To my other GT6 pages.

August 9, 2019

Front Hubs

The

front stub axles on the GT6 carry pretty conventional wheel hubs.

The hubs use opposed tapered roller bearings with a felt grease

seal at the base of the axle. The brake disc is bolted directly

to the rear of the hub.

My hubs were appropriately rusty and dirty...

...but they cleaned up well. They both appeared to be in good condition.

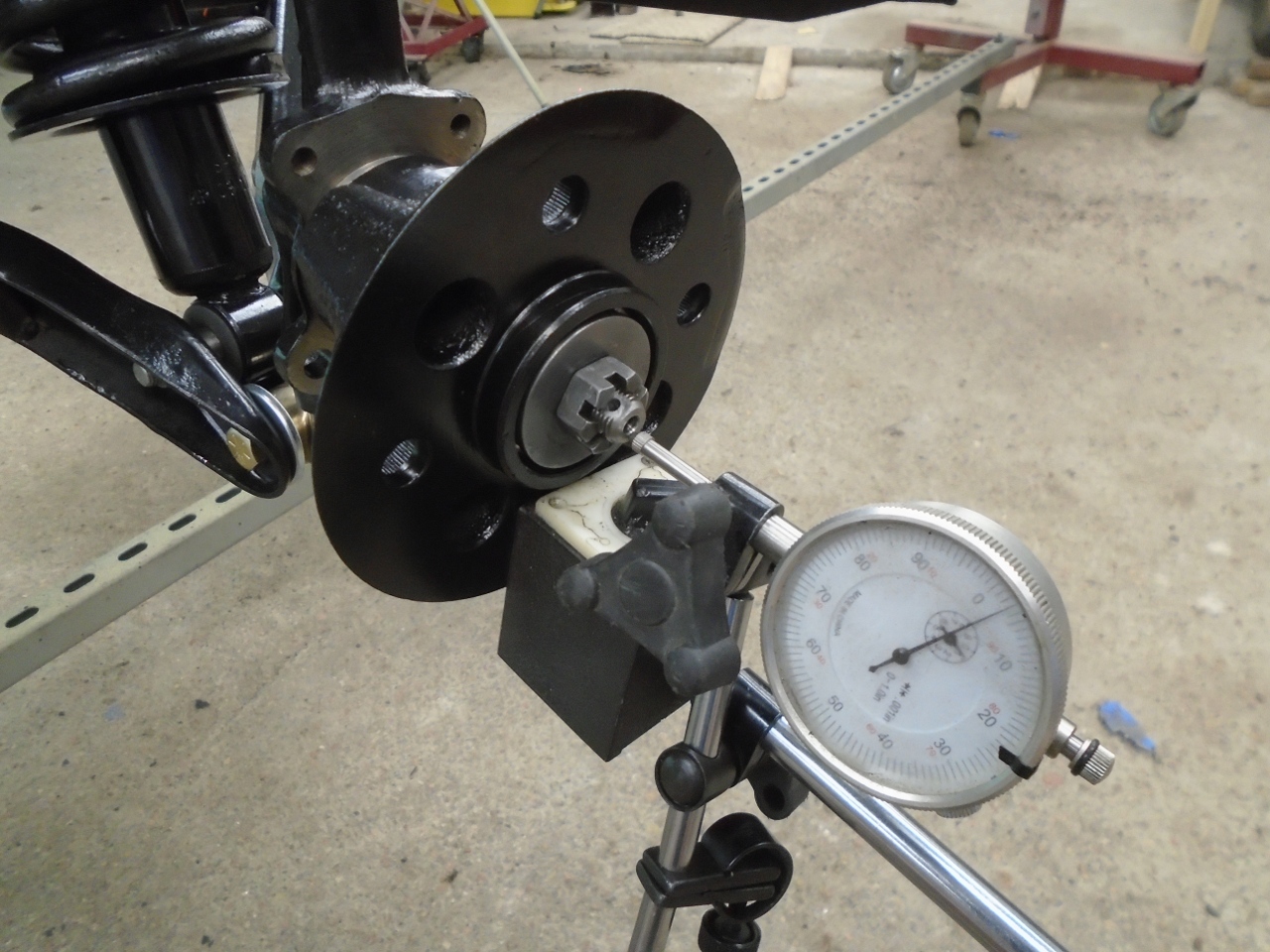

I

checked the wheel mounting surfaces for runout, and found essentially

none. I did a light skim of the surfaces just to clean up some of

the rust pits.

I

ordered bearing sets from one of the Big 3 suppliers. The

bearings looked and felt fine, but they were a Chinese brand I

didn't recognize. Now, I don't necessarily have anything against

Chinese products--I have and use a lot of them. On the other

hand, I considered the quality of these bearings to be unknown.

In the end, I ordered bearings from an industrial supplier in a

brand I was familiar with. The cost was actually about the same

as for the foreign units.

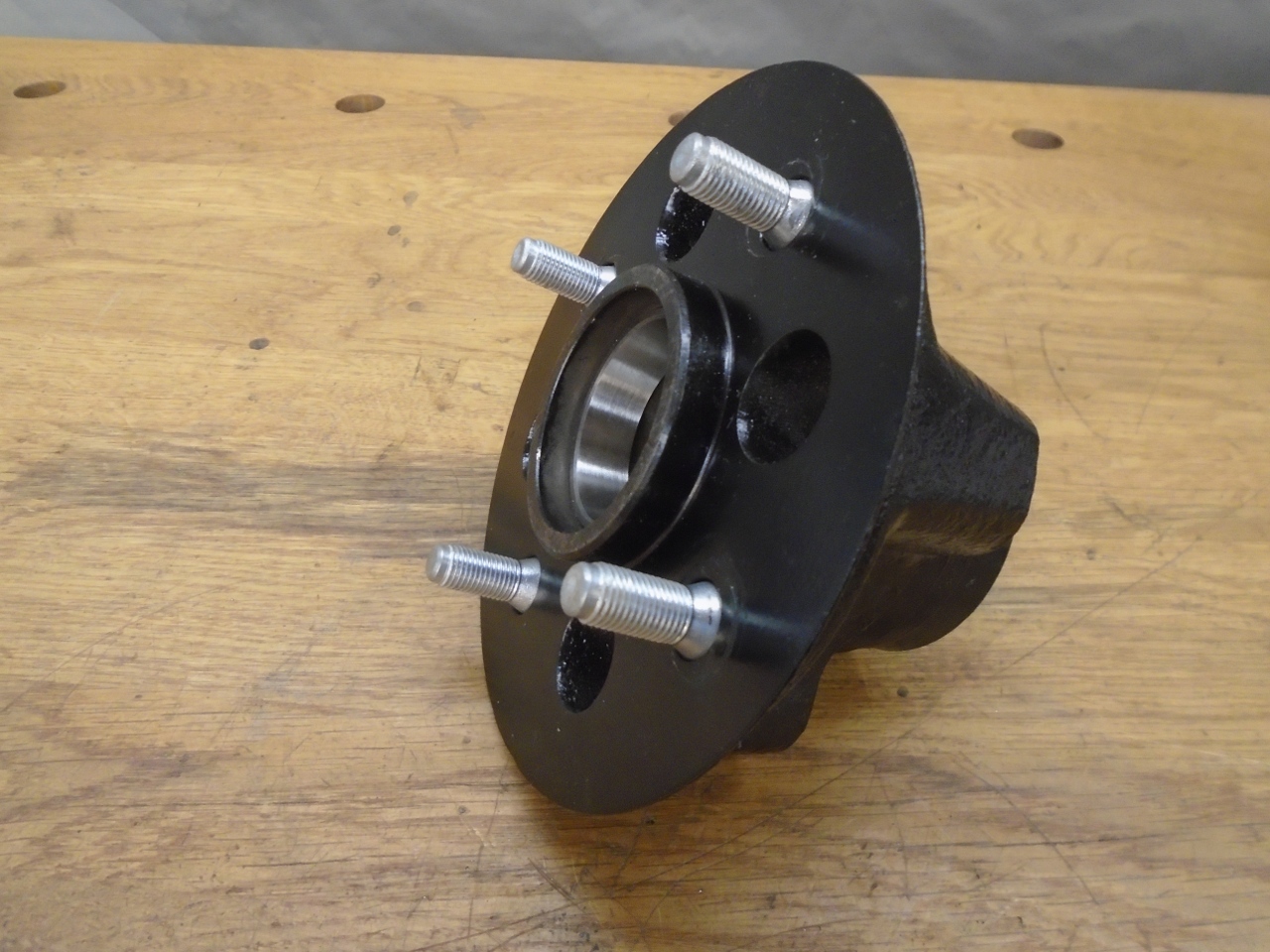

After a nice powder coat, the cup races went home.

And here is where it gets a little more interesting.

Bearing

arrangements like these like to have a small amount of float, or play,

to make sure they don't run too tight. Triumph chose to provide

for the specified 0.003-0.005" clearance by requiring that the axle nut

not be tightened, but left a little slack. This is disappointing to me.

Beyond this, since the axle castle nut can be pinned with a

cotter pin at only 12 different half-flat positions, a little

math shows that a 1/12 turn of the 1/2-20 nut will move the nut a

little over 0.004". This means that technically, it might be

impossible to hit the factory spec.

So,

to fix what I consider a bit of lazy design, I borrowed the arrangement

used by many other cars, including at least some MGs of the era.

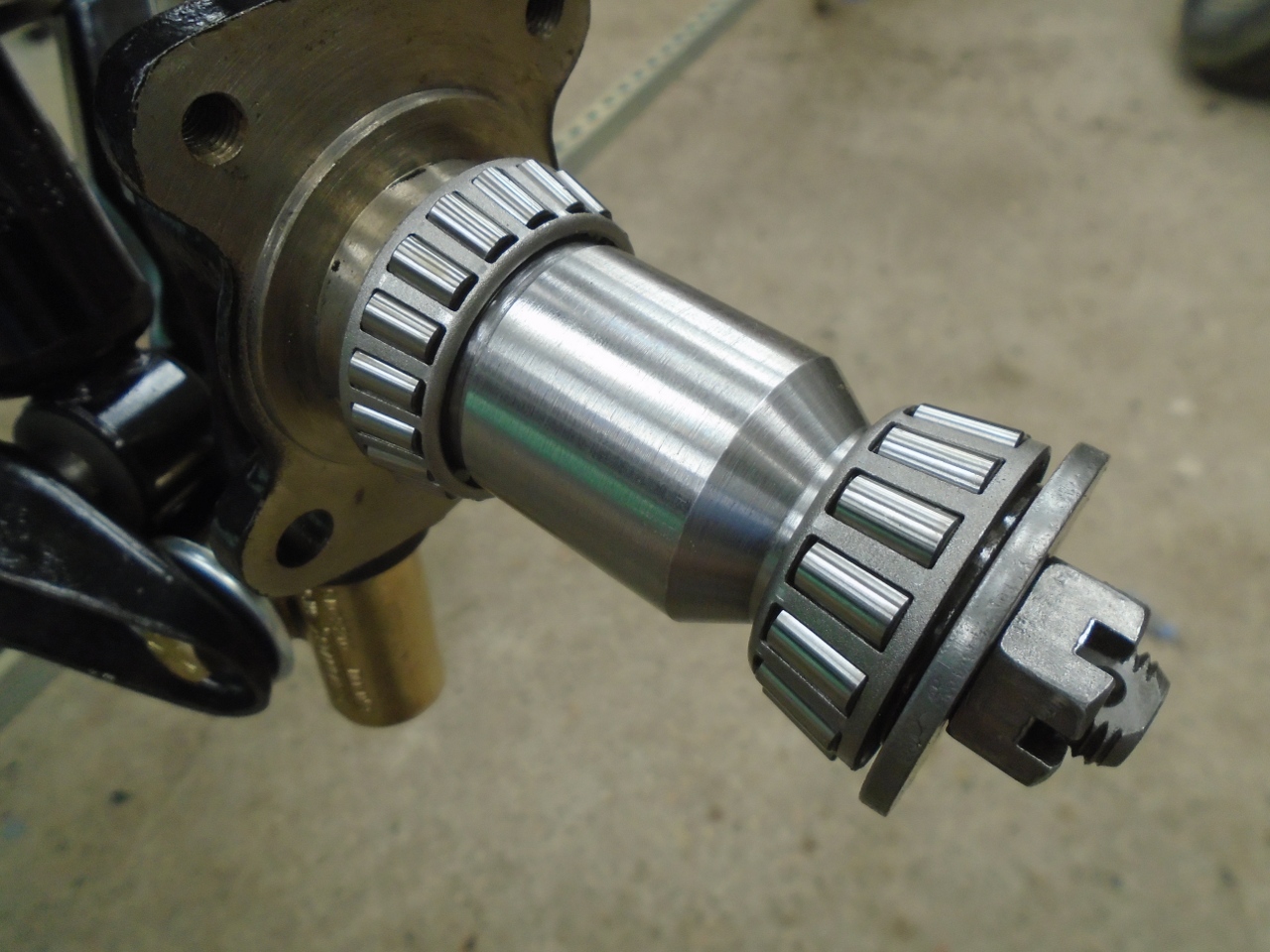

These cars use a distance piece between the inner races of the

two bearings. This spacer sets the spacing of the bearings, and

thus also sets the clearance positively.

Another

side benefit of this approach is that it significantly strengthens the

stub axle. When the axle nut is tightened down, the stack

composed of the spacer and the two bearings' inner races is placed in

compression. The stub axle is in tension. This

compession/tension configuration is essentially a pre-loaded truss.

In

the TR6 world, kits are available to do this, but I didn't find them

for Spitfire/GT6 cars. So to make the spacer, I started with a

hunk of really good steel...

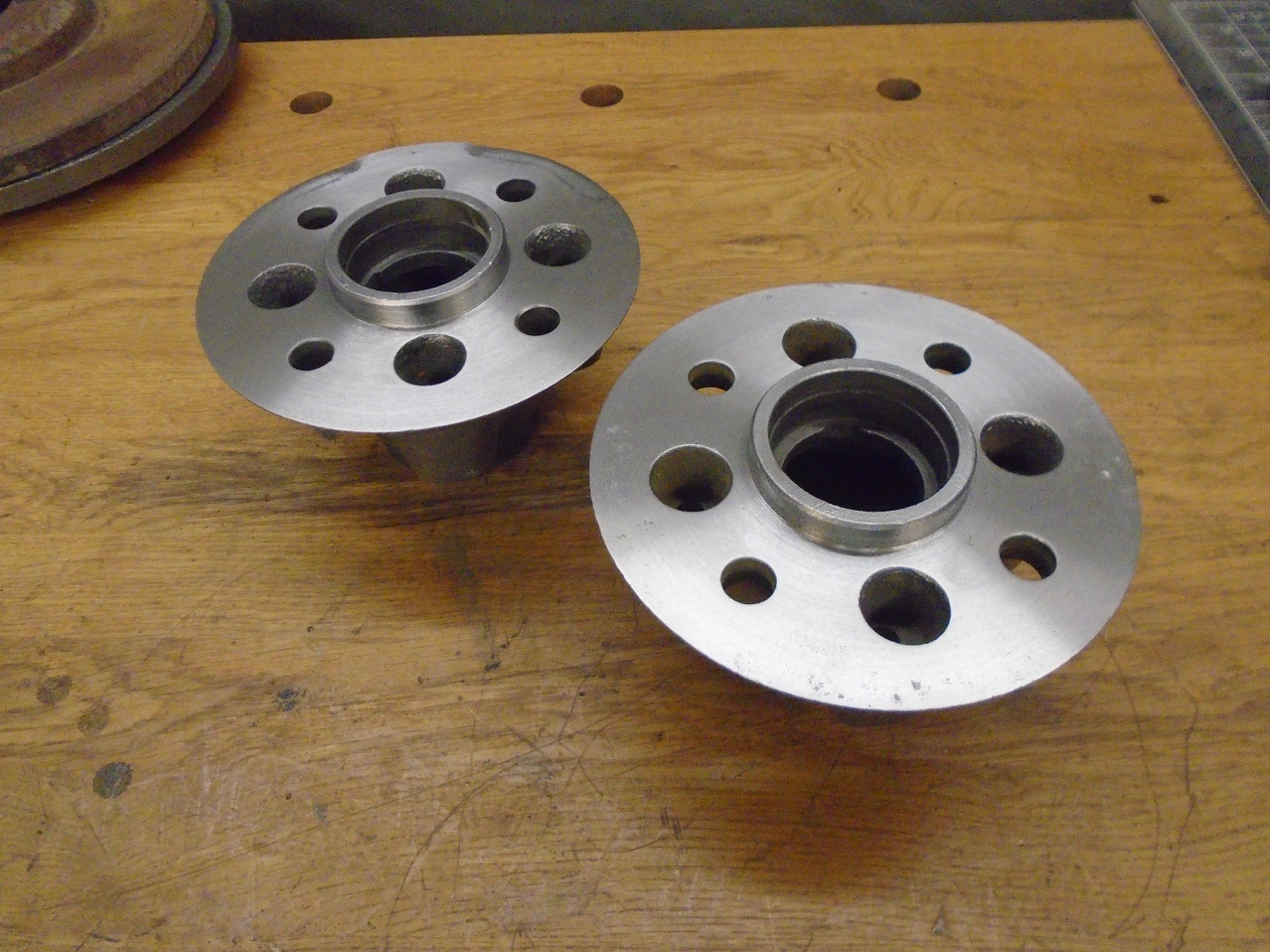

...and fashioned these barrels that fit over the stub axles and match the inner races of the two bearings.

Adjustment

of the actual clearance is done with shims between the spacer and the

outer bearing. Once the shims are determined, the setup is very

repeatable.

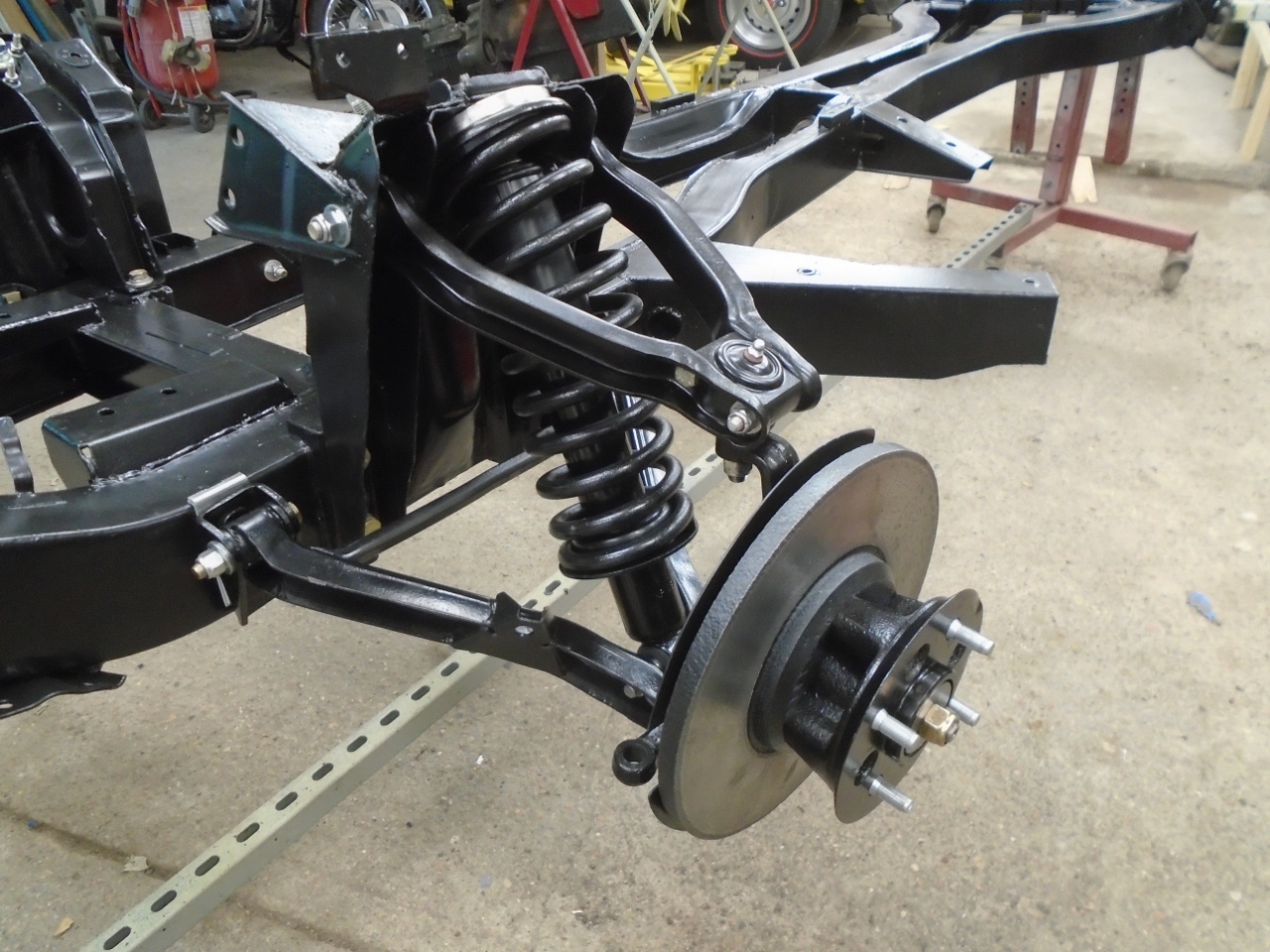

With

that sidetrack out of the way, the hubs can be mounted, but a few other

items have to be bolted on first. The caliper brackets and the

steering arms were powder coated and the original hardware replated.

The disc shields were a little awkward for the PC oven, so they were shot with some 2-pack epoxy.

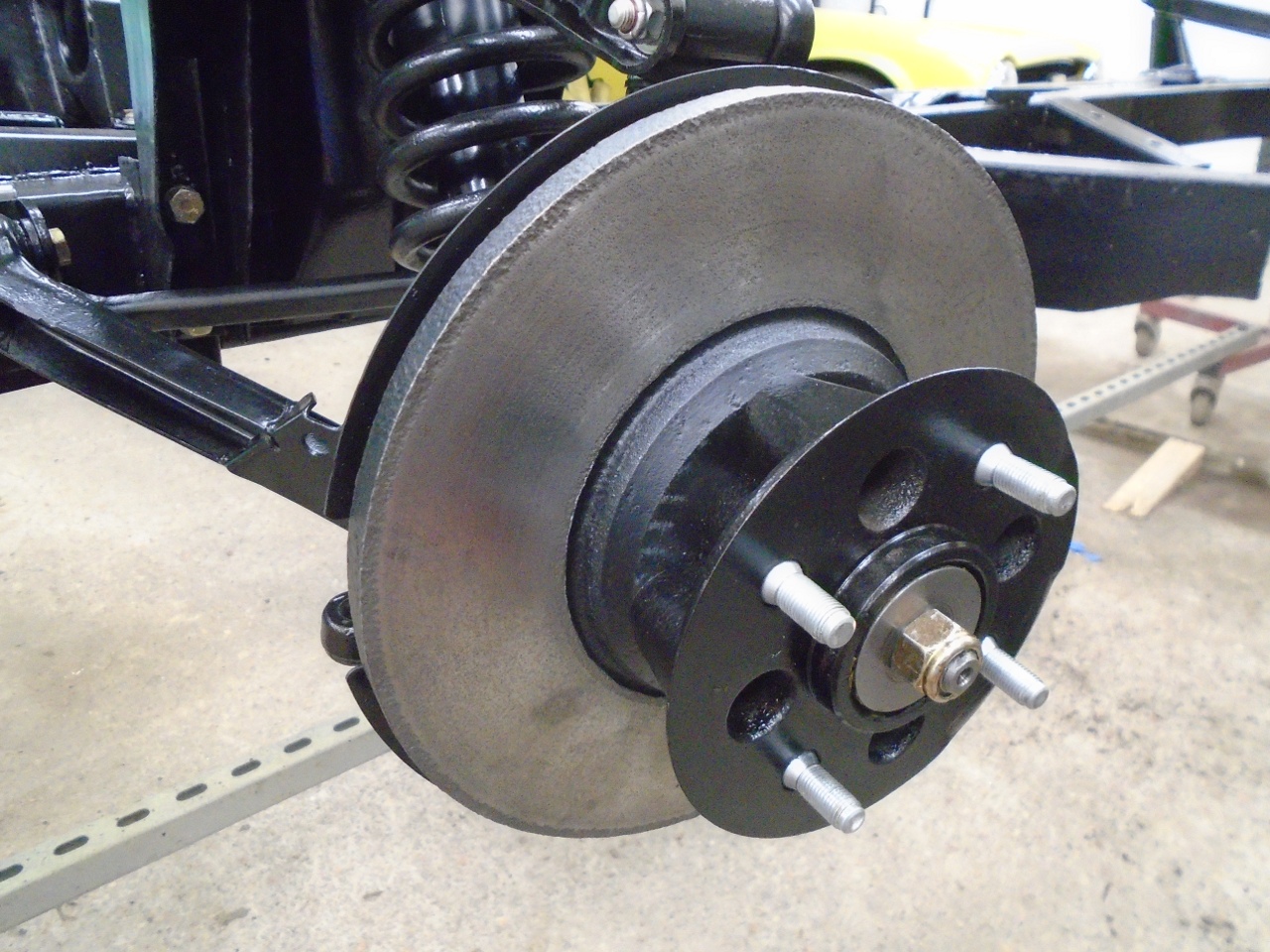

Replated wheel studs have to go in the hub before attaching the brake disc.

My

brake discs were a little pitted from the rust, but must have been

replaced shortly before the car was put away. They measured

essentially full new thickness, so I reused them.

The

last thing to do before sliding the hubs into place was to install the

hub grease seal. I had some trouble with the grease seals I got.

I traced the problem to them being about 0.020" larger in

diameter than the originals. The metal cup part was also quite a

bit taller.

I ended up removing the felt from the new seals and using it with the original metal cups. The felt was soaked in oil.

Then packed the bearings and the hub cavities with wheel bearing grease...

...and

put the hubs in their rightful places. Since the axle nut now has

nothing to do with setting the bearing clearance, it can be a Nylok.

This was a sort of fun project. I think total cost was under $50 for bearings and other materials.

Now it's on to brakes or steering.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages.