To my other GT6 pages.

August 12, 2019

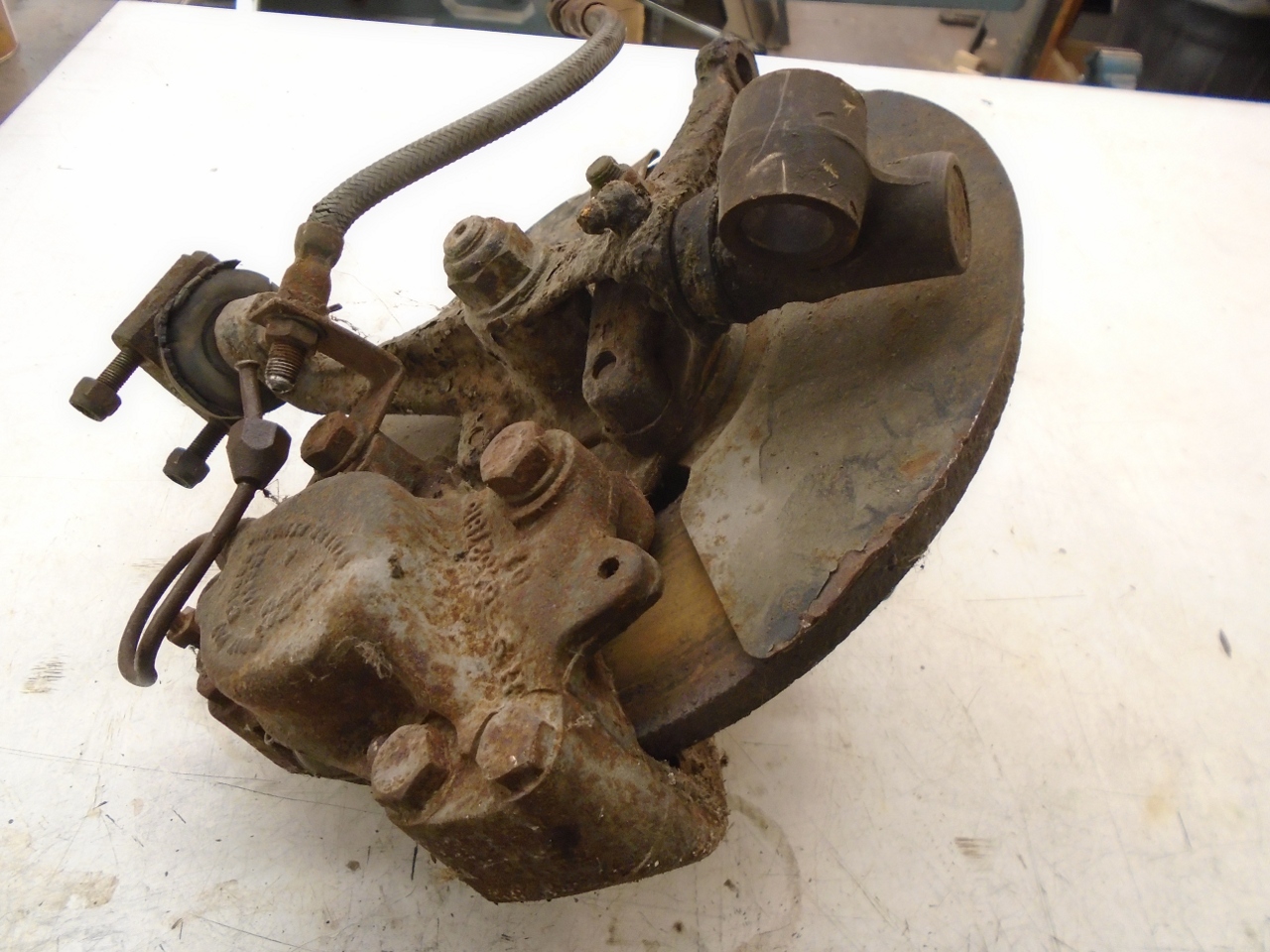

Front Calipers

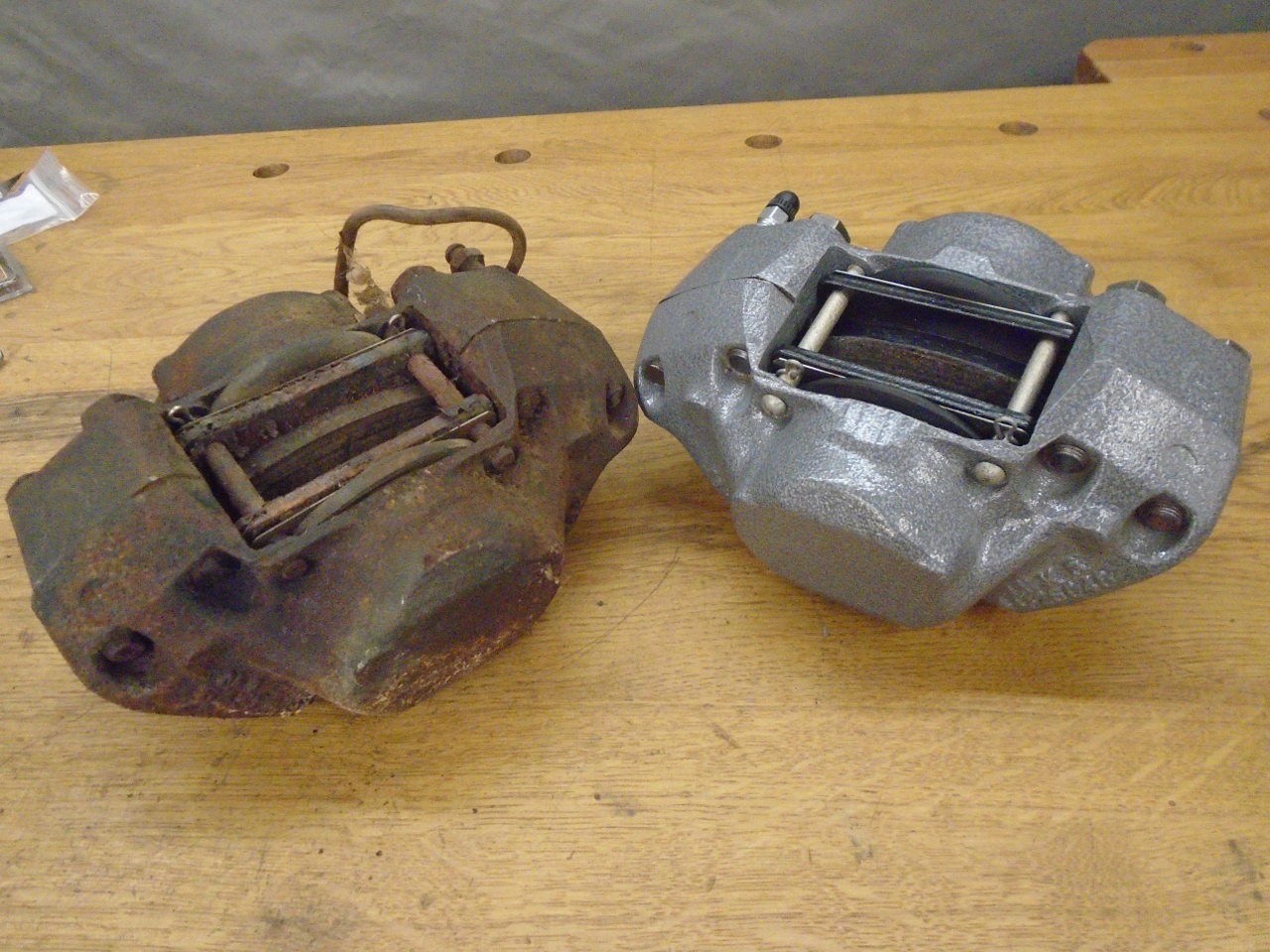

GT6 cars had disc brakes at the front. Each caliper has two opposing pistons actuated by hydraulic pressure.

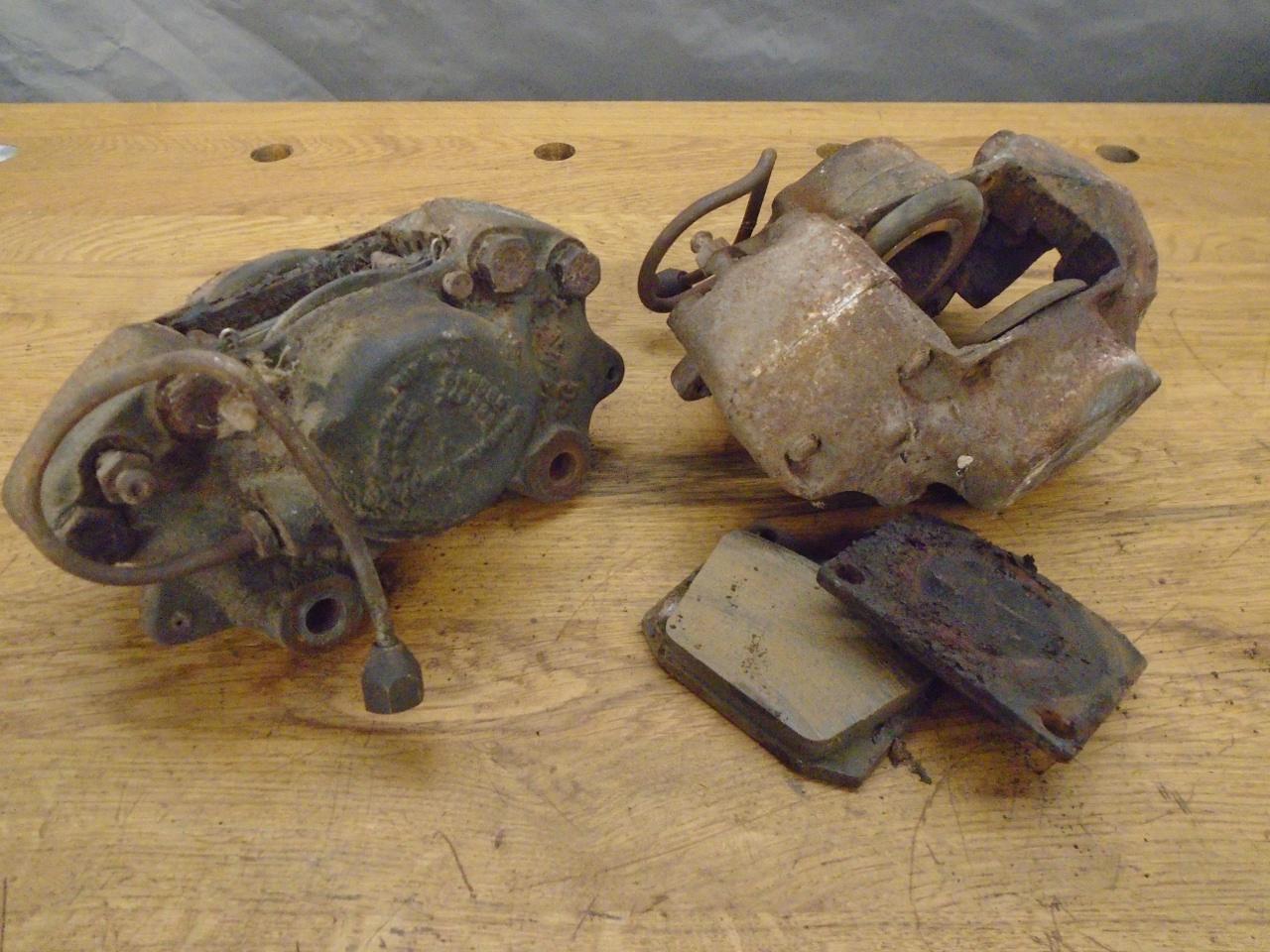

I dragged the pair of these rusty lumps down to the shop to extract the calipers.

These units spend their lives in nasty conditions down close to the road, so they were both crusted with dirt, rust, and glop.

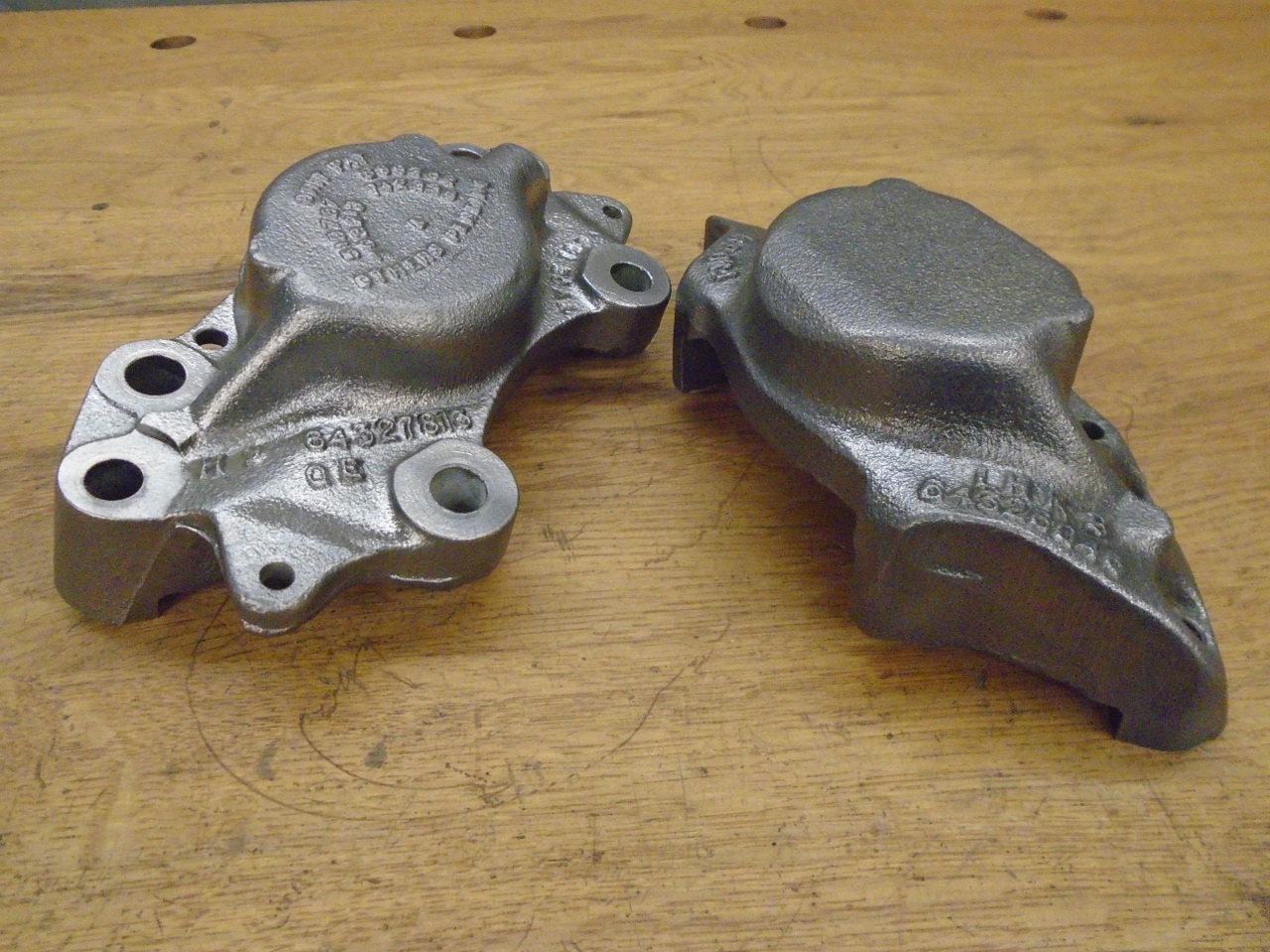

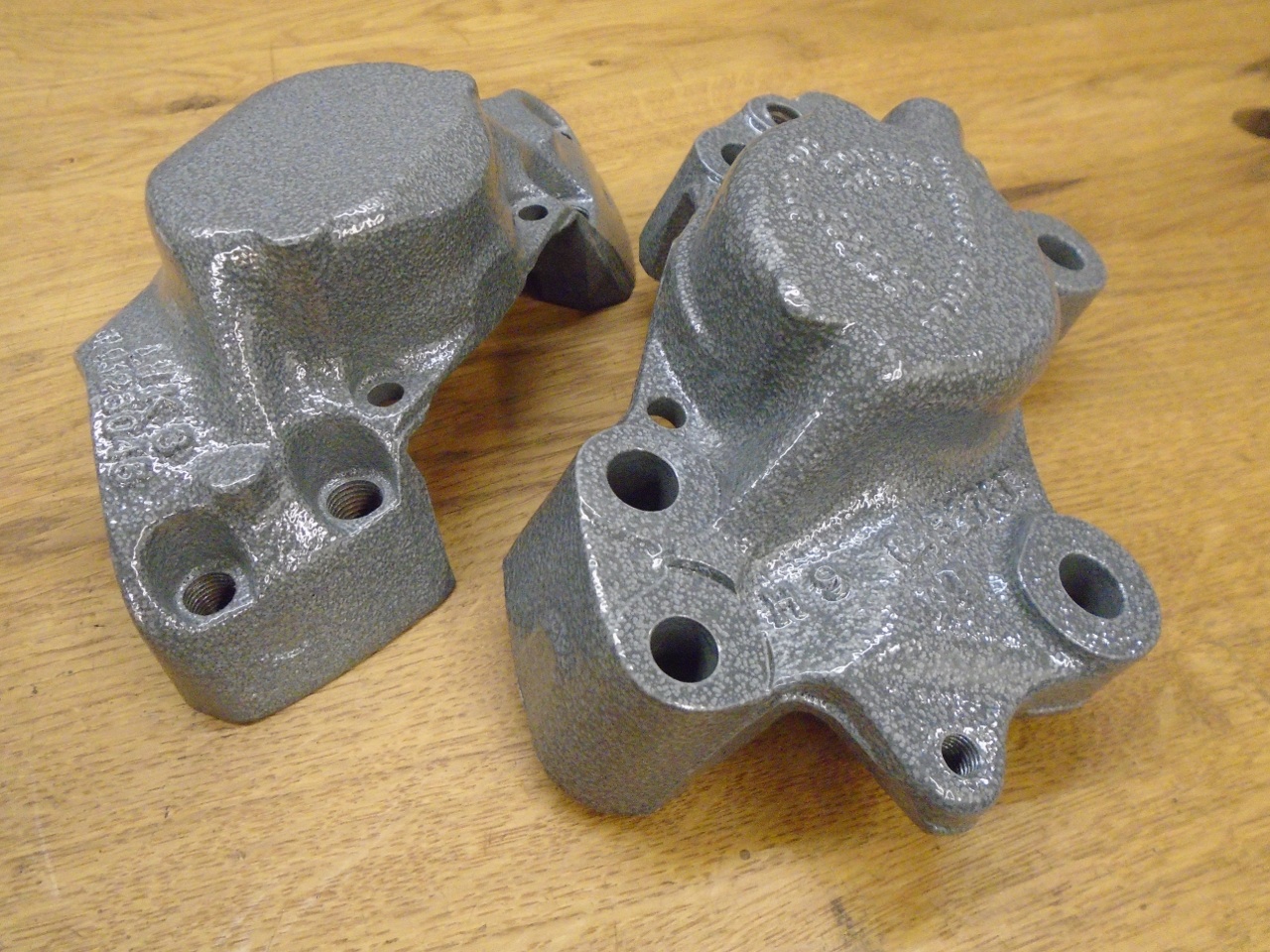

But the main bodies cleaned up really well. The piston bores were in excellent shape.

But

the pistons--well, not so much. In these calipers, the seals are

in the walls of the bores, so the piston surfaces have to be perfect to

maintain a seal. I ordered new pistons along with basic rebuild

kits.

I

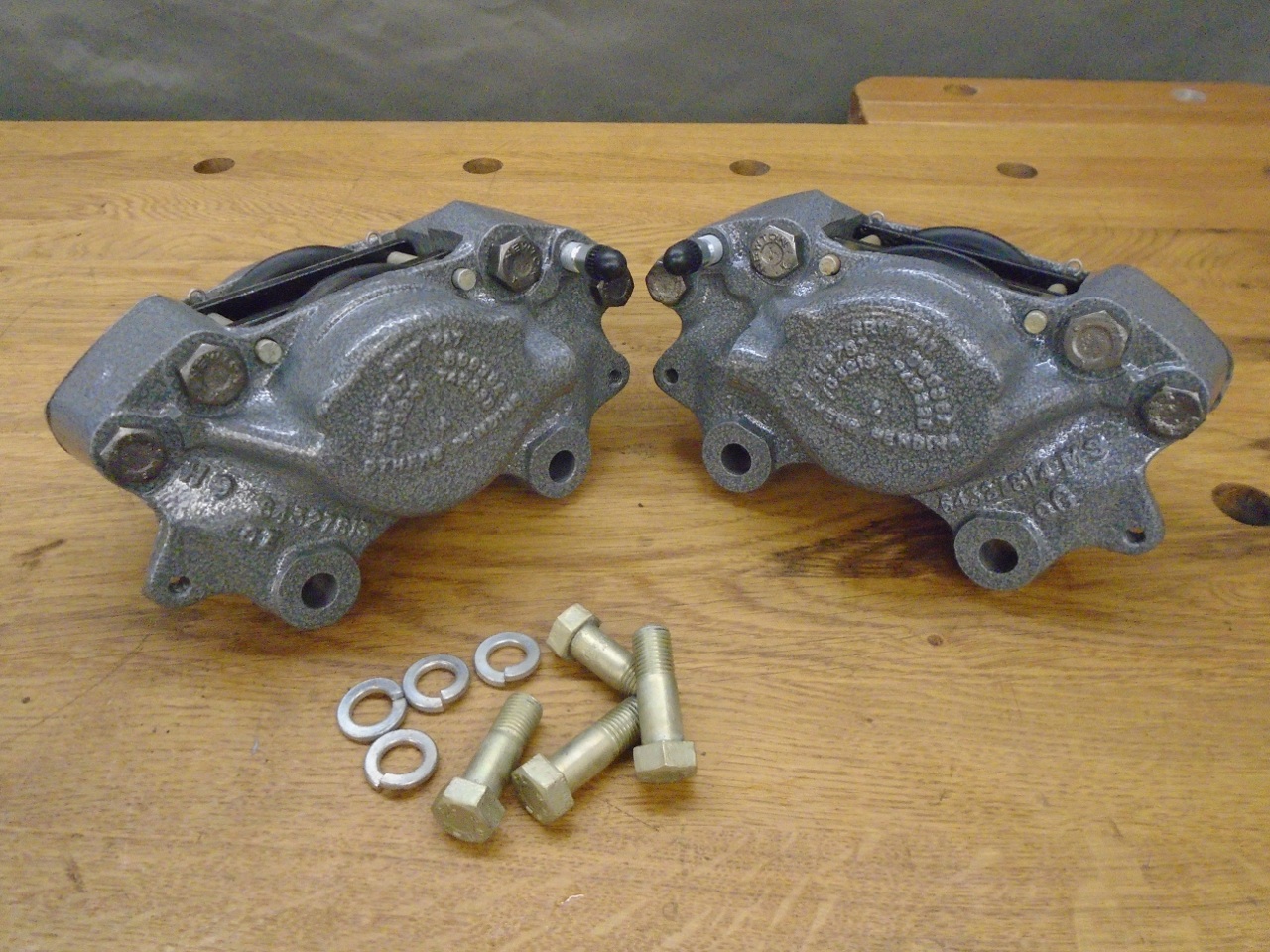

struggled with the urge to paint the caliper bodies a bright

contrasting color, but in the end, compromised on a tasteful silver

hammertone.

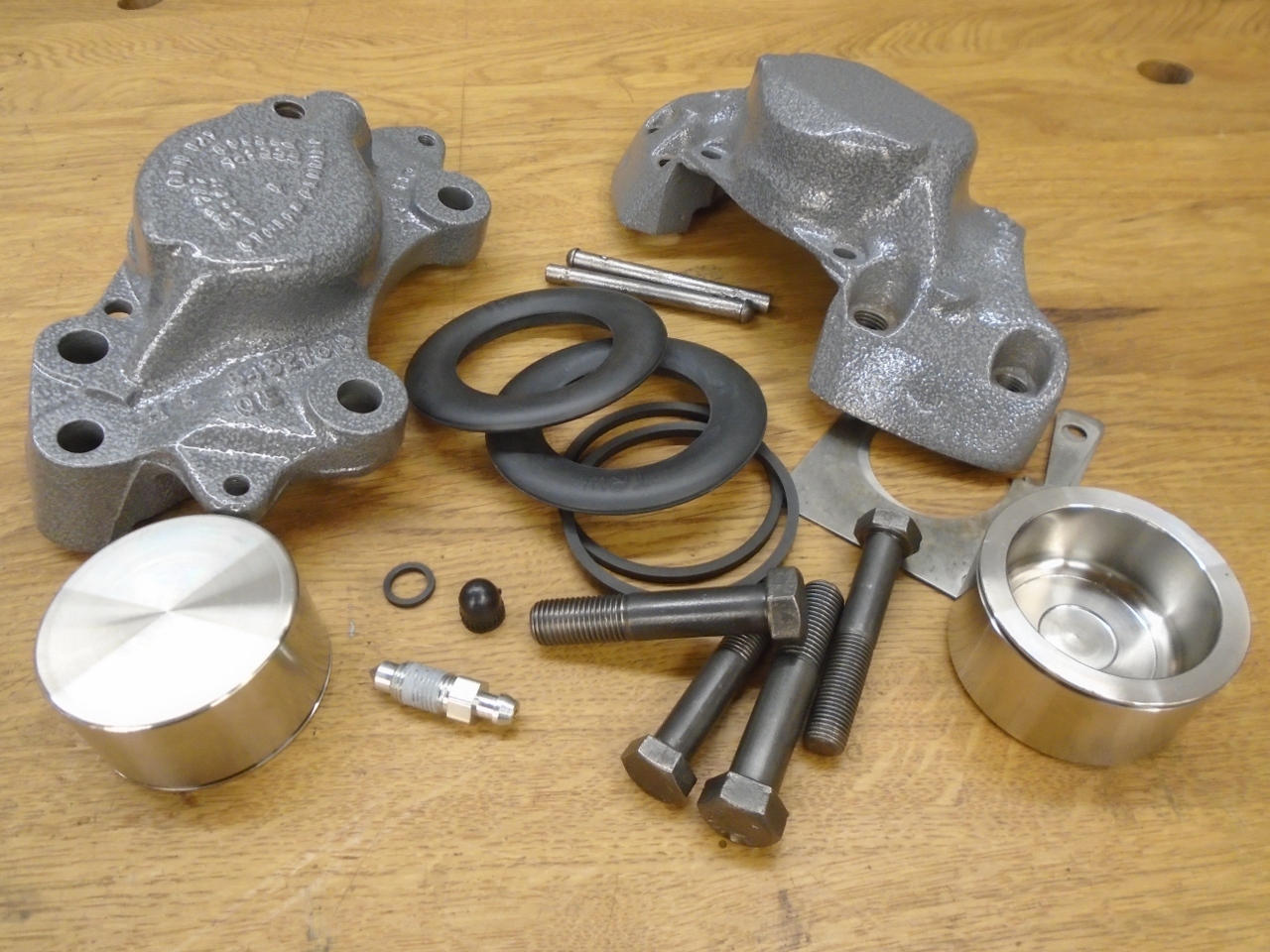

The pistons and kits arrived and everything was ready. I opted for stainless steel pistons.

Though

I very often replate hardware on the car, the body bolts on the

calipers are an exception. These bolts are Grade "Y", meaning

they are very high tensile strength--actually higher than SAE Grade 8.

The problem with these very high strength steels is that they can

be subject to hydrogen embrittlement, where hydrogen gets absorbed into

the surface of the steel. The hydrogen can come from processes

like electroplating or acid pickling. Though there are baking

operations that can drive out the hydrogen, I opted for the safer path

and skipped the plating and acid cleaning. Obviously, these

fasteners are not items to be replaced by corner hardware store bolts.

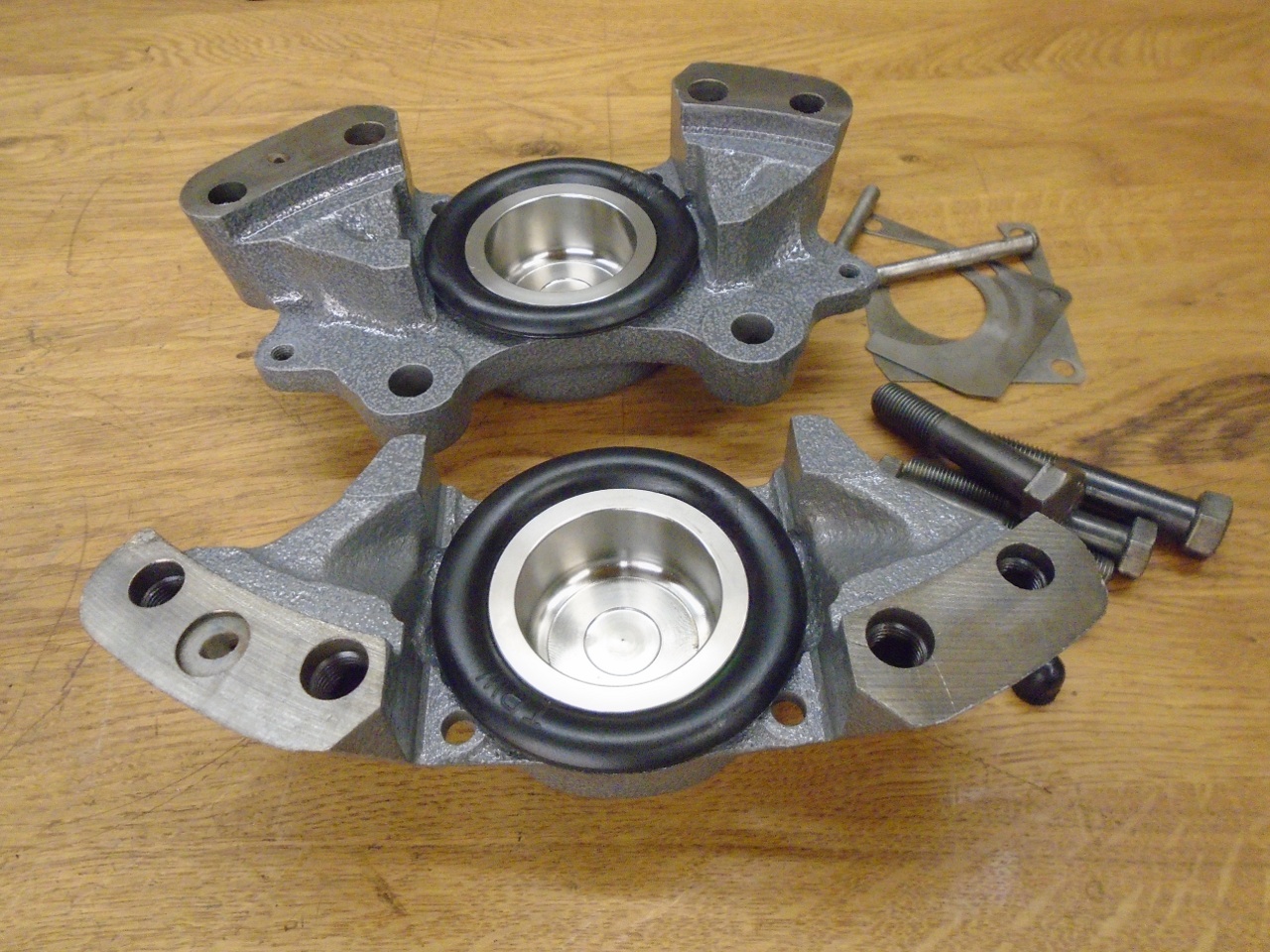

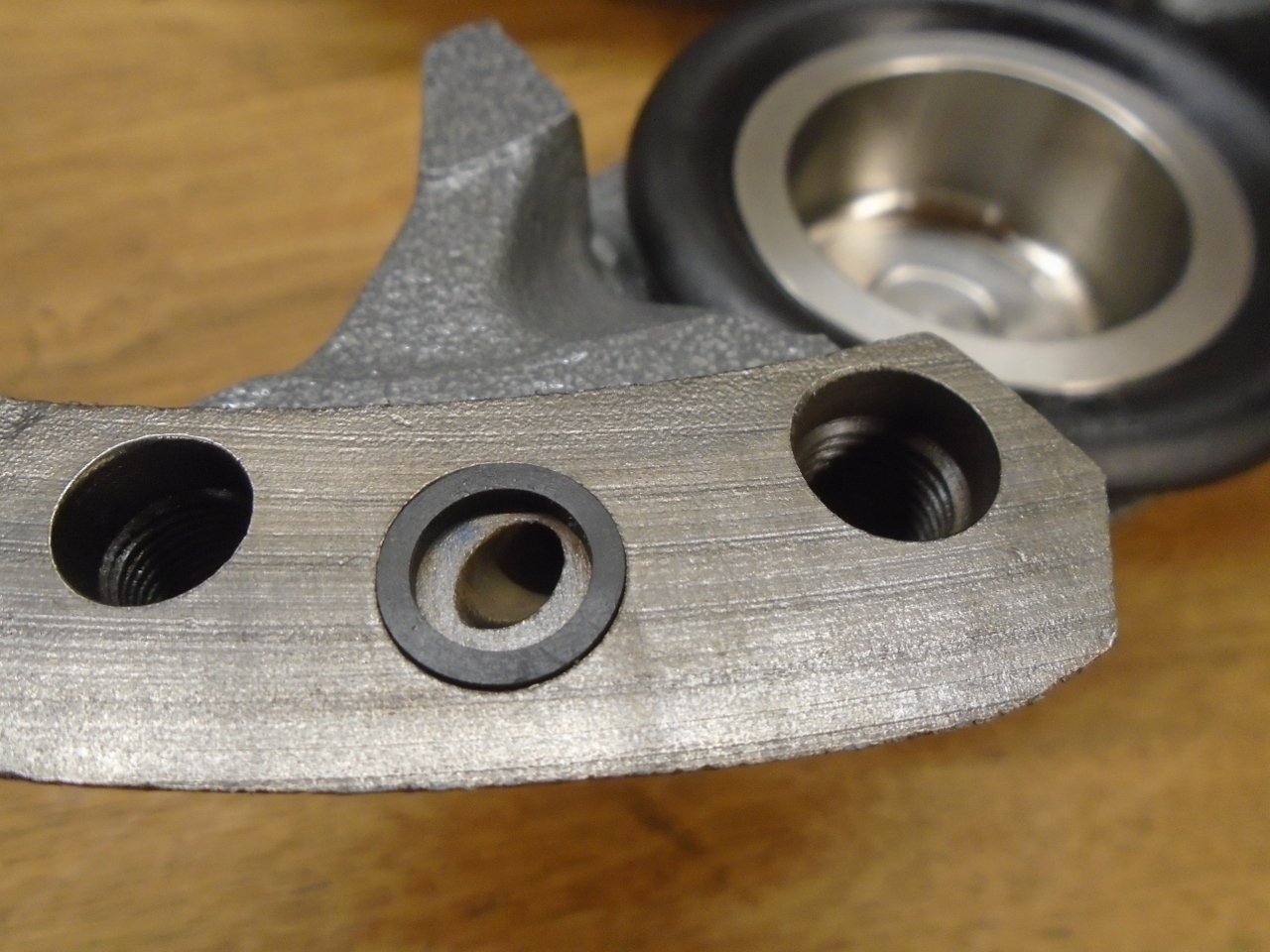

The dust covers can be a little tricky, but perseverence pays off.

The seal between the two body halves is available from at least one

LBC vendor, but I got these from and industrial supplier. Thay are a

standard size.

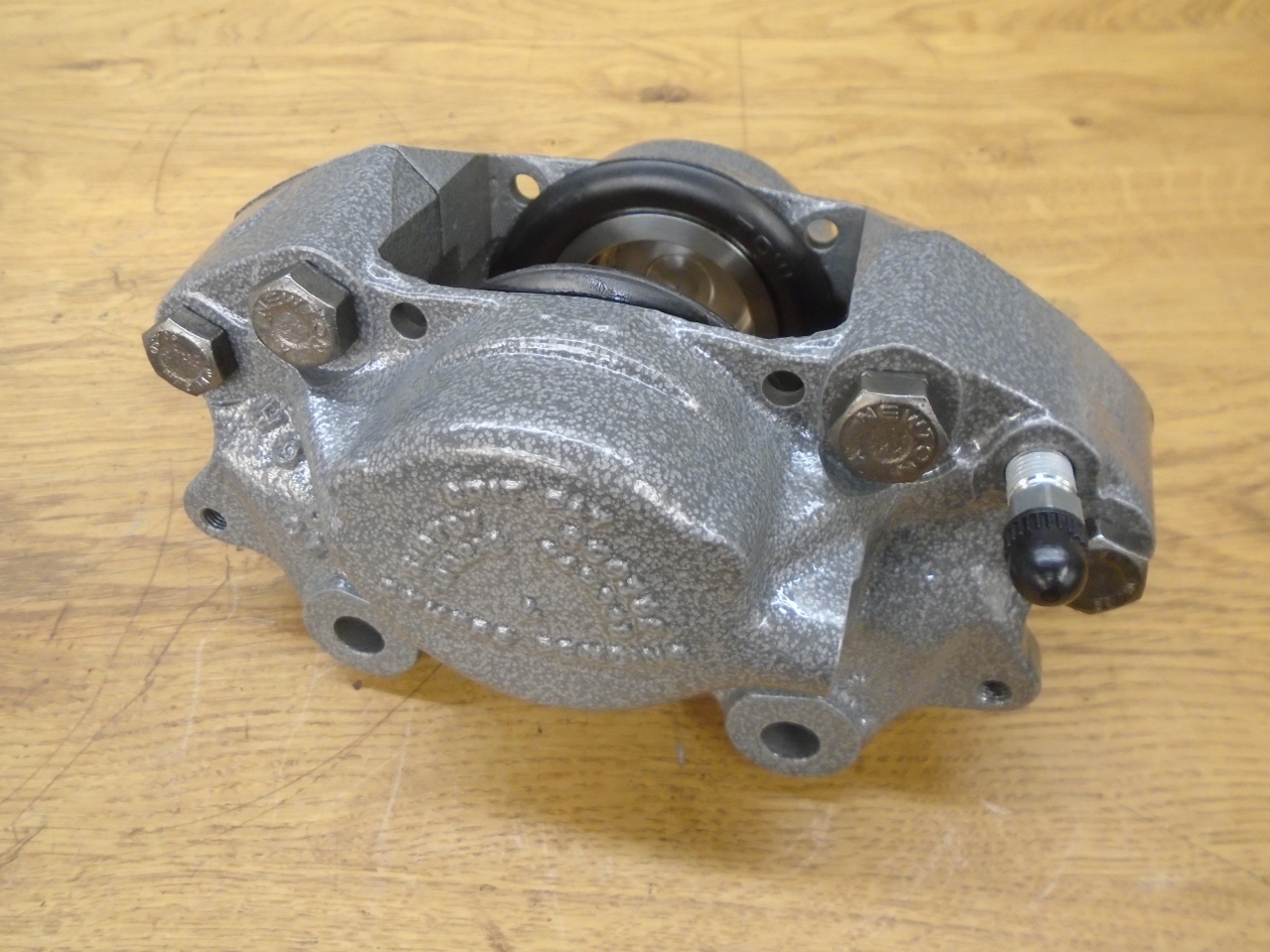

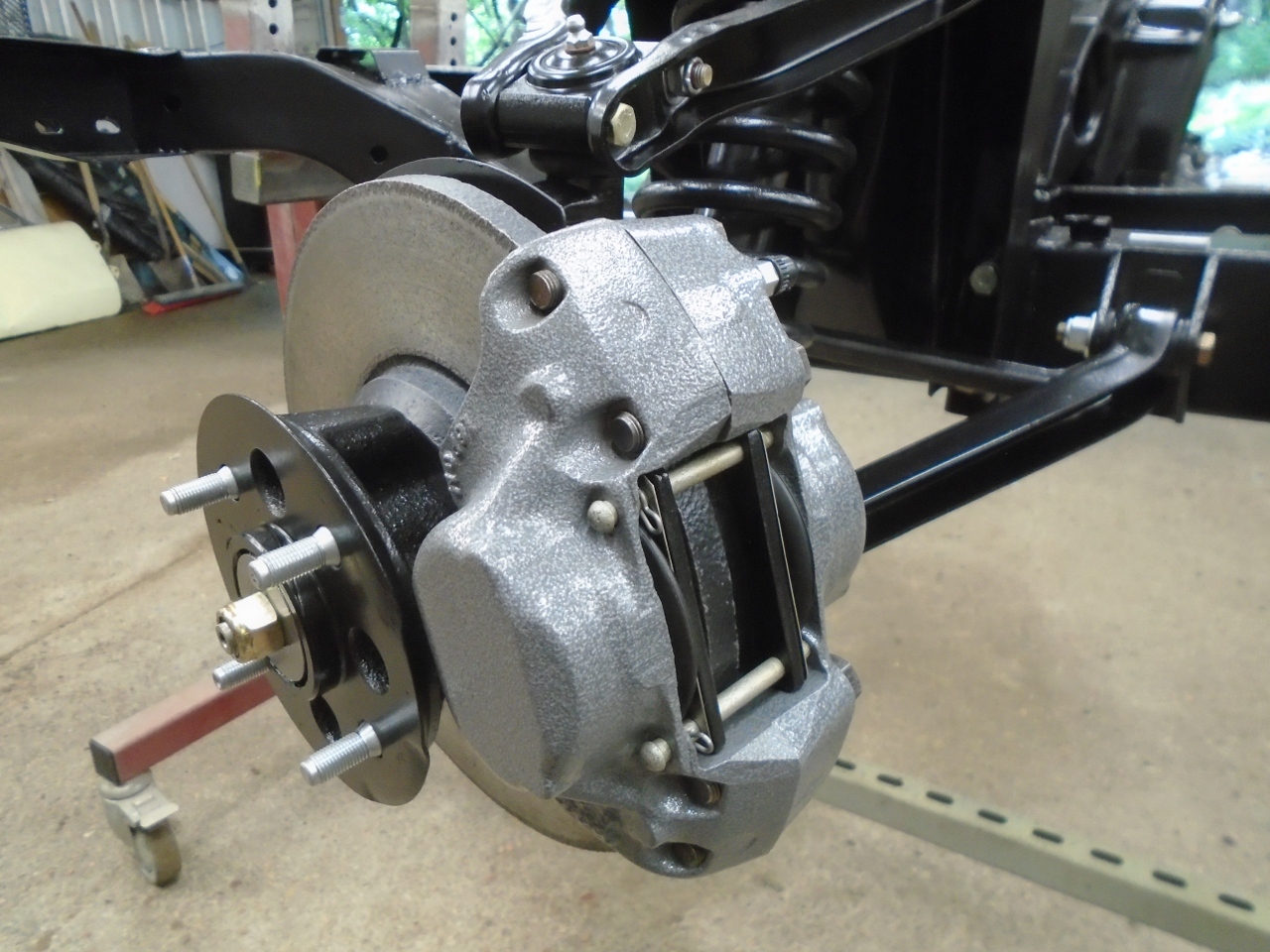

One

rebuilt caliper. On things like this that I don't tackle often, I

do one side at a time, so I have the other for reference.

The

other caliper proved to be a little harder. One of the pistons

didn't respond to compressed air to remove it. It was stuck good.

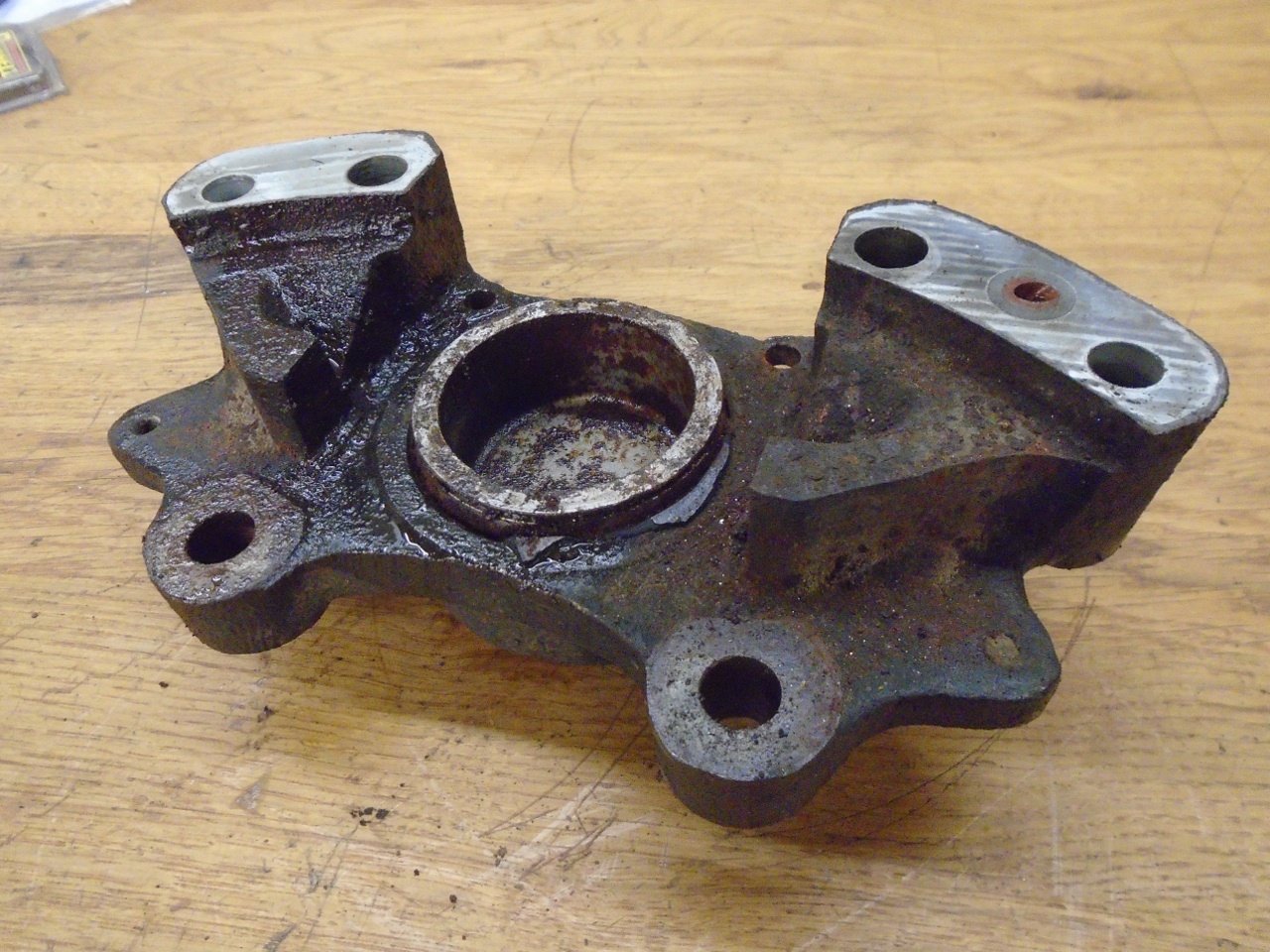

This

is what it took to extract the piston. The bore looks rusty in

the picture, but that was just dirty brake fluid. The bore was

good.

Ready to go!

A little step forward.

This job was fairly quick--only a few days of off and on work. Cost was around $100, mostly for the stainless pistons.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages.