To my other GT6

pages

March 3, 2020

Speedometer and Tachometer

GT6 cars of course came with a speedometer, but

also with a matching tachometer as an obligatory piece of sports

car hardware. They are simple mechanical instruments, not

really designed or built for either longevity or repairability.

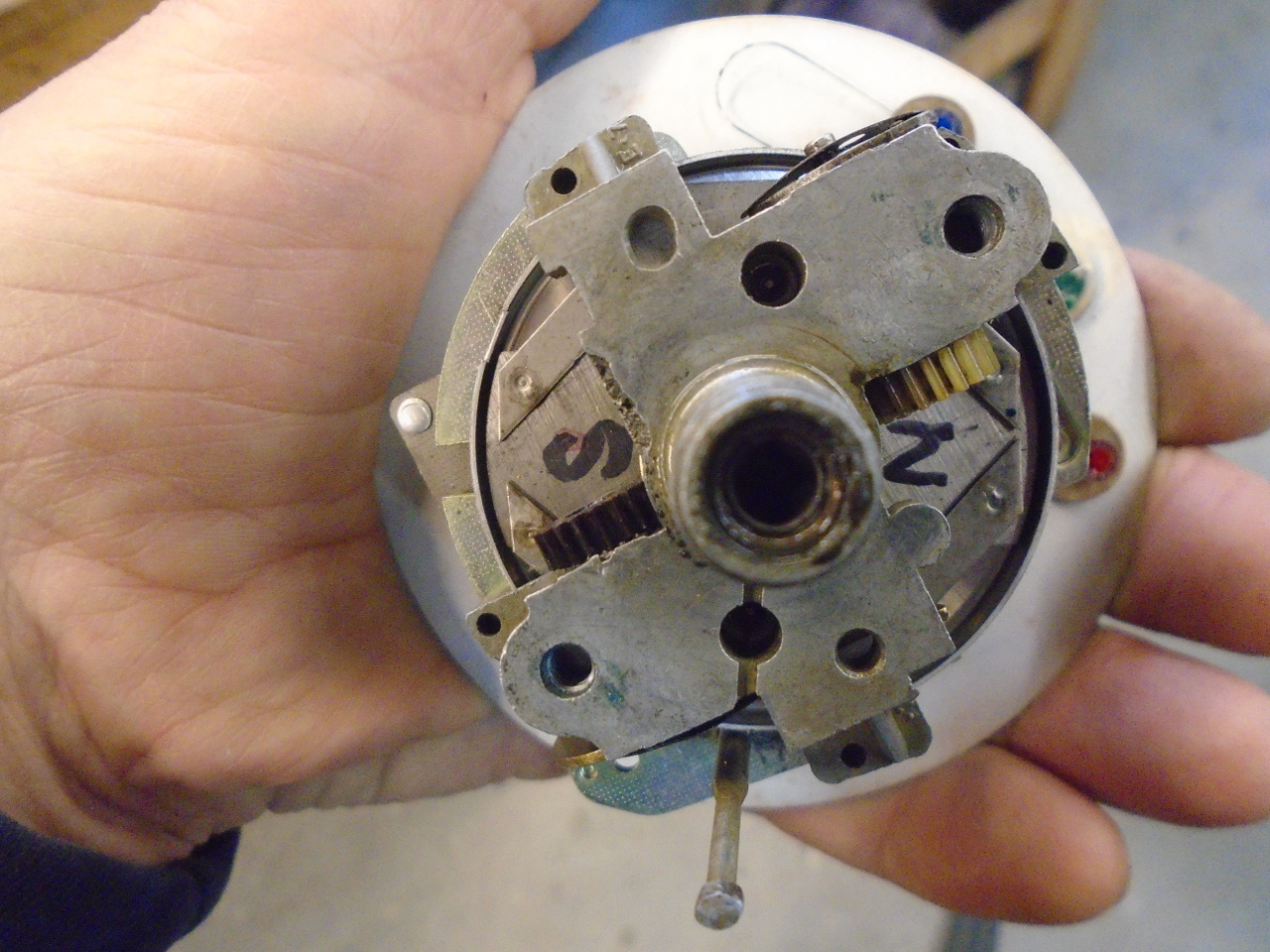

These rudimentary instruments both work on the same principle,

and have a lot in common internally. A cable with a

spinning inner core is connected to the back of the instrument,

and turns a spindle attached to a bar magnet. The magnet

is housed inside, but not touching, an aluminum cup. The

spinning magnetic field induces currents in the cup, which in

turn generate their own magnetic field. The two fields

interact such that the aluminum cup wants to spin with the

magnet. But the cup is restrained by a small watch spring

on its spindle. The amount that the cup and its spindle

can rotate is determined by the speed of the magnet and the

resisting force of the spring. The result is that the

rotation angle of the cup spindle is proportional to the speed

of the magnet. A pointer on the cup spindle indicates the

rotation, and indirectly, the speed of the input cable.

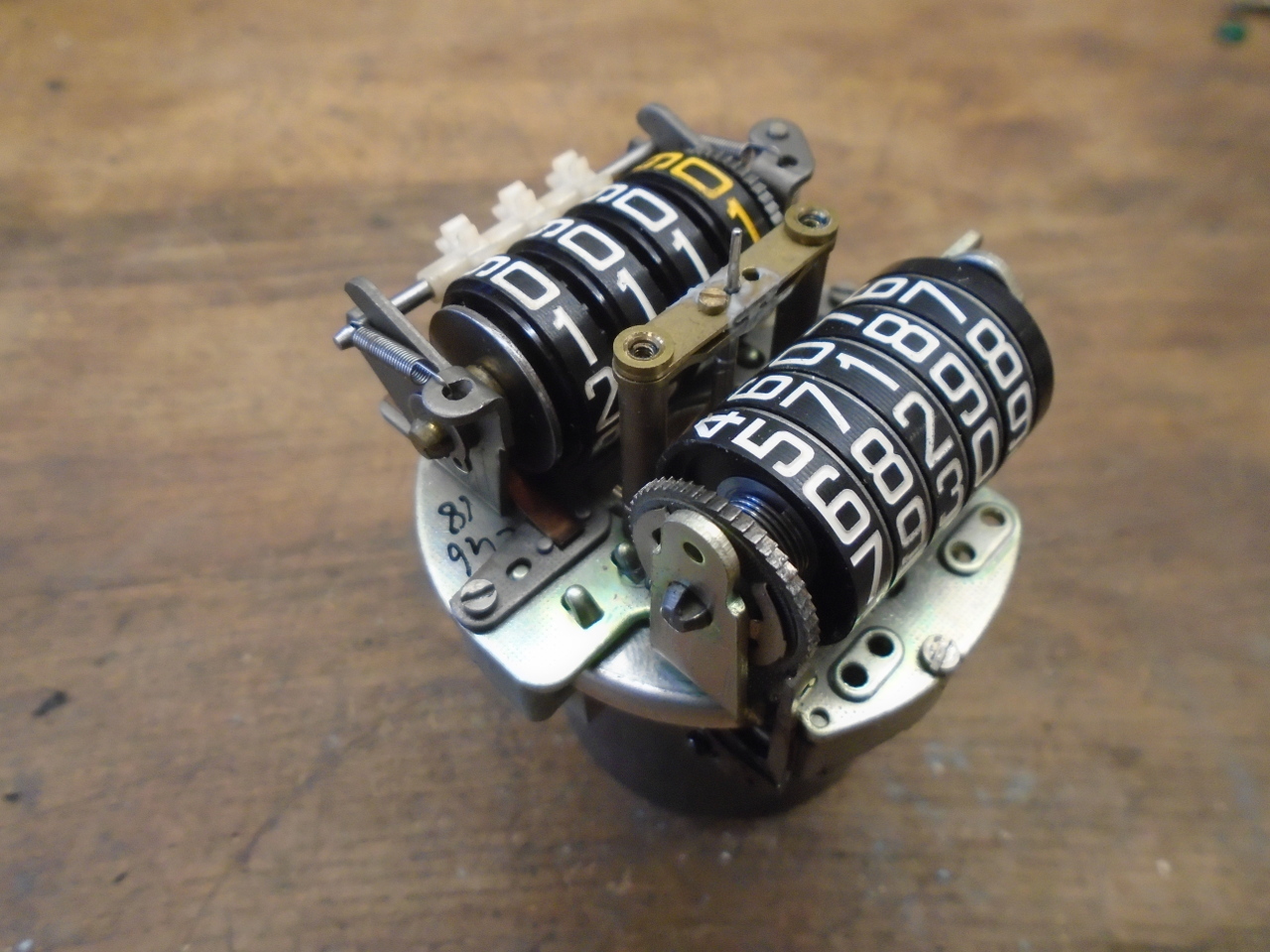

The speedometer also has a pair of odometers. On my

speedometer, the input spindle carries a brass worm gear, which

drives a pair of spur gears. Each spur gear has an

eccentric shaft that imparts a reciprocating motion to a pawl

arm. Each pawl arm bears against a ratchet wheel, and

advances the ratchet one tooth for each cycle. The ratchet

wheels drive the two odometers--the main odometer, and a

resettable trip odometer.

My instruments were pretty cruddy. They were also

mismatched, with the speedo having an incorrect chrome

bezel. Since the car has been in storage since 1980 or so,

it has to be a 70s replacement.

A simple test is to spin a small screwdriver inserted into the

input spindle. On the speedo, this resulted a little lurch

of the pointer, which is a good sign. On the tach, the

input spindle appeared to be seized, which is not a good sign.

I worked on the instruments in parallel, so the pictures that

follow might be from either the speedo or the tach.

The front bezel comes off bayonet-style, by twisting it until

the bezel fingers reach slots in the housing lip. It was

quite a bit easier to say it than to do it. The back of

the bezels had the remains of some dried-up sealing substance.

Inside, there is an inner bezel that holds the glass. A

thin hollow rubber tube served as a gasket between the glass and

inner bezel.

The guts of the instrument are freed up by two screws on the

back of the case.

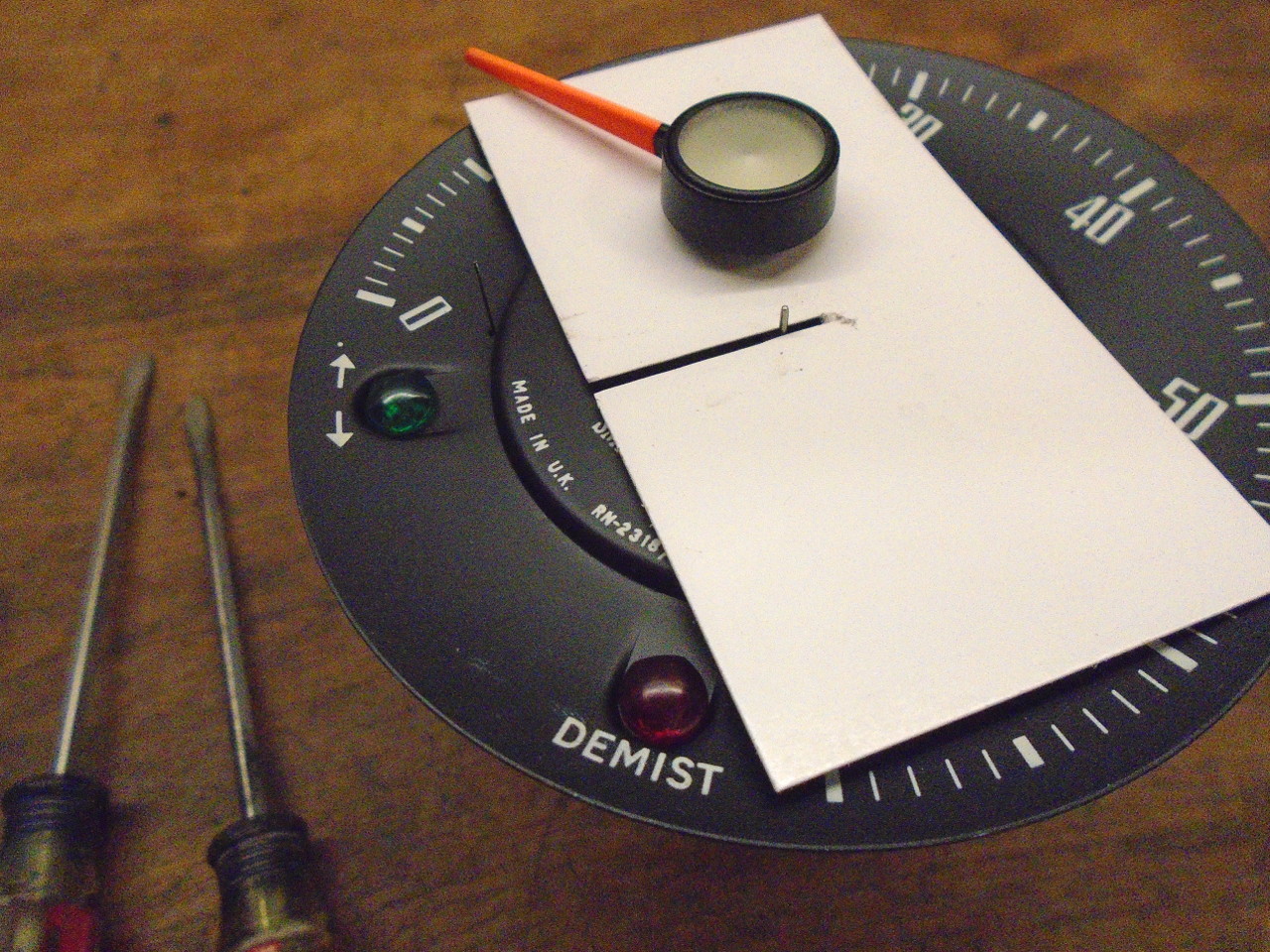

To really see much of the mechanism, the face had to come off,

but first the pointer. It is just a press fit on its

spindle. A couple of prying implements and some card stock

to protect the face did the job.

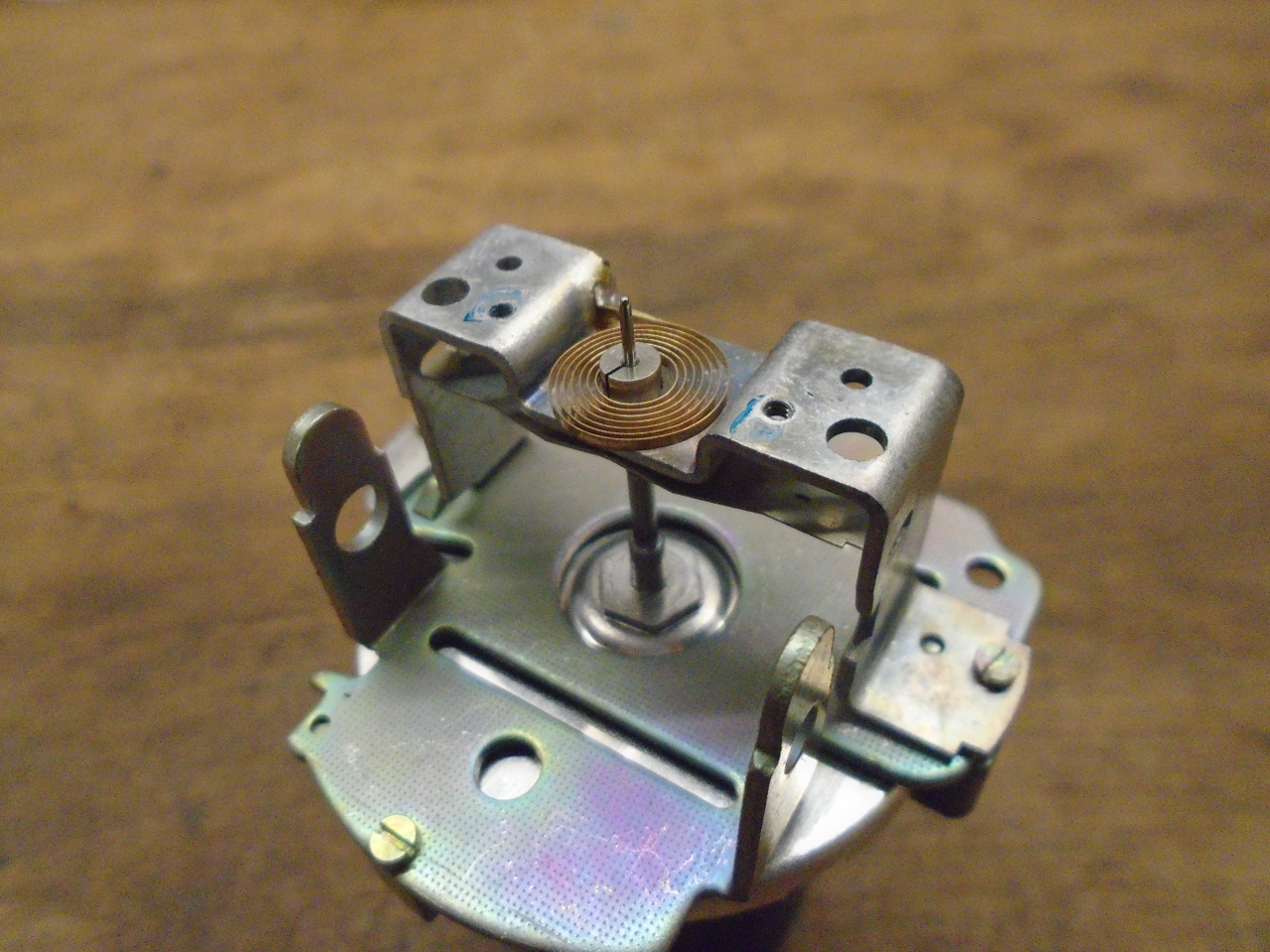

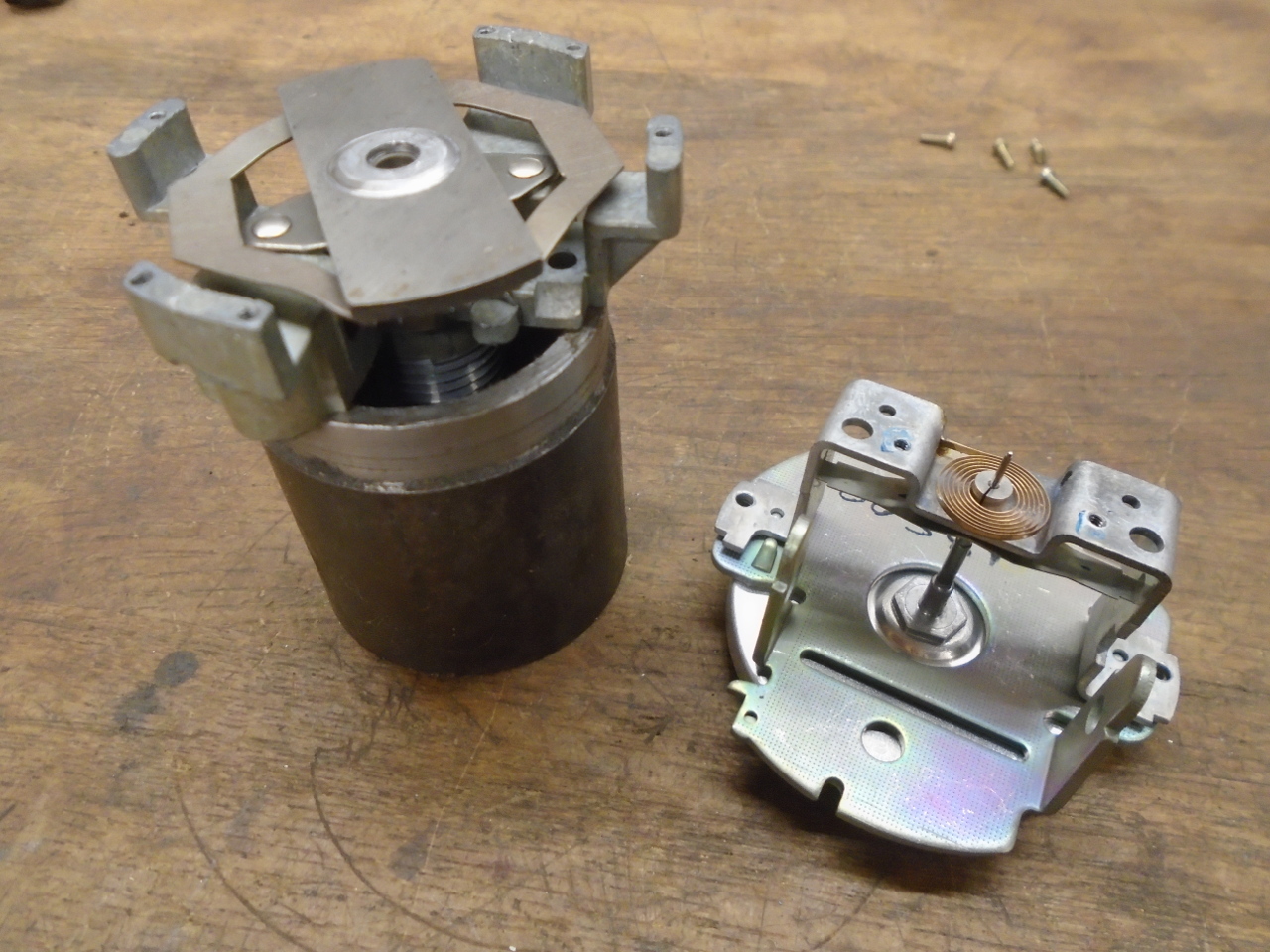

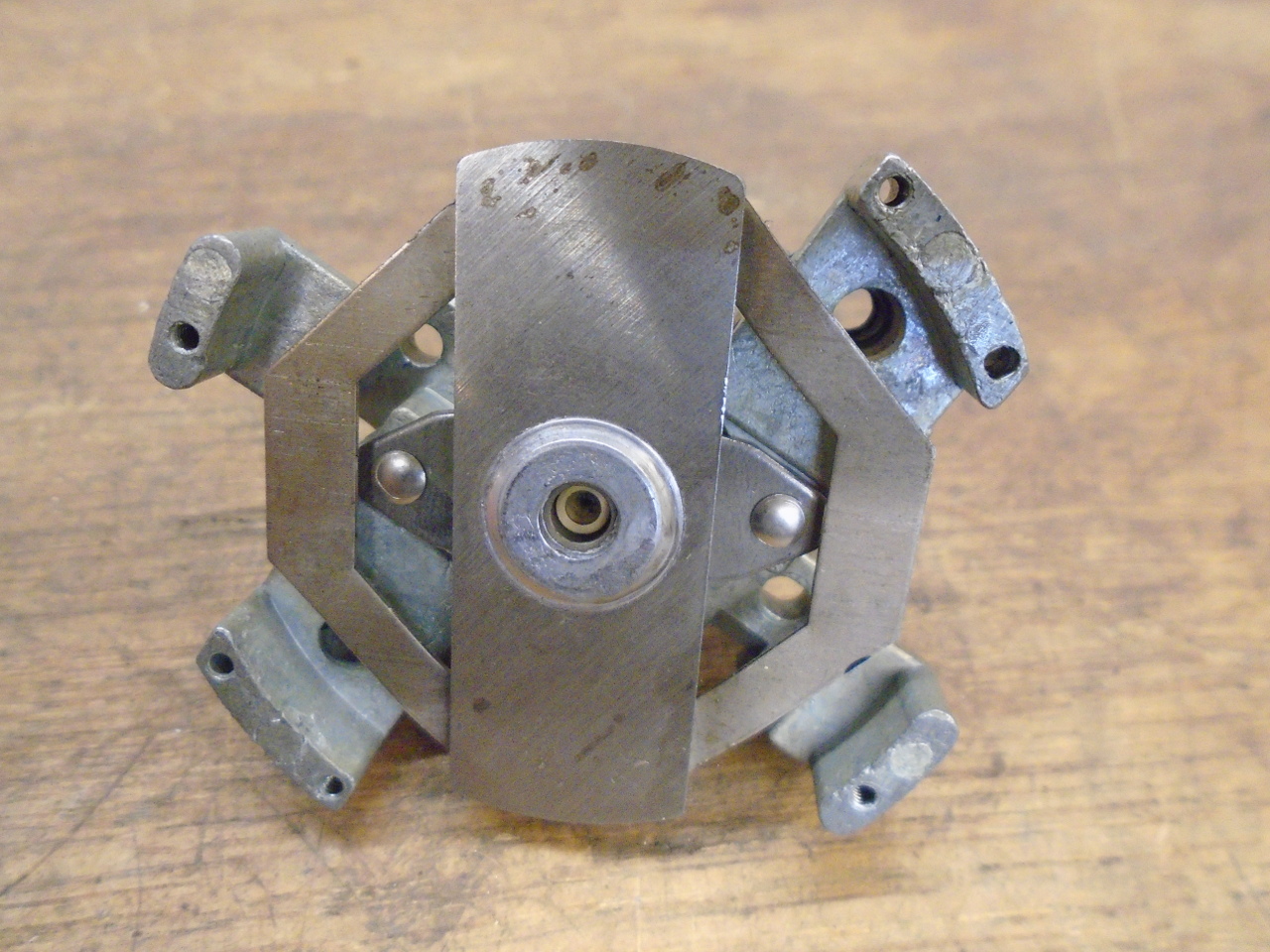

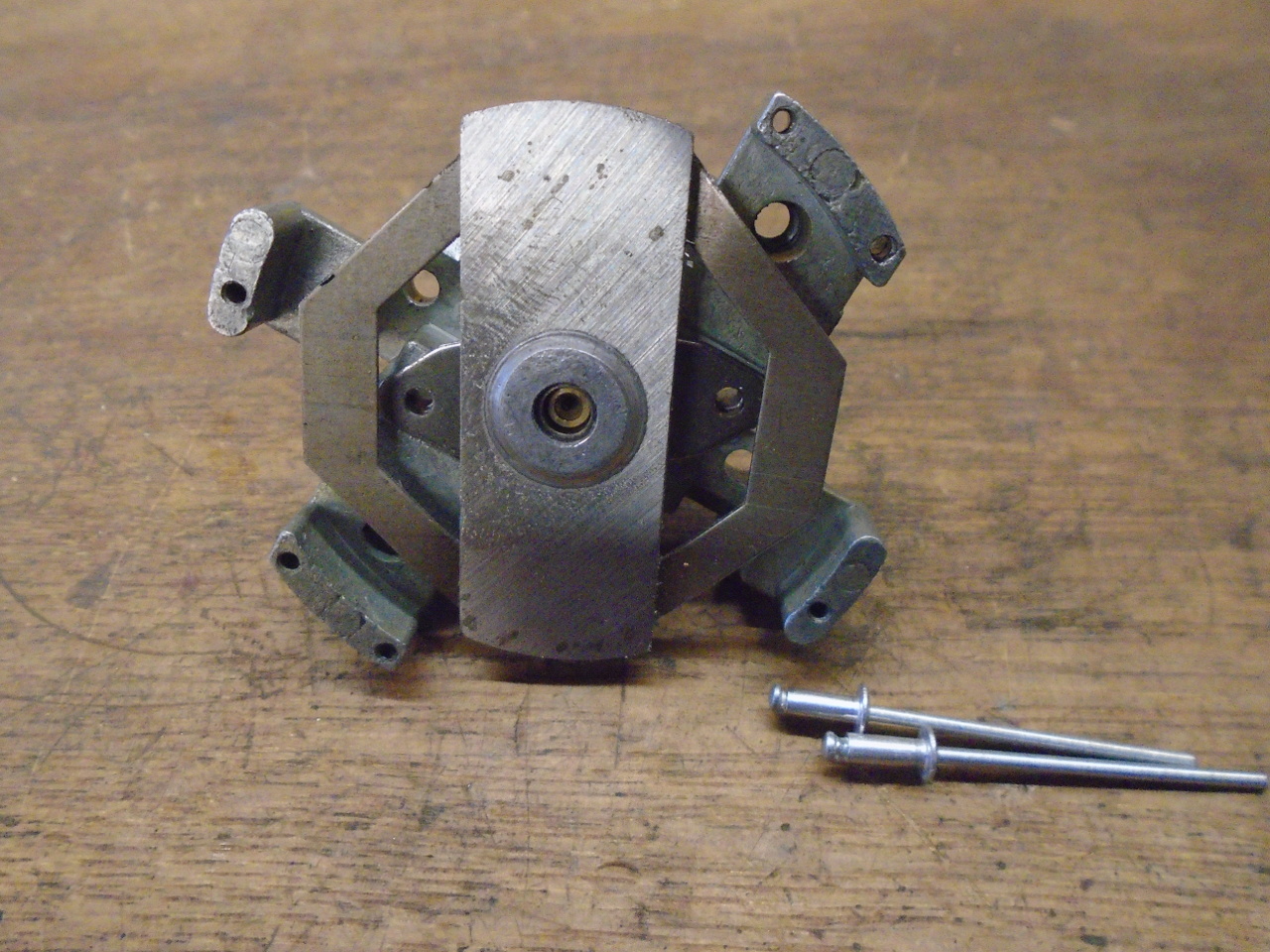

Then the mechanism can be separated into the magnet part and the

drag cup part. The magnet is that long piece on the top of

the assembly on the left. The cup is underneath the

assembly on the right. At this point, the magnet spindle

was still seized on the tach.

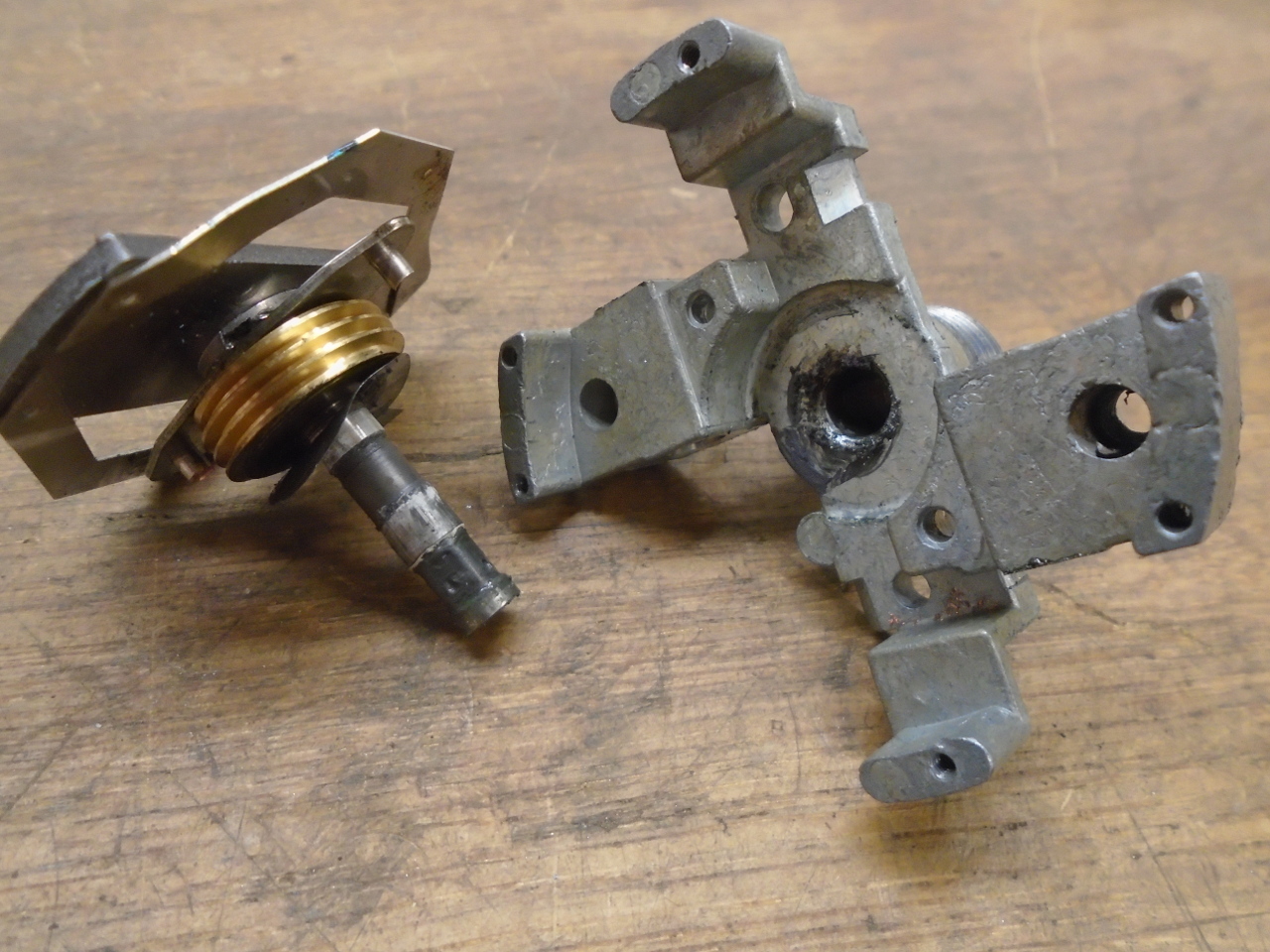

With some effort, I was able to get the magnet spindle turning,

but it was tight and rough. The spindle had to come

out. The magnet and spindle are held in the body by a

keeper and two rivets.

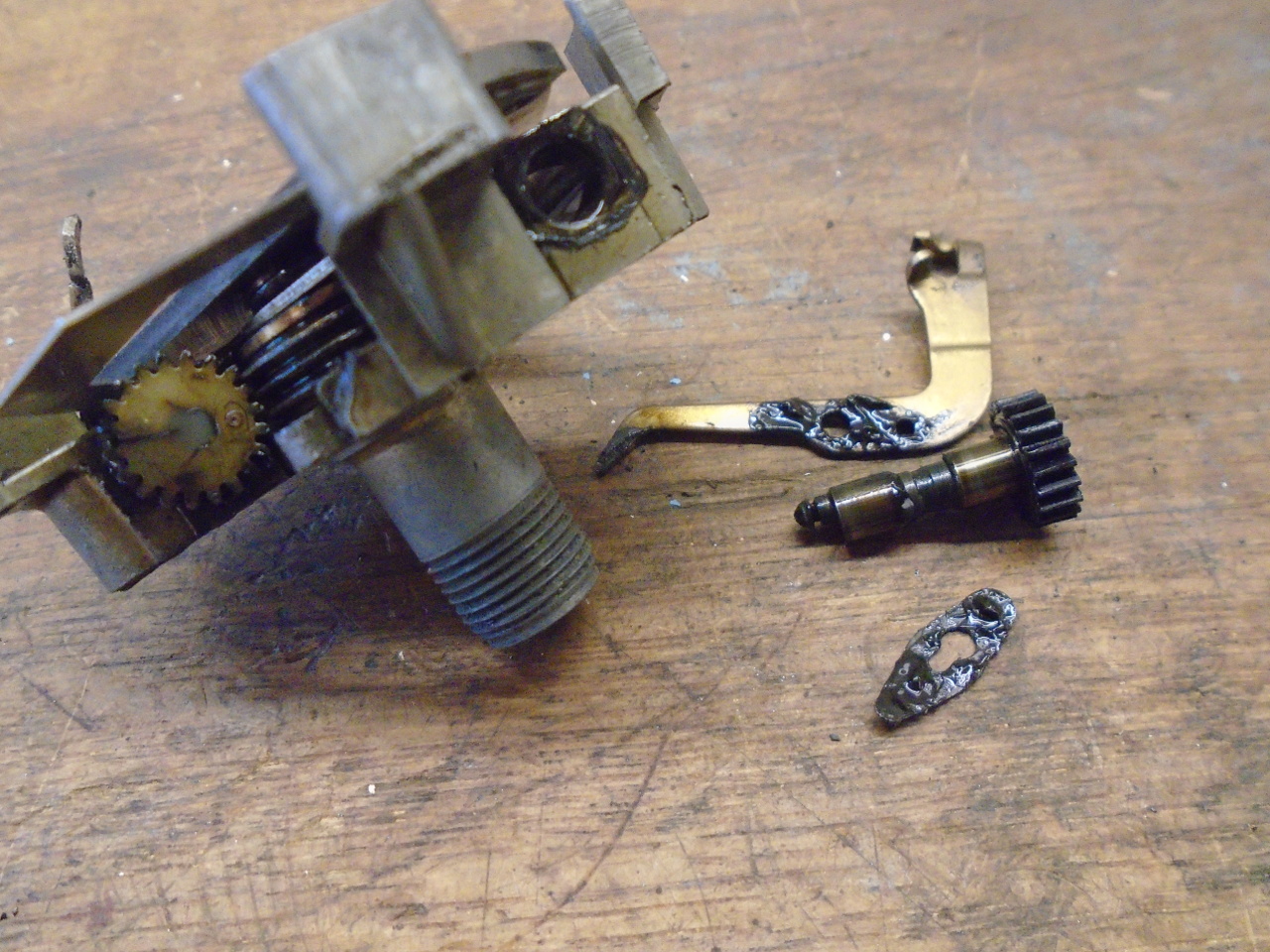

Drilling out the rivets freed the magnet. The tachometer

had the brass worm gear for the odometers, even though it is not

used for that. It just retains the spindle.

It looked to me that the problem was that the magnet spindle

just ran in the pot metal housing with no true bushing or

bearing. This surprised me a little, since the TR6 tach I

worked on a few years ago had a bronze bushing in that location.

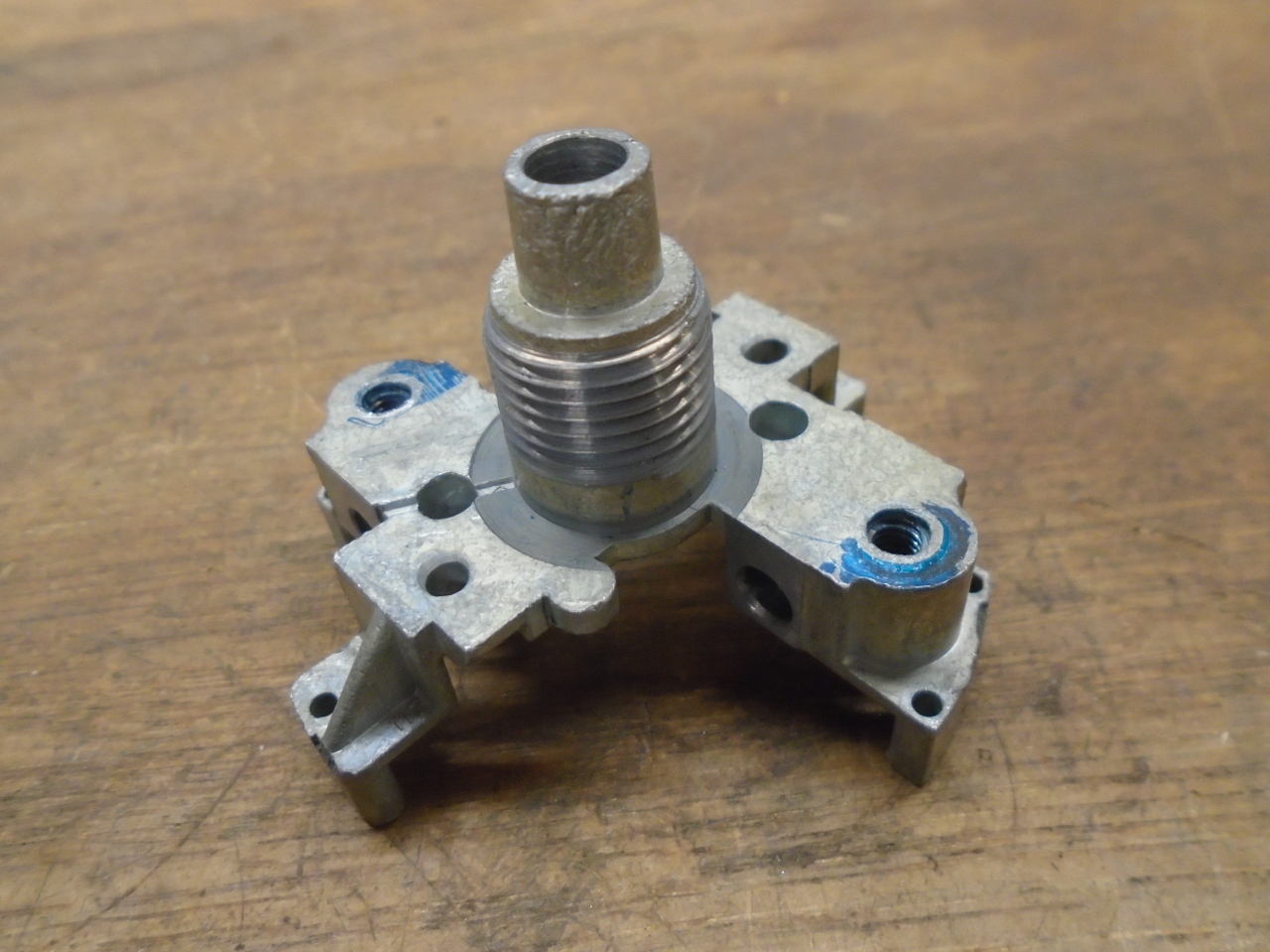

Since the bore was chowdered up pretty well, I decided I could

fix the tach and improve the design all at the same time.

I'd just put a bronze bushing in there.

I didn't really have much choice on the size of the

bushing. In drilling out for the bushing, that little nose

protruding above the threads would pretty much be gone, but

since it looked like it was a necessary feature for the cable

seating, I'd have to replace it. The simplest way I could

see was to just let the new bushing be the nose.

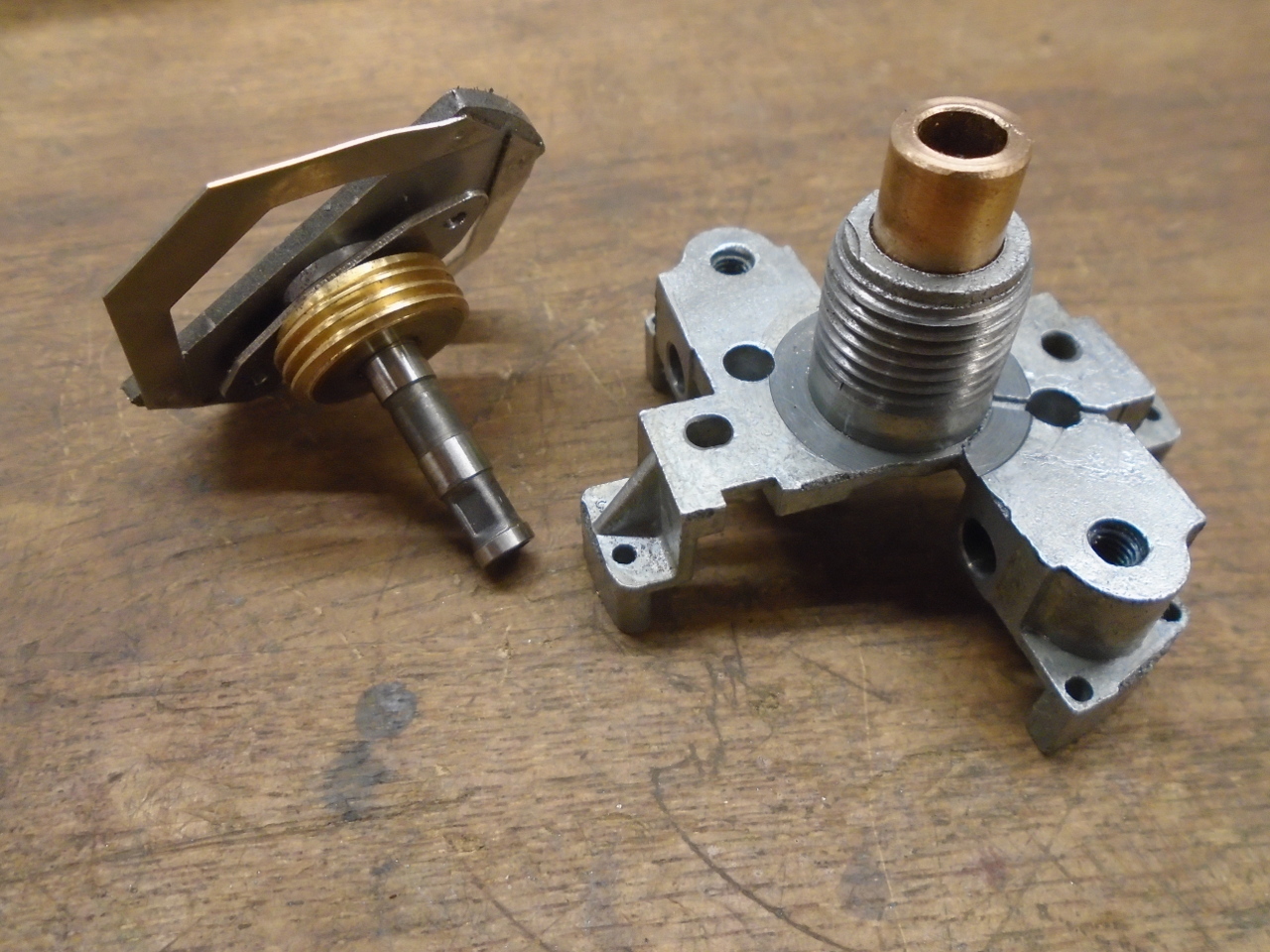

This set the OD of the bushing at 3/8". The ID had to

match the spindle, which was 6 mm.

I didn't think I'd have much luck finding a bushing with a

metric ID and an Imperial OD, so I just ordered some 6mm x 10mm

Oilite bushes, and turned the OD down to 0.376" to be a tight

fit in the reamed 0.375" bore. I couldn't find the length,

so I just pushed in two, and trimmed the excess.

Then inserted the magnet spindle with a nice coating of light

oil, and riveted it back in place.

Then put everything back together. The pointer is pressed

on so that when at rest, it aligns with a small dot below the

zero on the face. Then the pointer stop is retracted so

that the pointer can be rotated past it. This provides the

small amount of preload to the spring so the pointer bears

lightly against the stop at rest.

To bring the speedometer to this point was a little

different. The internals of the speedometer work the same

as the tach, but the added odometers dominate the construction.

On checking the rotation of the input spindle, it felt very

smooth and free, except very occasionally, I could feel a

mechanical catch in it. It seemed to be related to one of

the odometer pawl gears, so I took all of those parts out for

cleaning and inspection. They had a lot of grease on them

for some reason.

I finally traced the problem to one of the gears that had a

split in it. The gear was still firmly attached to its

shaft, but the split spread two of the teeth apart slightly, so

the mesh would bind in that area. Without much hope of

finding a good replacement part easily, I just reshaped the

teeth slightly with a file so they still meshed, but didn't

bind.

There was also the little green jewel for the oil light that I

found loose in the case. I was apparently just glued in

place. I put it back where it belonged, and staked the

back with a hot soldering iron.

Then there was the issue of the mileage reading on the main

odometer. Given that the speedometer is not original, plus

the fact that it was not even working for most of the time I

drove the car, the reading has no relevance to this car.

Also given that the car will be for many practical purposes a

new car when finished, I justified my desire to return the main

odometer to zero.

One way to zero an odometer is to take it apart and reassemble

it with all zeros showing. I did this for my TR6, and

found the process to be harrowing. I wanted an easier

way. I could spin the ratchet wheel by hand either forward

or backward, and change the reading by about 32 miles in a

minute. I did the math, and decided this was maybe doable,

but not practical. I finally fiddled with it and

inadvertently stumbled on a way to get individual wheels to turn

independently. I can't explain how I did it because I

really don't know.

So, then with both instruments apparently working smoothly, I

wanted to have some confidence in their accuracy. This is

a calibration rig I made years ago when I did my motorcycle

instruments, and used again for the TR6. It is basically a

universal motor (it is a Craftsman chainsaw sharpener motor,

modified to run backwards) on a speed controller, an optical

digital tachometer to read the speed of the motor, and a stand

to hold the instrument and everything else in the right

relationship. The motor drives the instrument spindle

directly.

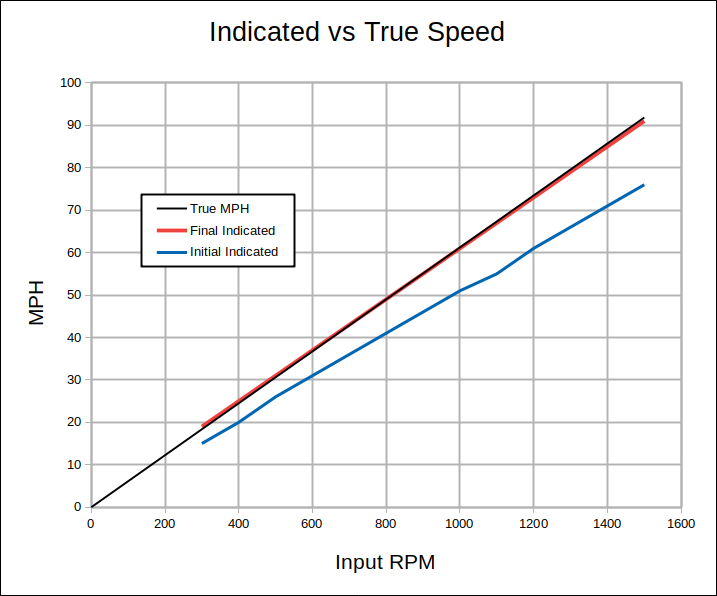

I did the speedometer first. Speedos of this type will

normally have a number printed somewhere on the dial face that

indicates how many turns of the input spindle it will take to

rack up one mile on the odometers. A little thought and

arithmetic will show that this is also the input RPM that should

indicate 60 MPH on the dial. On my speedo, this number was

980.

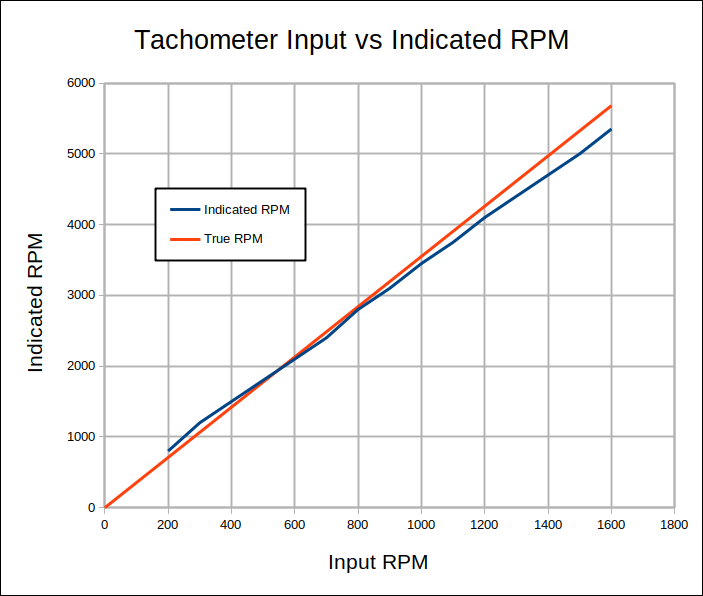

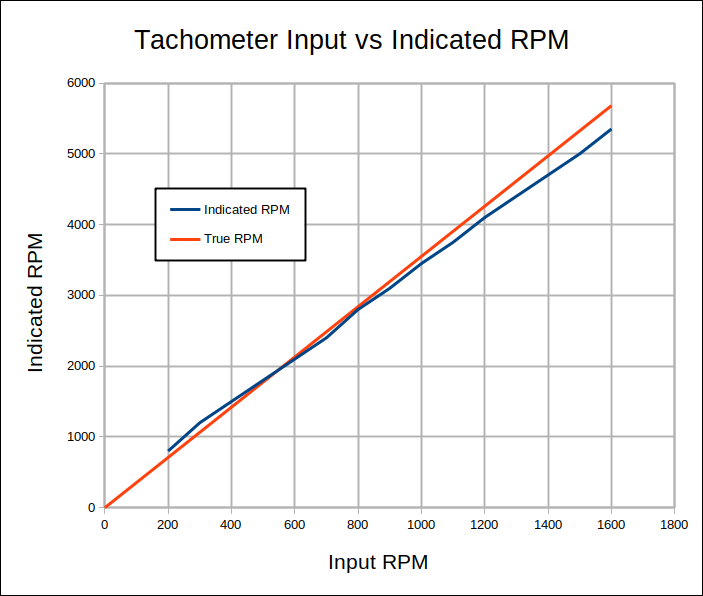

So, by taking readings at various input RPMs, it is easy to

graph the results and compare to what the readings should be.

The black line in the graph below shows the perfect relationship

between input RPM and dial reading. The blue line is what

my speedometer initially showed. It was around 18% low

across the range.

This is what is known as a "slope error". The other common

kind of error is a so-called "offset error", where the error is

a constant number across the range. The fact that the blue

line above is pointed towards zero is an indication that there

is little offset error here.

The slope of the line is determined in this kind of instrument

by two things: the strength of the spring, and the

strength of the magnet. Either of these can be manipulated

to change the slope. I chose the magnet.

A stronger magnet will steepen the slope. Magnets can be

strengthened by bringing a stronger magnet in close

proximity. I stacked some rare earth magnets and added

some steel extension pieces. I hoped the extensions would

allow me to contact the instrument magnet without taking

everything apart again.

It's also important to know the polarity of both magnets.

I found that by using a magnetic comapass.

It seemed to work OK. In fact, it worked so well that

after the first "strengthening" attempt, the speedometer was

reading almost 90 MPH when it should have read 60. OK, a

little too much of a good thing. Luckily, reversing the

polarity will reduce the strength of the weaker magnet.

It took a few iterations, but I was able, partly by luck, to get

the red line in the graph above. The speedo read about 3%

low at the high end and slightly high at the low end. I

would have been very happy with 5%.

I repeated the process for the tach, and the results are shown

below. Since I don't really rely on the tach that much, I

was satisfied with this.

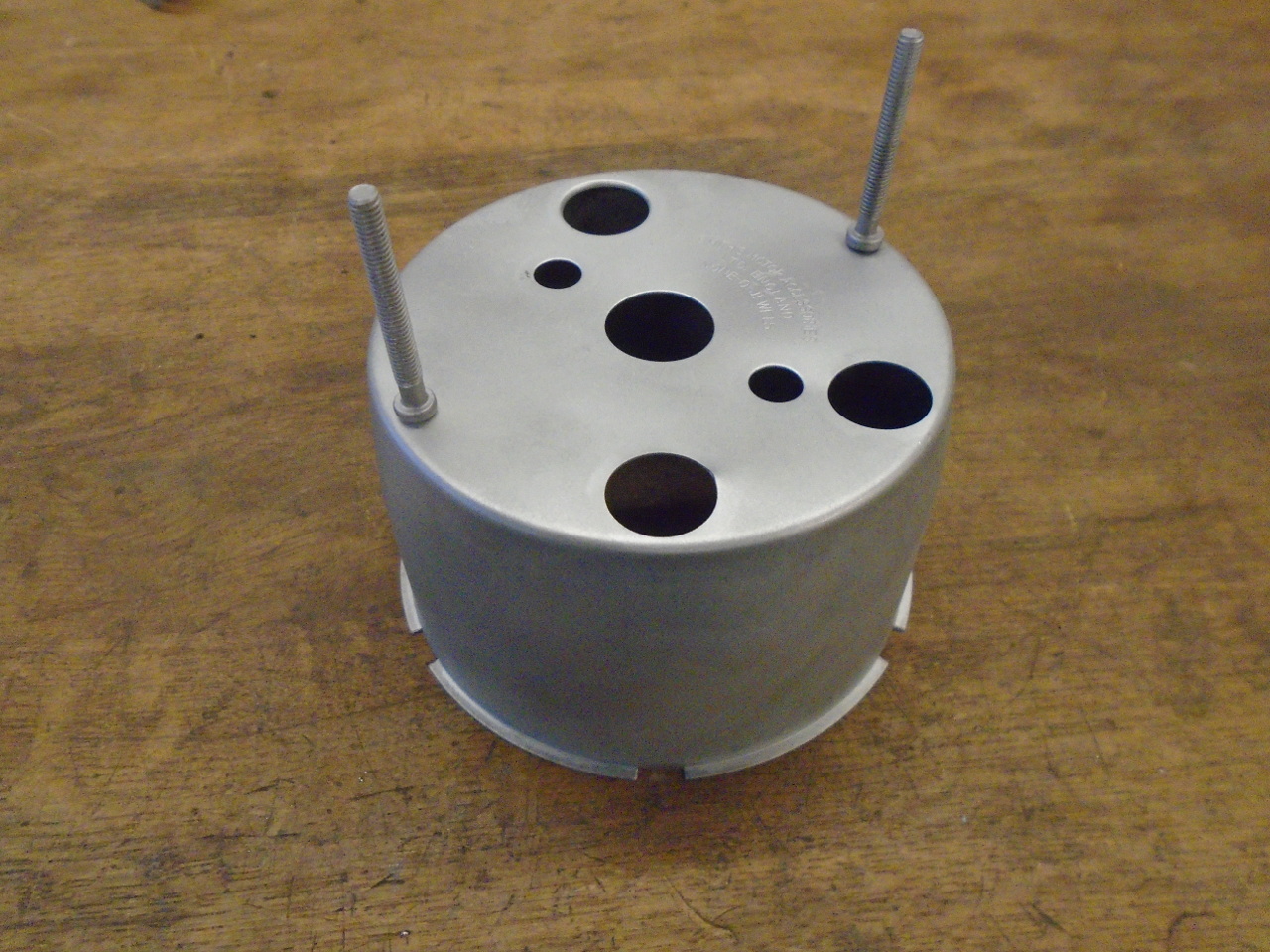

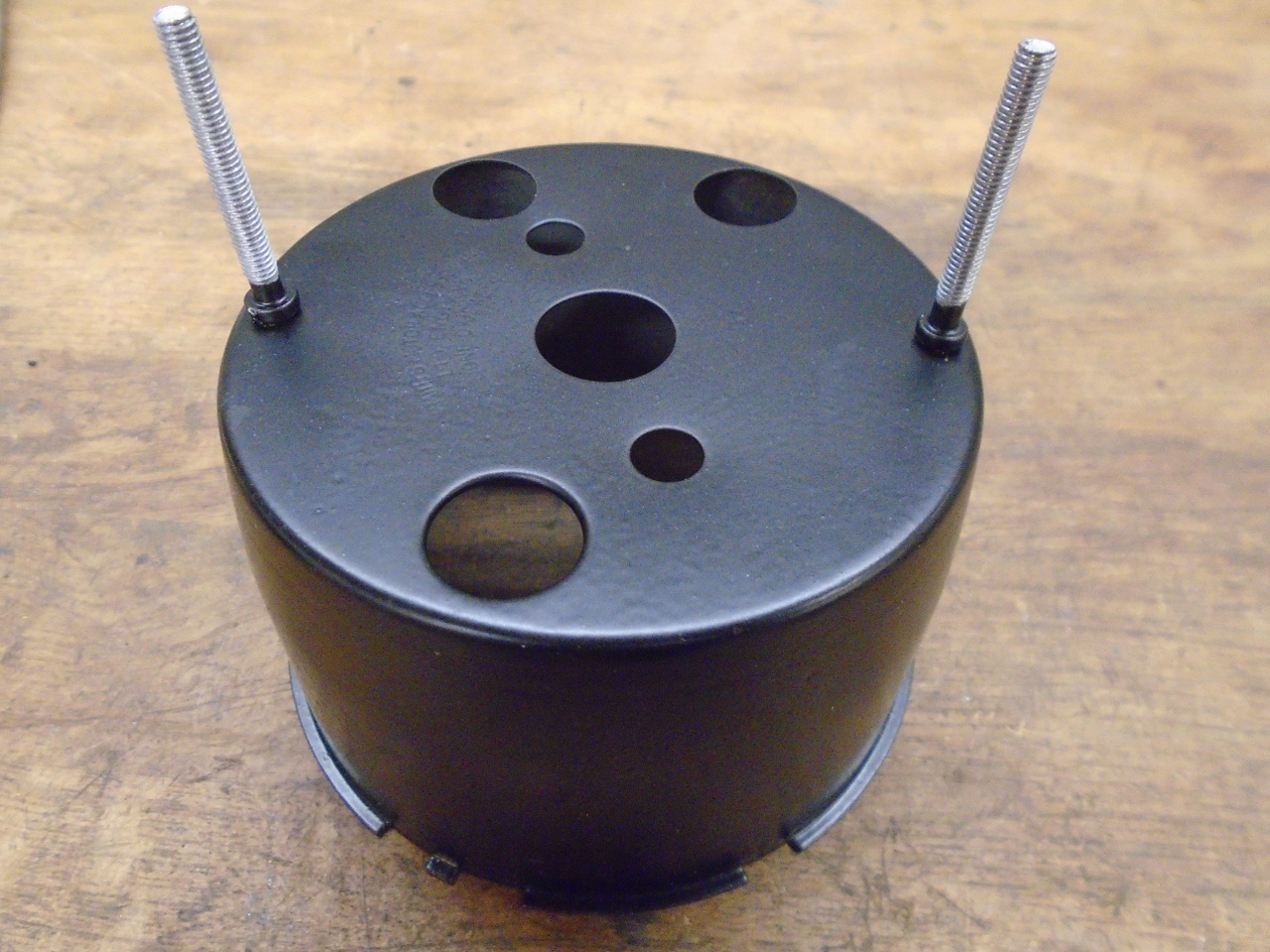

OK, so I was pretty happy with the way the instruments were

working. All that was left was to button them up. I

blasted the cases...

...powder coated the outside...

...and painted the inside. I matched the blue color the

best I could. I think it was an attempt to even out the

light intensity around the perimeter of the face.

Added the little plastic tubes that isolate the indicator lights

from the face lighting, and the rubber isolator for the

attachment points. The original isolator was usable, but

barely. The third picture shows the little white rubber

sleeve thingies that were on the ends of the light tubes,

apparently to bridge the gap to the jewels. I found two of

the four had buckled over and were blocking light rather than

guiding it. I didn't replace them.

Brought the guts home. The 28 miles on the speedo was what

it took to get the calibration rig set up and the speedo

adjusted right.

Then prepped the inner and outer bezels.

Inner bezels were painted, outer ones were powder coated for

durability.

This stuff is O ring cord stock It is silicone, and pretty

soft. I got it to see if it could replace the seals on

either side of the glass.

The smallest size worked well for the underside of the glass,

while the largest made a good seal under the outer bezel.

I wiped it with a thin smear of petroleum jelly to make twisting

the bezel on a little easier.

After all this, I think they will do.

This one was finicky work. I enjoy it to a point, but I'm

ready to move on to something that doesn't require tweezers.

The only cost was for the bushings, the cord stock, and some

consumables. Certainly under $20.

Comments to Ed at: mailto:elhollin1@yahoo.com

To my other GT6

pages