To my other GT6

pages

June 2, 2020

A & B Posts, Sills, Inner Wings

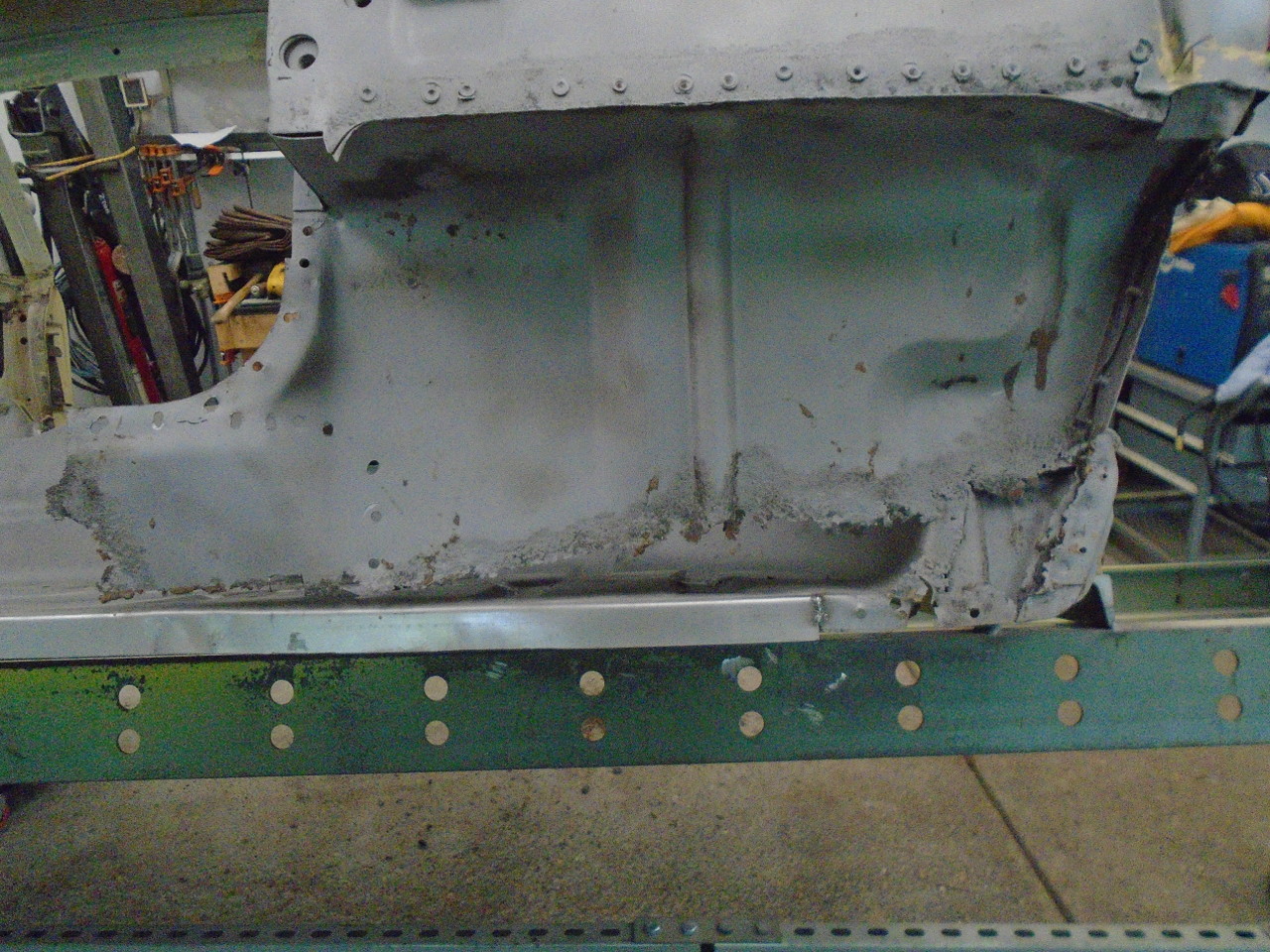

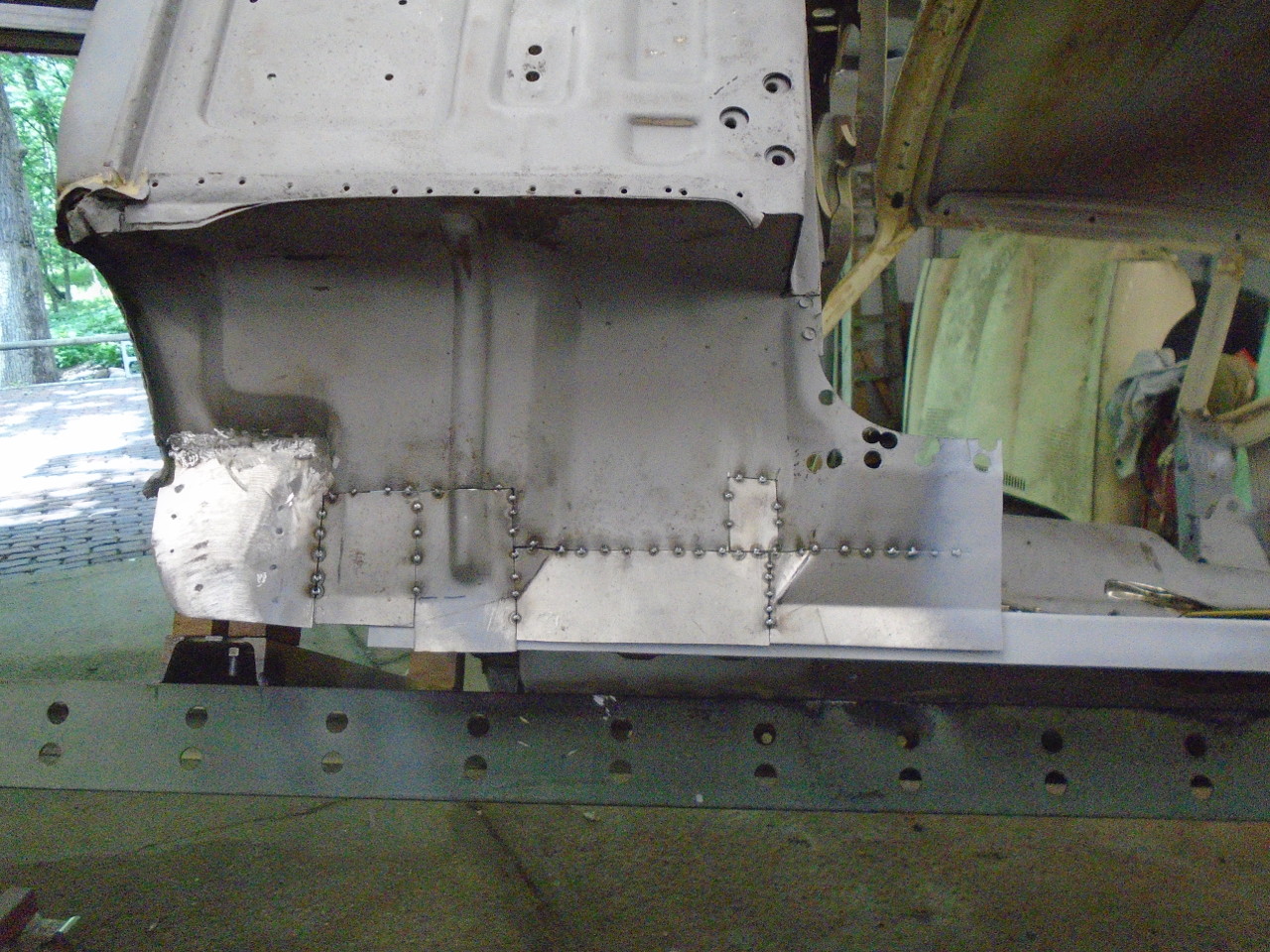

With the right side floor

finished, I had a good foundation for the inner sill, but

the A and B posts really needed to be repaired first, so I

pulled the car outside, and blasted those areas. In

GT6-speak, the "A post" is really everything in front of the

door. The lower three of four inches of my A post was

essentially missing. The new floor flange at least showed

what had to be done.

A little piece of the floor had to be patched, and the flange

fixed.

There is actually quite a bit of shape in the piece of the A

post that I needed to replace--several angles, and a sort of

half-round channel feature. I briefly considered trying to

make it all in one piece, but finally wimped out and decided to

make patches with one feature each. A man has to know his

limitations.

The pieces with the angled bends weren't too challenging, but

the half-round feature had me spooked. The fact that it

ends in mid-panel freaked me a little. I have a bead

roller, but it has no rollers that matched the contour, and no

good way to do a nice end shape.

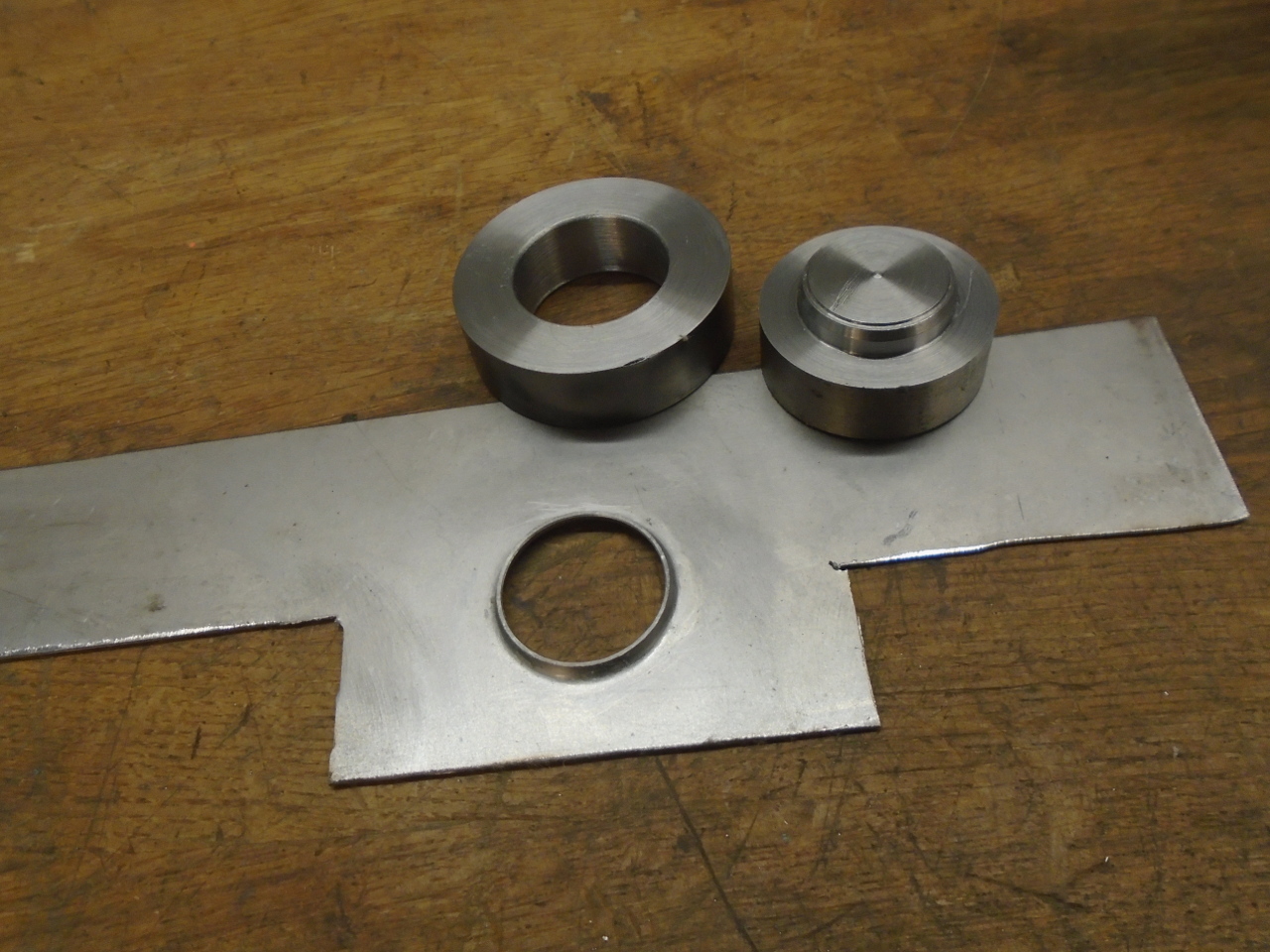

Enter the 3D printer to the rescue. I printed a simple

tool and die that did the job. Certainly not production

tooling, but for one or two pieces, it worked great.

The rest was easy by comparison.

Then, another common rust area on these cars is this seam midway

up the A post.

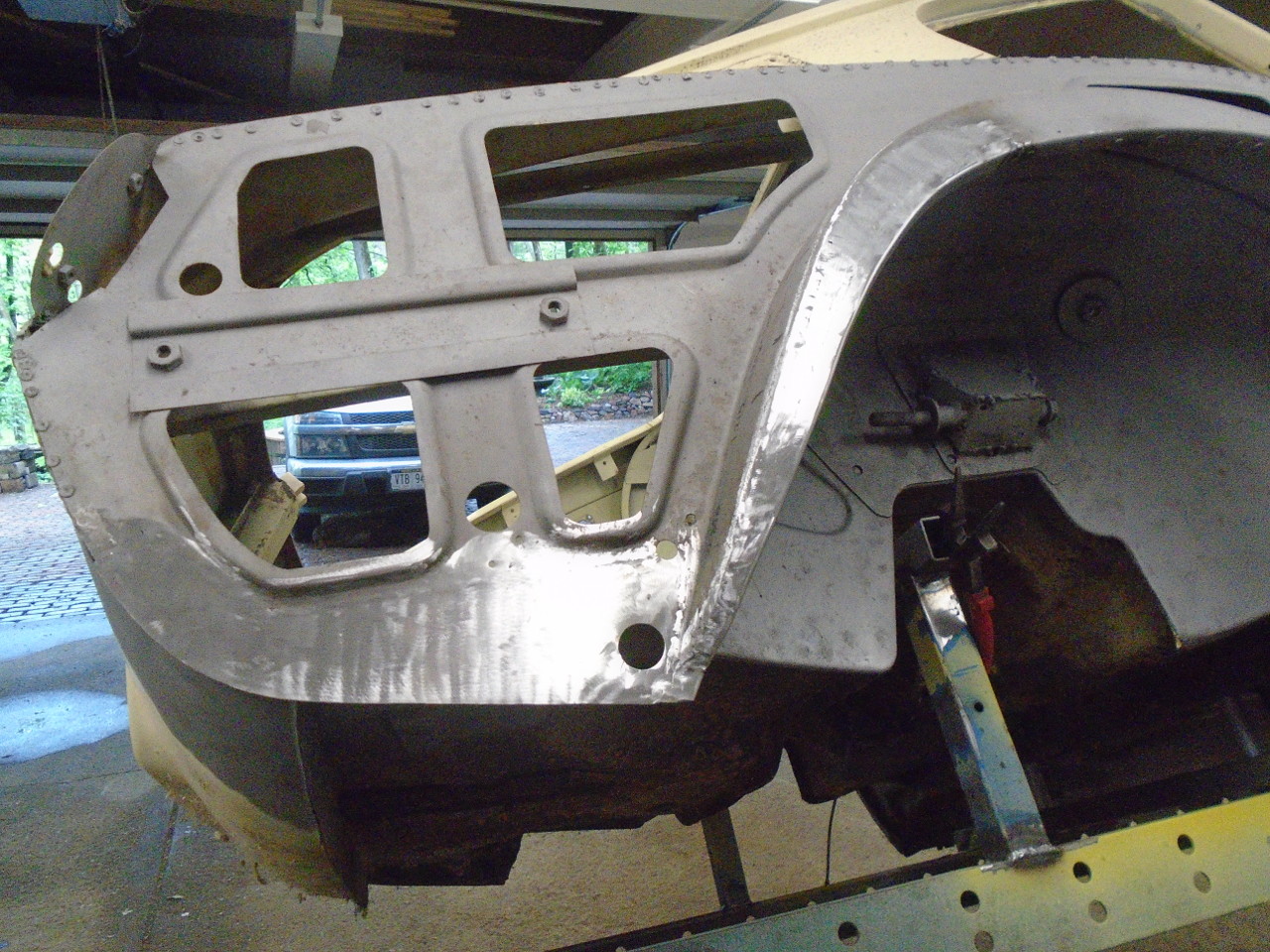

Moving to the B post, I was having a hard time seeing exactly

what the construction and the damage was. Considering all

the rust on the wing, I decided to remove it. That

revealed a lot of rust damage that would be hard to see, let

alone fix otherwise.

Tabling the B post repair for the time being, I started rust

repair at the rear. Blasting the area really gave a much

clearer picture of the damage.

A plan emerged.

The boot floor first had to be patched under the stiffener for

the bumper brackets.

Finally applied inner wing the patch. Almost forgot the

stiffener underneath the boot floor.

This brought me to the really scary part: the wheel

arch. It was pretty much all curves. Compound

curves. There were two rusted areas: one on the trailing

edge of the arch, all the way to the top, and a smaller area on

the leading edge. The rear one was up first.

Not confident that I was good enough to do it in one piece, I

did it in two. The first one was the easy one.

With maybe 50 trips between the car and my Harbor Freight

shrinker-stretcher, I had something that seemed to fit OK.

The numbers on the arch are measurements of the thickness of the

face of the arch, taken from the remnants of the original metal.

Then to the front of the arch.

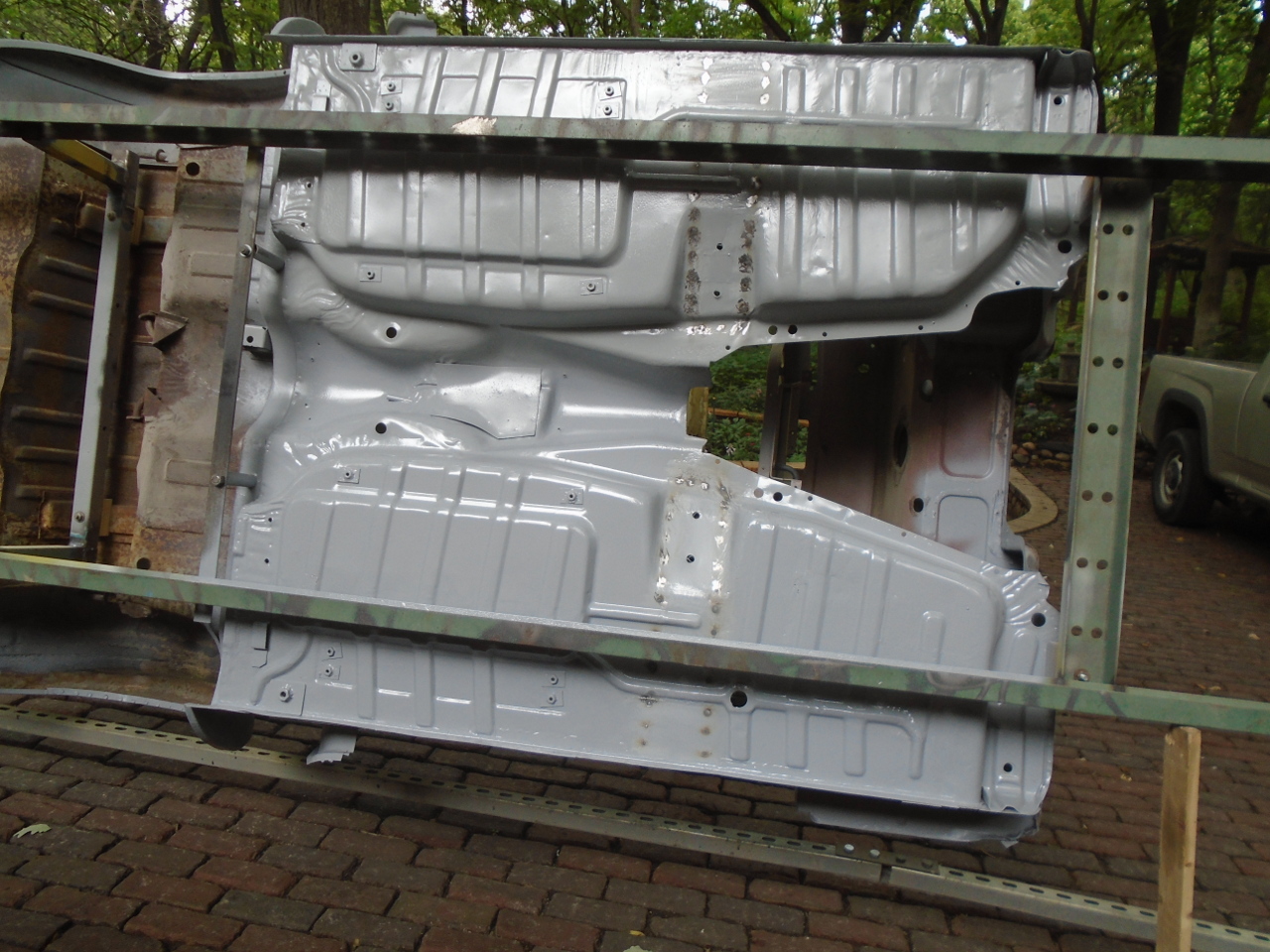

Before the lower part of the arch front, a little patch on the

cross member, and one on the front face of the arch. The

body is upside down in these pics.

Then a curly pieces.

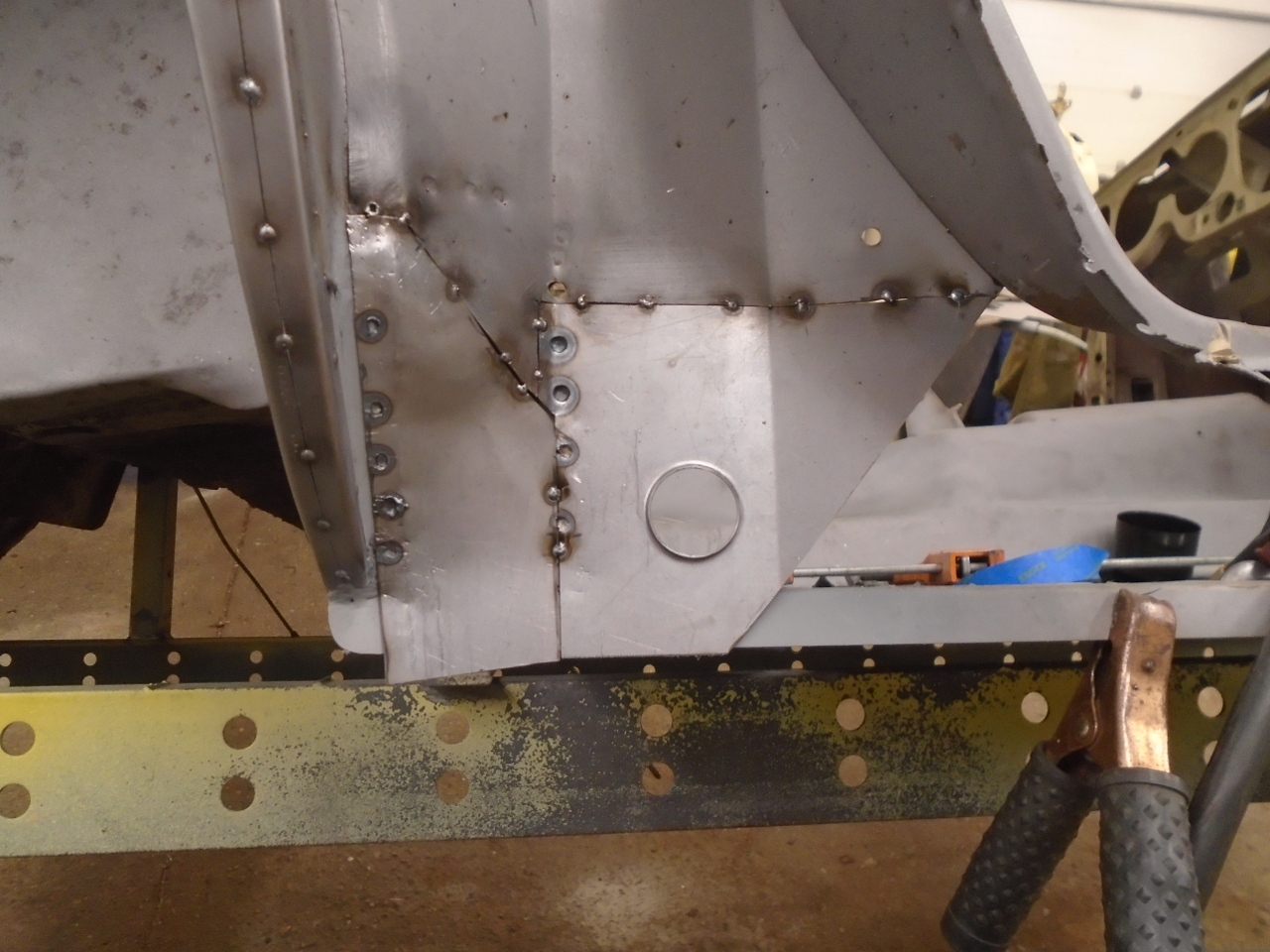

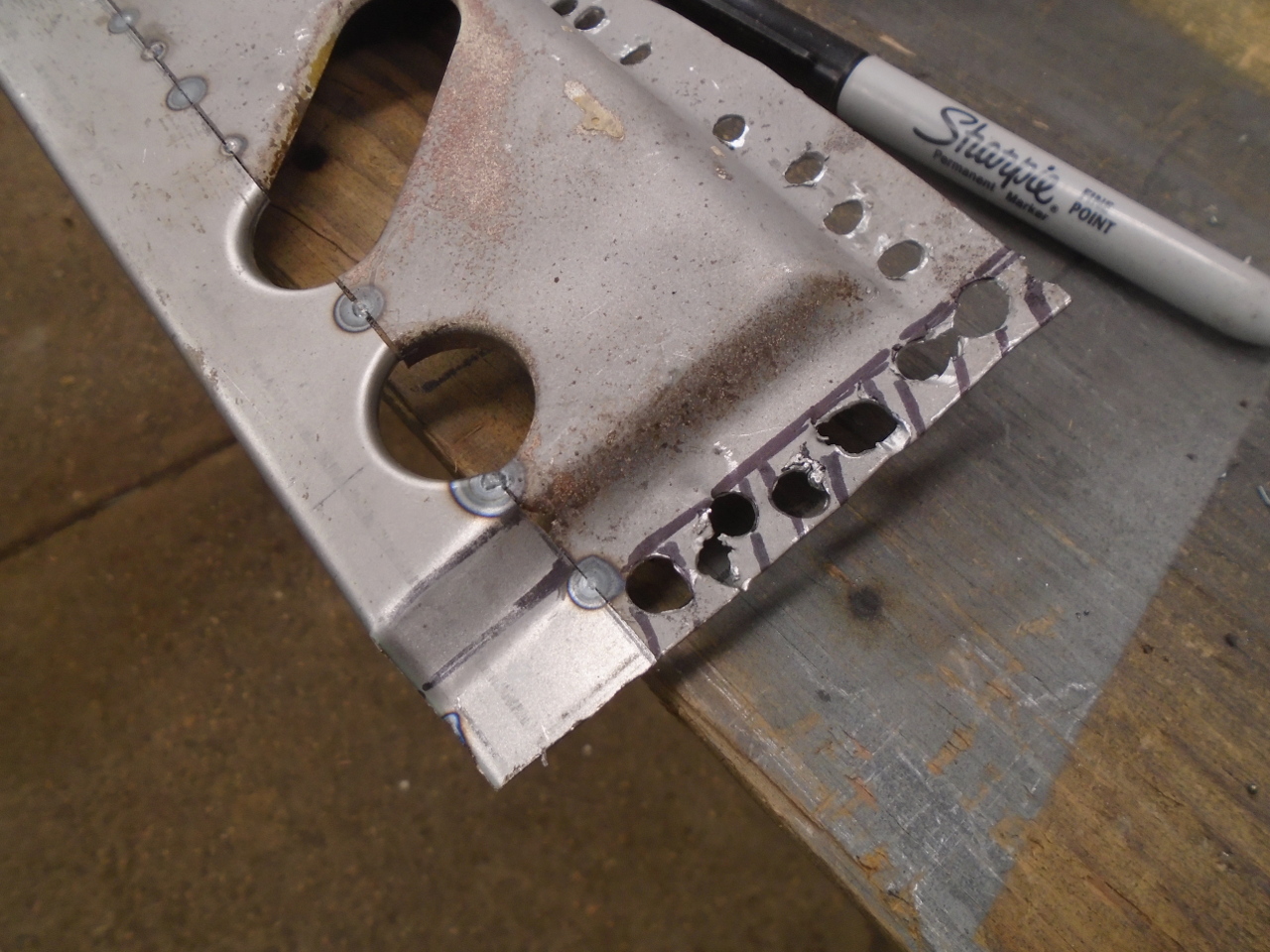

So, now finally back to the B post where this all started.

I cut back the original metal beyond all the holes left from

removing spot welds., and also replaced that swiss-cheese

flange.

Then cut a new piece to fit. The original panel had a

largish hole that was "dimpled" around its perimeter. A

simple little die and a large washer made a nice reproduction

dimple.

Here it is in place.

All of this was in preparation for the inner sill.

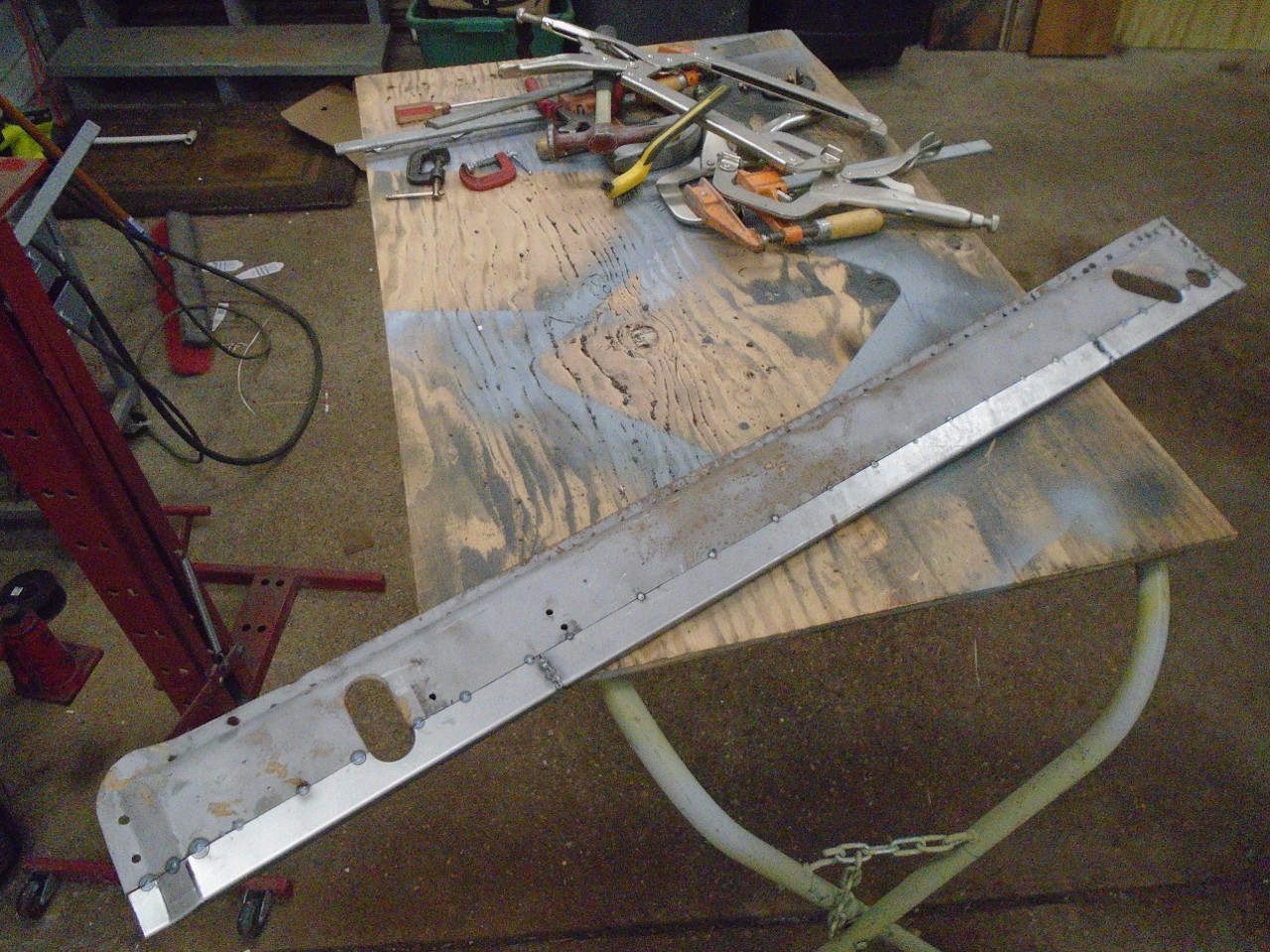

The inner sill itself was in OK shape except for the bottom inch

and the bottom flange. These are available as

reproductions, but I thought I could repair the one I had.

At least I knew it would fit.

There were a pair of elongated holes in the inner sill. I

wouldn't realize what they were for until later, but the bottom

portion of both of them was gone. The holes were dimpled,

but sadly, a different size from the dimple die I had already

made.

I made a new dimple tool, and made a flared hole to match the

ones in the sill. I only needed half the hole.

Similar for the other end.

Then cut off the bad part and replaced it with good metal.

Replaced the end flange. There wasn't much left of it

after removing the spot welds.

Test fit went OK. I could use the old spot weld holes for

alignment.

I went to great lengths to keep the bottom flange straight while

welding the seam. The minor warpage I had was fixed by the

shrinker/stretcher. I welded the sill from the inside to

keep the outside looking better. I only did minor grinding

on the inside.

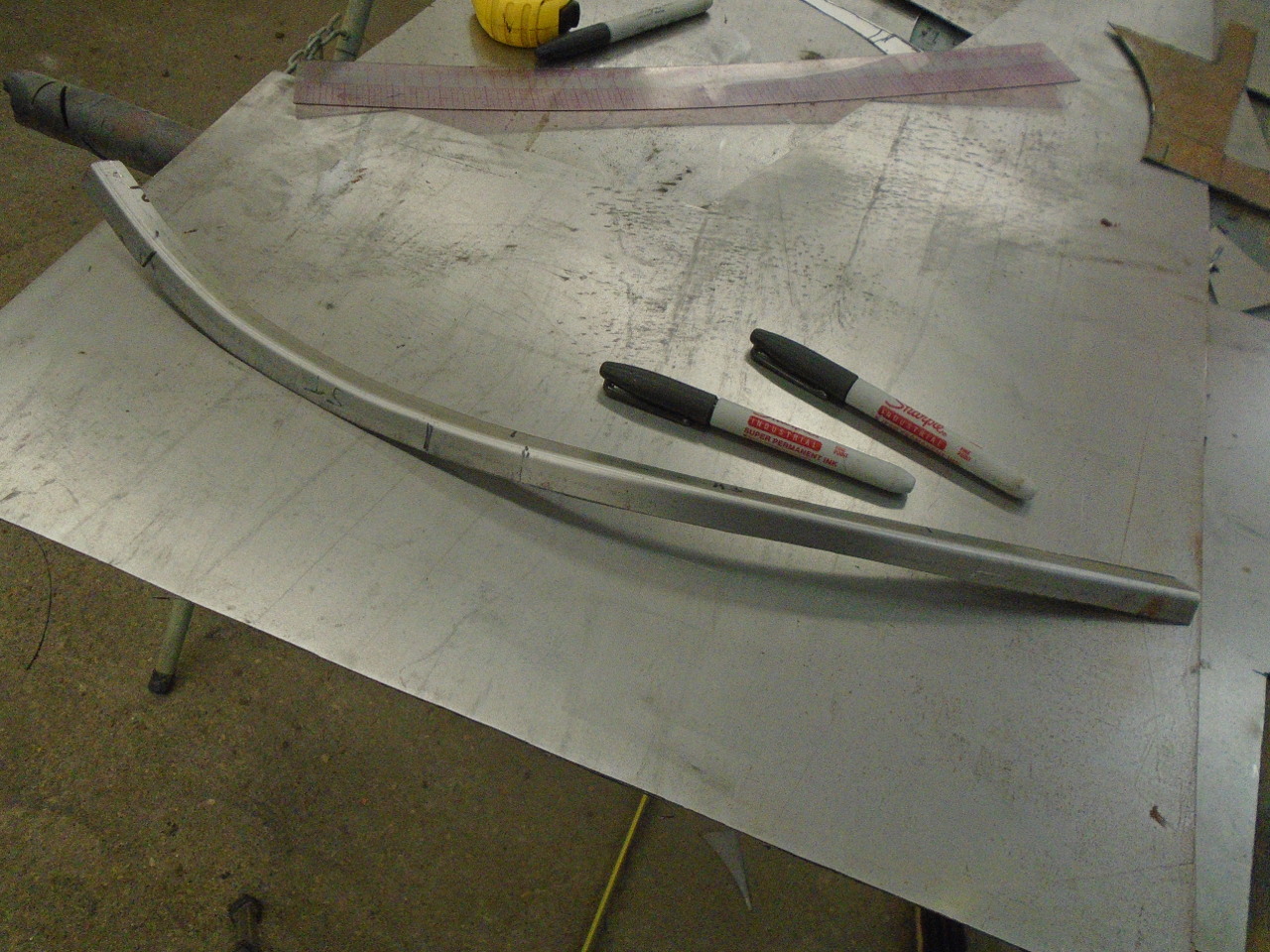

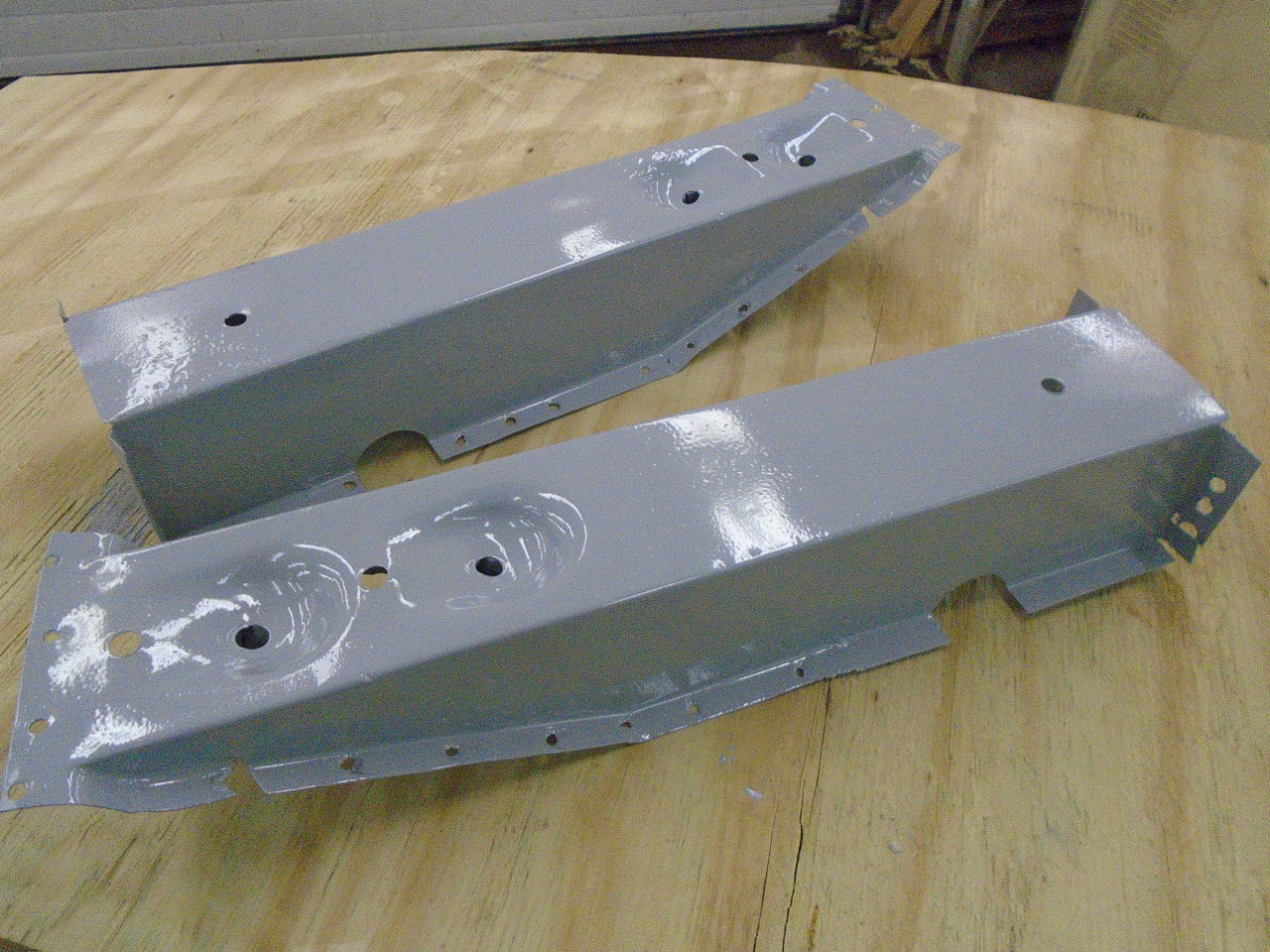

Between the inner and outer sills is a "strengthener"

piece. Mine was mostly toast, but making one is pretty

simple. Forensic examination of the remains suggested the

size and shape, and the location of holes. Online pics

helped, too.

Since the space between the inner sill and strengthener would be

inaccessible after put together, it made sense to coat them

before assembly. Two coats of a good epoxy primer should

hopefully be adequate. The flanges got a couple of coats

of weld-through primer instead.

Mounting surfaces on the body were prepped with weld-through

primer, and the inner sill was positioned and spot welded.

Then inserted the strengthener. This is when I realized

what those big slots were for in the inner sill. They are

for spot welder access for the ends of the strengthener.

At this point, I thought it prudent to get this side of the car

under some kind of rust protectant in anticipation of our

wonderful Midwest summer humidity. A coat or two of a

2-part epoxy primer.

Not much doubt about where to go next.

The only thing I didn't finish on this side of the car is this

rust damage to the bump stop and wheel well. Both sides

are similar, and I think I'll wait until both sides are done to

do those areas.

This has been a pretty involved job, taking over a month so far,

including the floor repair. Hopefully, the other side will

be quicker now that I know what to expect, and have some of the

tools made. Cost was just some consumables.

UPDATE

June 28, 2020

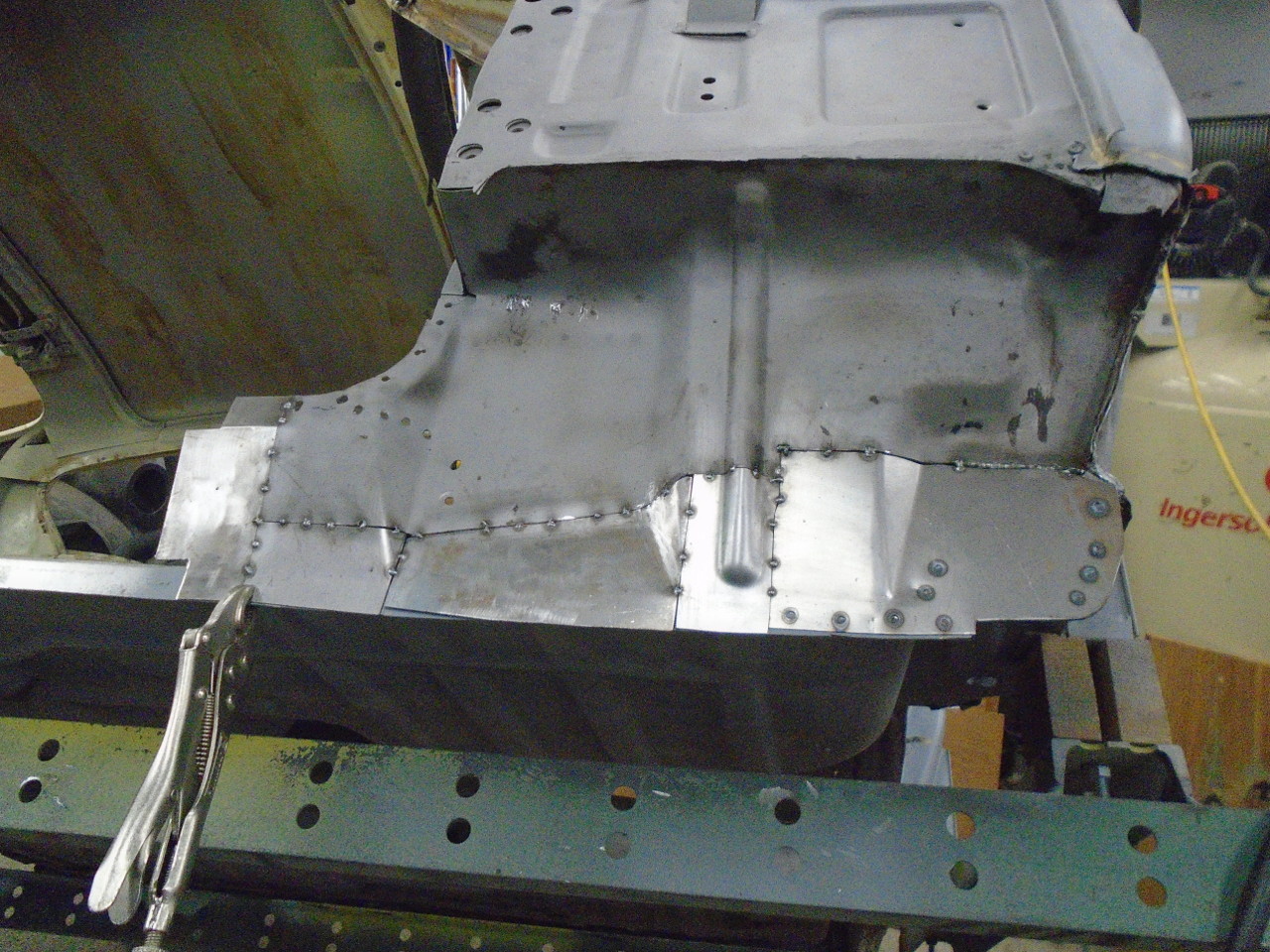

Today, I finished the drivers' side floor, sills, posts, and

crossmembers. Starting point was similar to the passenger

side...

...but the front section of the floor was a little worse.

It might have been easier to just fabricate a front pan and

install it wholesale. I call this the Frankenfloor.

The new drop flange on the floor.

On this side of the car, there was some accident damage on the

rear corner, which was repaired (by me) over 30 years ago.

Part of that repair required cutting out a section of the inner

wing.

That got fixed, along with the lower edge of the inner wing, and

the rear of the wheel arch.

A and B post rust repairs were similar to the other side.

The inner sill and strengthener panel were in worse shape than

the other side.

I made a new strengthener, but wimped out and just bought an

inner sill.

I always cringe when I'm forced to buy panels, since the fit is

so often not great. With it's rear end fitting snugly, the

inner sill had a 1/2 inch gap at the front, but with a little

encouragement, it finally fit better.

A number of the welded nuts on the bottom of the floor pan had

to be replaced.

The last item up for the floors/sills was the floor cross

members. They stiffen the floor and attach it firmly to

the frame. Mine were largely missing the flanges that

attach to the floors.

A few patches here and there fixed that right up.

Test fit them, applied a few tweaks, and finally plug welded

them in place...

...which of course messed up my fresh primer underneath.

But a little more primer, and we're good again.

This marks the end of the floor/sill/post parts of the

body. On to the rear wheel wells.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages