To my other GT6

pages.

January 21, 2020

Intake Manifold

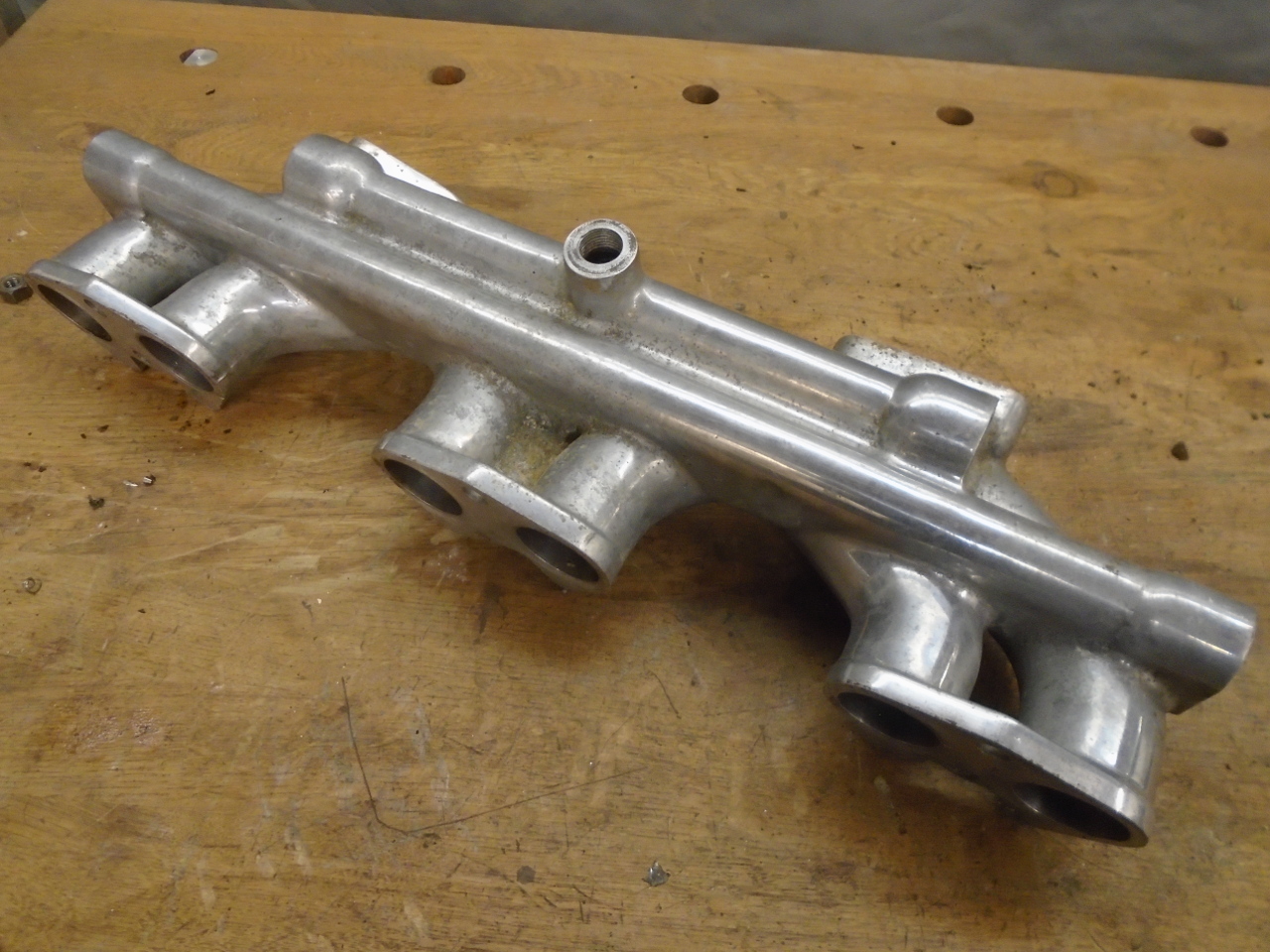

The intake manifold on the GT6 is an aluminum

casting that provides passages from each carburetor to three

adjacent intake ports on the cylinder head. In this sense,

the engine is a little like two coupled three-cylinder engines,

each with its own carb. It appears that the designer

attempted to provide approximately equal length runners for each

port, though this meant that the center runner of each bank

(cylinders two and five) has a pretty significant jog in its

path. The manifold also includes an integral balance tube

between the carb mounting throats, and a passage for coolant,

presumably to improve warmup, and to keep the manifold at a

relatively constant temperature during operation.

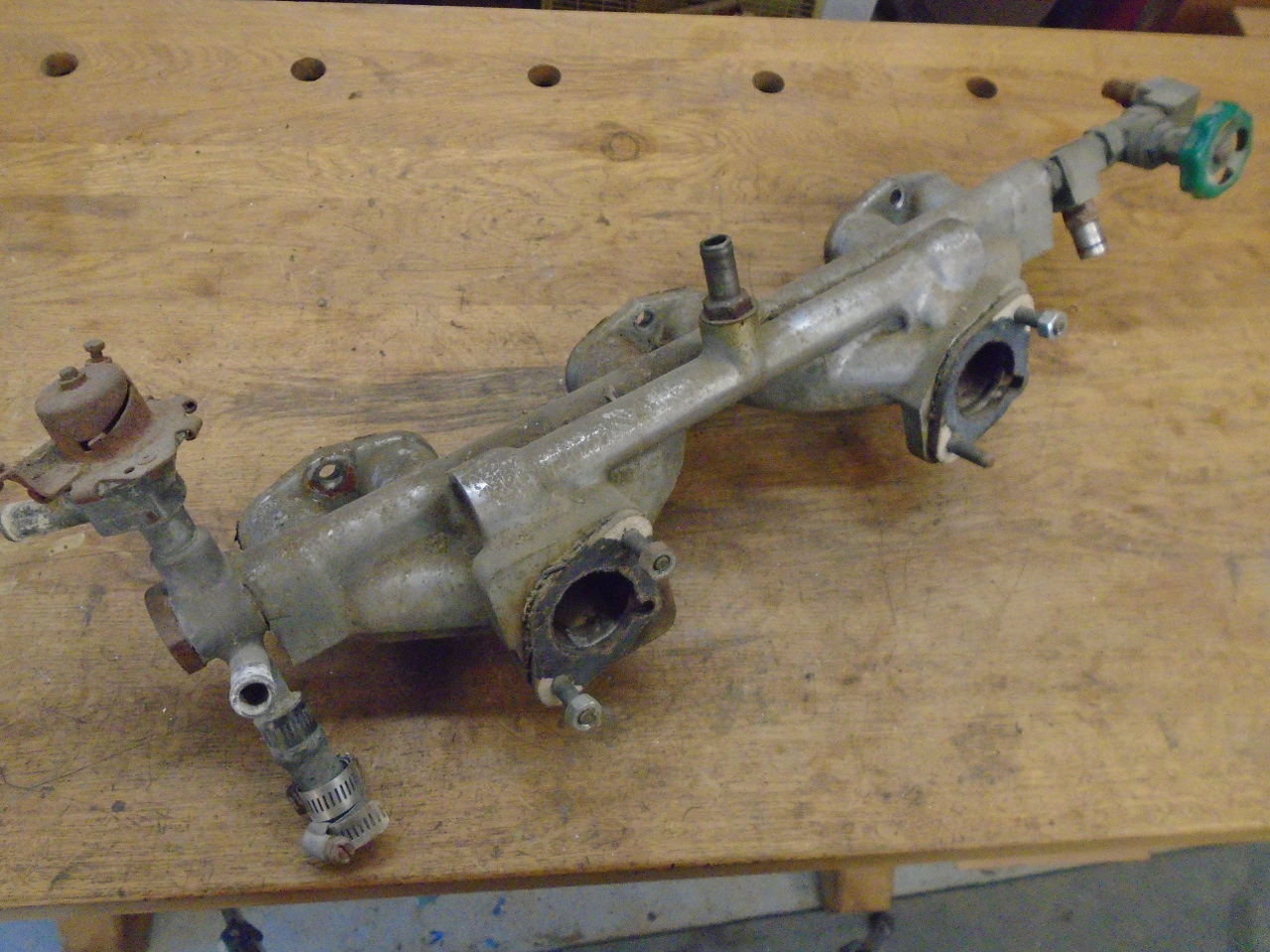

My manifold was grimy, but appeared to be intact. I think

the non-standard fittings at the far end were my early attempt

to mitigate the effects of the stuck-open heater valve.

Removing the various attachments to the manifold casting

produced some heartache. First, the heater valve left most

of its threads behind when removed. Then the banjo bolt

was being troublesome. When I had to resort to an impact

driver, the bolt decided to sacrifice itself rather than come

out peacefully.

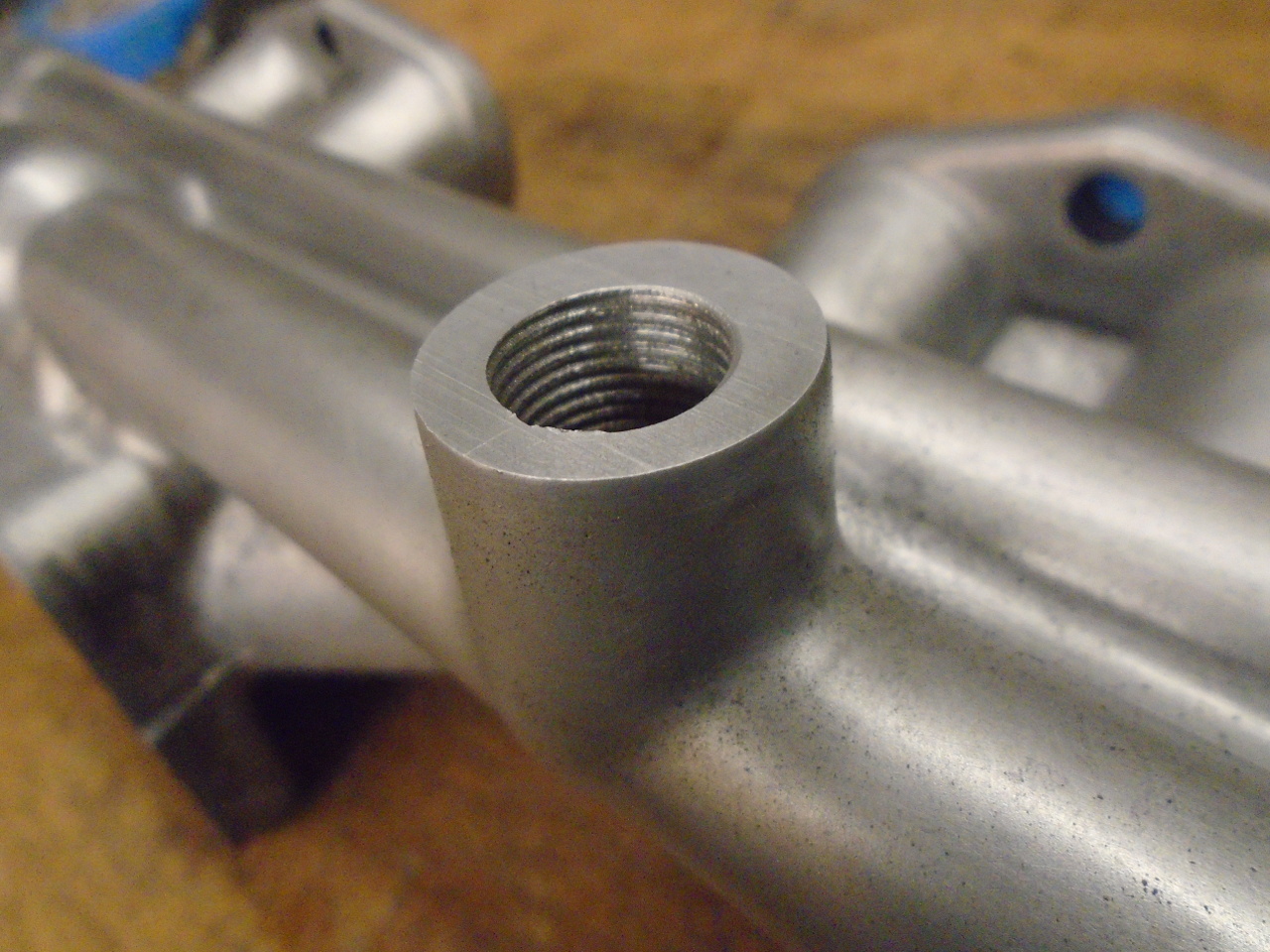

Removing the remnants of the banjo bolt was a couple of hours

detour. The threads in the manifold were a little damaged,

but running a tap into them improved them a lot.

There wasn't really a lot to do inside the manifold. I had

already matched the head-side openings to the head gasket

decades ago. Likewise with the carb side openings.

Other than that, there was just a little shaping of some ridges

on the carb side where the machined throats meet the cast

cores. It wasn't much--maybe only 1/16" or so is all it

took to make a smooth transition.

After cleaning up the casting with soap and water, I remembered

that I had polished up the topside back in the 80s. It

still looked sort of OK, but there was a lot of stains and

mottling on the shiny surface.

To try to even out the surface finish, I popped the manifold

into the blast cabinet and gave it a light once-over. The

result was a more even, but matte, finish.

A little wire brushing and some Scotchbrite brought back the

shine.

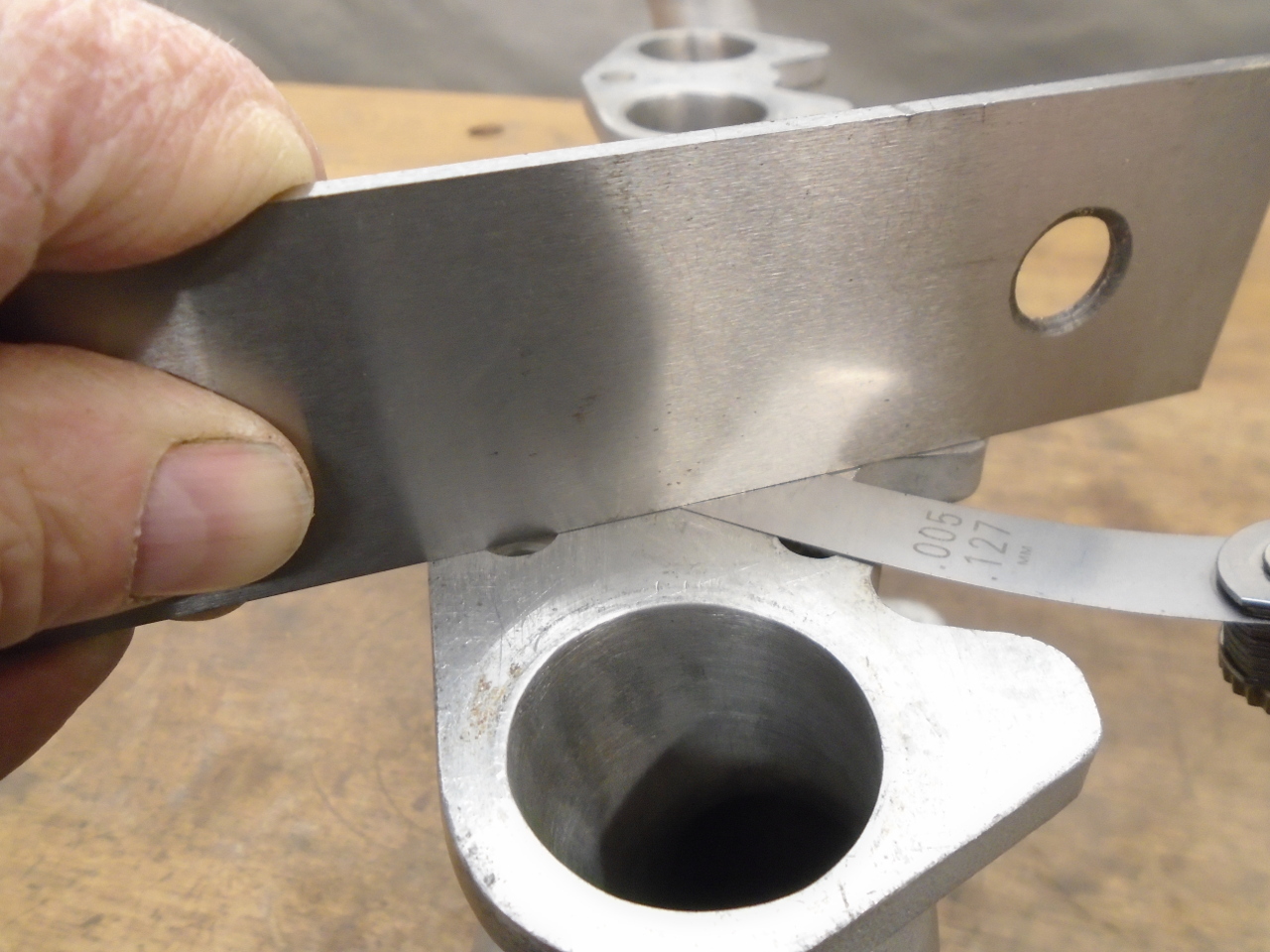

Before I went any further with the surface finish, I wanted to

check out the mating surfaces. This is blue layout

compound on one of the head side mounting flanges. Giving

the flange a few rubs on a flat plate with fine sandpaper glued

to it easily shows the high spots. Not surprisingly, it

was high where it was clamped. Once I knew the pattern, I

could check the other flanges with a straightedge and feeler

gauges. The un-flatness was a little under 0.005" on all

of the flanges. That's not huge, and may not even

represent a problem, but on the other hand, it's pretty easy to

fix.

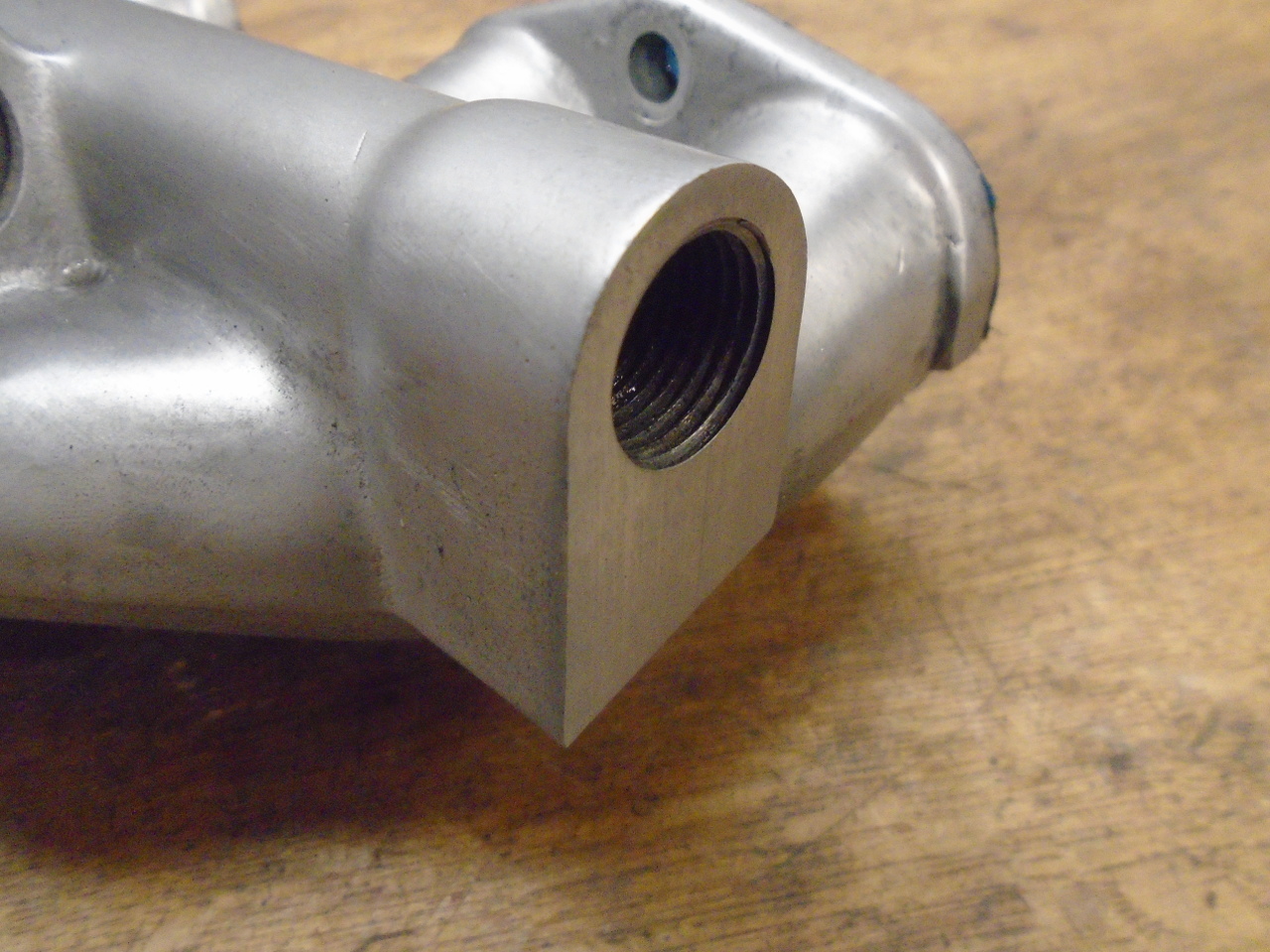

Skimming 0.005 cleaned up the flanges nicely. They are now

all flat and co-planar.

I did the the smaller sealing surfaces, too. They took

quite a bit more to clean up--almost 0.020".

Then I had to decide what to do about the surface finish.

The manifold looked OK from a few feet away, but up close, it

was easy to see some imperfections--mostly porosity. Also,

I knew that even though the aluminum will take a pretty good

polish, it won't last long in the hostile environment of an

engine bay. I decided to try a clear powder coat to

preserve the shine. Clear powder coat goes on white.

It was a tight fit in my small oven.

Well, the clear powder coat was a big fail in several

ways. First, I decided I didn't really care for the high

gloss finish. Second, there was a lot of bubbling on some

areas. I blame this on a combination of the porosity and

my cleaning regimen. Before applying the powder, I washed

the part in detergent and water. Even though I dried it

well, I think there was still water in some of the pits.

The water boiled off in the oven, causing the bubbles in the

melted powder.

An additional reason for abandoning the idea of powder coating

the manifold was that I began to doubt that the coating could

withstand the temperatures near the head and exhaust manifold.

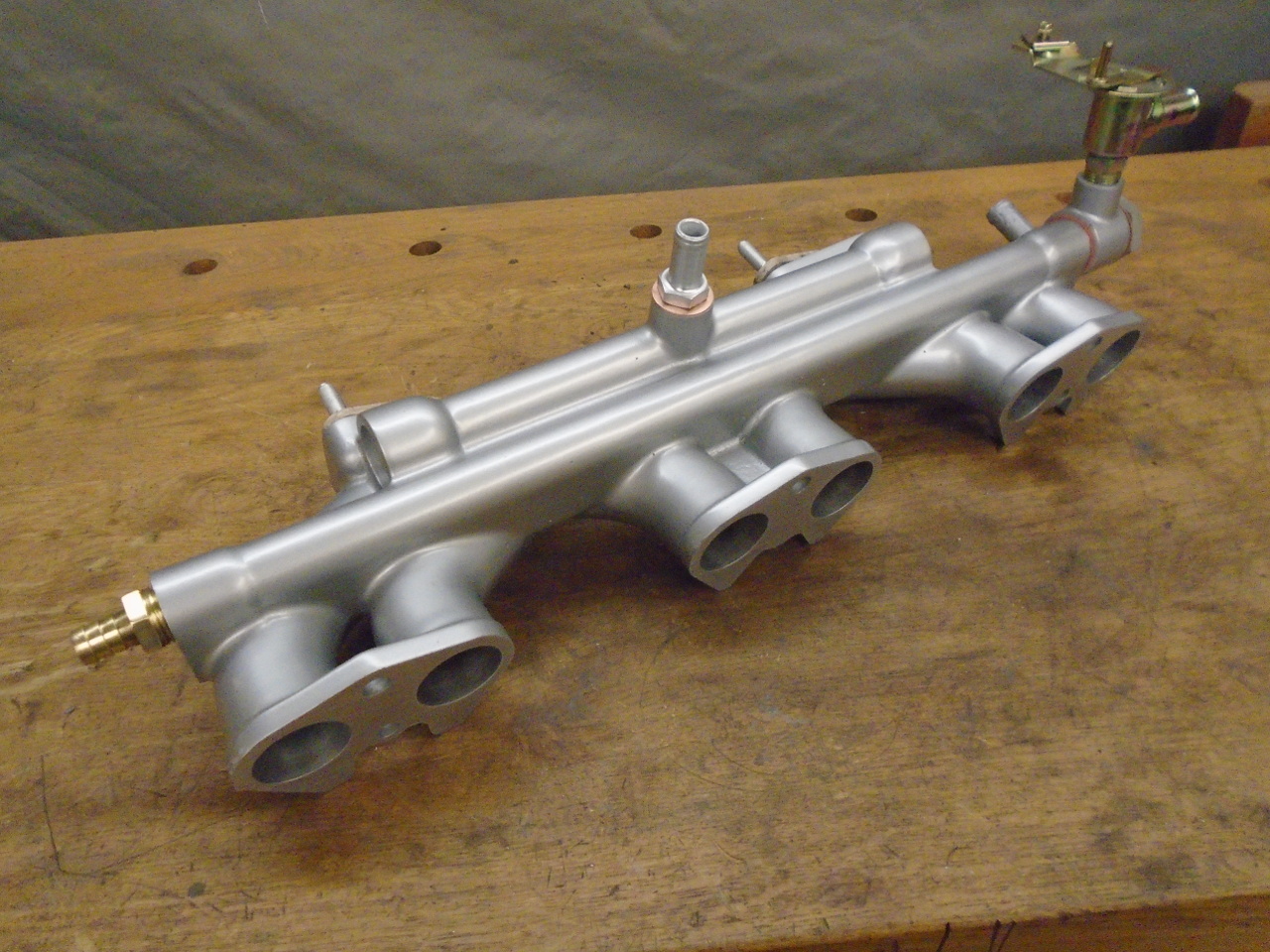

In the end, I decided to just paint the manifold with a good

high temp engine paint. This is all of the parts

associated with the manifold, including the replated original

studs and hose barb fitting. The heater valve is a popular

replacement that uses a much more reliable internal design.

On the shelf with this dude.

I really wish I could have achieved the look I wanted on the

manifold without resorting to paint. But, in the larger

scheme, it's a pretty small issue.

Cost was around $30 for the heater valve.

Comments to Ed at mailto:elhollin1@yahoo.com

To my other GT6

pages.