To my other GT6

pages

February 14, 2020

Throttle Linkage

One of the things that contributes to the

experience of driving a car is how the controls feel. One

thing that most people expect from a sports car is controls that

are quick and responsive. To a large extent the feel of a

control is influenced by the linkage between the cabin control

and the ultimate device it controls. A sloppy linkage

feels like a sloppy control.

Some people consider the throttle linkage arrangement on GT6

cars (also TR6) as a little Rube Goldberg-ish, especially on

left-drive cars. There are more than half a dozen joints

in the linkage train that can get worn and loose, leading to

slop in the pedal response.

One popular solution to this situation is to install a throttle

cable kit that effectively eliminates some of the joints.

This is apparently effective, and not very expensive, but really

just trades issues with articulated joints for those of

cables. Even though there are a lot of joints in the stock

design, there is no reason they can't be tightened up and maybe

even improved upon.

I'm only focusing here on the part of the linkage that lives

under the carburetors. It consists of a horizontal link

that transmits linear motion from the throttle shaft behind the

engine, a bell crank that converts the horizontal motion to

vertical, and an arm that converts the vertical motion to rotary

motion for the carb throttle shafts.

My assembly was dirty, crusty, and what wasn't loose was

frozen. The vertical link was missing altogether. I

think it fell apart in disassembly.

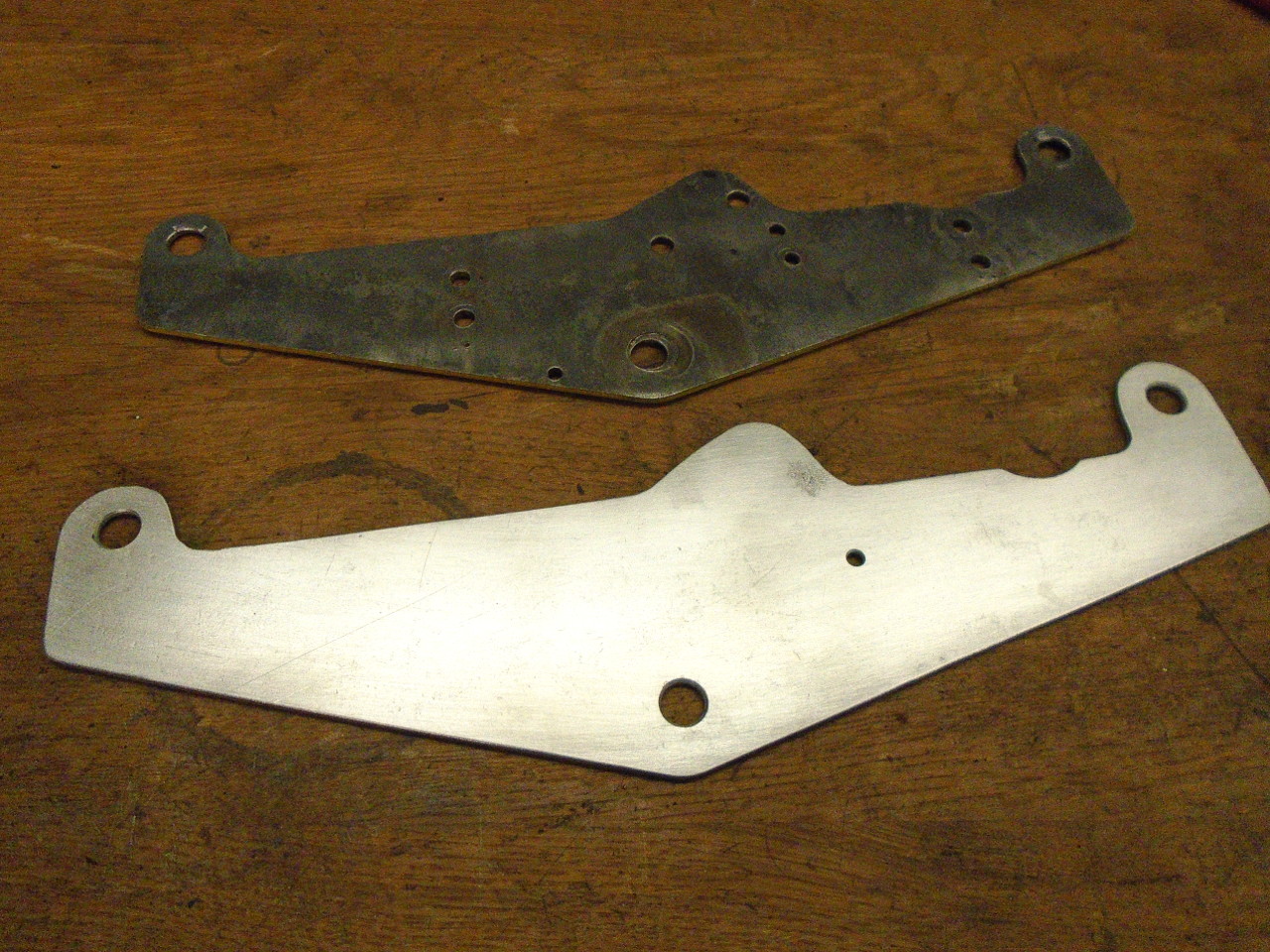

The bracket that spans the carbs and holds the bell crank was in

pretty bad shape. It had deep wear marks from the crank,

and seemed to have a lot of holes that weren't used. It

was pretty simple to just make a new one. It's 14 gauge

steel, like the original.

Next, I looked at the horizontal link. It is adjustable

length, and has a ball joint on the bell crank end. The

ball joint was a little loose, and though there is a provision

for tightening it up, that adjustment was frozen. I ended

up damaging the joint trying to free it up.

I believe at least one vendor may sell a reproduction of the

original ball joint, but I found a pretty good modern

replacement for it. It is not adjustable, but is all

stainless steel, and has a rubber boot to help keep the joint

clean.

I cleaned up, de-rusted, and re-plated the parts of the link.

I liked that new ball joint so much that I ordered a couple more

in the next smaller size to make a new vertical link.

Then, on to the bell crank. The pivot hole of the bell

crank was loose on its shoulder bolt, and was the source of a

lot of the slop in the linkage.

The first mod to the crank was to remove that staked ball.

The original vertical link just had a plastic ball socket that

would snap onto that ball. Those plastic pieces didn't age

well.

I had also noticed that the hole where the horizontal link

connected was wallowed out, so I welded it closed and redrilled

it for a snugger fit.

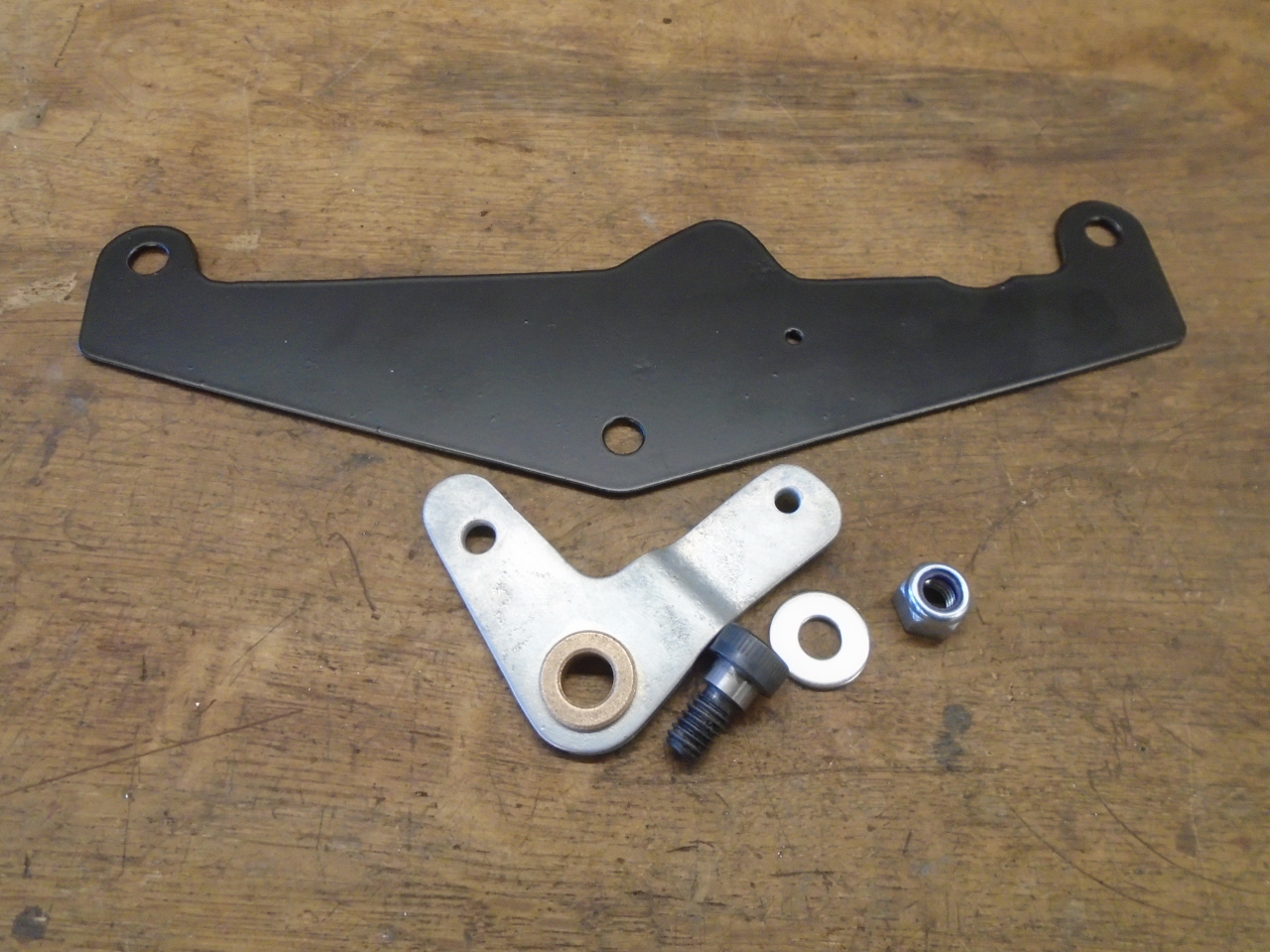

Then, to address the pivot hole, and to even improve the design

a little, I bored the hole for a pressed-in flanged Oilite

bushing. The flange will bear against the mounting bracket

so the crank can't rub.

Then I could mount the bell crank with a new shoulder

bolt. I thought the bracket looked better black.

It's powder coated.

Then added the stop. It limits how far the bell crank can

rotate.

The last assembly was the lever arm for the carb throttle

shafts. It includes a lost motion arrangement. In

any linkage system like this, it is often wise to provide for a

small, controlled amount of slop, euphemistically called "lost

motion". This ensures that the linkage is not bound tight,

and makes sure that the carb throttle shafts can fully rest on

their stops at idle.

The lever arm also had to have it's ball removed to make way for

the new vertical shaft ball joint stud.

The steel parts were re-plated, with a chromate treatment.

Putting everything together. The whole mechanism is tight

and smooth (if that makes sense).

This seems like such an insignificant thing, but I really think

it will contribute to a good driving experience.

It really only took a few hours of hands-on time, and I think

the cost was around $20 for the ball joints and bushing.

Comments to Ed at mailto:elhollin1@yahoo.com

To my other GT6

pages