To my other GT6

pages.

March 14, 2021

(pi day)

Exterior Lighting

I've spent the winter this year working on things that can be done

in the warm shop rather than in the chilly garage. The last

week or so was occupied, among a few other things, by the exterior

lighting assemblies. There isn't anything much remarkable

about these items. They are pretty much all Lucas products,

and so they do have their challenges as far as reliability and

longevity go. Most of the assemblies were complete without

much overt damage. The headlights must have been in a

different box.

Other than a few mods to enhance reliability or ease of

installation, the only major change in these parts was to go to

LED lamps. The motivation for this was primarily current

draw. I anticipate adding some significant loads to the

electrical system, and I can offset those by reducing the load

from lighting. Excluding headlights, with all exterior lights on,

I calculate the load to drop form nearly 18 amps to just a little

over two amps by going to LEDs. (I realize that having all

exterior lamps on at the same time would not be all that common,

but it could happen.)

To jump ahead to a particular assembly:

Front

Park/Turn Assembly

Headlights

License

Plate Light

Rear

Turn Signals

Reverse

Lights

Tail/Brake

Assembly

Front Park/Turn Lights

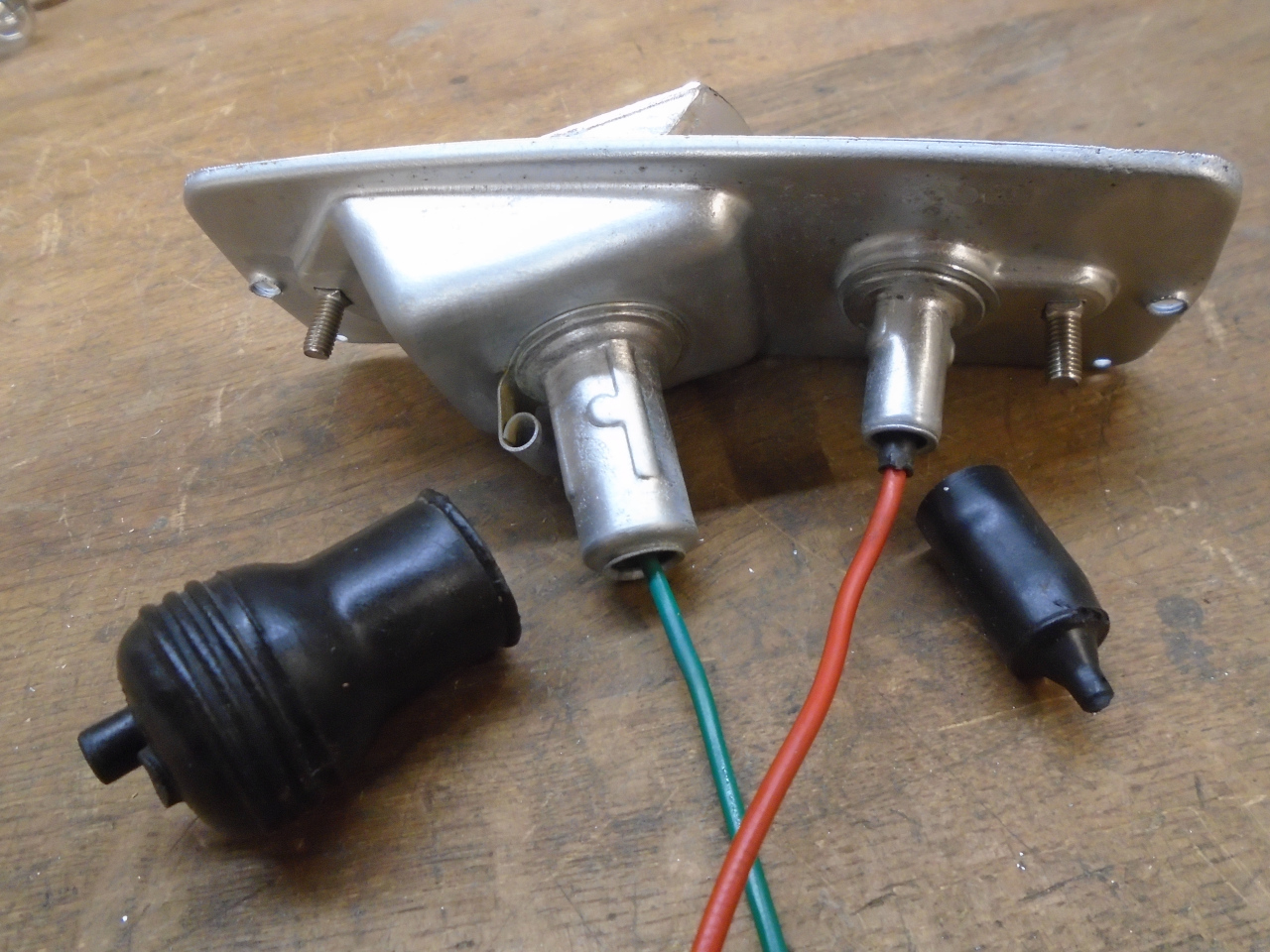

The front park/turn signal lighting assembly contains a socket for

a standard 1156 type lamp for the turn signals, and a socket for

the smaller 1895 type lamp for the parking lights. Standard

wattage for these lamps would be about 27 and 4 watts,

respectively.

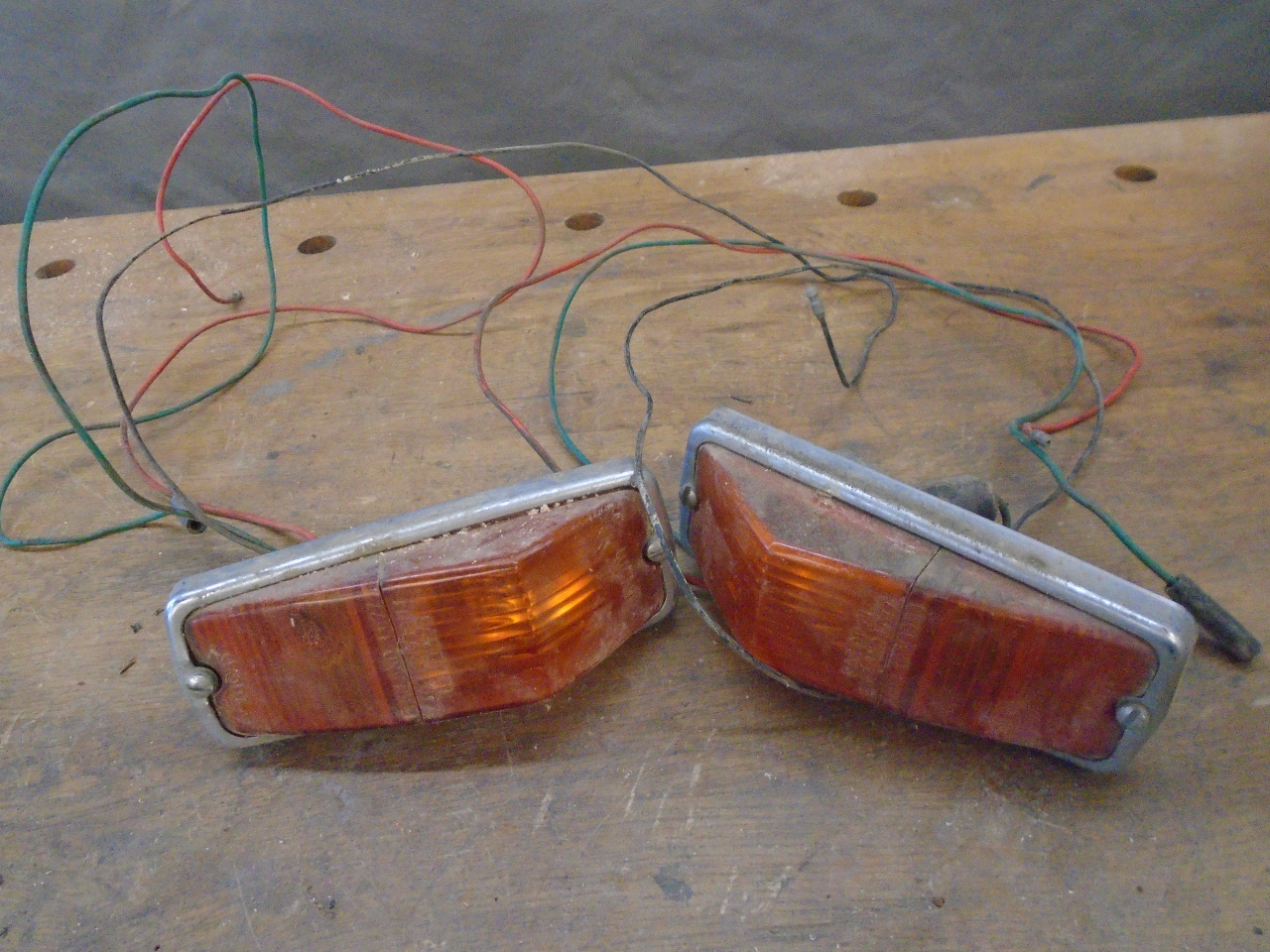

My units looked pretty grody, but from the outside, didn't appear

to be damaged.

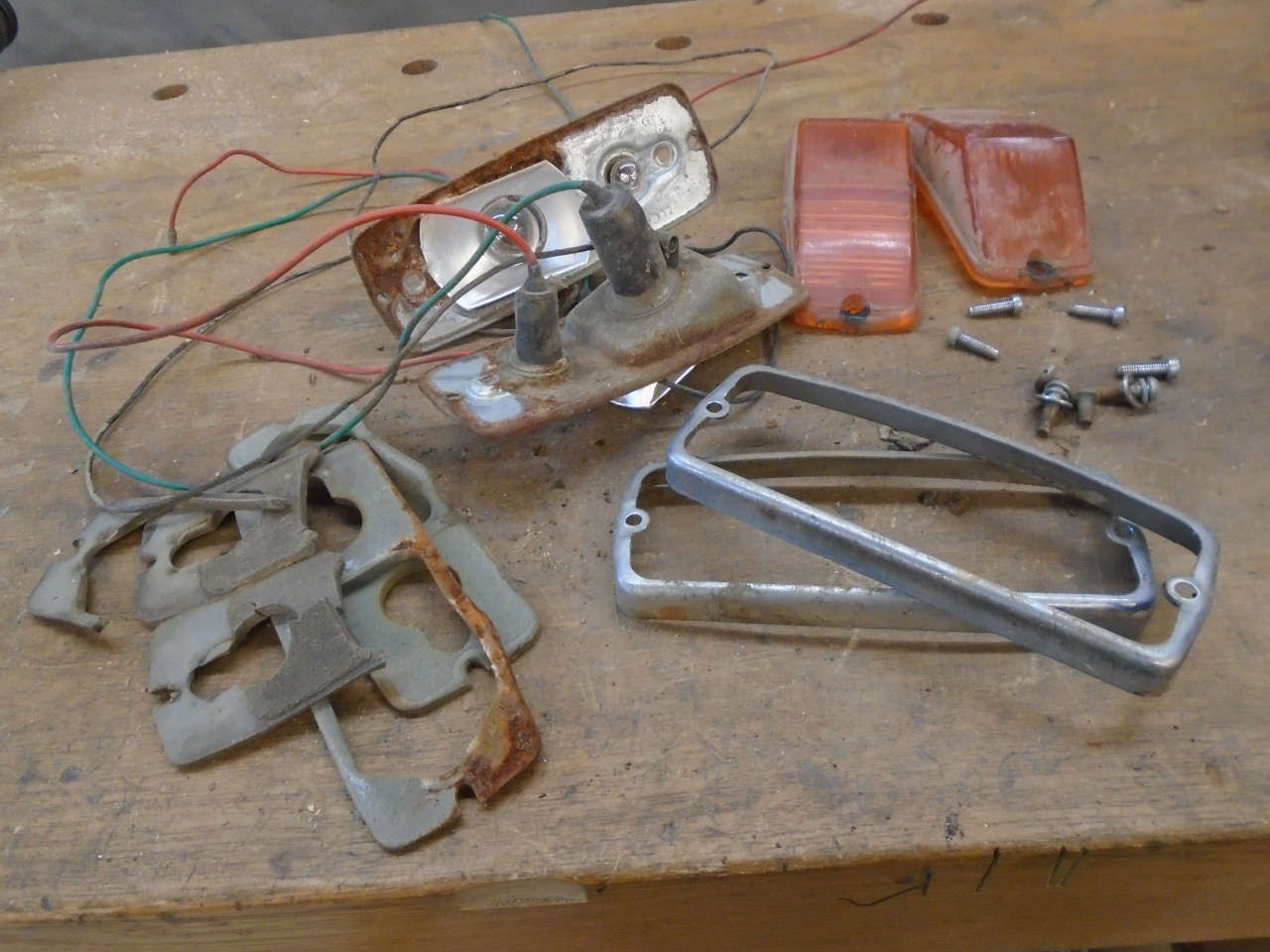

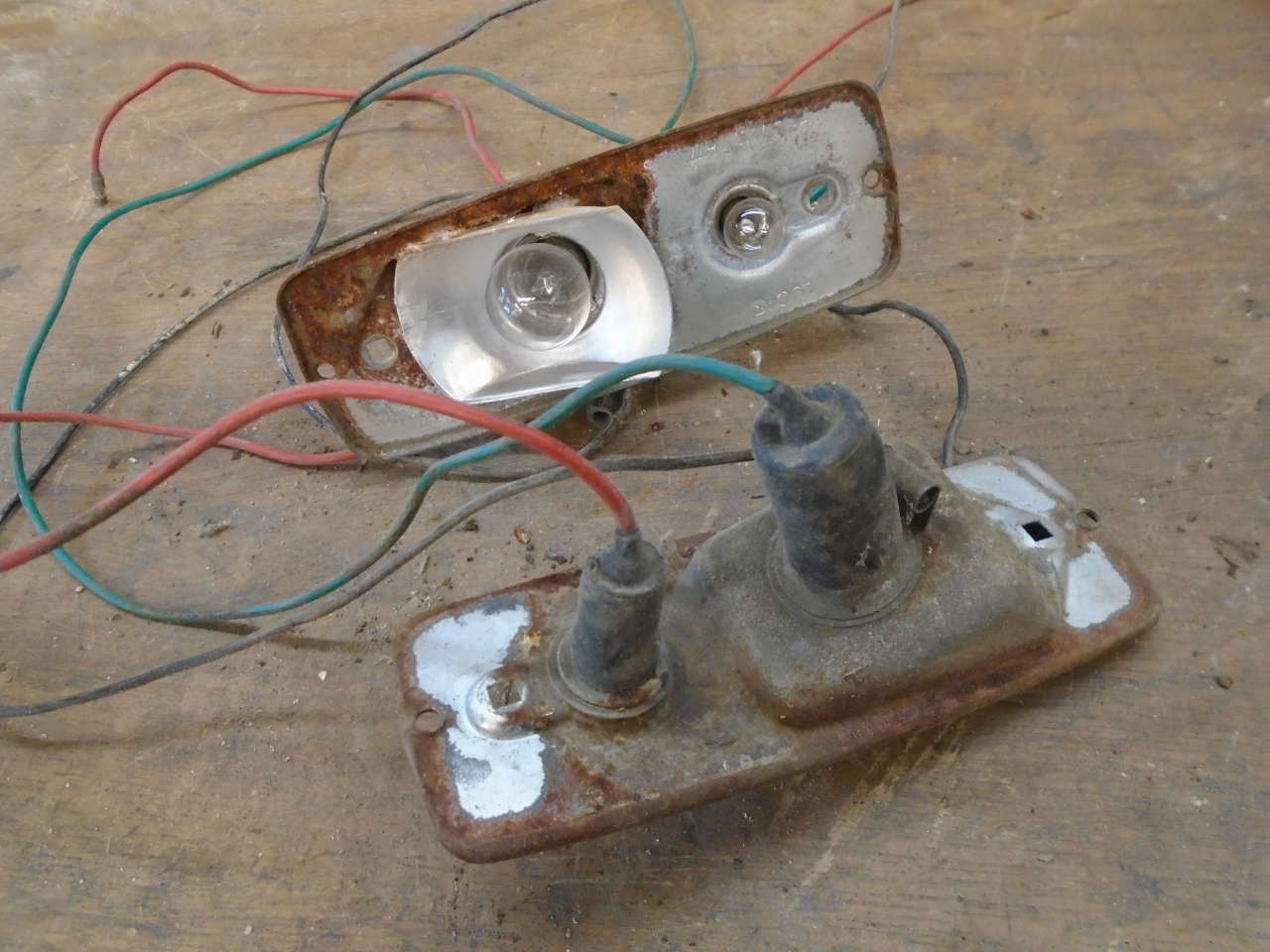

Inside, they were a little worse. The zinc plated steel

housings had quite a bit of rust.

The rust is not difficult to remove, but since I thought there was

enough of the zinc plating left to save, I chose a chelate type

rust remover, which will not attack the zinc or the aluminum

reflector. In this case, it was Evaporust. It's easy

to see the difference between the zinc and the bare steel

surfaces.

I considered paint to protect the bare steel, but in the end

decided to zinc plate the housings. My hesitation was with

the anodized aluminum reflector. It didn't seem practical to

remove it, and I wasn't sure how it would react to the plating

process. I ended up masking the reflector with some lacquer

paint. It dies quickly and is easy to remove.

I tried the process on one housing, and it ended up looking pretty

good compared to the other one.

While fiddling with these housings, I noticed that they had square

holes for the mounting screws. However, the mounting screws

I found were just ordinary 10-32 machine screws, though I can't be

sure they were original. I'd seen these square holes on

Triumph lighting assemblies before. My TR6 had them, and

used a carriage style bolt with a short square shank that snapped

in to the square hole. It seemed unmistakable what the

intent of those holes was here, and whether Triumph opted to just

use ordinary fasteners, or whether the original fasteners had been

lost, it seemed appropriate to go back to the square shank

hardware. They should make installation a little

easier. Mostly, they snapped in and are self-retained,

One had to be helped with a drop of CA glue. A side benefit

of this is that the assembly can be removed or installed without

removing the lenses.

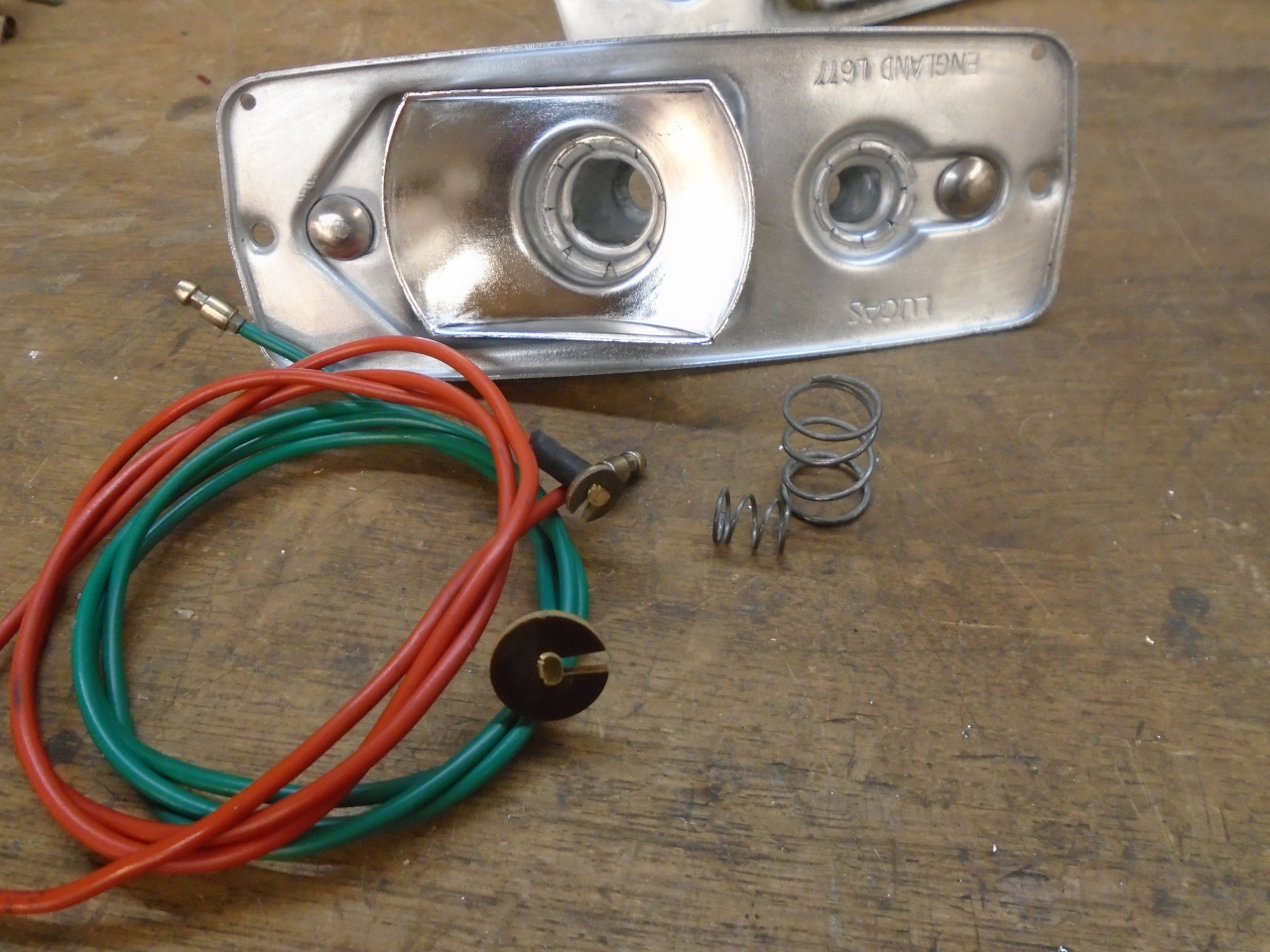

Next up was to clean up and install the contacts and lead wires

for the lamps, and push on the cleaned up rubber boots. I find it

not unusual to find 50 year old British rubber parts to be in very

good shape.

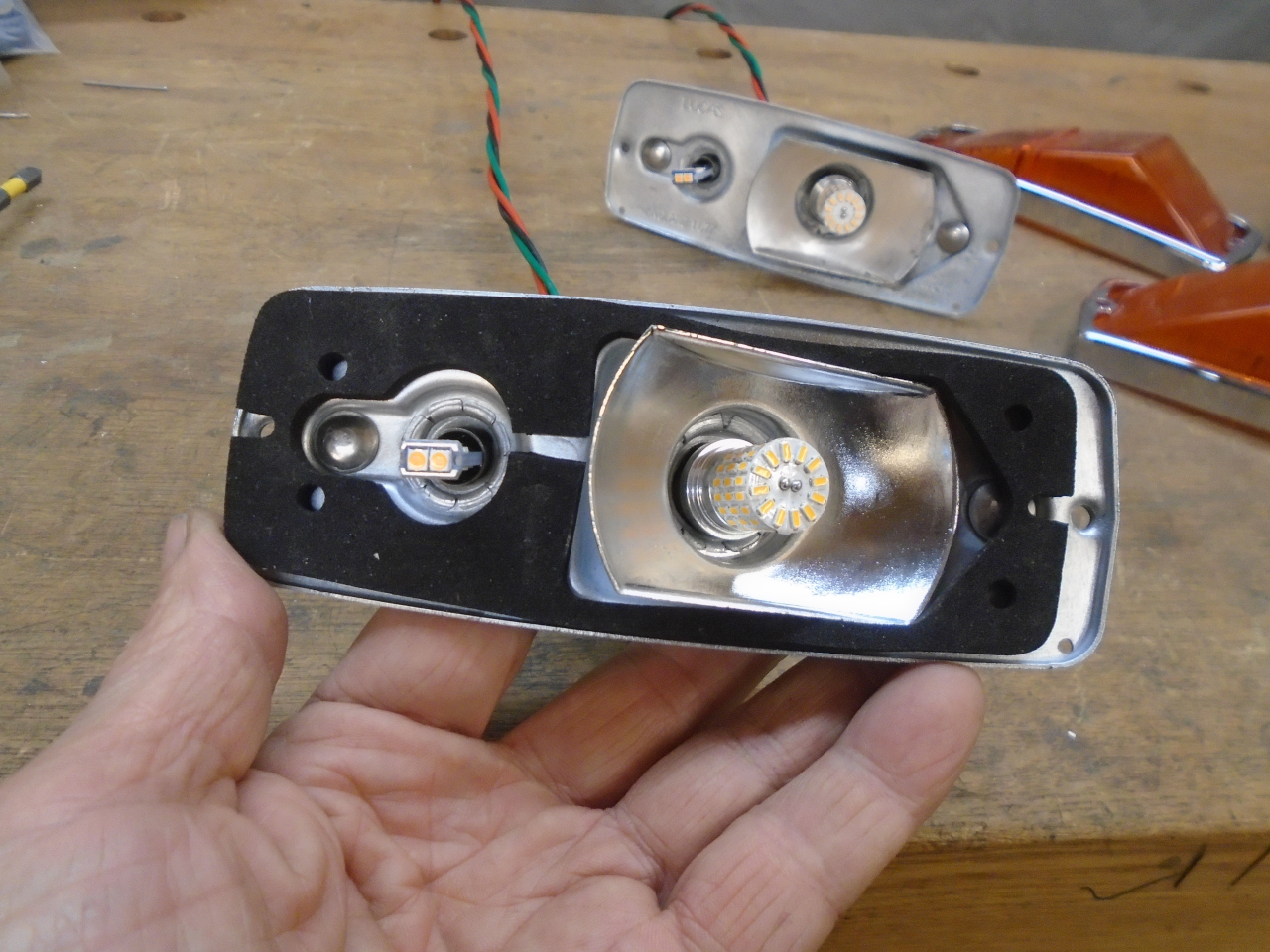

Then install and test the LED lamps. A word about replacing

incandescent lamps with LEDs: Incandescent lamps provide a

broad spectrum white light, and this light can be filtered by

colored lenses to allow only the desired color range

through. It's a little trickier with LEDs. Basic LEDs

emit a pretty narrow spectrum of color. White LEDs are

typically made by starting with a blue LED, and adding a phosphor

to absorb some of the blue light and re-emit it as light more

towards the yellow orange part of the spectrum. This is

engineered such that to the human eye, the combined light looks to

be a shade of white, but is not broad spectrum like incandescent

light is. For this reason, white LEDs can give disappointing

results when used with colored lenses. It is possible that

the light frequency that would pass through the lens may not even

be present in the LED light. For this reason, we need to

pick LEDs with a color that matches the lens color.

These are amber LED lamps. You can't normally tell the color

of an LED until it is on.

Cleaned up the lenses...

...and prepared for final assembly.

Oops! One of the brand new lens gaskets was too short!

No worries. This is a piece of 3/16" closed cell neoprene

foam. The material is pretty similar to the store-bought

gaskets, but a little finer texture, and maybe a touch

firmer. Paper template was made from the fixture itself.

Home made gasket fits way better than the bought one.

Final assembly.

Headlights

My headlight assemblies were just dirty, with a little corrosion

in a few areas.

Blasted the buckets and the lamp carriers, and powder coated them.

Cleaned and inspected the pigtail wires and connections.

Installed new adjusters. These were the only parts I had to

buy for the headlights.

And put everything together.

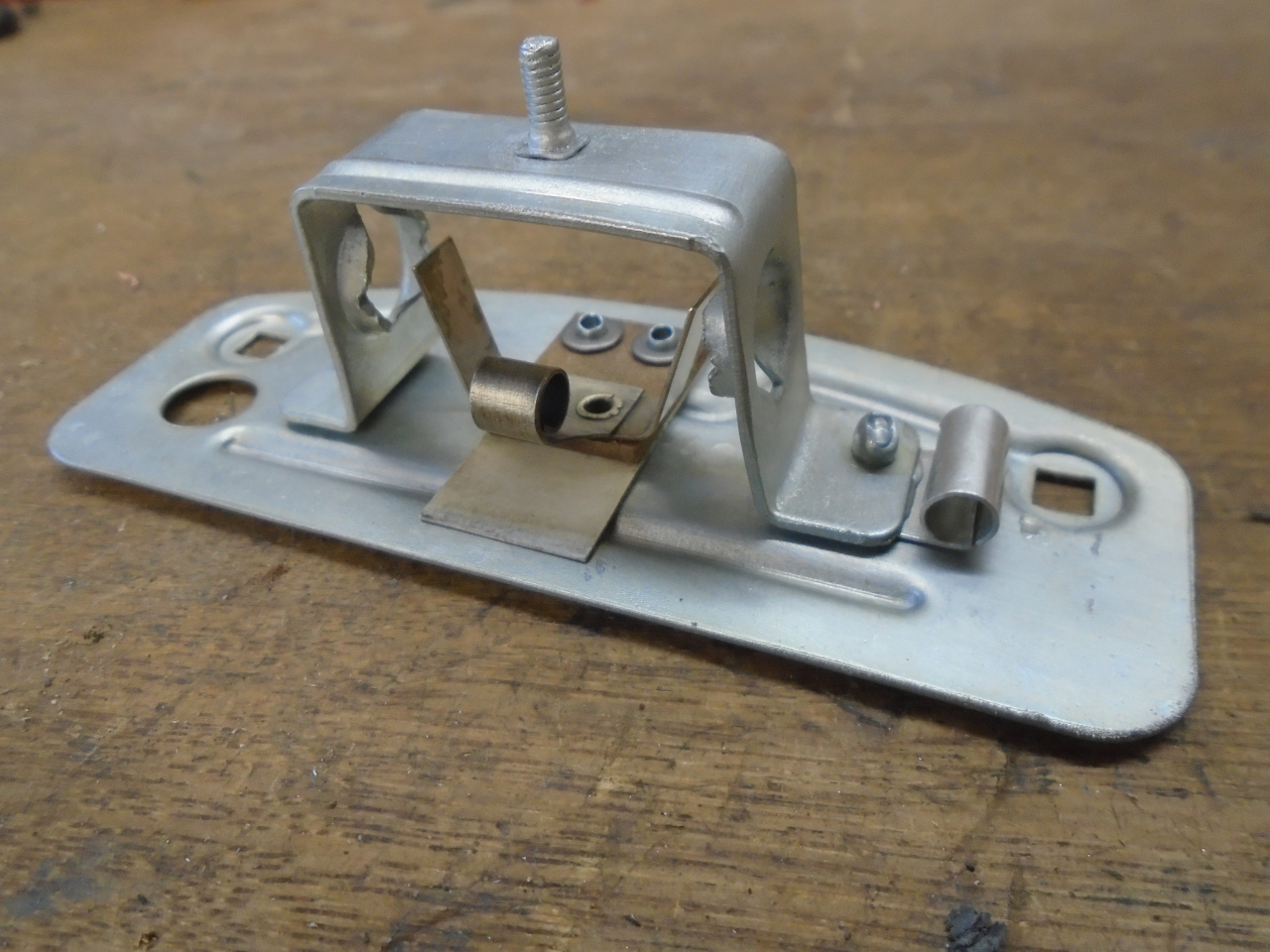

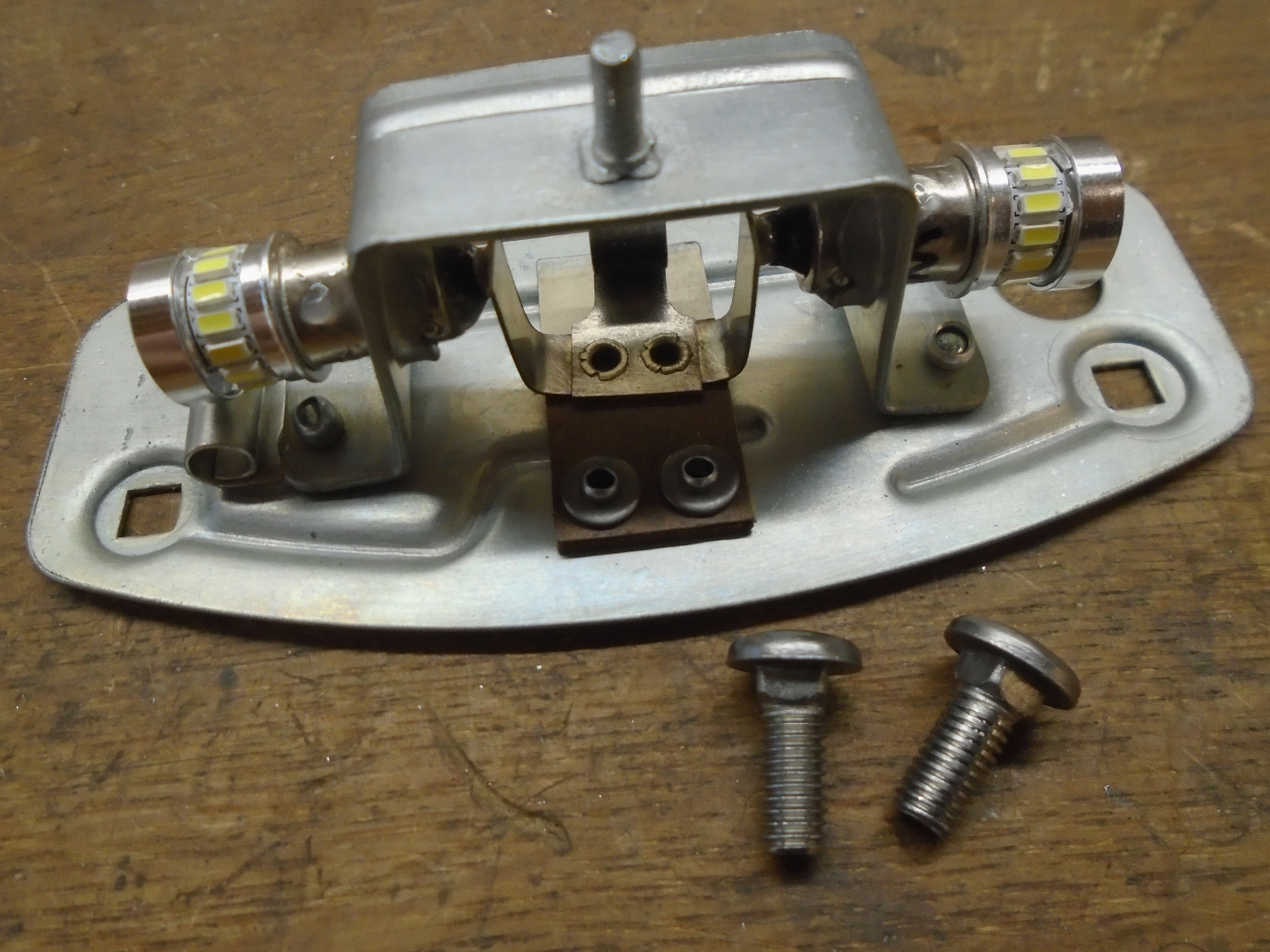

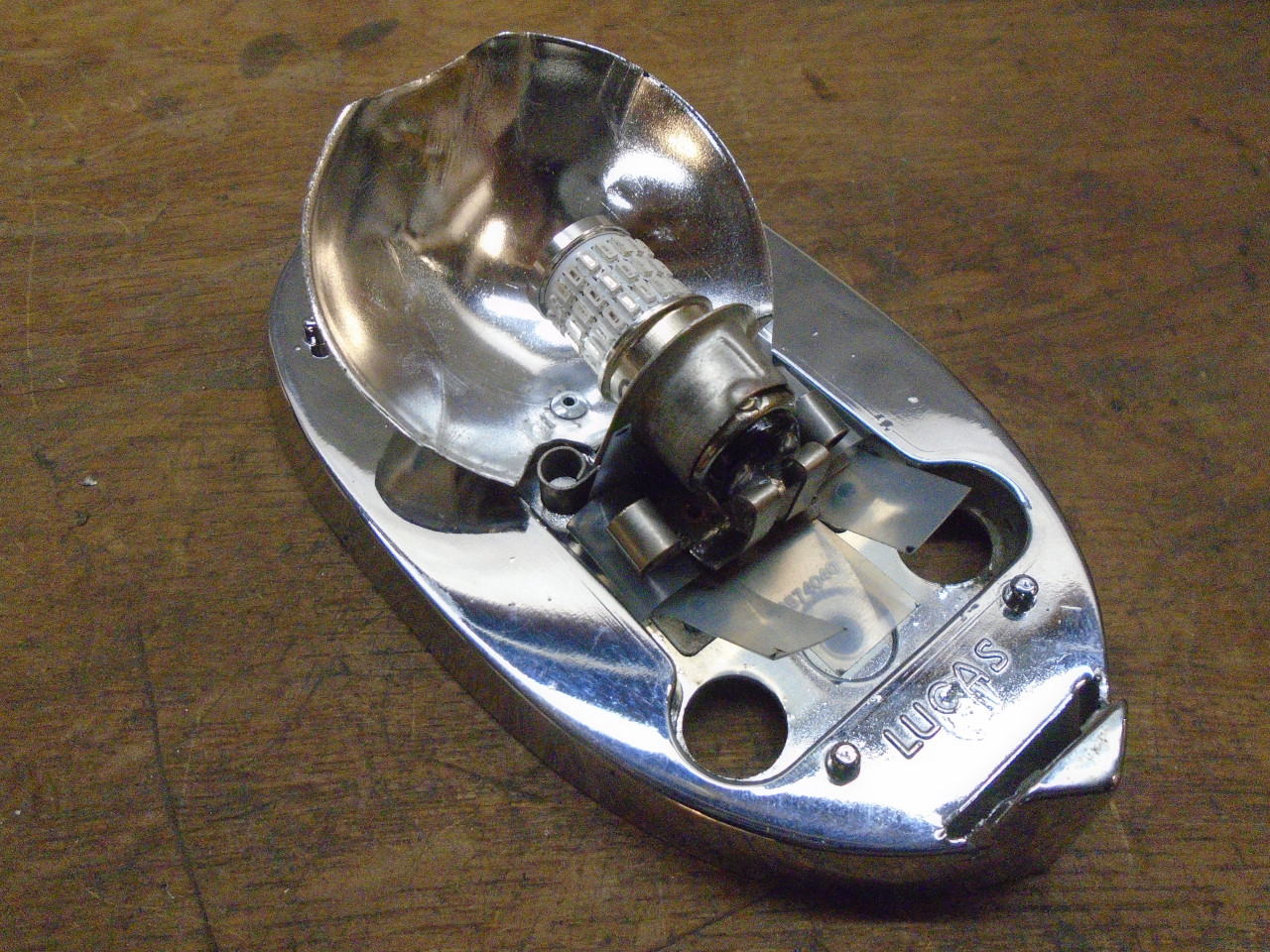

License Plate Light

The license plate light assembly was all there, but was dirty,

with some corrosion damage in a few places. I noticed it

used one of those fake bullet connectors that you just wrap the

bare wire around. I'll fix that during wiring.

The chrome cover had a broken corner. It looks like someone

(probably me) tried to solder it, but it didn't hold.

The internals were pretty crusty. This is bad for electrical

continuity.

Apart it came, and the steel parts got stripped and re-plated.

The electrical contacts got cleaned up and tested for good

continuity.

Then the unit was re-assembled.

I had noticed that this assembly lacked an explicit ground

connection. Since I'm not a fan of using the car's body as

an electrical return path, I added a bullet socket for a ground

wire. Unsoldered joints like this get a coat of dielectric

grease to protect the surfaces from oxidation.

This unit also had those square mounting holes like the front turn

signals. Carriage type bolts snapped right into them.

Added the gasket, and put her back together. I fixed the

chrome cover by epoxying a wire reinforcement around the corner on

the inside. The repair isn't visible from the outside.

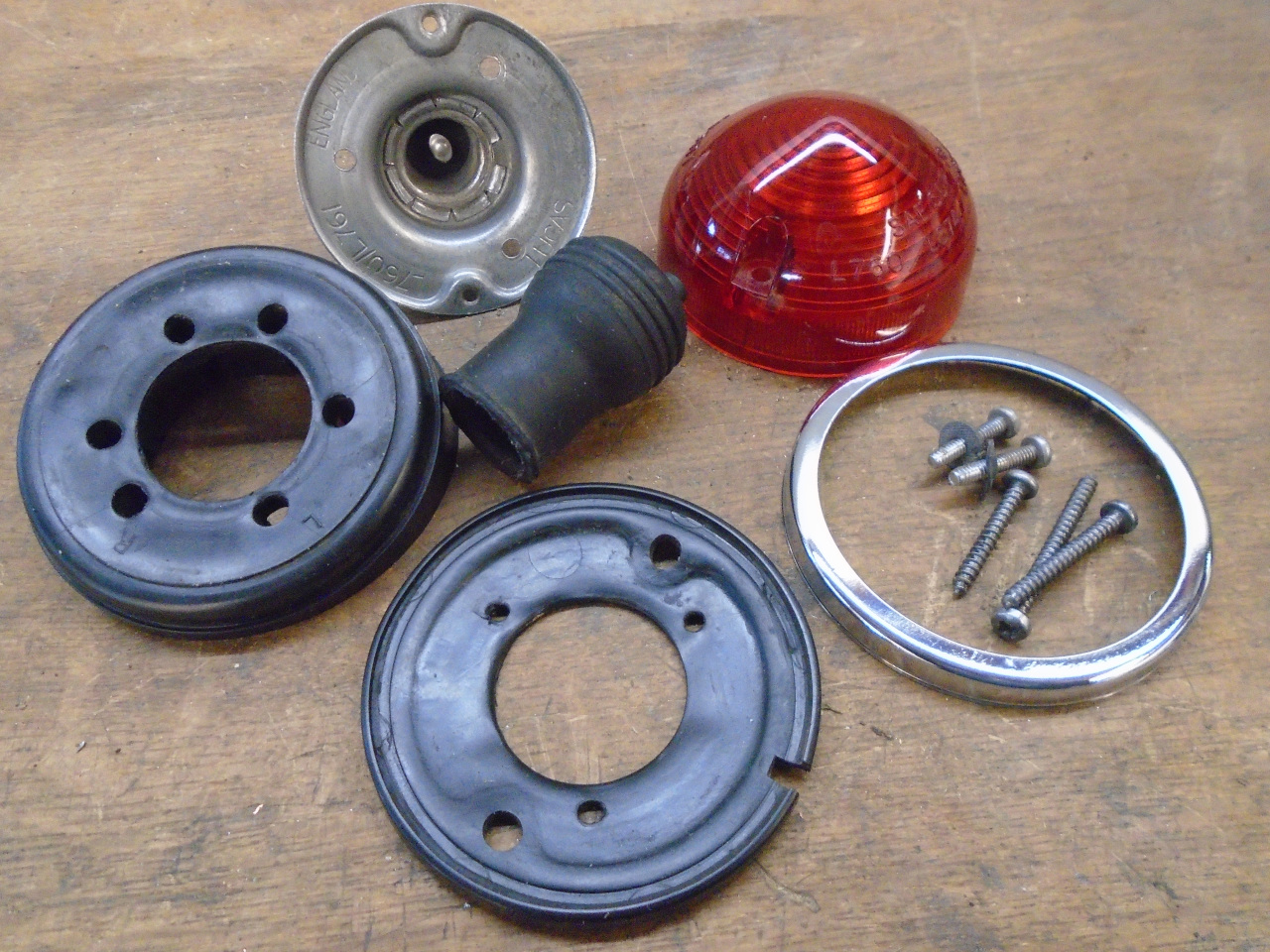

Rear Turn Signals

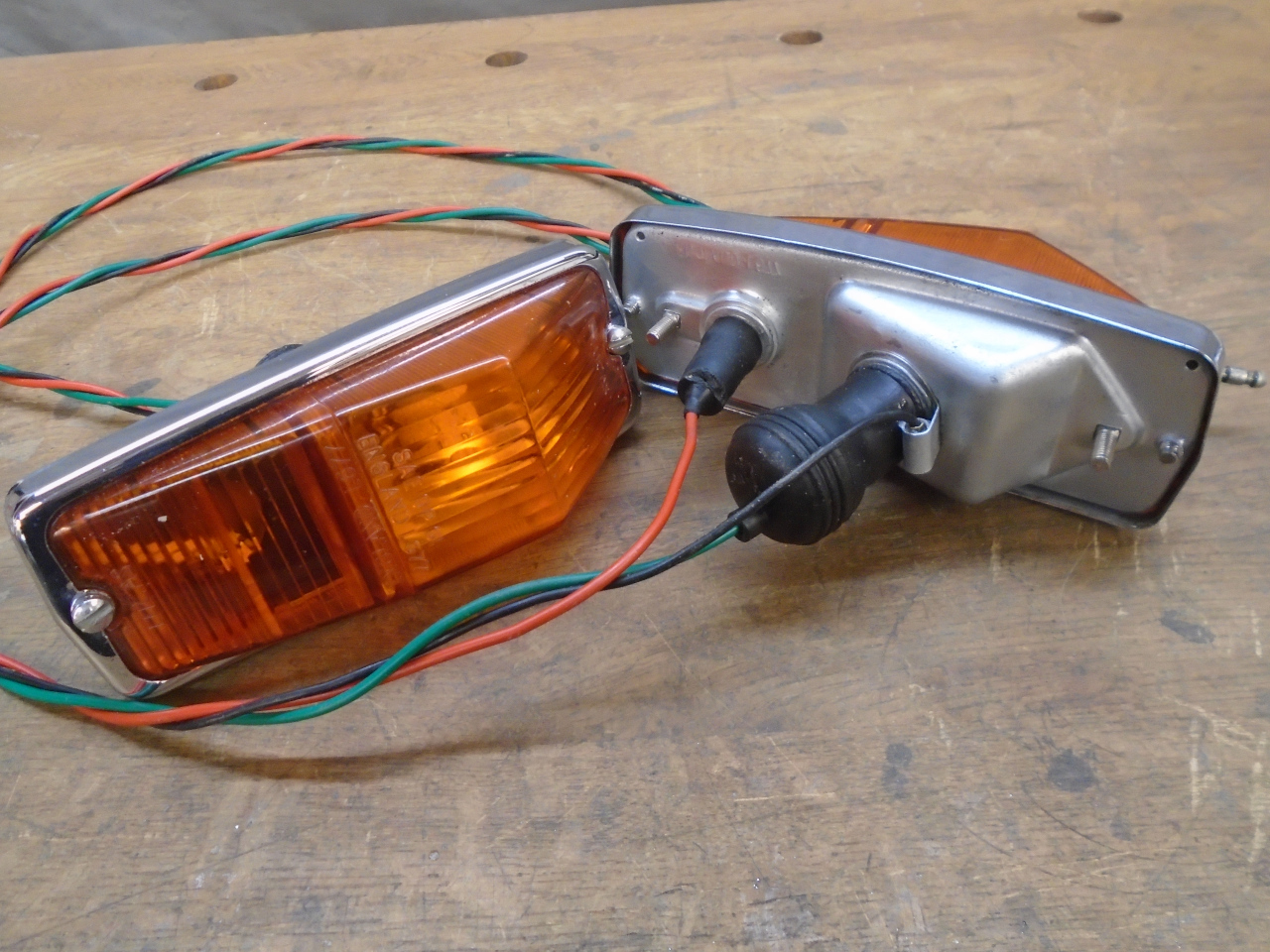

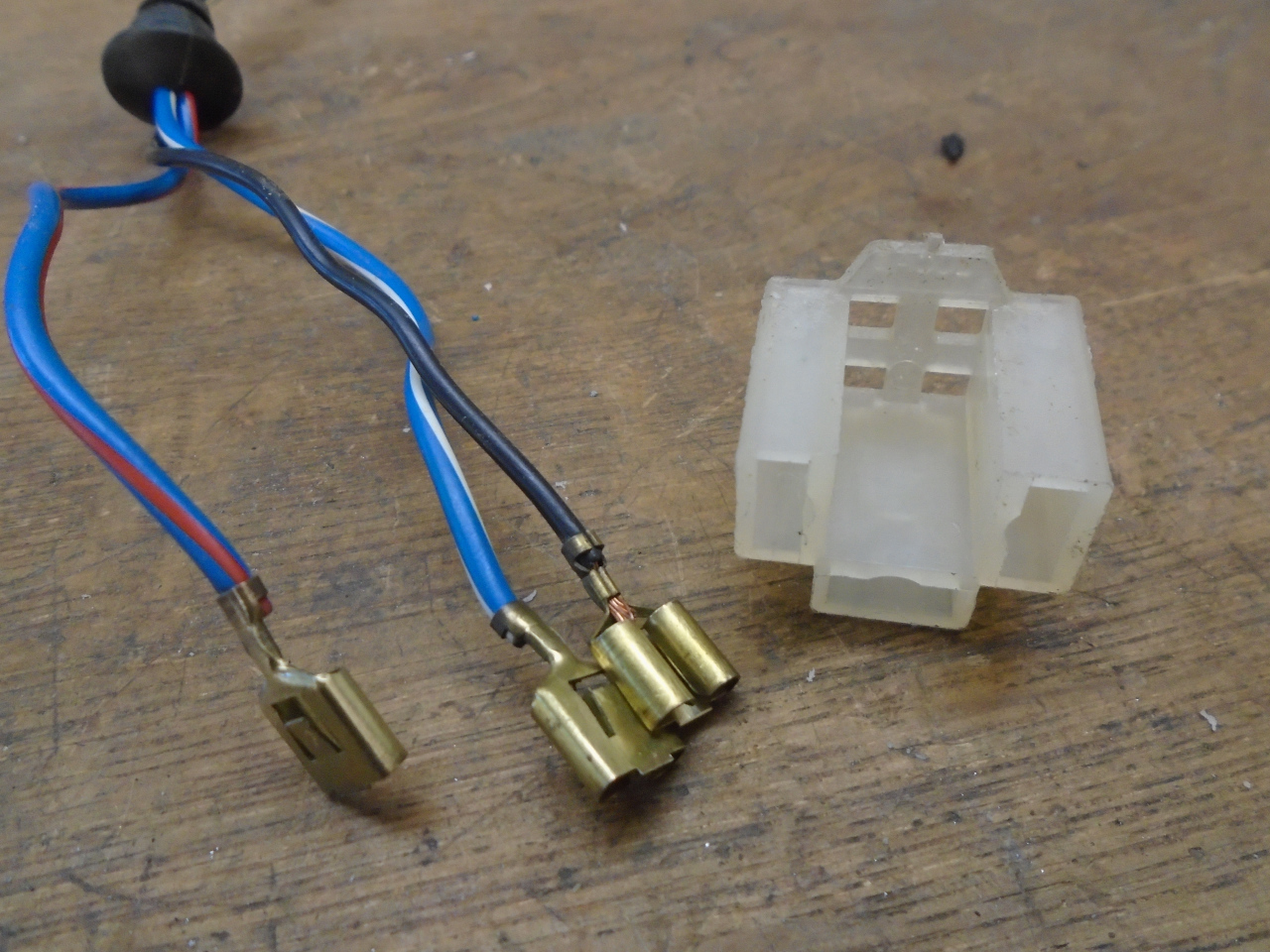

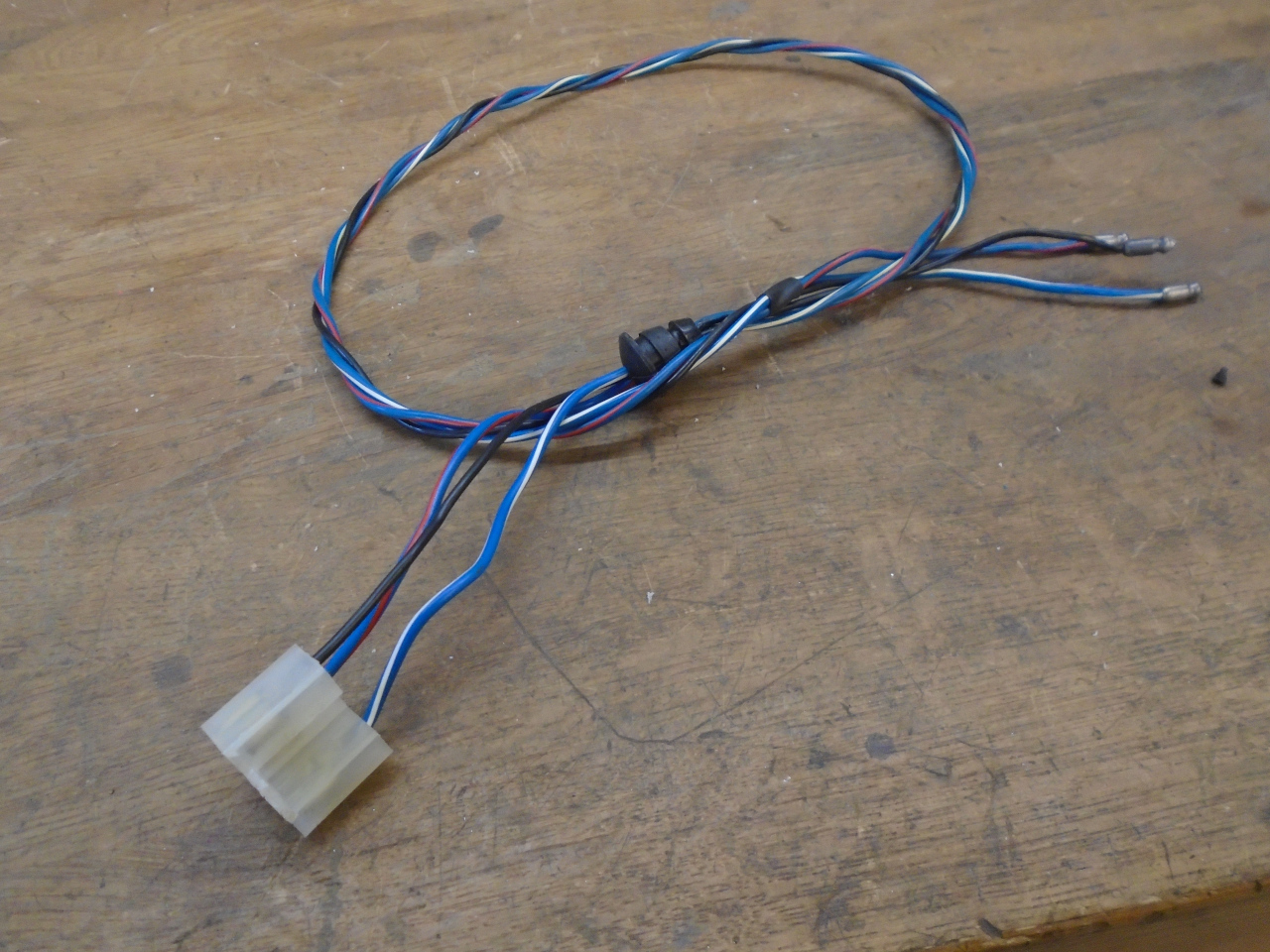

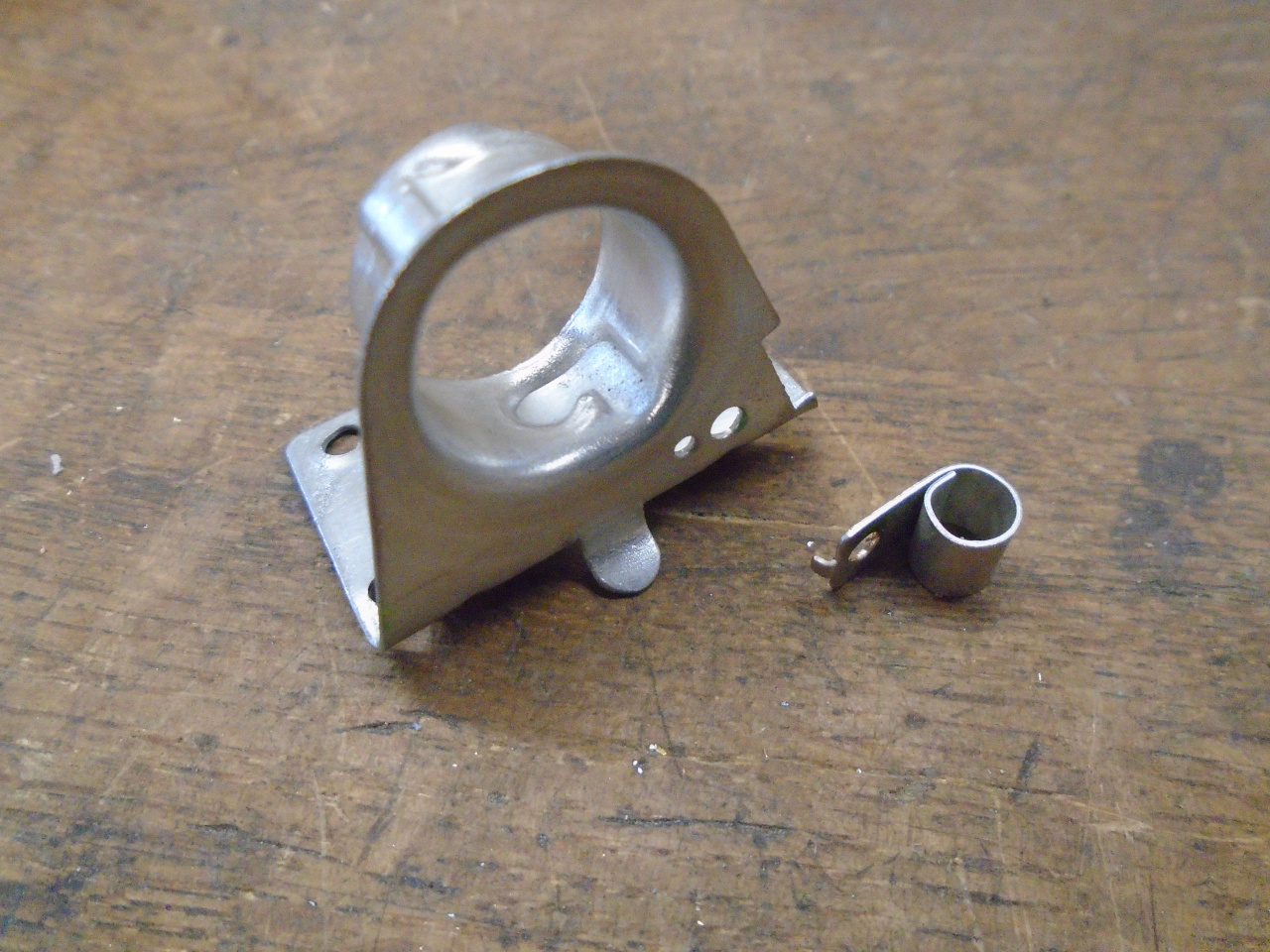

One of my rear signal lights appeared to be intact. The

other had a broken lens, a missing rubber gasket, and a broken off

ground terminal. Here are the parts for the good one.

I endeavored to fix the missing ground on the other fixture:

I was pretty proud of myself until I realized that the rubber boot

would now not fit over the new ground terminal. So I had to

backpedal and order a new socket, which appeared to only come with

an amber lens (at least from SpitBits). There appears to be

some confusion about which models and years had red, and which had

amber lenses. So I ordered a red lens, too.

I always fear the worst when I have to order parts like this, but

the part I got appeared to be New Old Stock. I was pretty

happy with it. The red lens, though, was definitely not NOS.

The final assemblies. The mismatching lenses is a minor

irritation, but I'll get over it.

Reverse Lights

The reverse lights didn't need any mods or

repairs at all. Just cleaned them up.

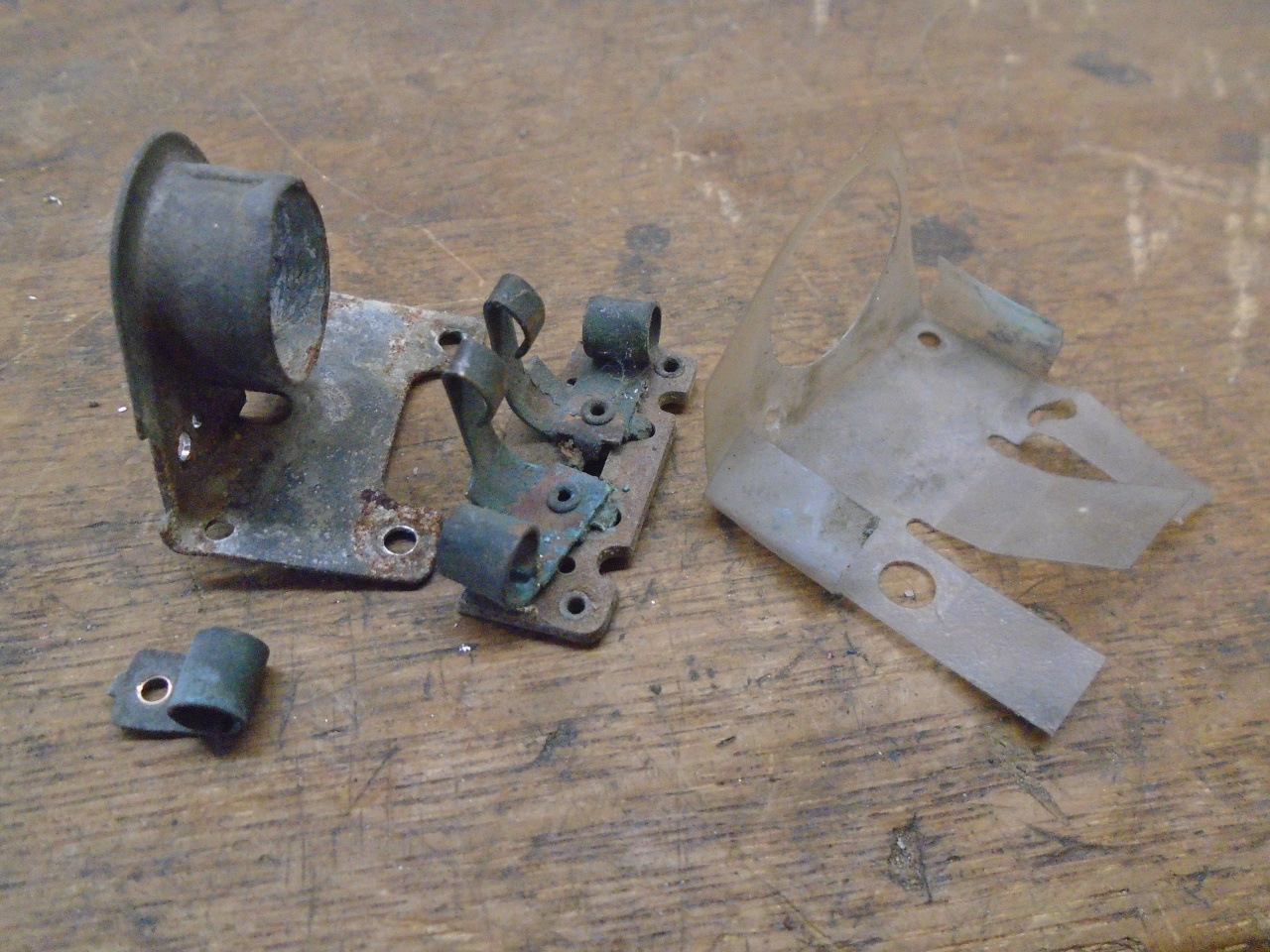

Tail/Stop Lights

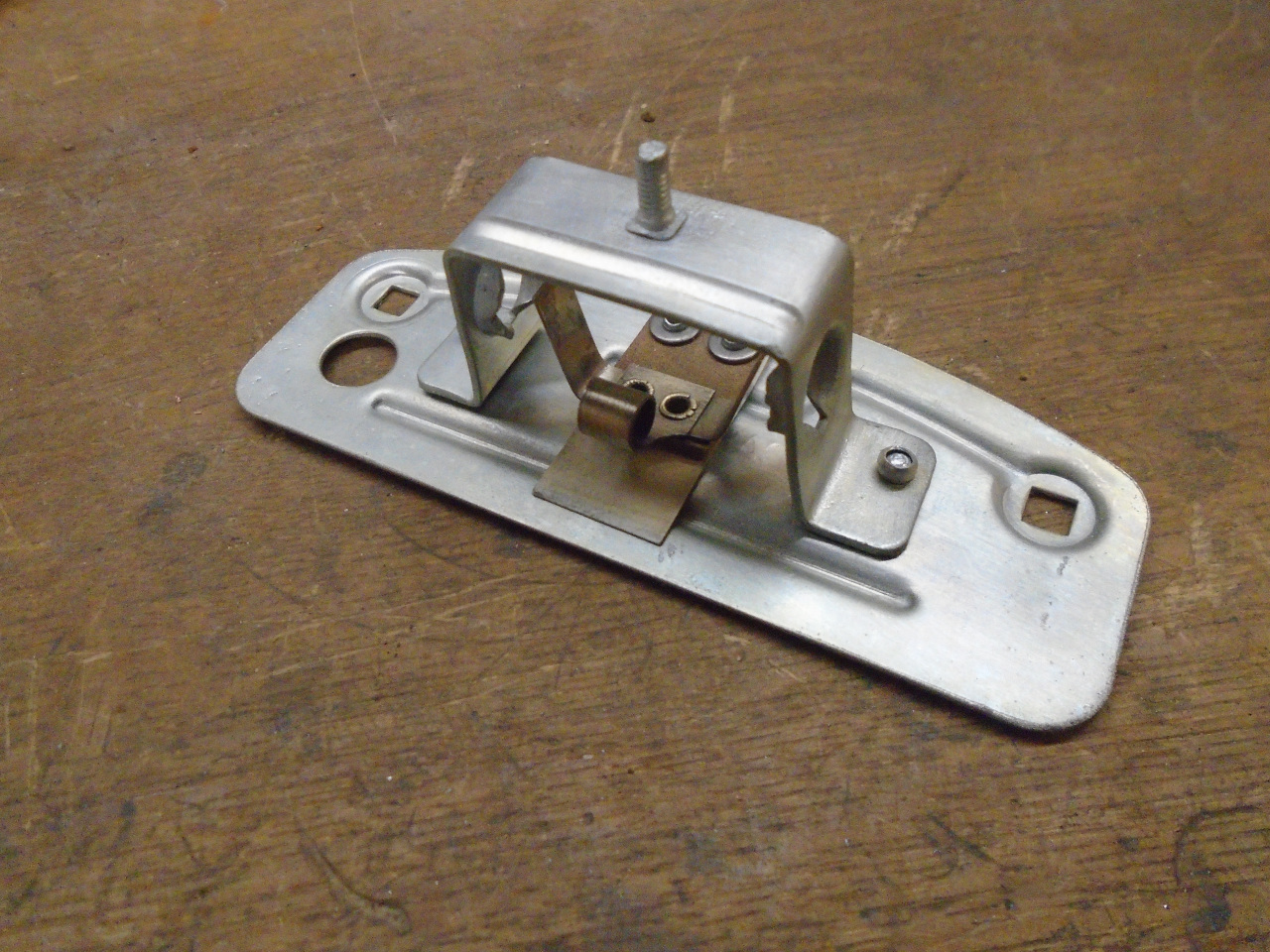

The tail/stop light assembly was designed for a standard 1157 dual

filament lamp. These lamps have wattage ratings around 27

and 8 watts for the stop and the tail light filaments

respectively.

My fixtures were pretty cruddy inside and out, especially around

the electrical bits.

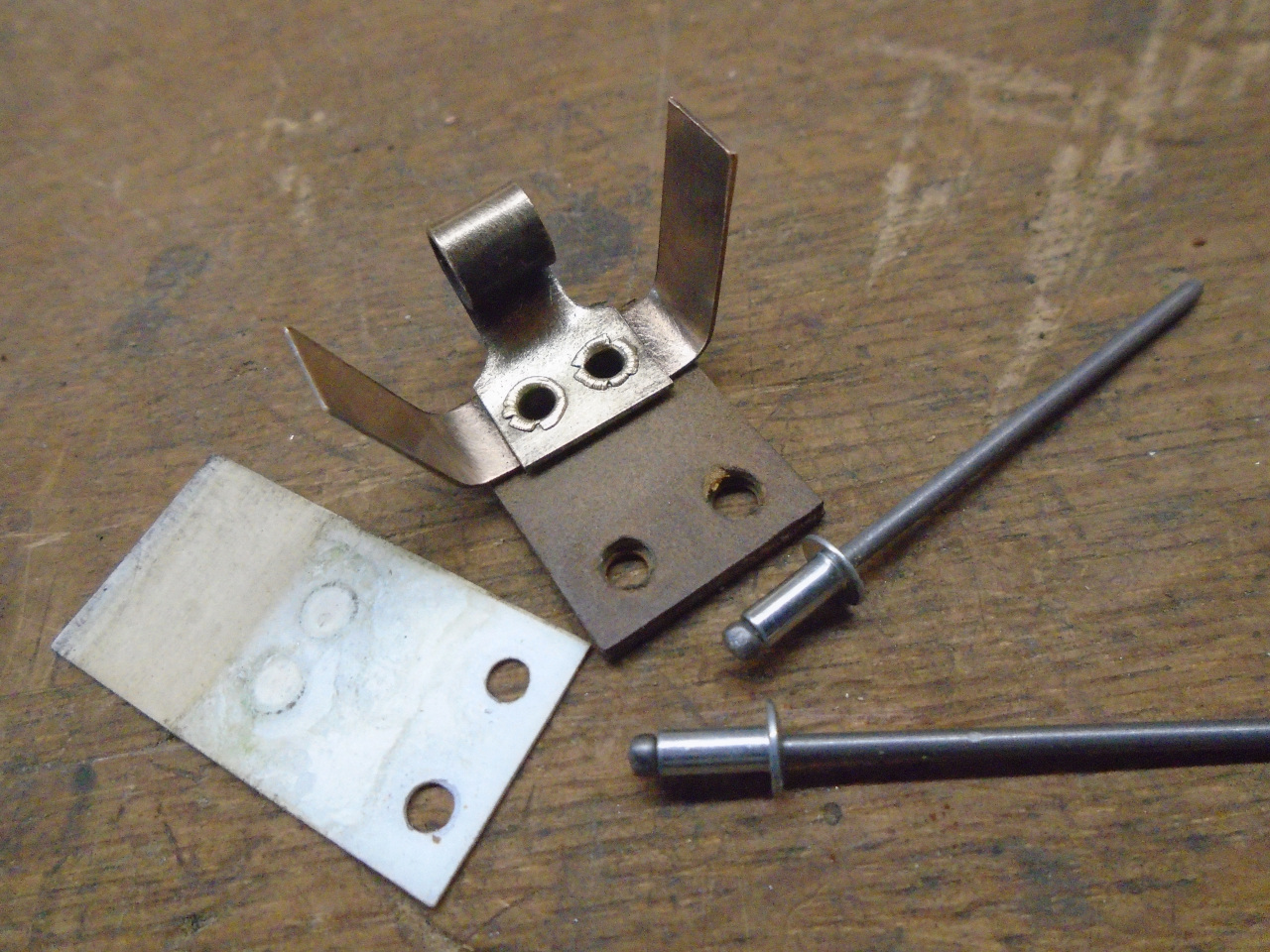

Drilling out a few rivets frees up the anodized aluminum

reflector, and the lamp holder assembly.

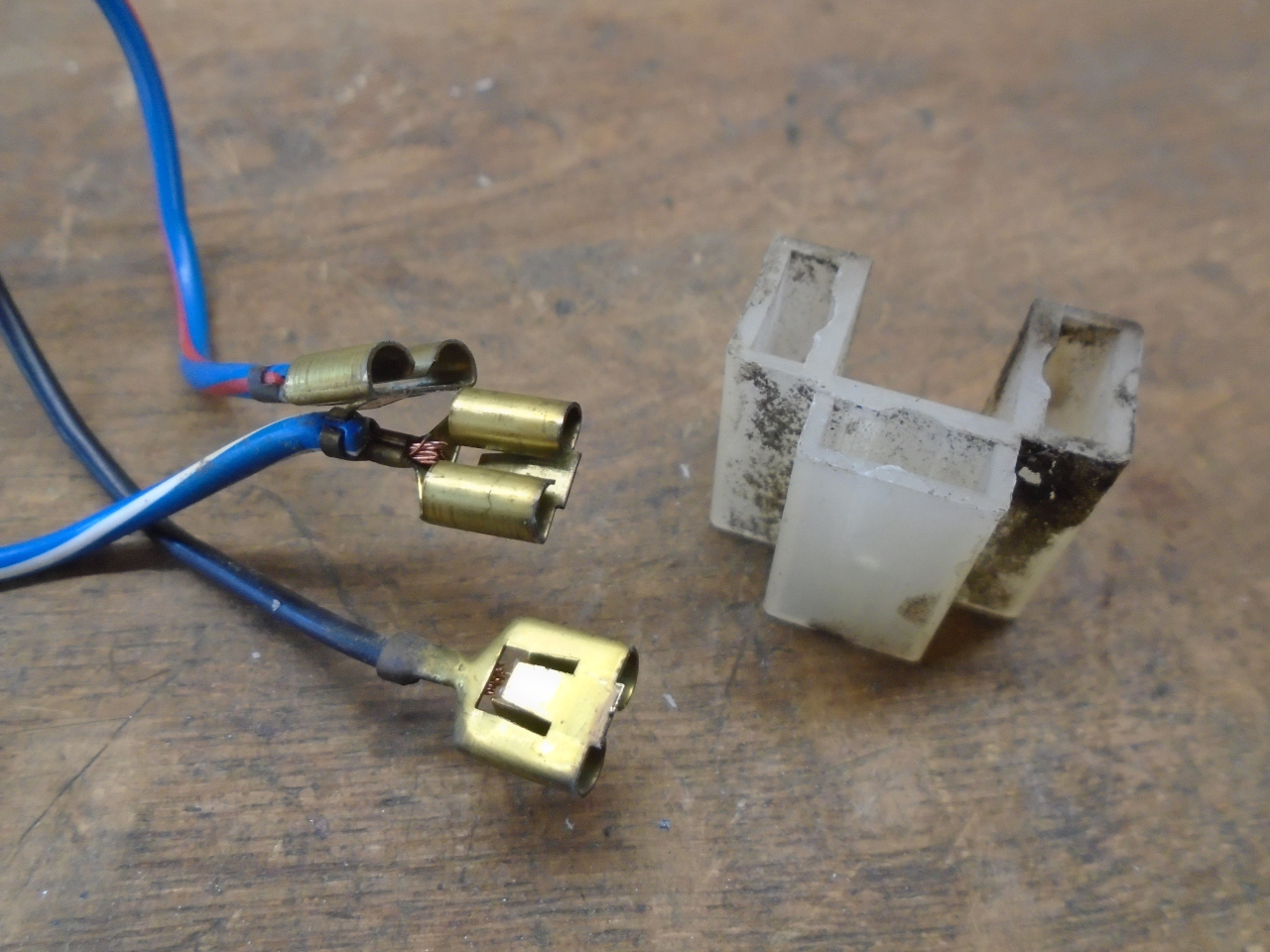

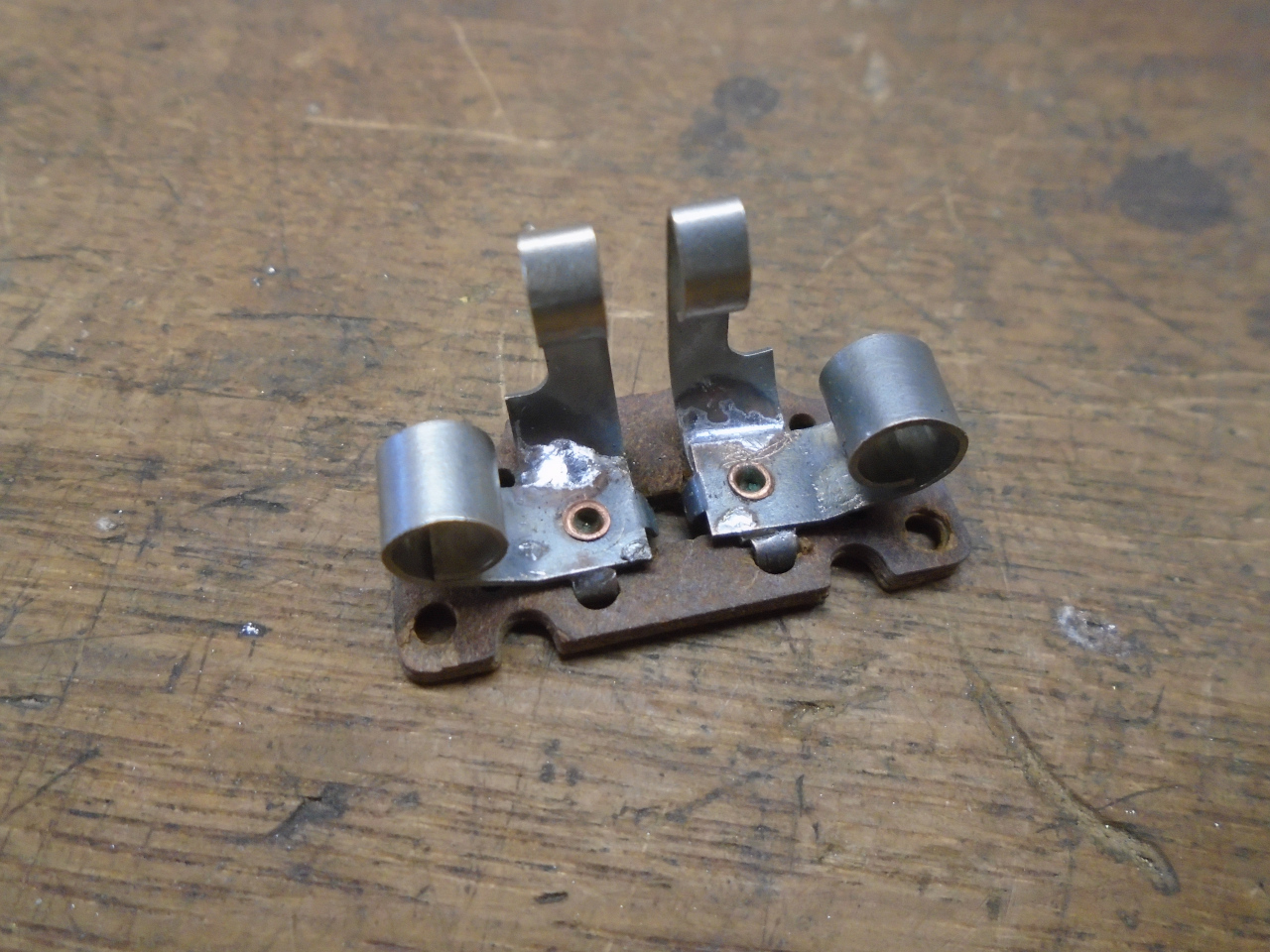

It was obvious to me that the lamp holder needed some serious

attention. Each circuit (tail and stop) had a copper (likely

bronze, actually) socket for a bullet terminal, and a copper

spring terminal for contact to the base of the lamp. They

were fastened together with a single rivet. The parts were a

little loose, and there was corrosion all over them. The

ground bullet socket had a single rivet as a fastener between

dissimilar metals. This is not a reliable electrical design.

I thought I could turn this into a proper electrical device with a

little TLC. I removed the contact parts from the lamp

holder, and freed up the contacts from their phenolic carrier.

The bulb holder got stripped of the corrosion, and any zinc that

might have remained.

I was getting ready to zinc plate the carrier when it occurred to

me that for an electrical component, copper plating would be more

appropriate.

The copper/bronze parts all got rid of their corrosion, then got

treated to a tinning bath, along with the lamp holder. The

tin protects the copper from tarnishing, and also makes soldering

way easier.

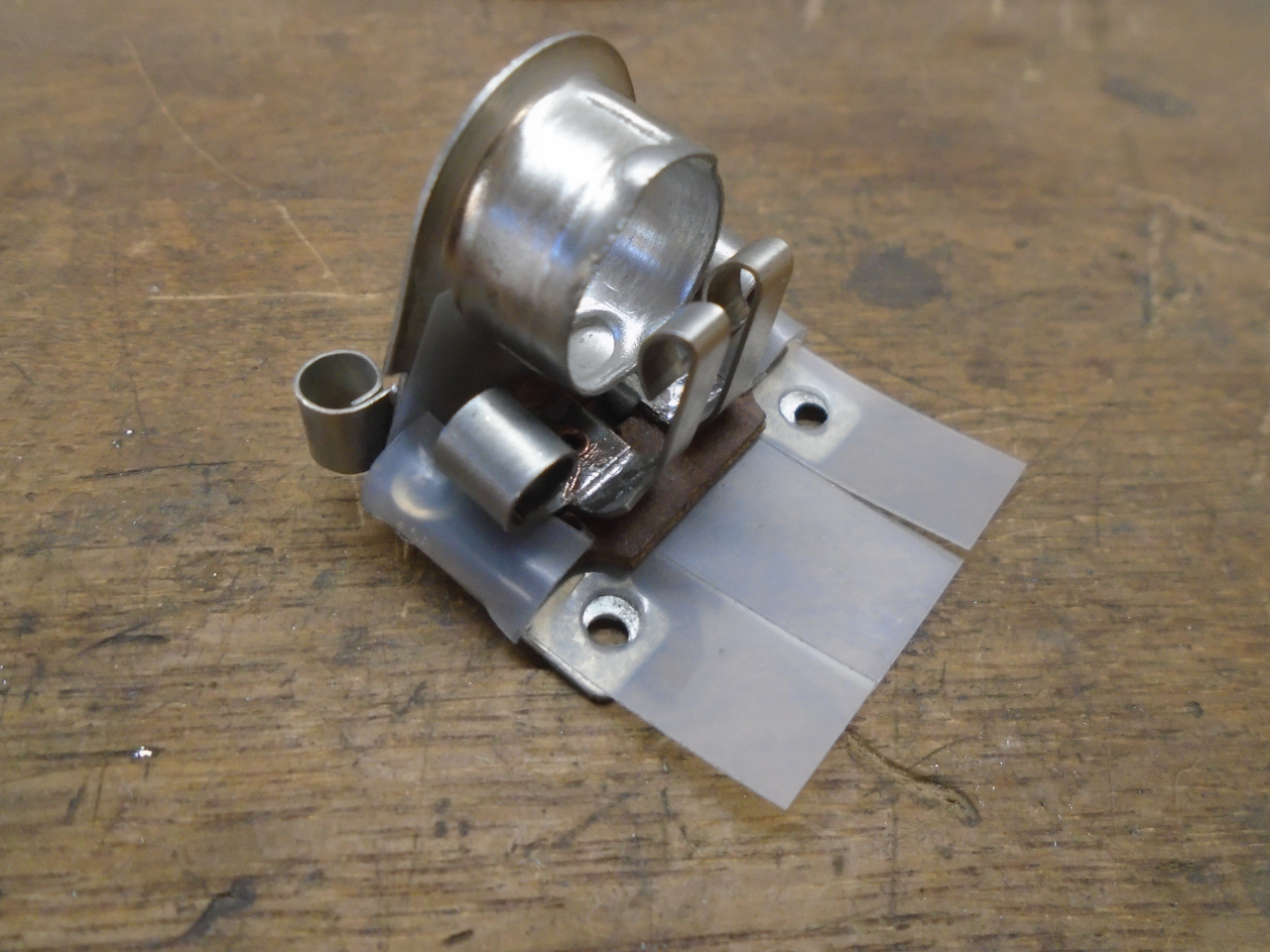

The ground bullet socket got riveted back in place on the lamp

holder with a copper rivet, and then soldered.

The two parts of each lamp contact were also soldered. Those

should have been designed as one piece in the first place.

Then they were riveted to their phenolic carrier board.

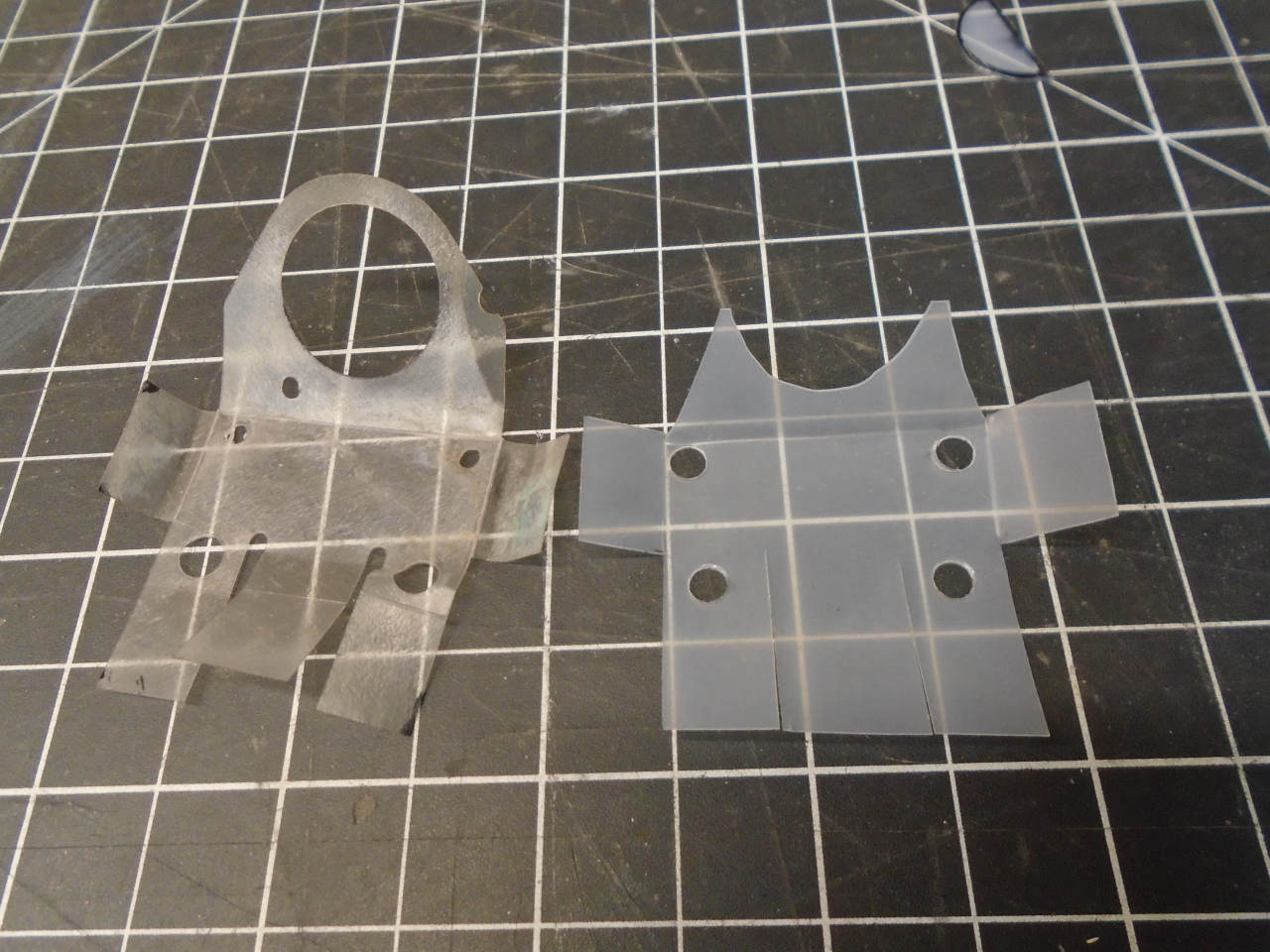

With so many hot and grounded metal pieces so close together in

this assembly, a little insulator sheet was included in the

design. The original wasn't in very good shape, so this is a

copy made from 0.010" nylon sheet--a material pretty close to the

original.

Finally, riveted the lamp assembly and the reflector back on to

the main frame.

The lenses responded pretty well to a good cleaning and polishing.

Oops, forgot to order the lens gaskets, and the one remaining

original was stiff as a board. That's OK, I had some foam left

over from the front signal lights.

I did have new body gaskets, though.

Looking pretty OK. There is some pitting on one of the

chrome bodies, but I don't seem to be stressing over it.

Conclusion

So this completes the refurbishing of the external lighting

assemblies. They will go in a box until the installation

ceremony.

This was a finicky project in places, but I'm pretty confident

that these parts are in original condition, or better. It

was fairly cheap at around $75 for various parts and gaskets, some

of which I didn't use.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages.