To my other GT6

pages

December 29, 2019

Fuel Pump

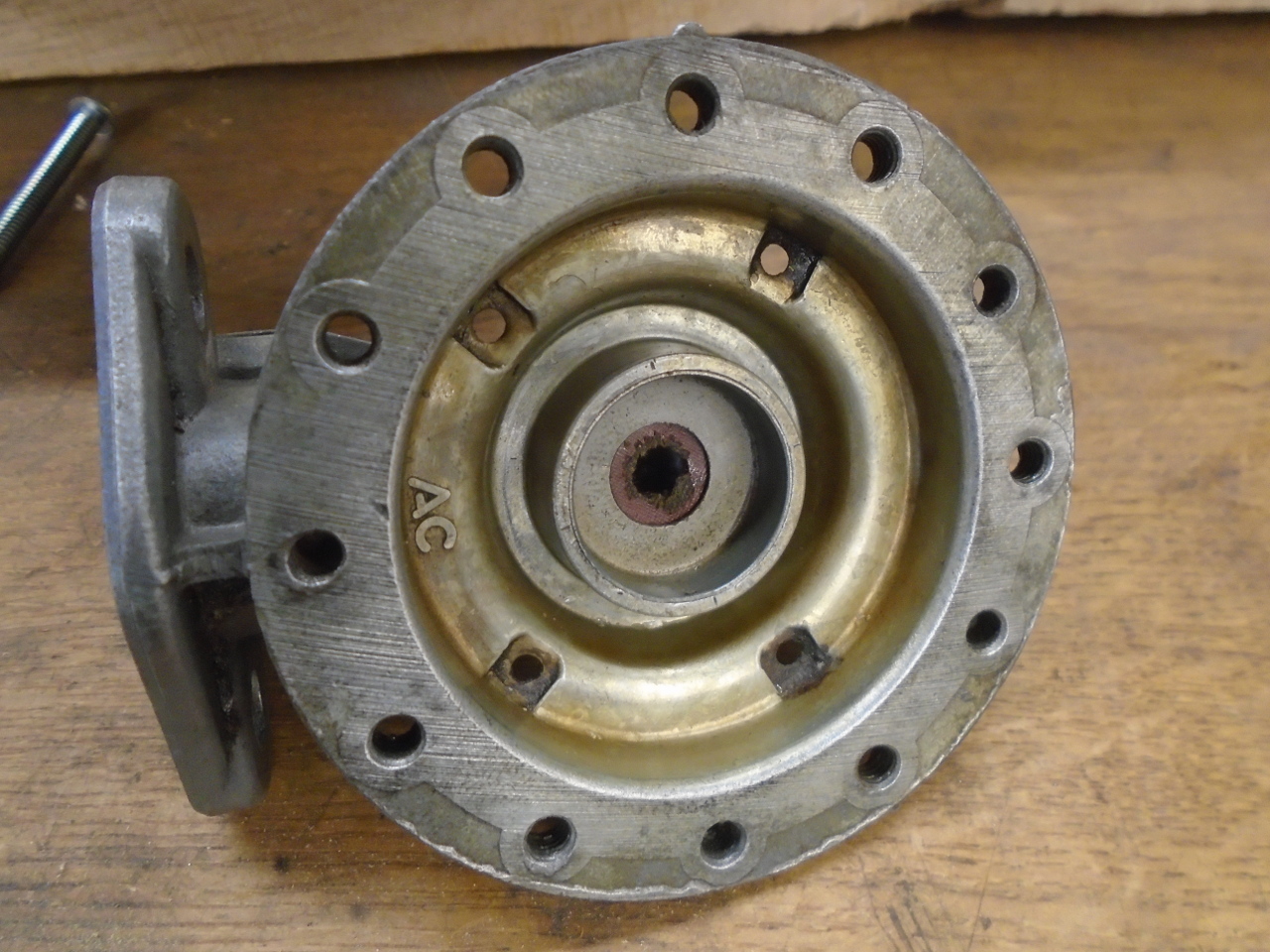

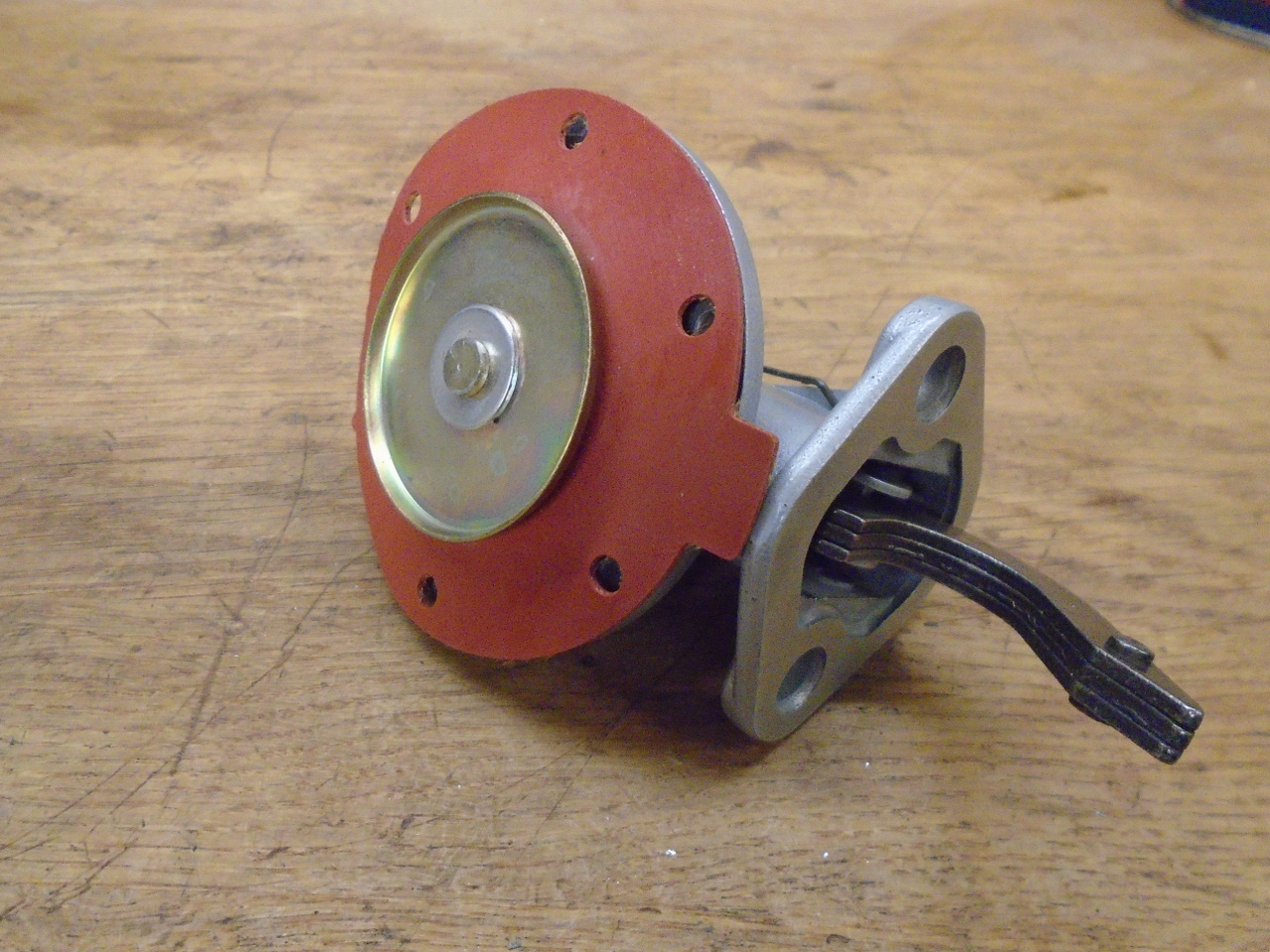

The AC fuel pump as found on my GT6, and a few variants, were

pretty commonly used on a range of British cars of the era.

This pump is probably original, or at least a period replacement.

Though reproduction pumps are easily available, there is always

the nagging question of the quality of aftermarket parts.

There are good quality replacements out there, but their cost

makes rebuilding the original an even more attractive option.

The main body of the pump consists of two pot metal castings held

together with six screws.

One area largely ignored by the rebuild kits is the priming lever

mechanism. With some diligence, it does come apart, and

there are some seals to tend to.

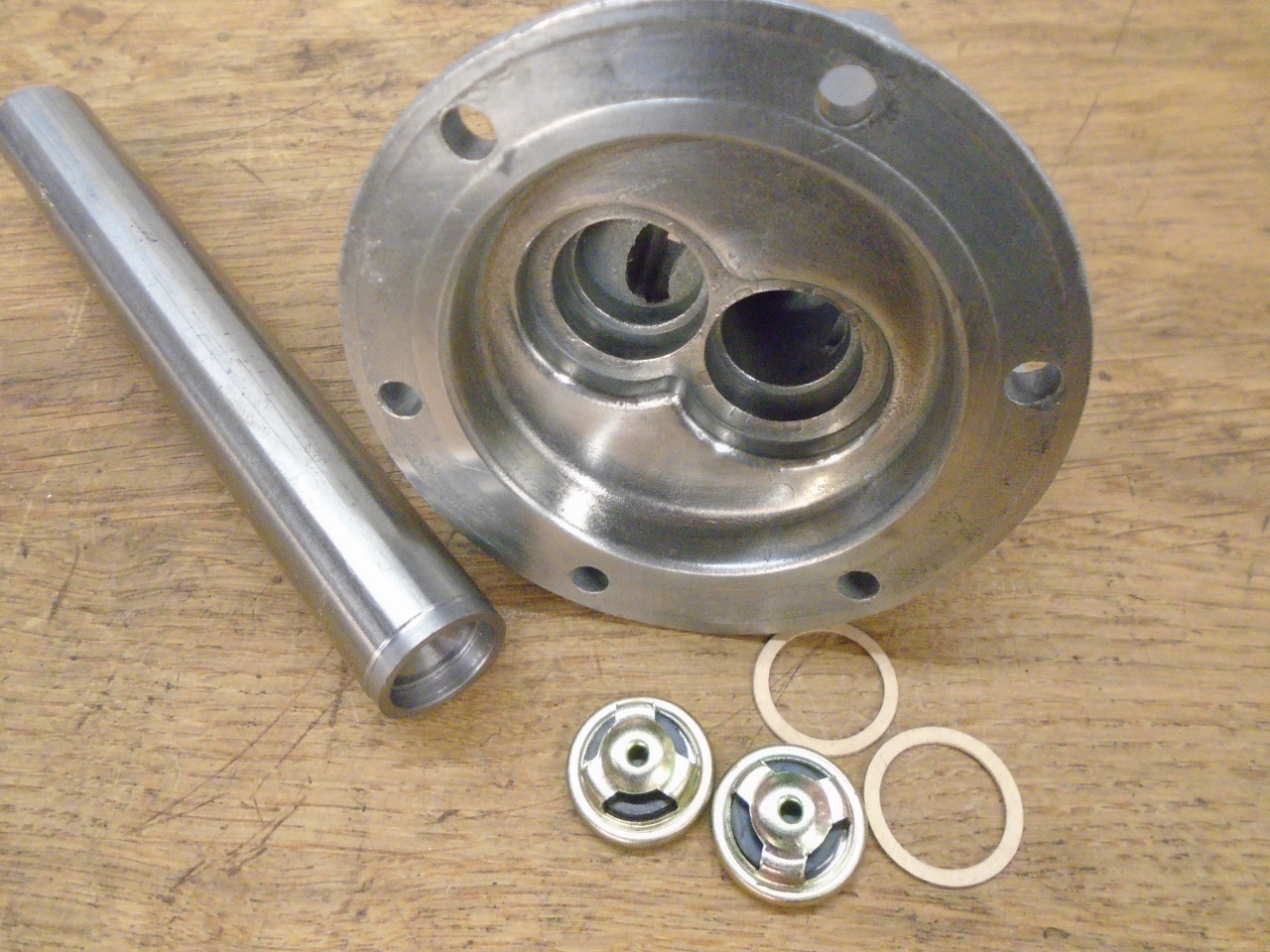

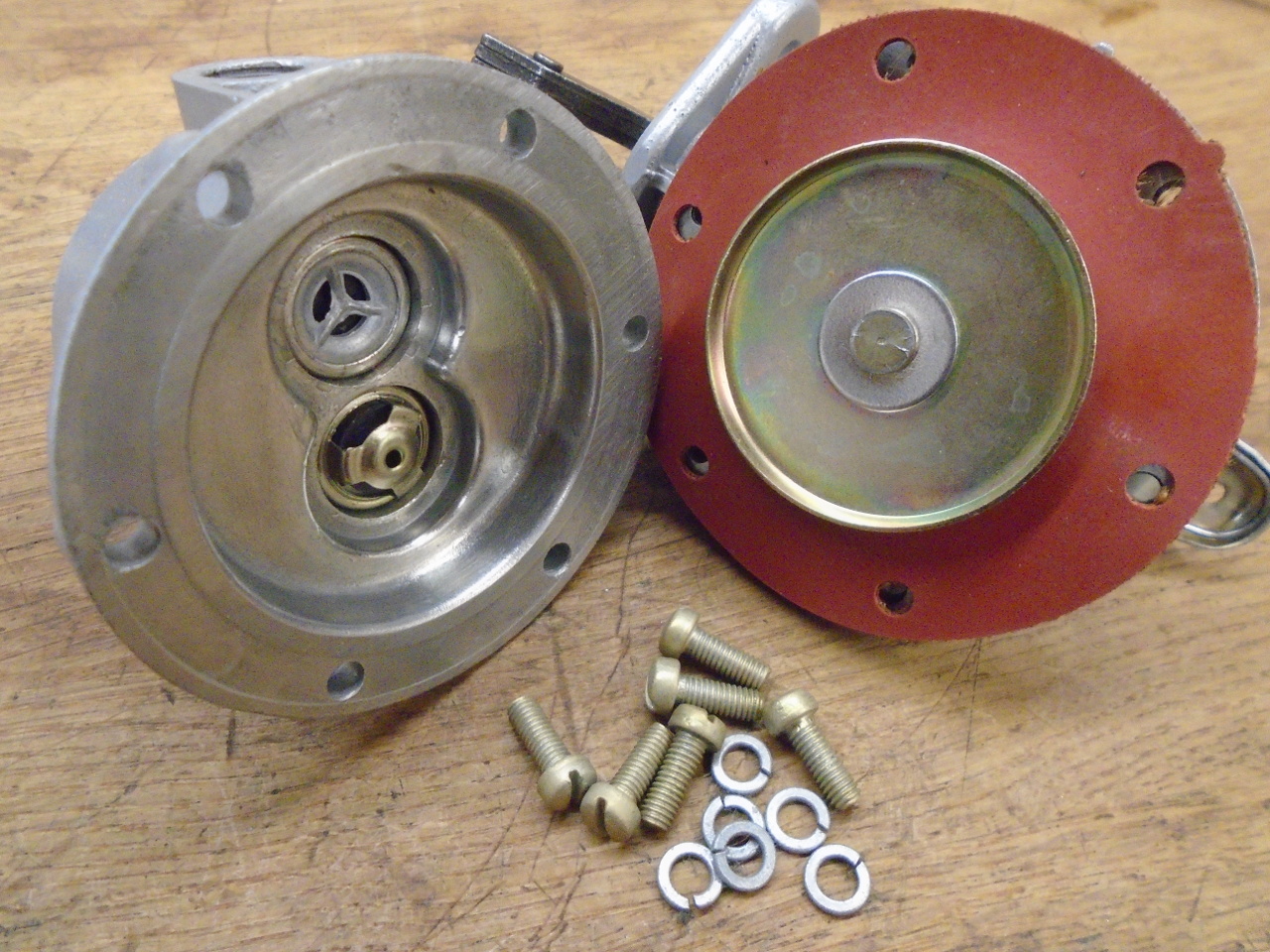

The top half of the body holds a pair of opposed check valves, one

lets fuel into the pump on the downstroke of the diaphragm, and

the other passes fuel out of the pump under a small

pressure. Sometimes these valves are staked in, and

sometimes there is a little metal retainer clip screwed to the

body. In this case, the check valves were just a friction

fit. One of them could be driven out from the top with a

drift, while the other had to be brutalized from the bottom side.

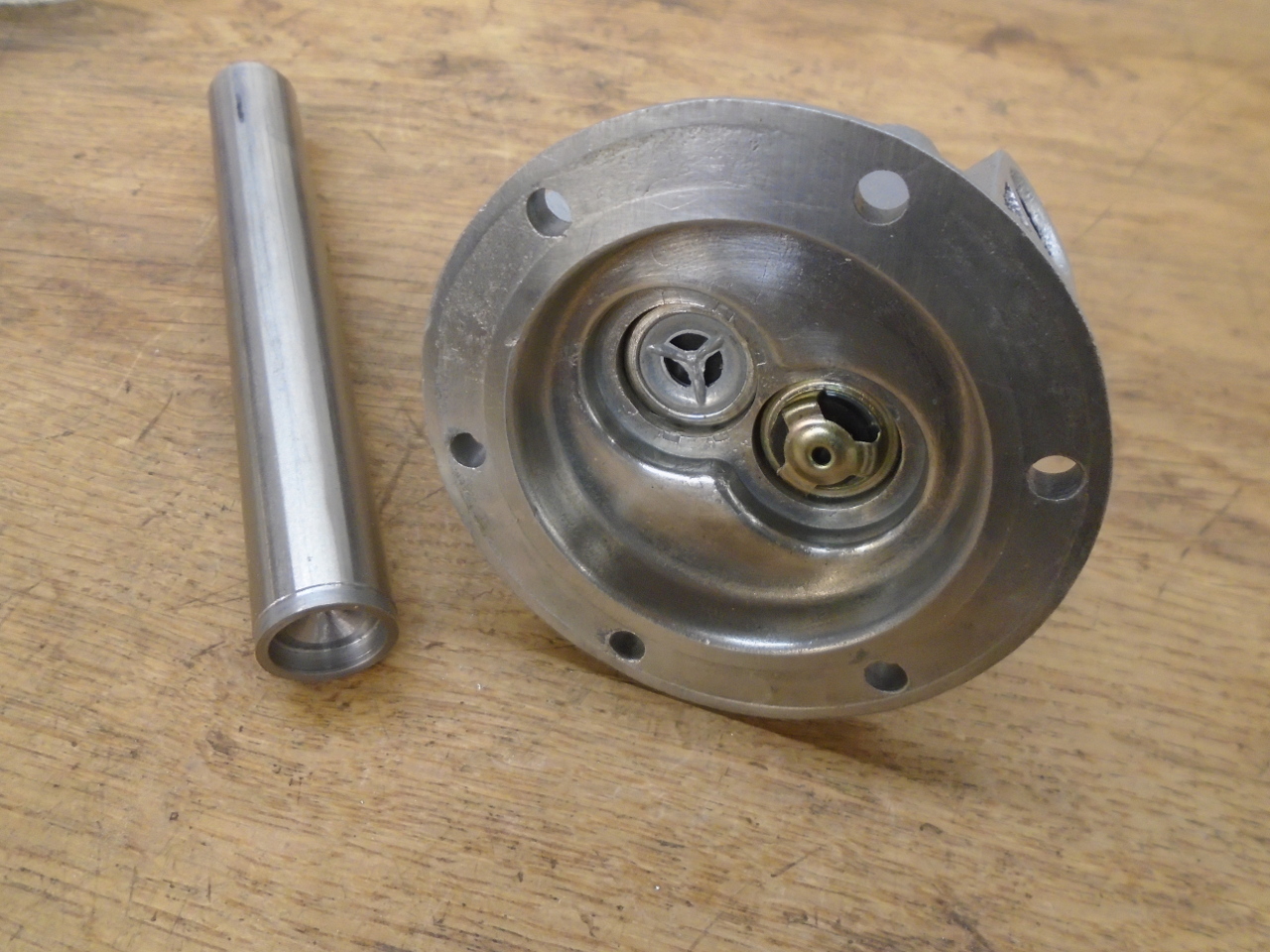

The bottom half of the body holds the lever mechanism to operate

the diaphragm, and also a seal for the diaphragm rod. The

seal allegedly separates the pump chamber below the diaphragm from

the crankcase to prevent fuel from entering the crankcase in the

event of a diaphragm breach. That could be true, but I have

my doubts. The lower pump chamber has a number of sizeable

vent holes in its floor, so most fuel would simply spill out of

the pump on to the ground and be pretty obvious. It is also

possible that the seal was to keep crankcase vapors out of

the pump. In any case, these seals seem to wear rapidly, and

are not typically included in rebuild kits, so many pumps out

there are operating without the benefits of this seal, whatever

they are.

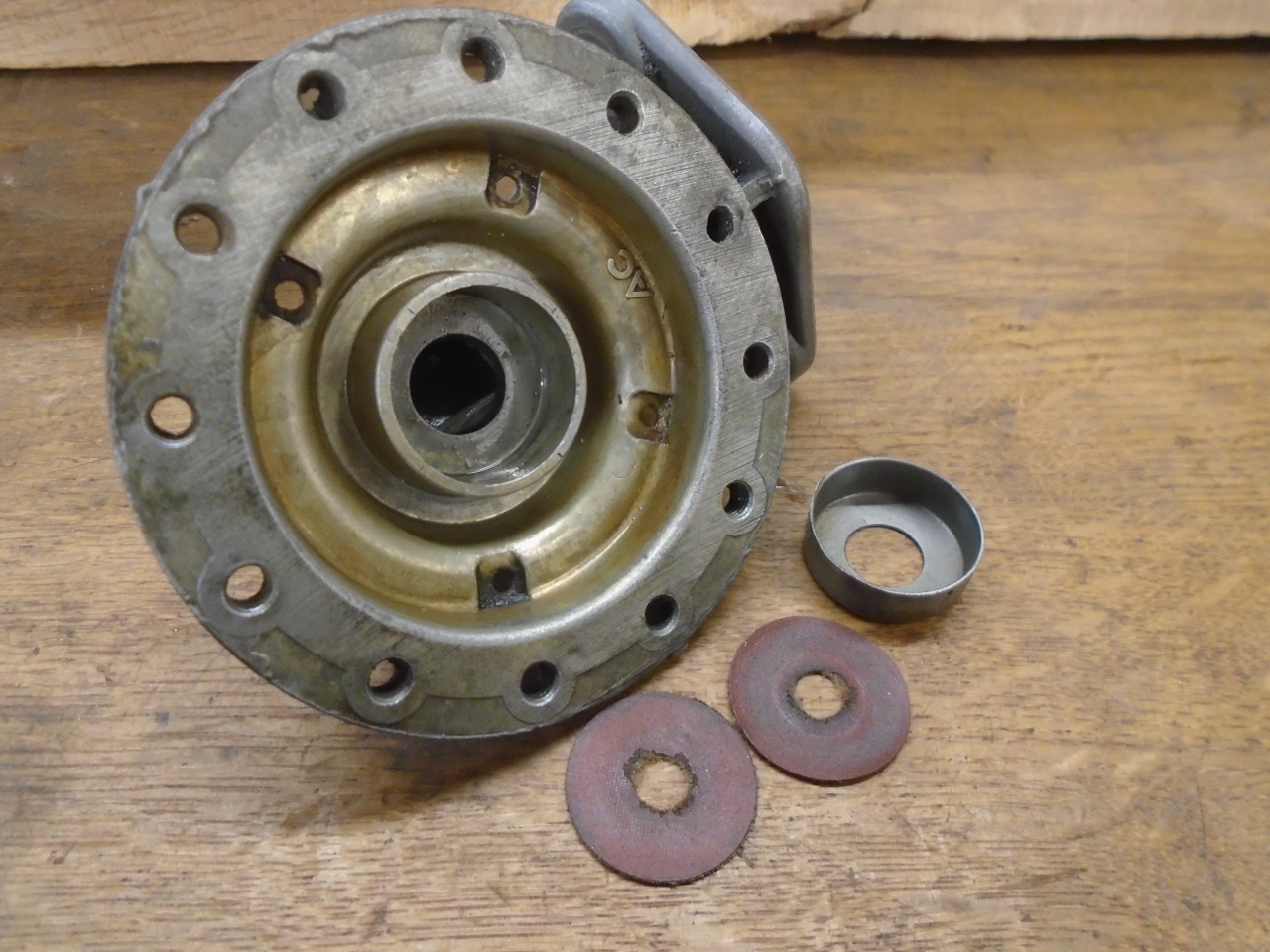

Though seal designs vary, the one on my pump consisted of a metal

cup which captured a couple of thin composition discs. The

discs appeared to be some sort of fabric reinforced resin

material, and were relatively stiff. At some time, they may

have been ore resilient, but in this condition, they were not

sealing anything.

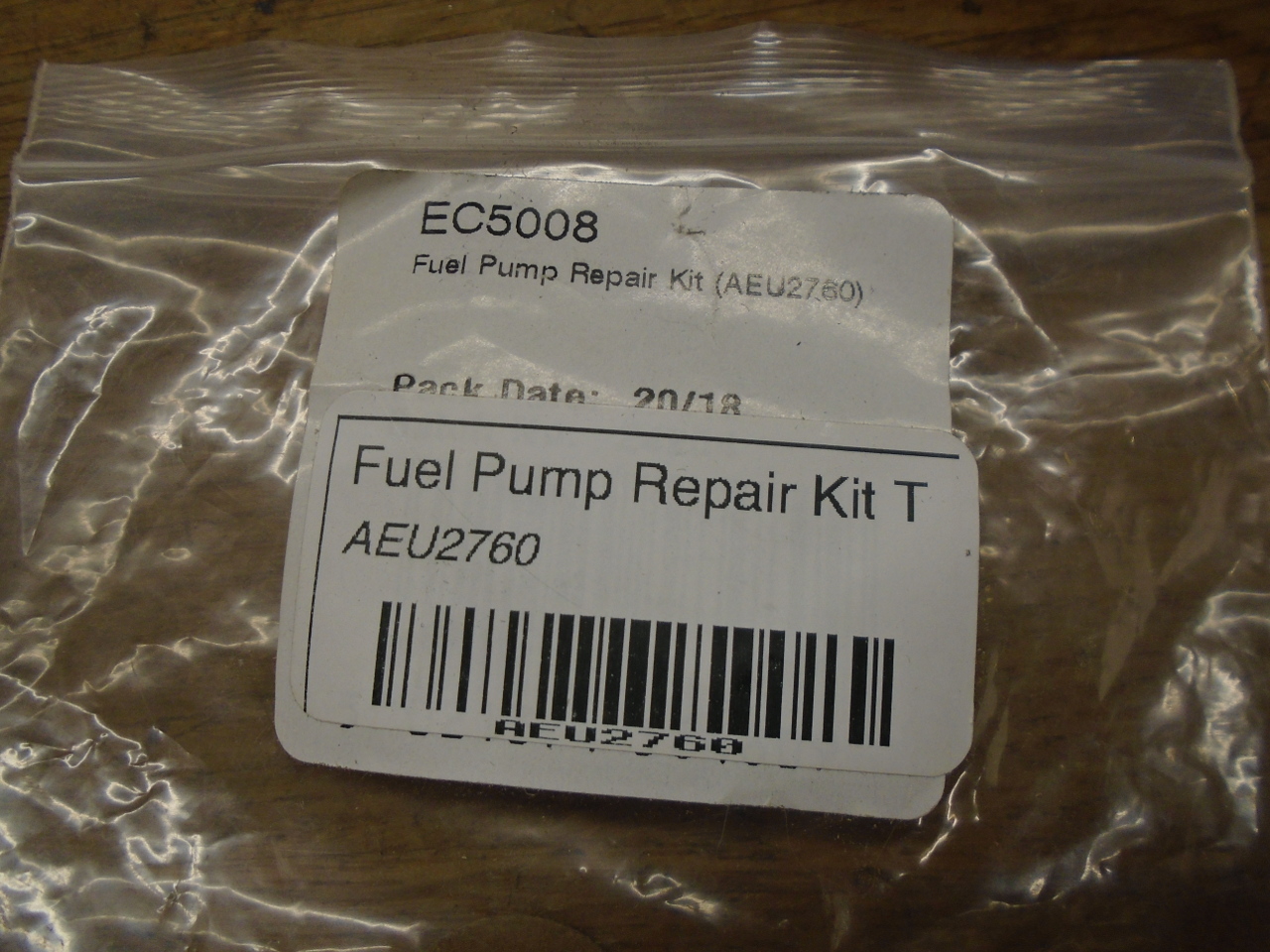

I found a funny thing about rebuild kits for these pumps.

They vary all over the map as to what is in them. The

universal part number for the kit is AEU2760. I had two of

these kits from different sources. For example, the

diaphragm in one of the kits was quite a bit different from what I

needed. In the end, it took parts from both kits to get the

job done. The one in the blue box came from a Rover

supplier.

I started the actual rebuild process by cleaning up the castings,

linishing the mating surfaces flat, and powder coating the

outsides. With some effort, these pumps can be polished to

look amazing, but pot metal being what it is, the shine doesn't

last long.

Next up was the check valve install. Since mine were a

friction fit, and some force would be required, I made the little

tool to help drive them in straight. Letting them get

distorted didn't seem like a good idea. Either or both of

these valves will happily go in the wrong way round. Of the

four possible permutations, only one will result in a working

pump.

I thought some about the stock diaphragm rod seal. Though I

doubted its effectiveness, and it was not included in either kit,

it seemed pretty easy to renew. I used a piece of fuel

resistant, fabric reinforced rubber about the same thickness as

the two original discs. The rod on my new diaphragm was

significantly smaller than the original, so I sized the hole

accordingly. The metal cup is pressed in such that the seal

can float slightly, so it can self-center.

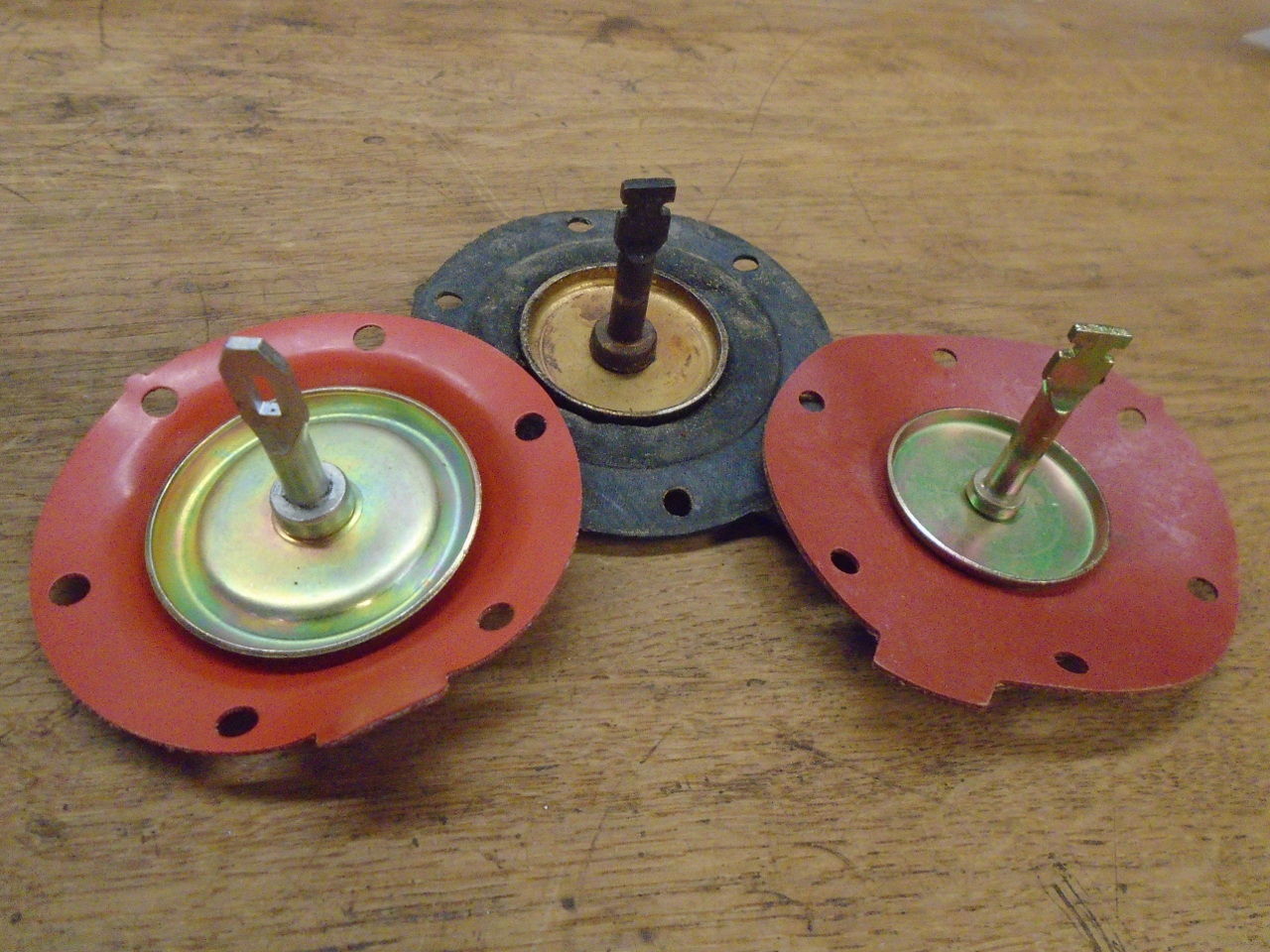

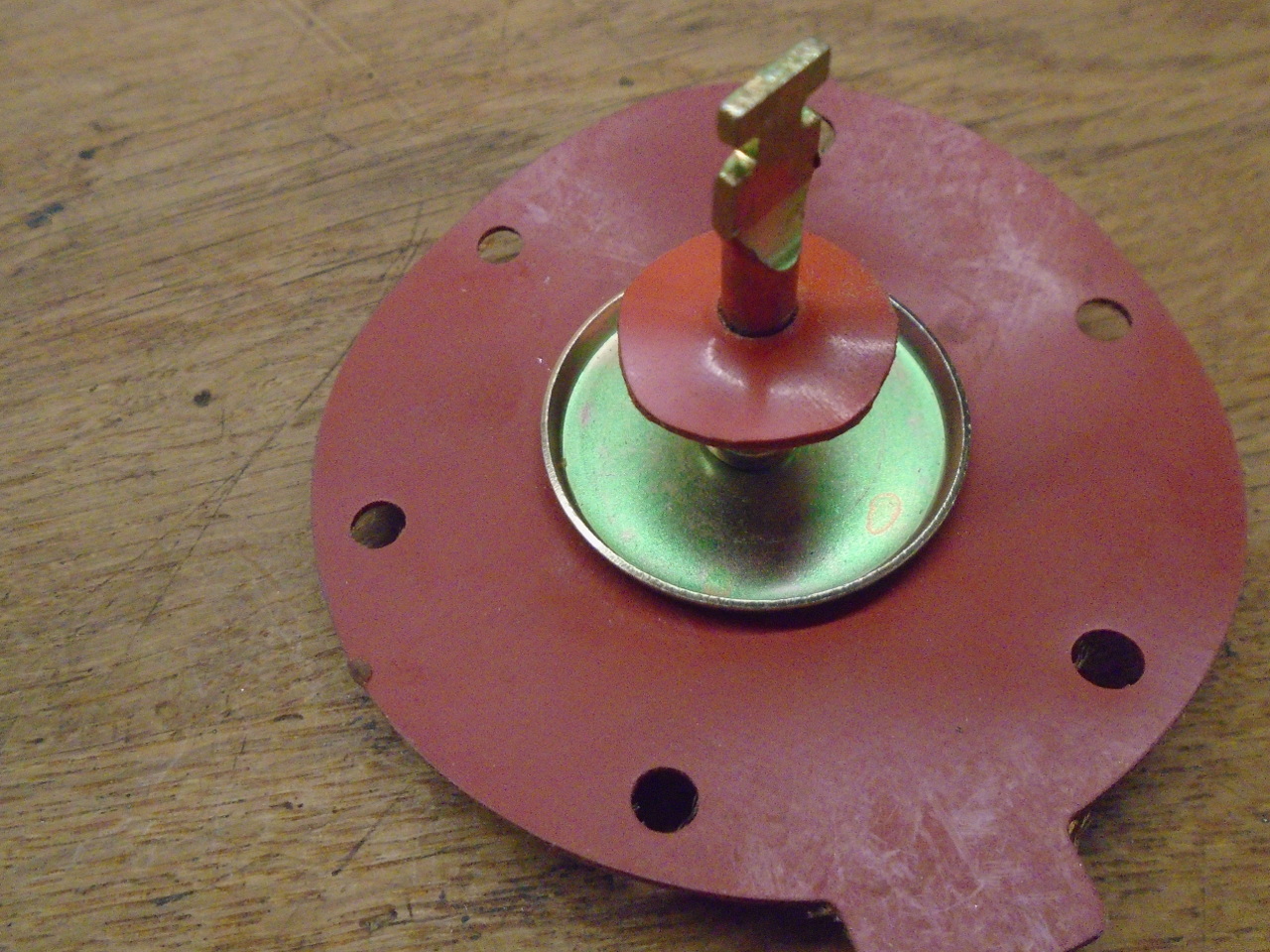

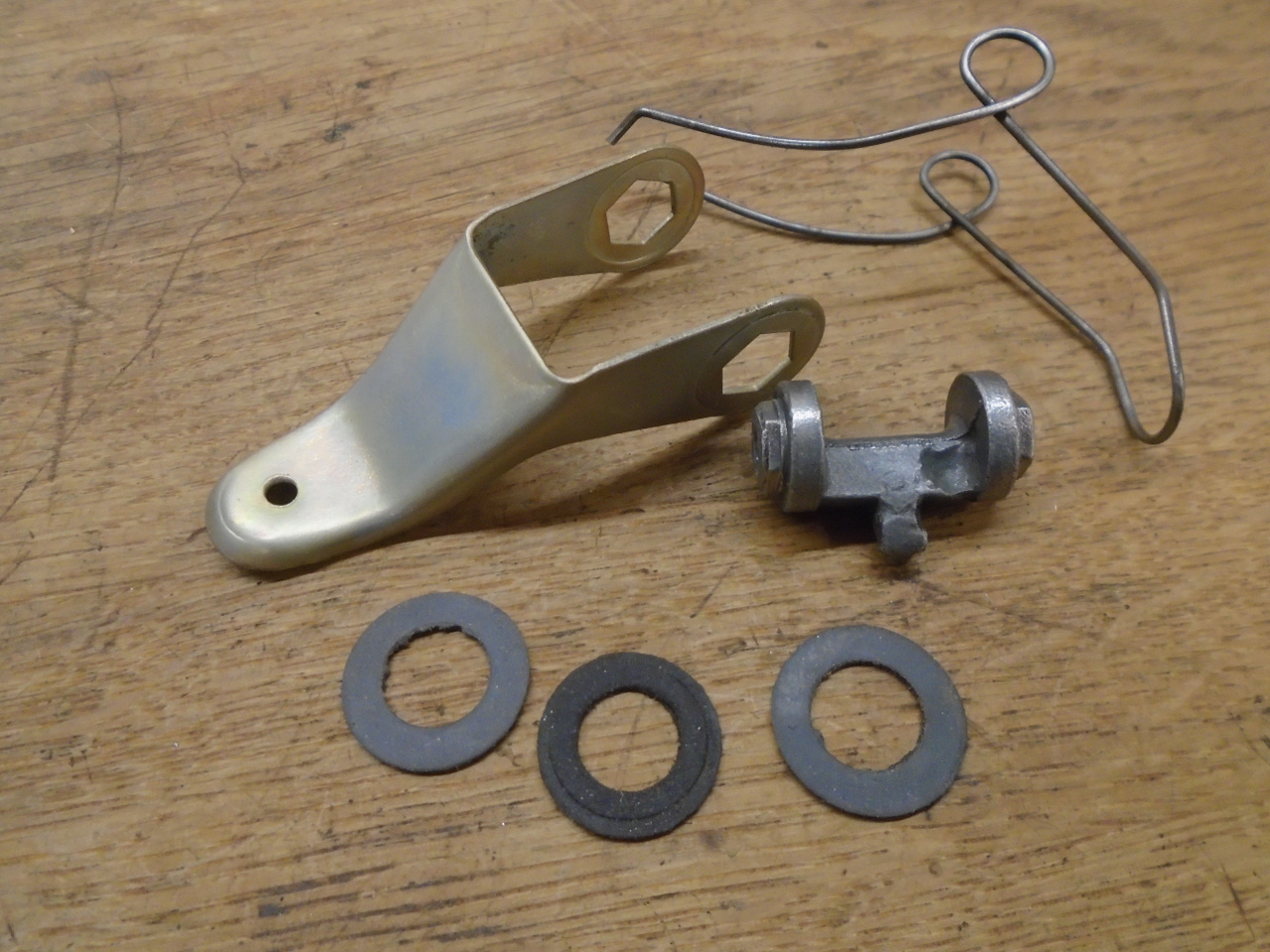

These are the parts of the priming lever arrangement. The

lever itself was stripped and replated. The original

washer/seal in the center appeared to be some slightly fibrous

material--maybe felt or severely aged rubber. The other two

are new ones cut from 0.032" rubber sheet. The spindle that

the lever attaches to shows a very visible casting defect. I

guess they thought no one would ever see it.

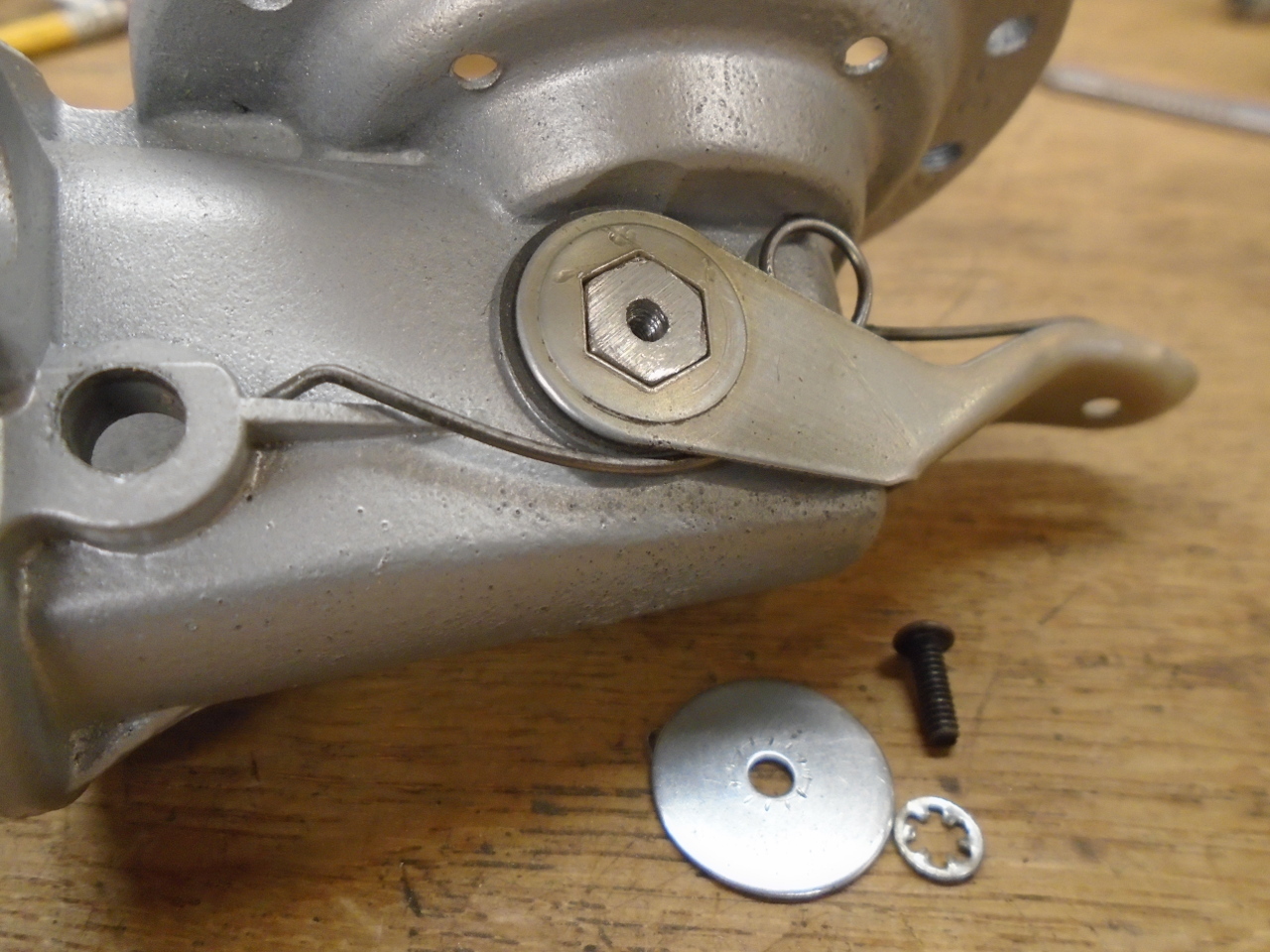

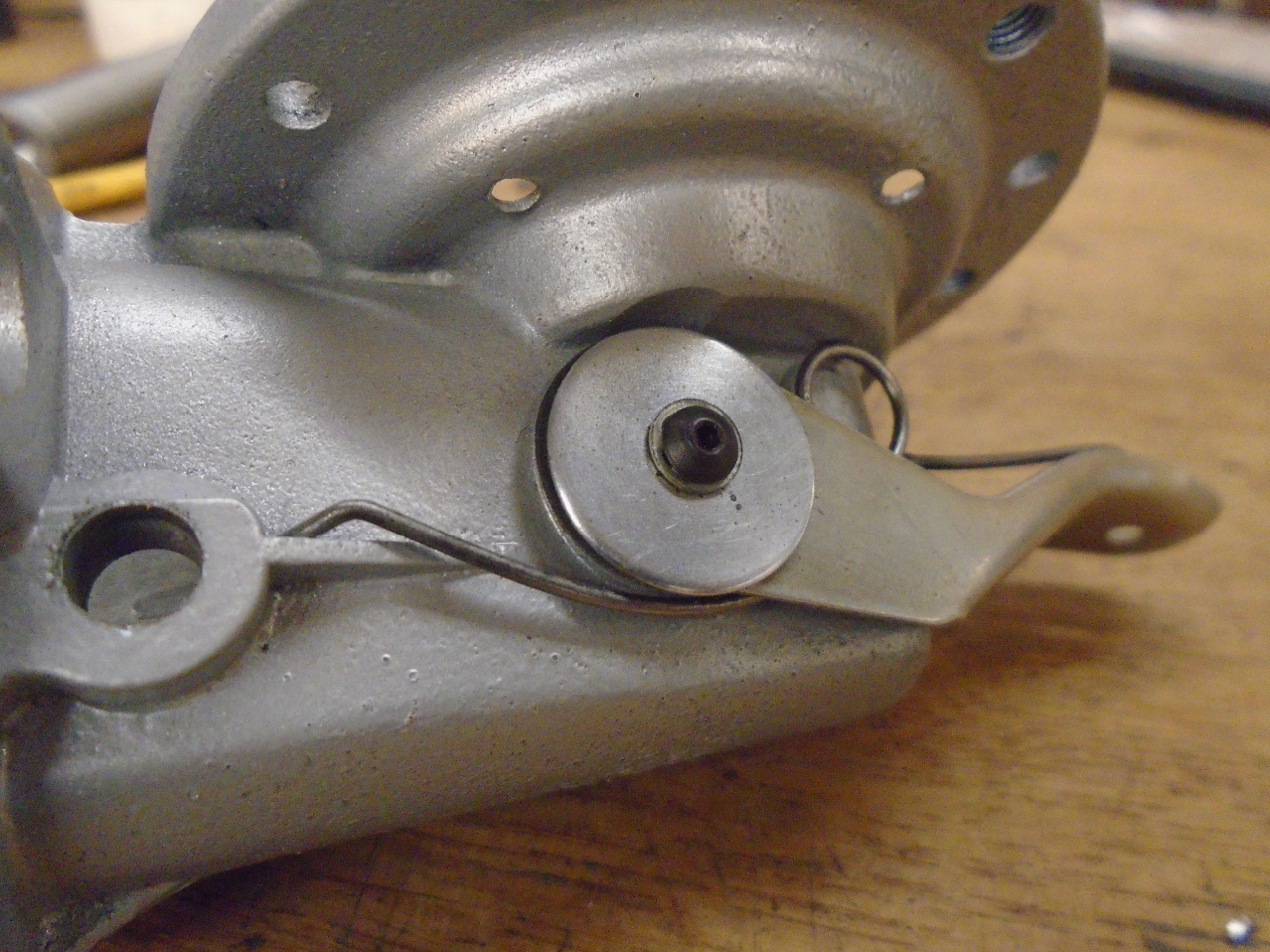

Originally, the primer lever arms were captured onto their spindle

by peening over the hex protrusions on the spindle. There

was probably still enough material to re-peen the lever arms

in place, but I opted to drill and tap the spindle for some small

retaining screws.

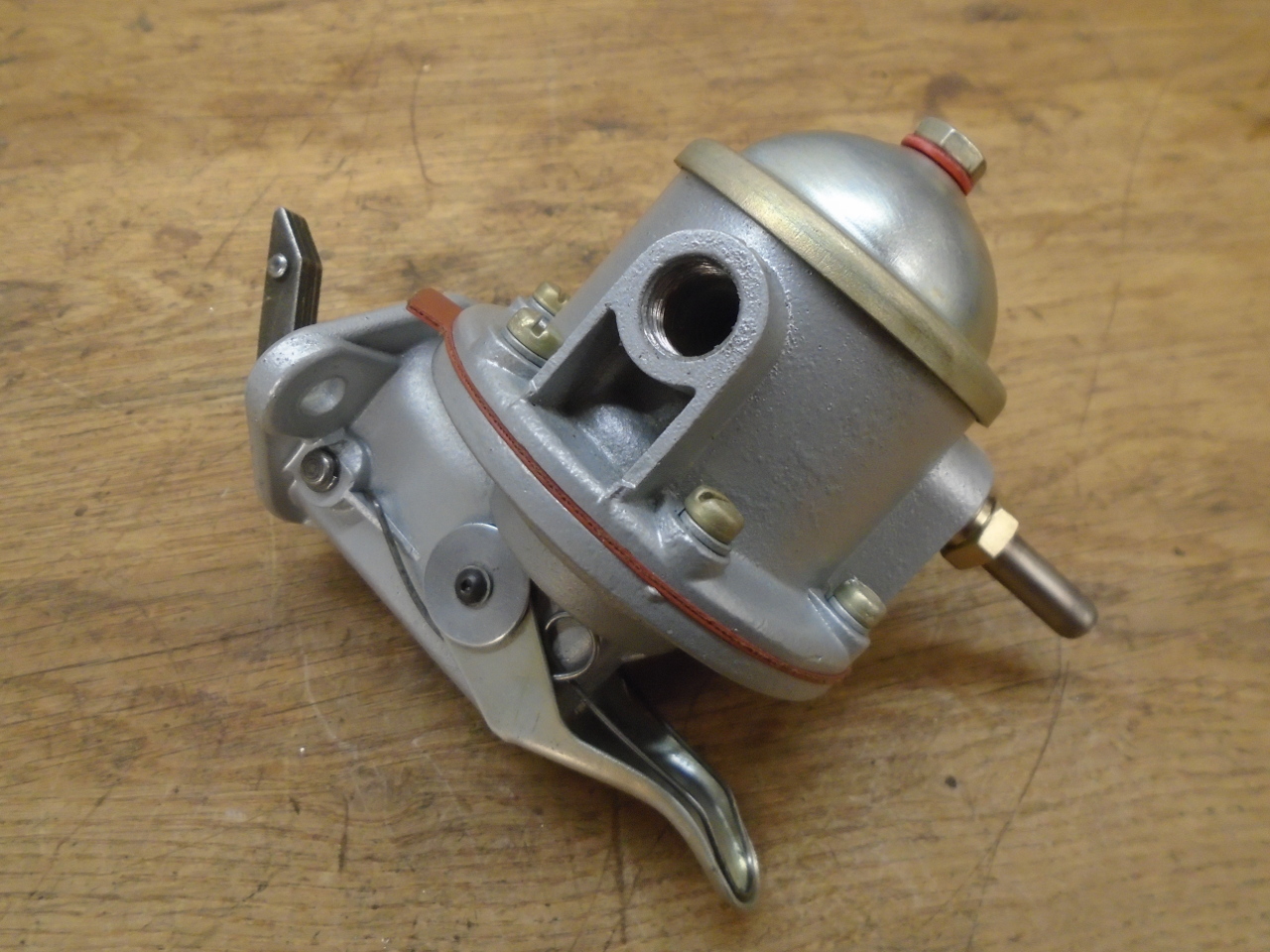

The main actuating lever and associated parts were next.

Most of these parts are hardened steel, which is probably one big

difference between a quality pump, and some of the cheaper

ones. The original lever shows a polished area where it

bears on the cam lobe, but no significant wear.

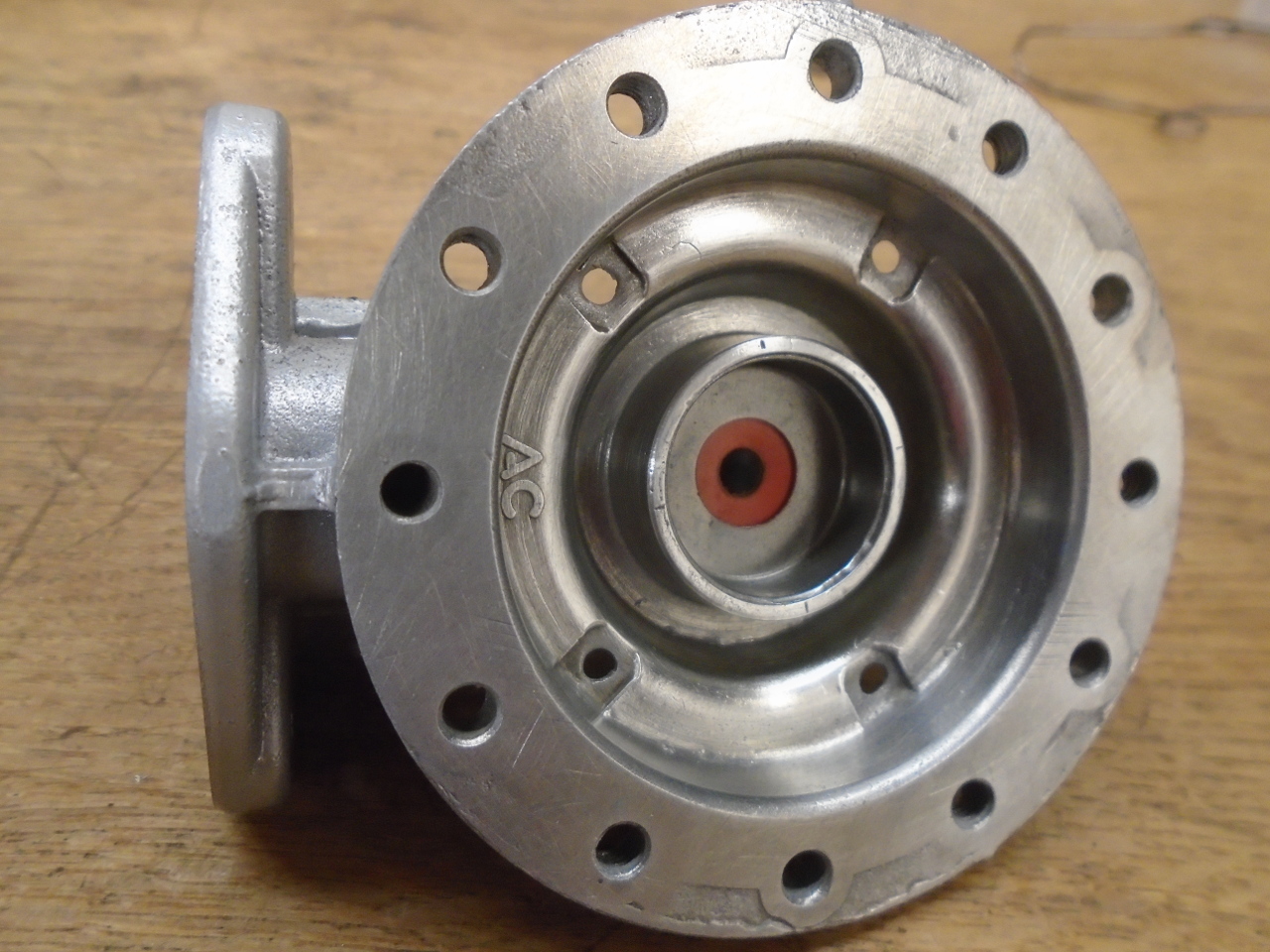

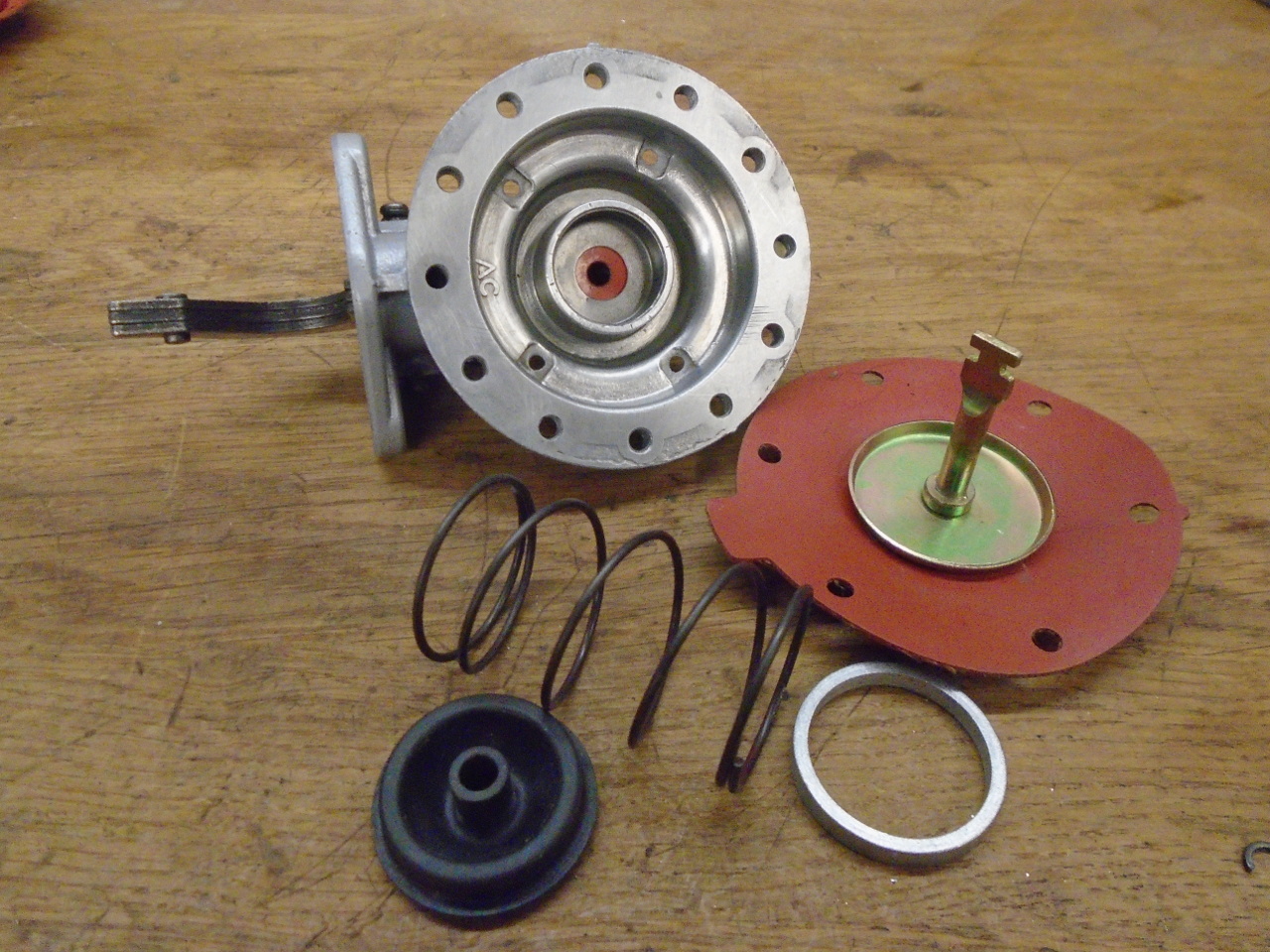

So then it was finally time to join the two halves of the

pump. First, the diaphragm had to be installed. One of

the kits had that black rubber piece in it. It is a seal for

the diaphragm rod to replace the function of the usually perished

original seal. Since I renewed the original seal, I guess I

now have a dual rod seal. An upgrade!

That seal must be for a slightly different pump, though. It

fits fine over the cylindrical protrusion at the center of the

casting, but its periphery doesn't reach down to the floor of the

casting. Since the diaphragm spring seats on the lip of the

seal, it would be better if that lip had some solid support.

Thus the little steel ring shown in the picture. It goes

under the lip of the seal.

Castings reunited. Replated original hardware.

The last of the parts to finish off the top. Replated the

top cap.

On the shelf with this dude.

I've done this job once before, so I sort of knew what I was in

for. I think I may have been able to buy a cheap pump for

what the kits cost, but I believe that I now have a quality pump,

and not a cheap one.

Comments to ed at elhollin1@yahoo.com

To my other GT6

pages