground

screw, then drilled a hole and tapped it. There is quite a bit of

meat there, so the hole is blind and doesn't communicate to the inside

of the rack housing. This will allow a full-time zerk on the

steering box.

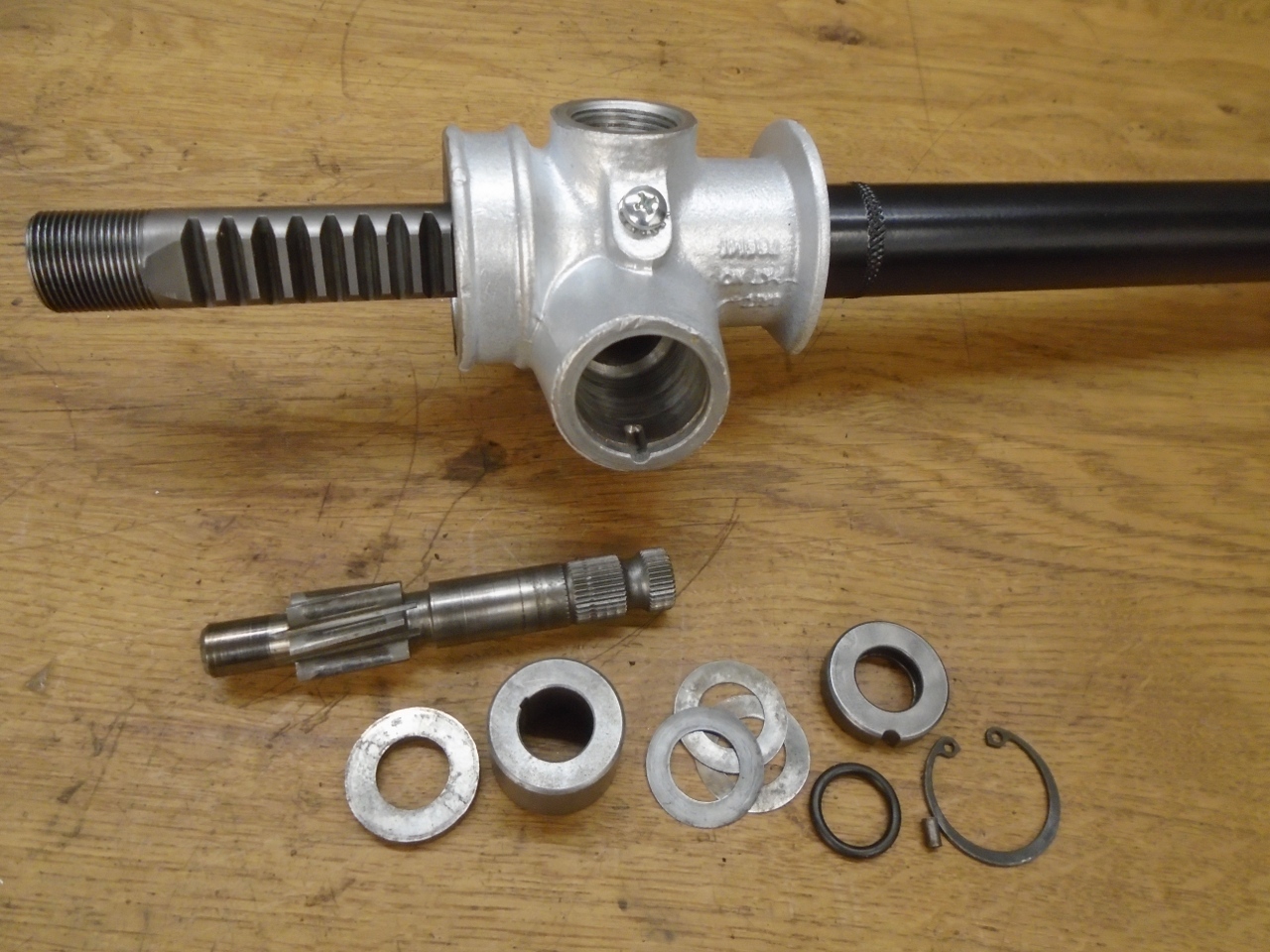

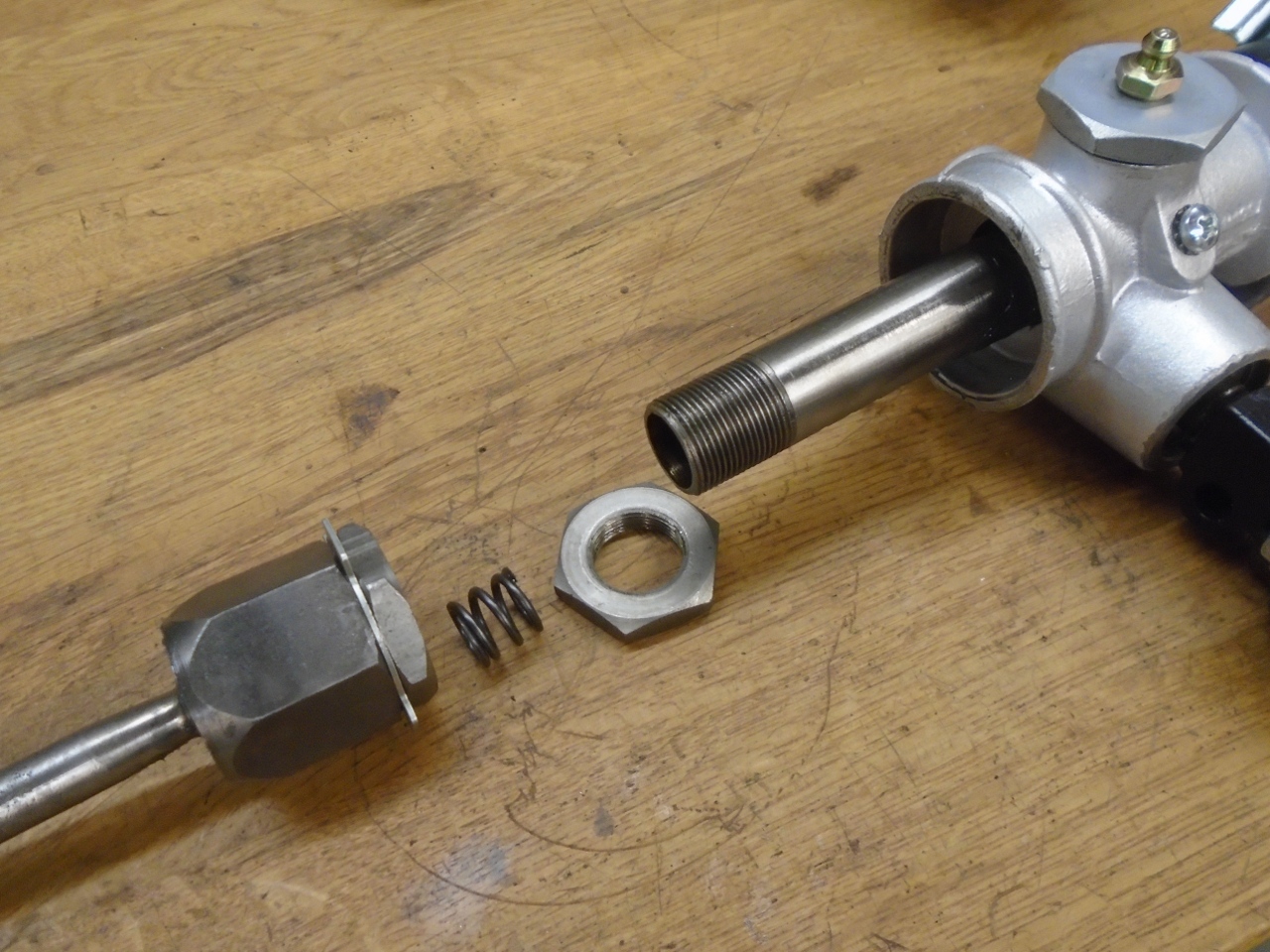

I

lubed up the rack and installed it in the tube. It was then time

for the pinion and associated parts. Pinion end play is adjusted

with shims. A dry fit showed that the original shims still

yielded smooth operation with undetectable play (undetectable by hand,

that is). The only replaced part was the O ring that seals the

pinion shaft.

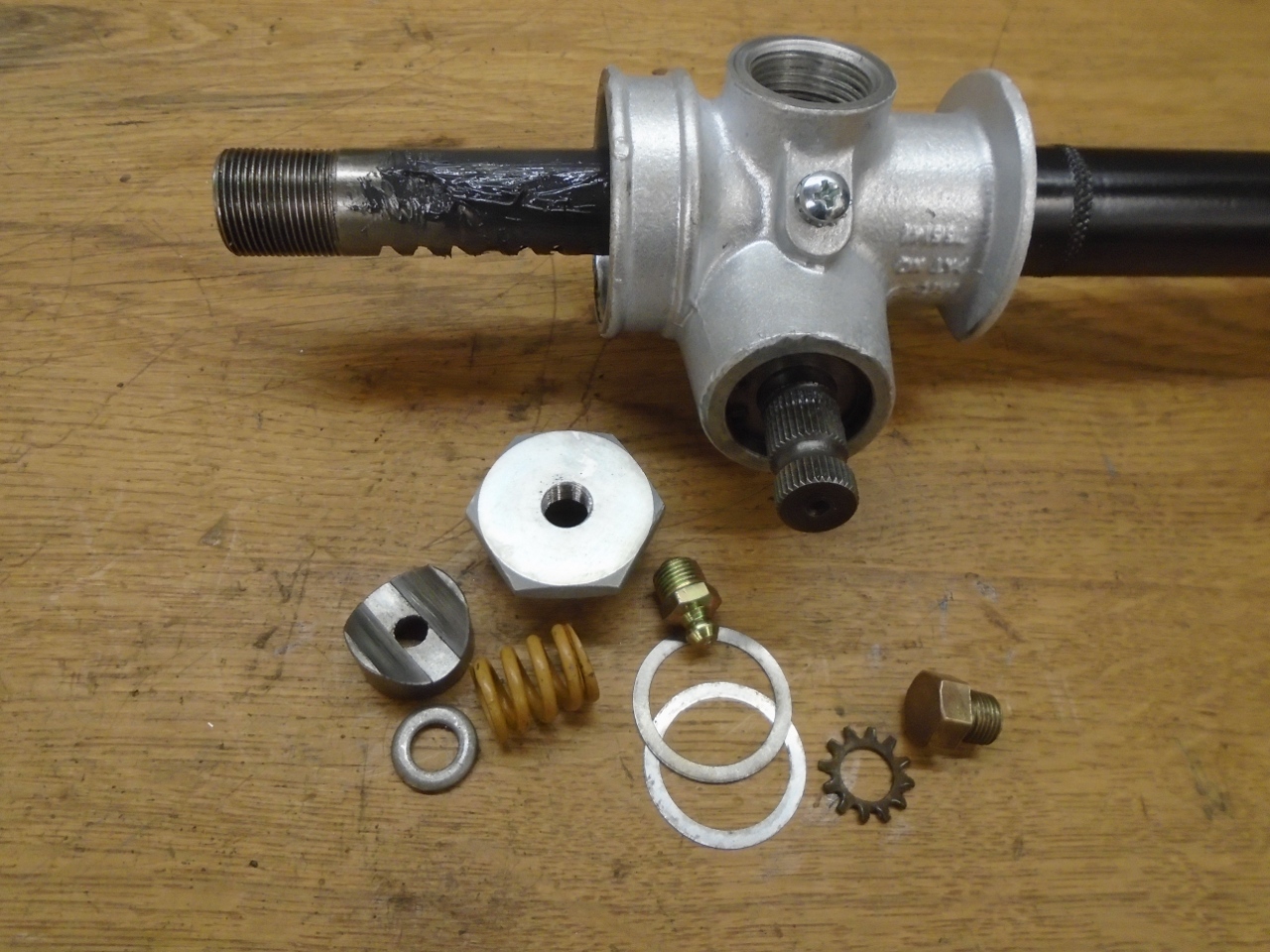

The

remaining pieces that go in the rack housing are those for the damper.

The damper "stiffens" the steering by a controlled amout to give

it a more positive feel. It consists basically of a spring loaded

wiper that bears on the rack just opposite the pinion gear.

Again, shims adjust the spring pressure on the rack. The brass plug is now excess.

With

the rack and pinion buttoned up in their housing, it was time to attend

to the inner ball joints. The large nut and the smaller cup form

a spherical space that the ball end of the tie rod is captured in.

A cap is screwed in to hold it all together. Shims under

the head of the cap adjust pressure on the cup to control play. I

had to remove the thinnest shim from one of the joints to get the firm

but smooth action I was looking for. This probably was due to

slight wear, but the tab washer also has an effect on the necessary

shims, and that is not a precision part. The other joint went

back together the way it came apart. After the fit was good, they

came apart again, got loaded with grease, and reassembled.

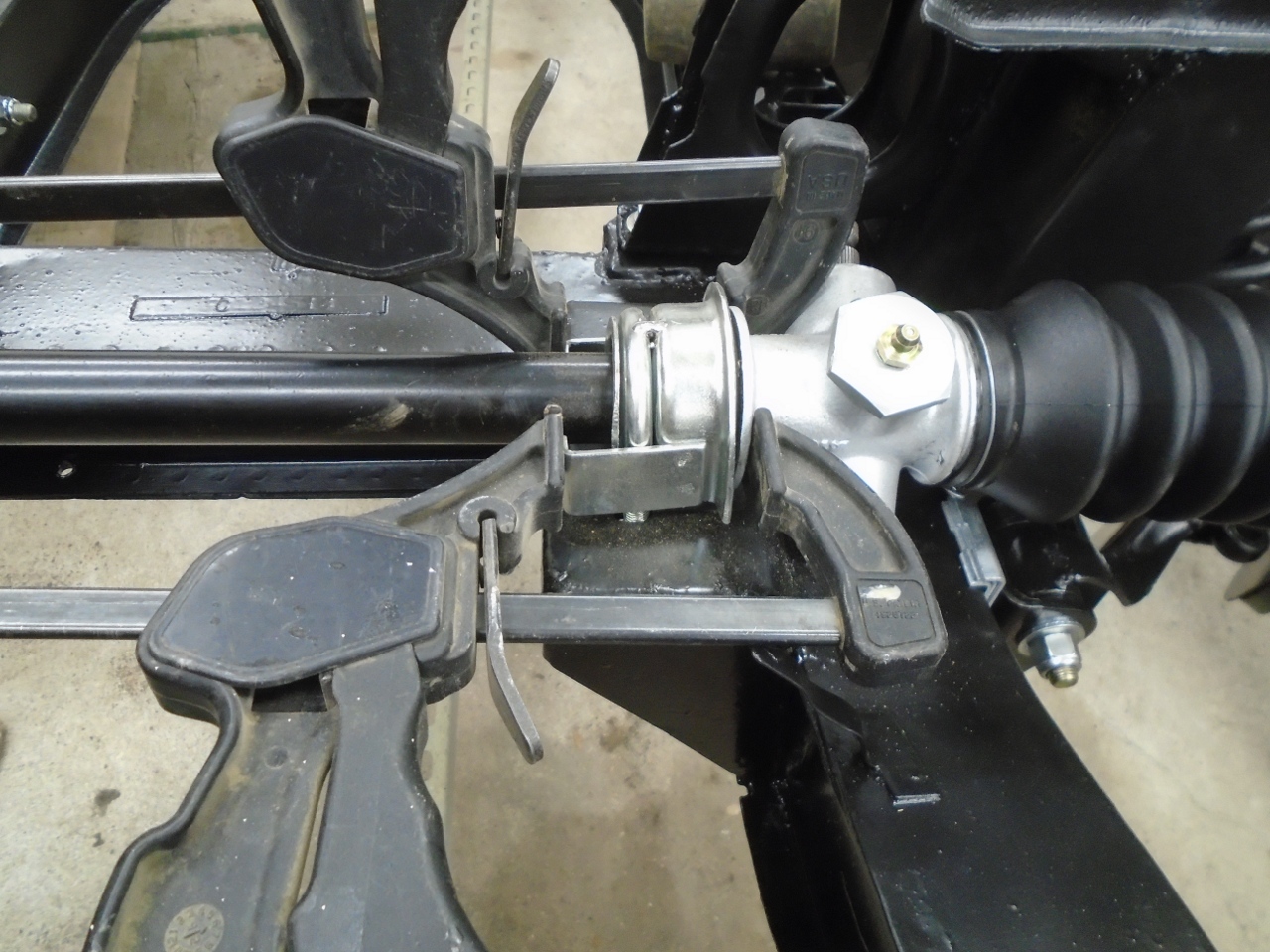

The inner ball joints screw onto the ends of the rack with a stiff spring to bias what little play there might be in the joints.

The boots can be a bit of a wrestling match to install, but they finally went home. Also got new tie rod ends.

The new U bolt mounts were to replace the ones that didn't come along quietly.

Just

in time, I remembered this little nylon button. It bears on the

rack under pressure form the right hand rubber steering mount. I

don't really know what it's for, but my TR6 had one, too.

To

prevent the rack and pinion assembly from shifting, the rubber mounts

need to be tightly captured between the U bolt brackets and the flanges

on the rack tube.

This job completes the front end of the frame, except for the anti-roll bar, which I can't seem to find.

On to the rear!

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages