To my other GT6

pages.

October 1, 2020

Remounting the Body

I waffled quite a bit about whether to paint the body while it

was up on the rotisserie, or to mount the body on the frame and

paint it later. One huge problem is that I haven't settled

on a color yet, and don't really want to be rushed in that

decision. Plus, I haven't even started the bonnet yet, and

it would make sense to paint them both when I set up the paint

booth. So, for these and a few other reasons, I decided to

remount the body to the chassis now.

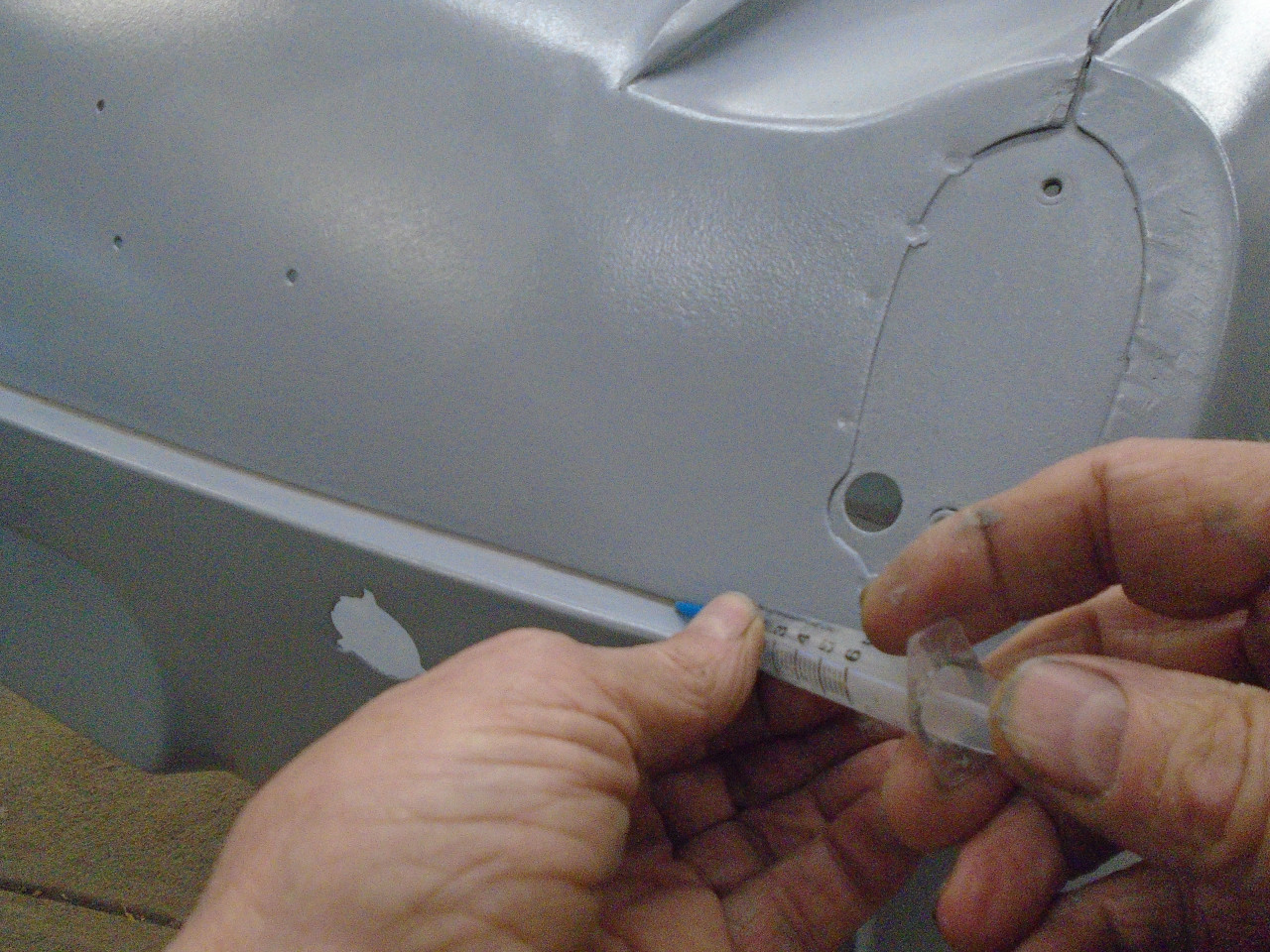

With that decision made, I considered all the prep work to do.

First, in an uncharacteristic instance of forethought, I

remembered that there was a small surgery that needed to be done

to the wheel well to accommodate the damper

extension brackets. The body is upside down in this

pic. That edge was welded closed before patching the epoxy

primer.

Then a 3M brushable seam sealer was applied to all the joints I

could find, both top and bottom. The sealer is gray, so

it's a little hard to see against the gray primer.

One sort sensitive seam is the horizontal one across the rear

valance. For this one I loaded some sealer into a syringe

with a small plastic tip so I could force sealer all the way to

the bottom of the seam. I could then tool it with a wet

finger without getting much on the surrounding surface.

I think the next step may be a little controversial in some

circles. When I did the TR6, I was a little queasy about

leaving the bottom surface of the tub with just body

color. Granted, it did have probably four coats of a good

epoxy primer under the color, but it still seemed like a that

little more protection for this very hostile environment would

have been good. I rationalized by reasoning that the

roadster, at least under my stewardship, would not likely see

much bad weather. I couldn't necessarily say that about a

GT car, though.

I decided to use a good quality undercoating on the bottom of

the tub. There are a few to choose from. Mainly from

the company reputation, and some good recommendations, I chose

3M Schutz. There is a paintable version of Schutz, but I

didn't really see the point of that. I've used the product

before on the TR6 rockers and wheel wells, so I knew that the

overspray can be difficult to remove. I spent some time

masking and taping over holes.

Then sprayed about two quarts on the underside and in the wheel

wells.

I also decided to do a little body work to the rear valance

before taking the body off the rotisserie. It was at a

much more convenient height for this work than on the

frame. At least two minor rear-end boo-boos and repairs

left some ripples in the metal back there. While I was at

it, I prettied up the more visible parts of the firewall and

environs.

After this, the entire body got another coat of epoxy to cover

the filler and seam sealer.

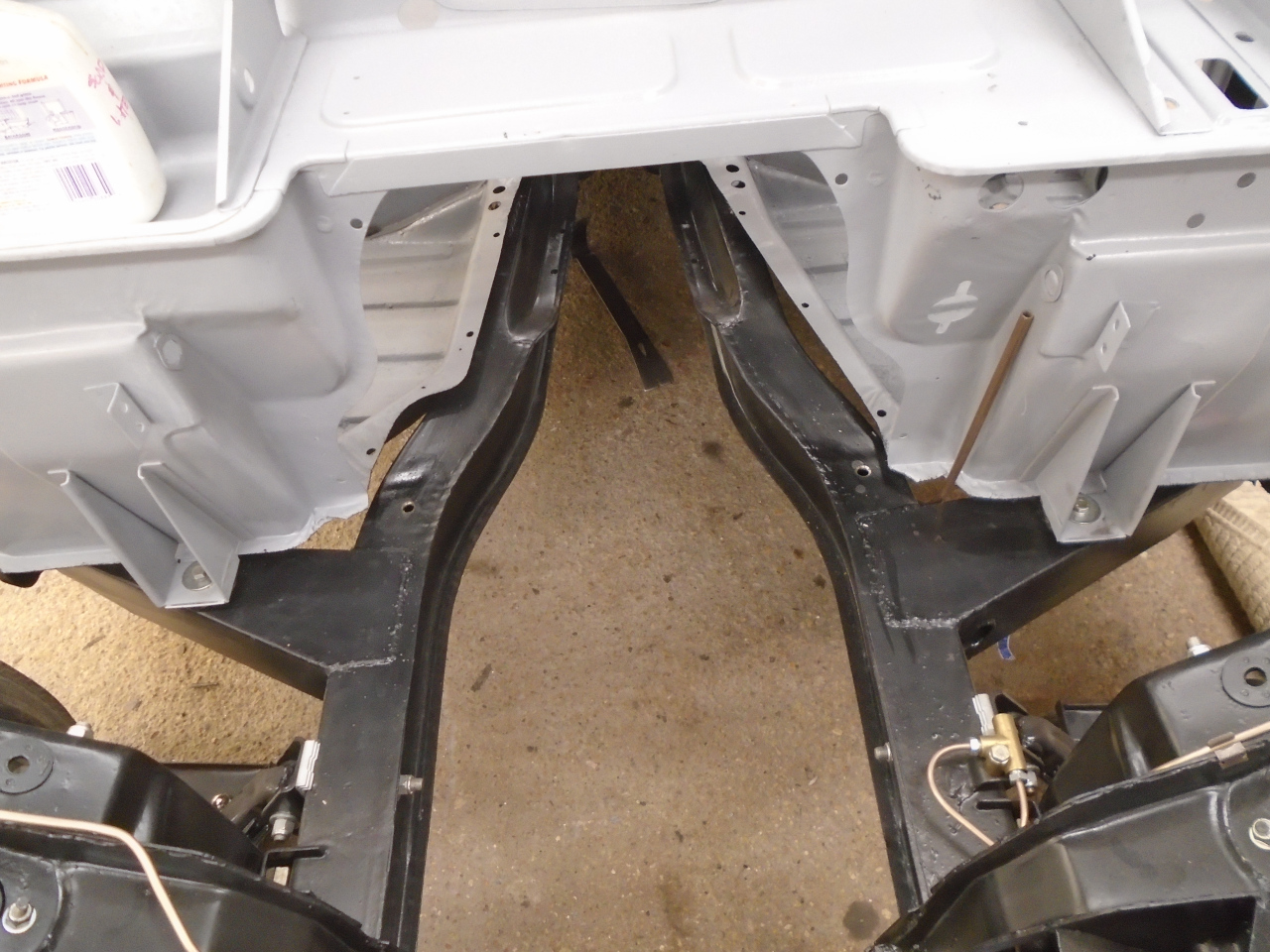

OK, so much for prep of the body. Now for prep of the

chassis. First, I had to retrieve it from the top bunk

where it spent the last year.

The first thing I wanted to do was do some rustproofing inside

the frame rails. I'm aware of, and have even used a

popular product called "Internal Frame Coating". As far as

I can tell, it is pretty much an ordinary zinc based paint, just

labeled and marketed for this very specific purpose. I

can't see anything about it that makes it uniquely suitable for

the insides of frames, other than maybe the extension tube and

remote spray nozzle that it comes with. Further, as with

any paint, success is heavily dependent on surface preparation,

and any meaningful surface prep inside a frame is just about

impossible.

My preference these days for rust protection of internal spaces

tends more toward the waxy substances that flow and penetrate,

but never harden. There are a number of products, most of

them appear to be similar. On this project, I used a

Transtar product. As a side note, it looks, smells, and

feels exactly like what Ziebart uses for interior

cavities. I assume it's the same stuff. I used the

remote nozzle that came with the Internal Frame Coating. I

was able to reach most areas of the frame through existing

holes, but I did have to drill a couple of new holes.

Then we come to the question of mounting pads that go between

the body and the frame--how many should there be, and where they

go. I checked all of the usual sources on this topic, and

found that there is no clear answer. The factory Workshop

Manual doesn't show any mounting pads. Some of the vendors

show them, but they don't agree as to number, type, and

location. The only thing that the Workshop manual says it

to put a ring of sealant around each mounting point on the

frame. So I did that.

One other clue I had was the pads I removed from the car at

disassembly. There were two 1/4" thick aluminum pads and

two similarly sized rubber pads. The semi-helpful note I

had included in the Ziplock bag said "Alum at front".

I had ordered half a dozen rubber pads, but just made a pair of

new aluminum ones to replace the severely corroded originals.

With all of the uncertainty about mounting pads, I decided to

just drop the body on the frame and see where the spaces were.

This resulted in the body rocking on one of the center pairs of

mounting points, clearly showing that pads were necessary at the

front or rear or both. I recalled the Ziplock clue, and

put the new hard spacers at the front, and a pair of rubber ones

at the rear. This seemed to stabilize the body

nicely. On inspection, I found that the rear outriggers

had about a 1/4" space between frame and body, so I stuffed a

pair of rubber mounts on each side. This is where I left

it.

I rounded up all of the original body mounting bolts, stripped

them, plated them, and re-used them. Washers got replaced.

Some minor shifting got all the 12 mounting holes lined up well

enough to fasten her down.

Having the body finally back on the frame then allowed a couple

of other areas to be finalized. One is the hard brake line

that runs across the car from one side to the other at the

rear. It is fastened to the body by a couple of clips that

are often forgotten when the body is lifted off. This

usually mangles the line pretty badly. I straightened it

out well enough to use as a pattern for a new copper-nickel

line. I couldn't really get a good pic of the line in

place.

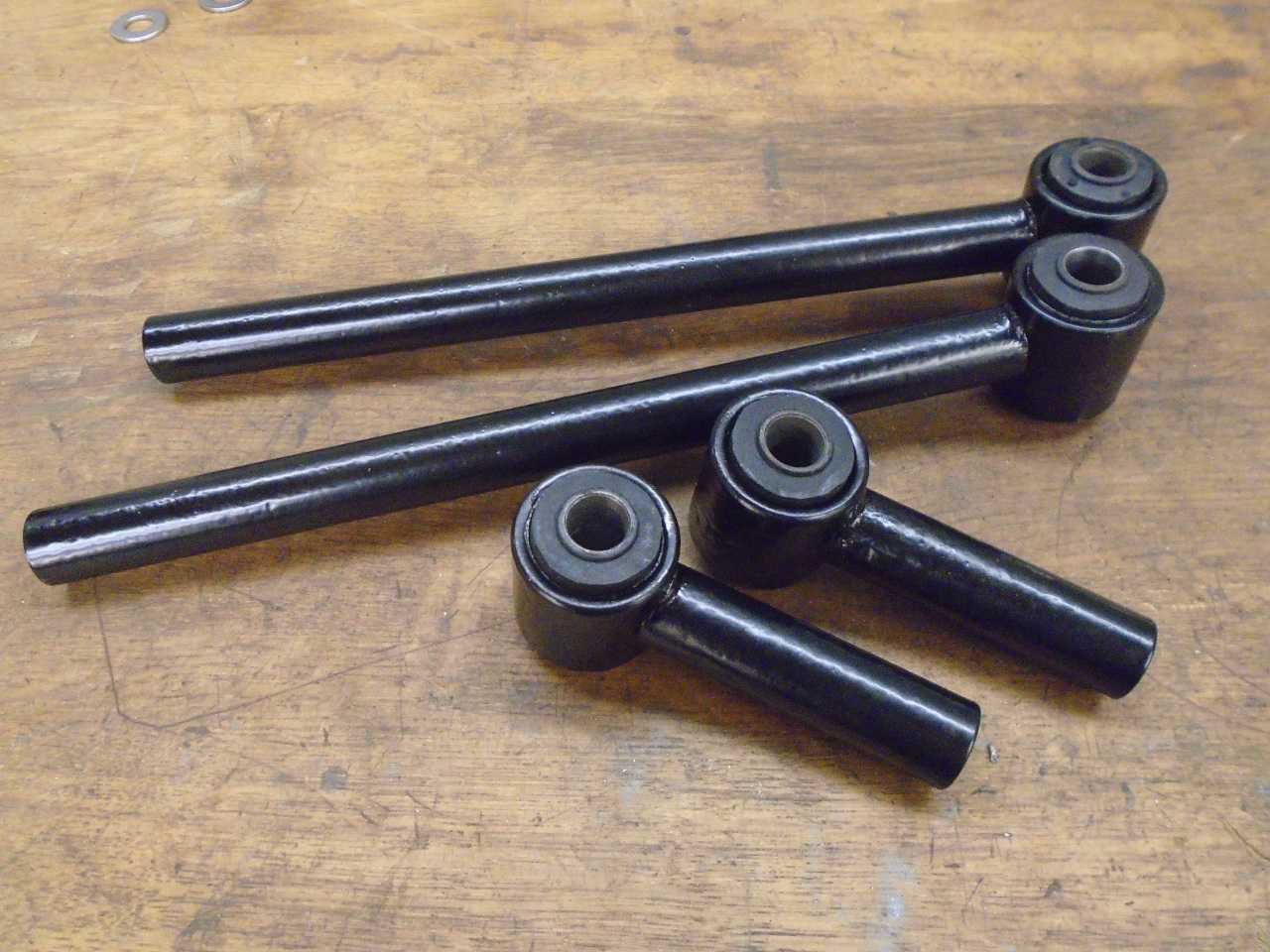

The last thing to do was to tend to the radius arms, which

attach to the rear suspension and the body. These

adjustable links stabilize the rear suspension, locate it in the

fore/aft position, and allow for adjusting the toe in at the

rear.

My links were pretty corroded, but did come apart after some

coaxing and threats.

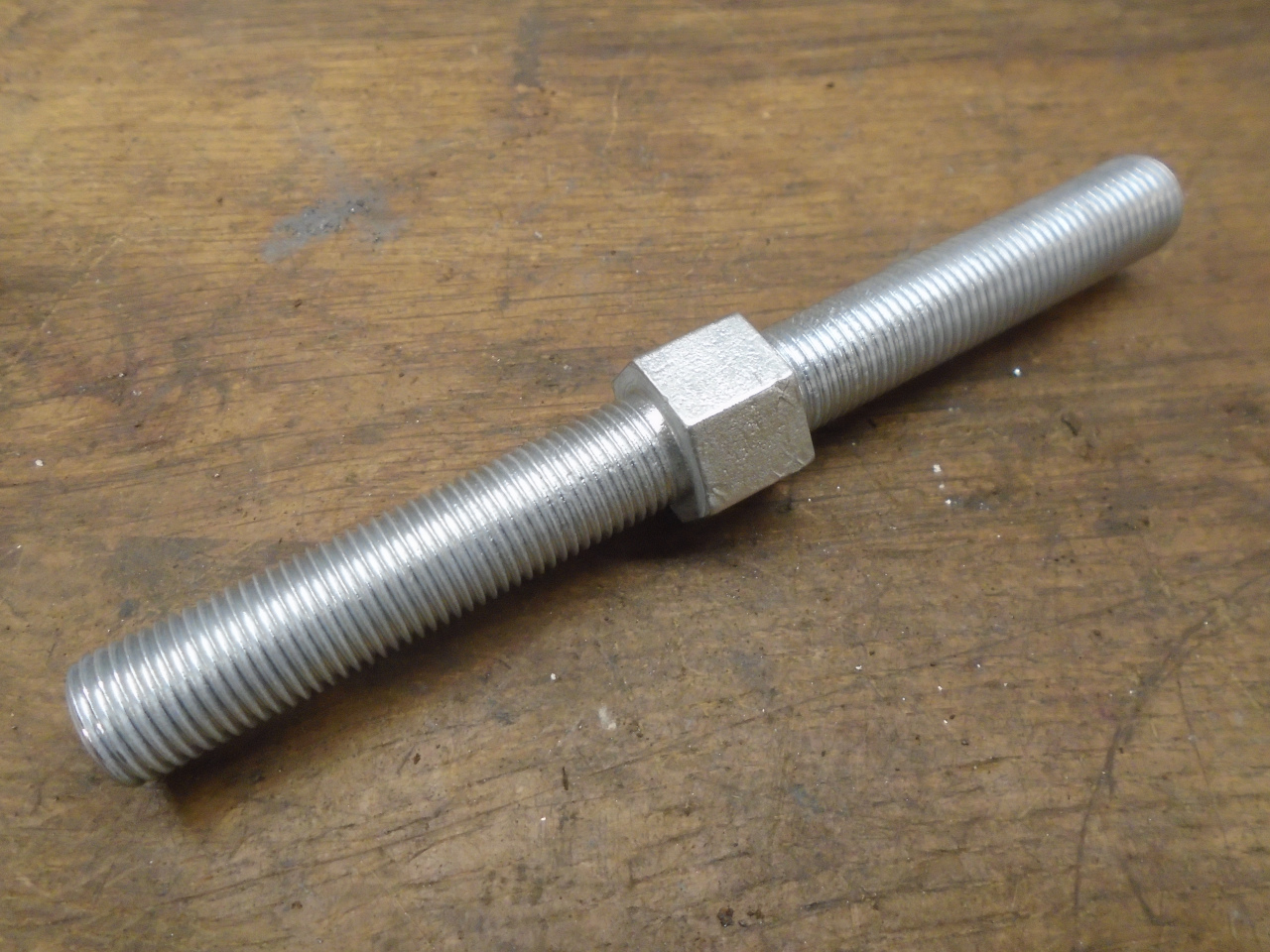

All was well, except one of the adjuster lock nuts decided to

gall and strip the threads.

These links are essentially just turnbuckles, with left and

right hand threads on the adjuster, and while I thought about

just making a new adjuster, I found that just buying one was

cheaper than the 1/2-20 Left Hand die I'd have to get. So

I ordered one.

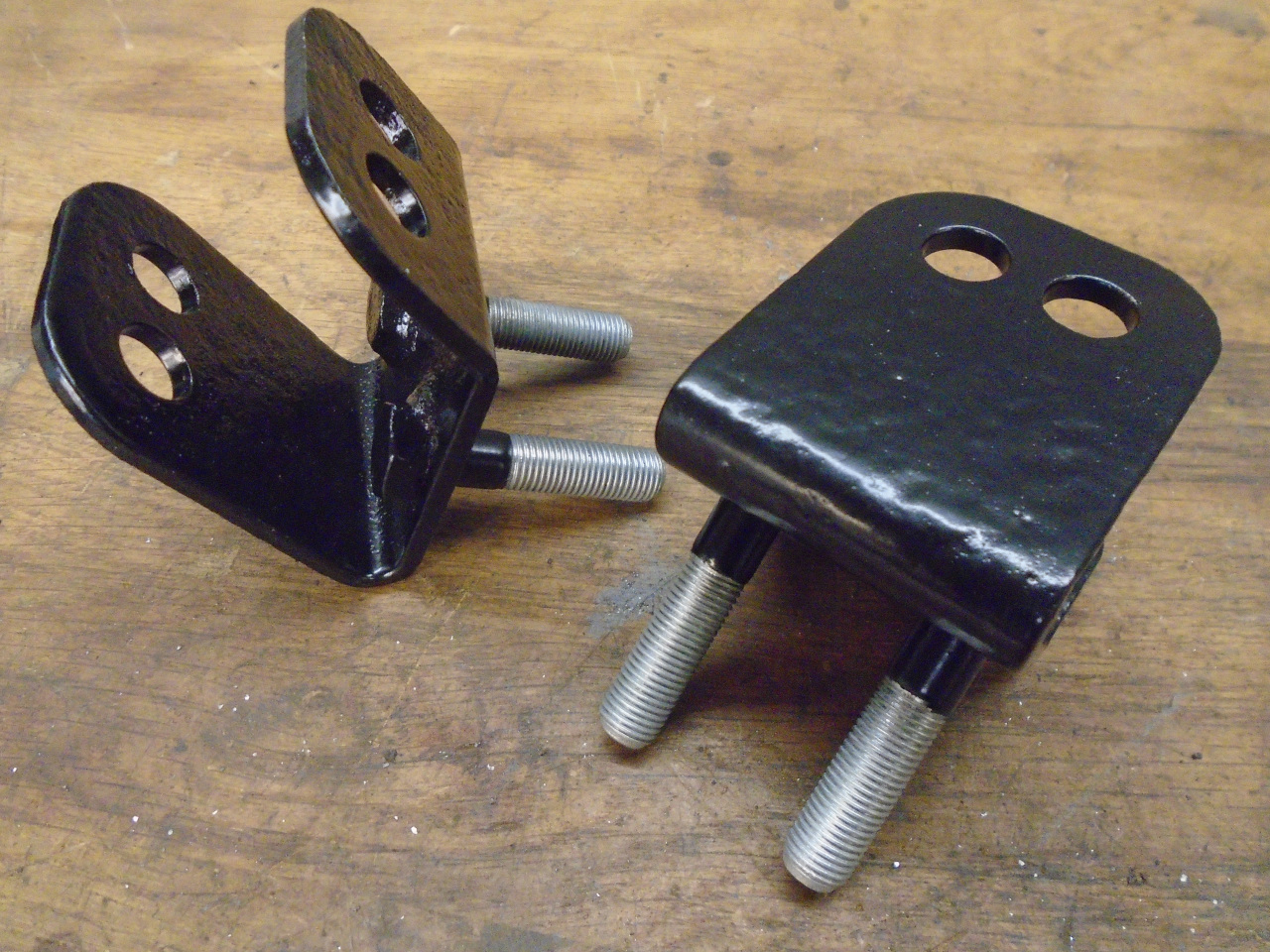

While waiting for the adjuster, I removed the rubber bushes from

the link arms and cleaned them up.

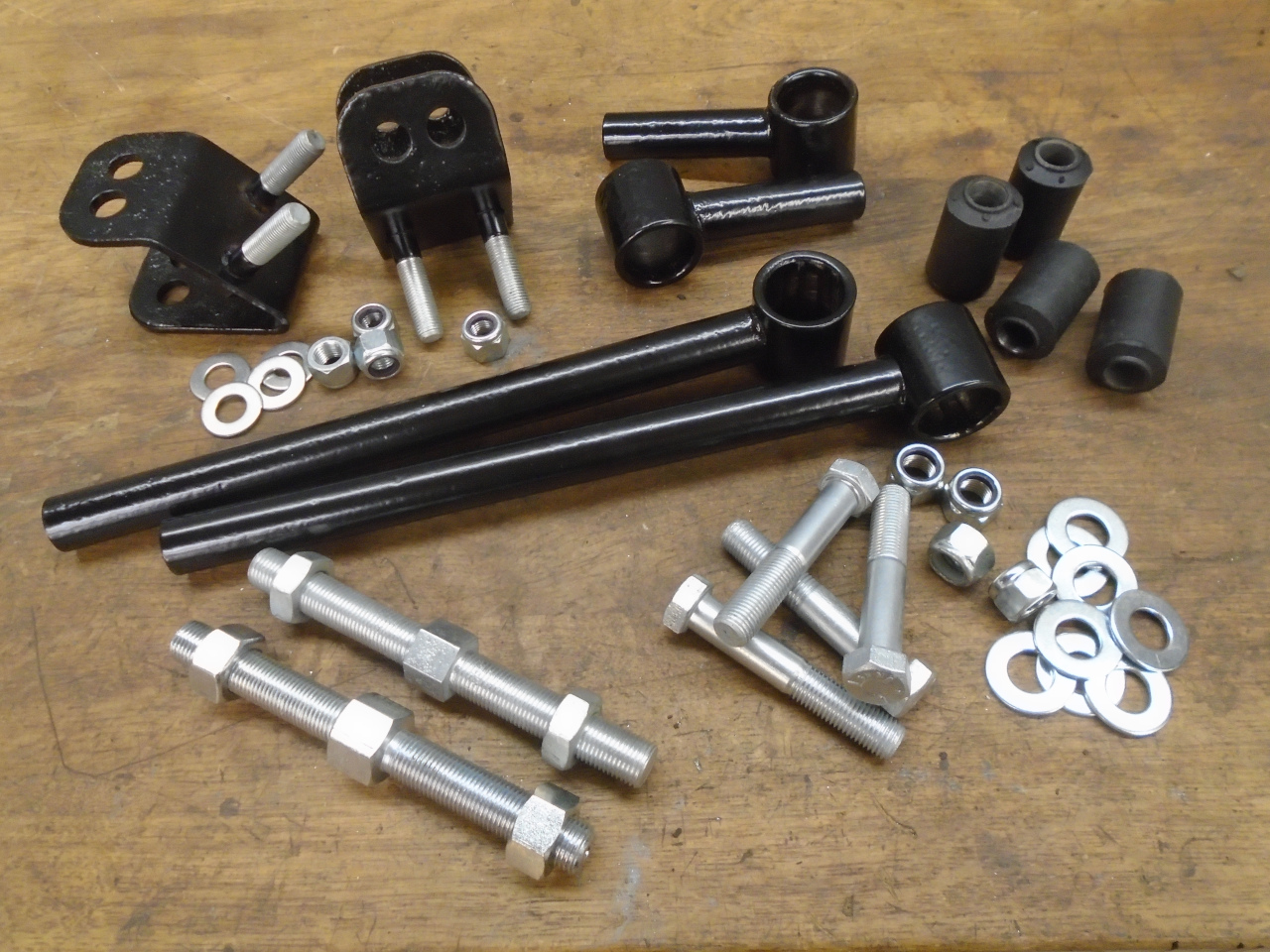

Then turned to the brackets that mount to the body.

These are a little problematic in terms of rust

protection. It would be hard to get plating to reach to

the inside of the sharp bend of the bracket, while powder

coating can't really be used on threads. In the end, I

just selectively plated the studs, and powder coated the rest.

The surviving adjuster and the mounting bolts plated

nicely. Plating original hardware does take some time, but

it always fits, saves a little money, and the distinctive head

markings are something that some future restorer might care

about.

Finally, with all the parts in, I could assemble the arms...

...and put them in place. I measured the arms before I

took them apart so I could return them to the original

measurement before final alignment.

This feels like another milestone. One important thing is

that by reuniting the frame and body, I've drastically reduced

the storage space needed for the project. Not much cost

here, either. Just some consumables, and bushes and the

adjuster for the radius arms.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages.