To my other GT6 pages.

December 5, 2019

Water Pump

Like

most other cars of the era, the GT6 used a pump assisted thermosiphon

liquid cooling system. Thermosiphon just means that there is some

natural coolant circulation through the radiator just due to

temperature differences. The pump enhances the flow.

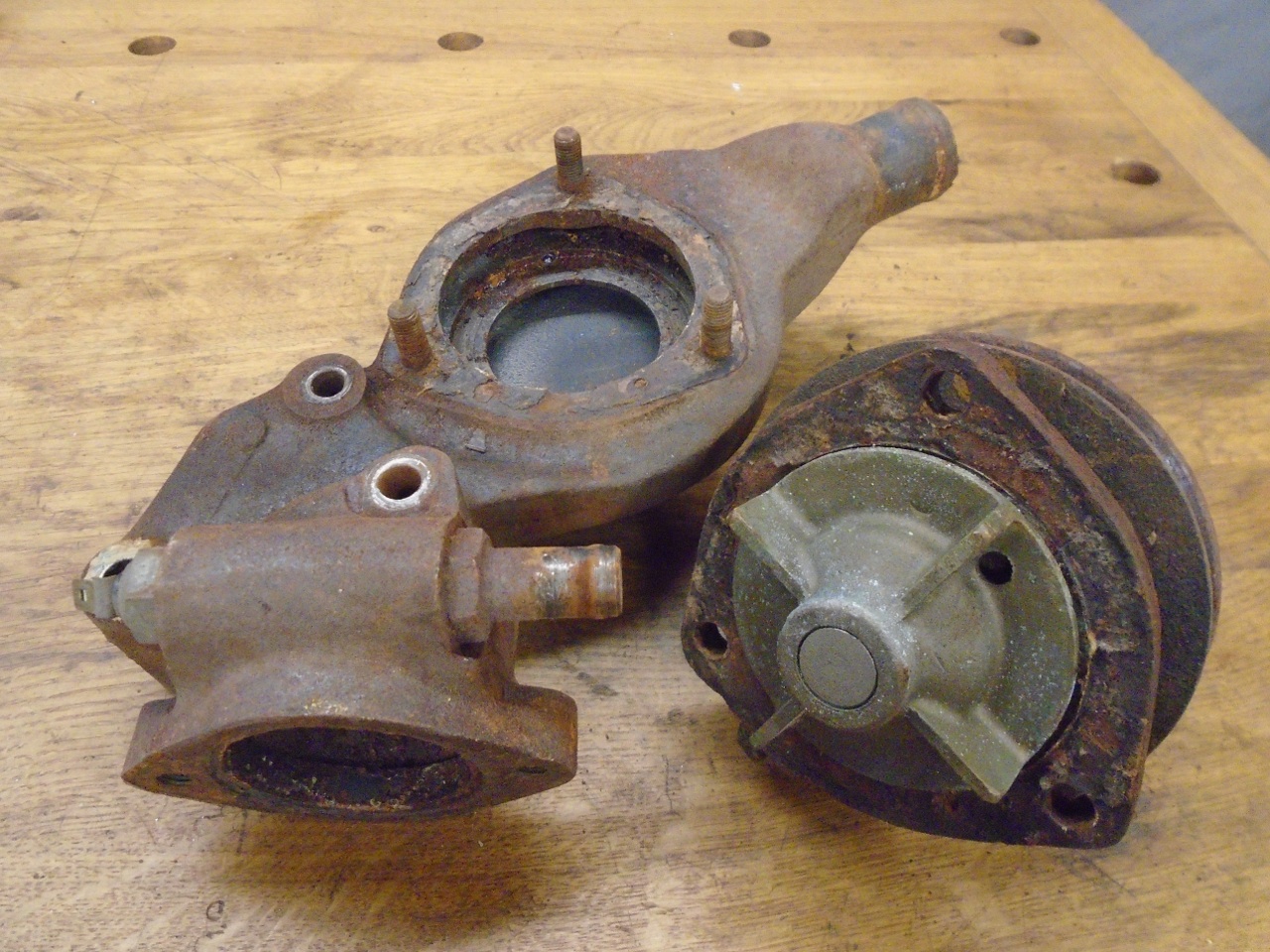

The

coolant pump consists of a cast iron housing holding a belt driven

impeller. In British car parlance, just the impeller assembly is

called the water pump, but in reality it isn't a complete pump without

the housing. My pump was pretty nasty, and appeared to be seized.

Since

there isn't much that wears or goes wrong with the pump housing, I

concentrated on the impeller assembly, first pulling off the belt

pulley. This revealed that it was a Back-Arnley rebuilt unit,

probably from the early 80s.

I pulled off the impeller and saw that the spindle was heavily corroded, and the mechanical seal was completely shot.

The spindle rode in a couple of ordinary ball bearings with a spacer sleve between them.

Though

I think I could have found the bearings, so one seems to sell the

spindle or the complete seal. A new spindle wouldn't be difficult

to make, even of stainless steel, but the lack of a source for the seal

was a problem. Mechanical seals like these used in water pumps

typically have spring loaded carbon or ceramic disks that rotate

against each other. They aren't hard to find, but there are

litterally hundreds of different sizes and configurations, so it would

be shots in the dark to try to find one that would fit.

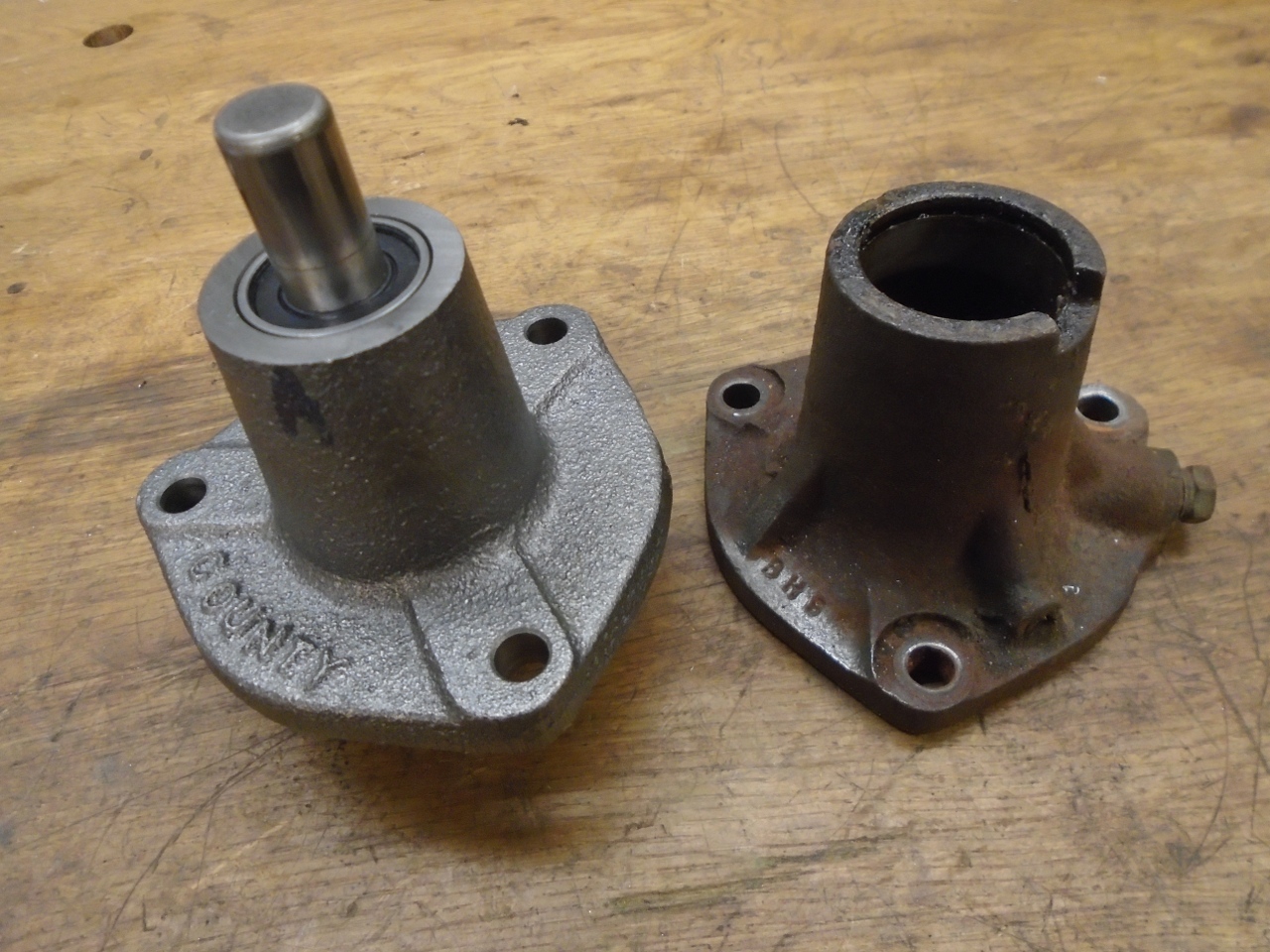

While

I love a challenge like that, I also try to choose my battles wisely,

so I just ordered a new pump. Pumps for the GT6, and Triumphs in

general, can be had in several price ranges, which would presumably

imply differences in quality. This is a mid-range pump from

County.

While waiting for the pump, I cleaned up the housing and powder coated it.

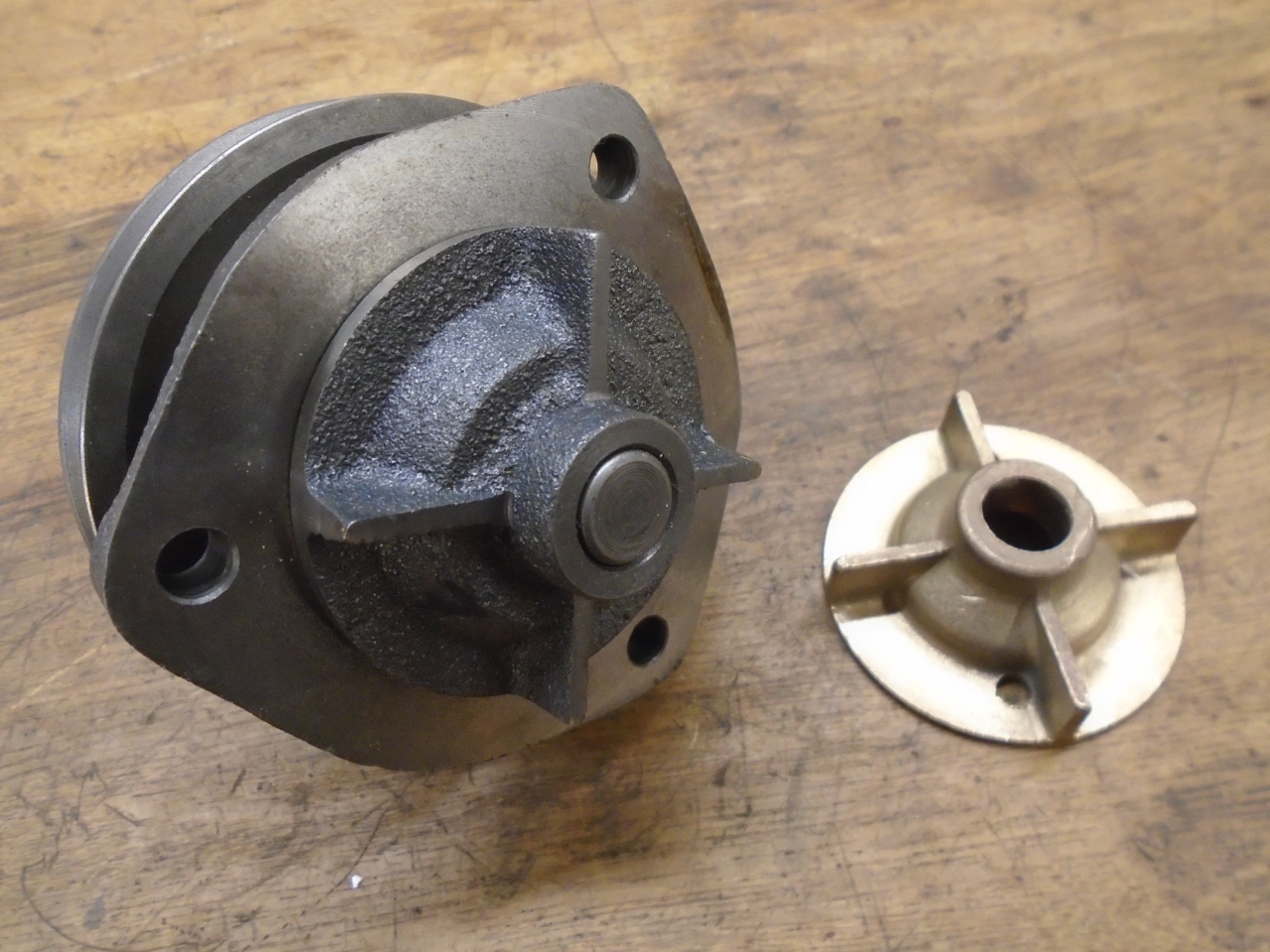

One

difference I noticed between the Beck-Arnley and the County pumps was

that the County's impeller was cast iron, while the original was

bronze. Also, the original pump had a provision for greasing the

bearings, while the new pump was apparenty "lubricated for life".

Finally, the pulley on the old pump was slightly heavier, and

keyed to the spindle, while the new one was strictly a press fit.

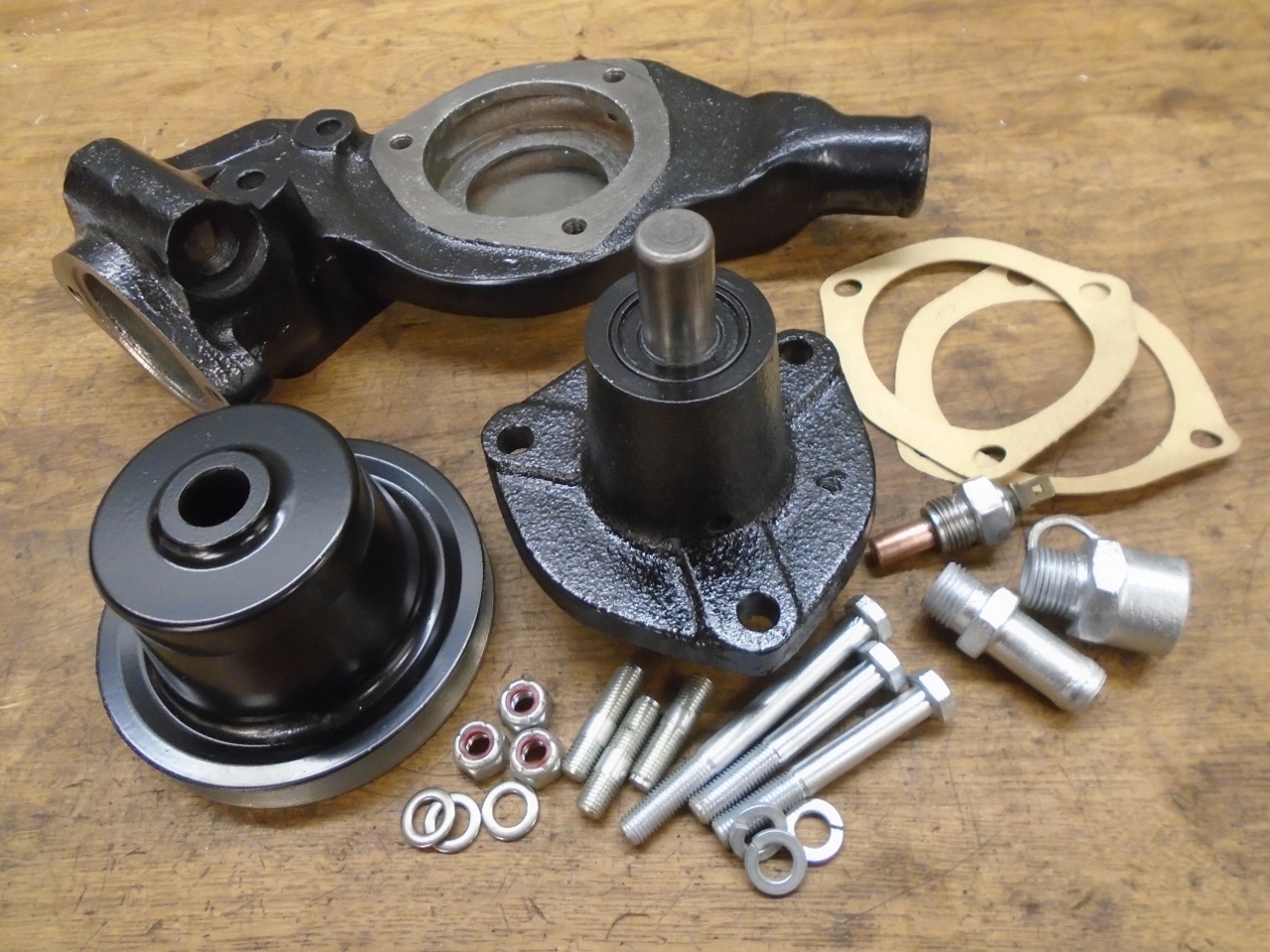

I

had removed the new pump's pulley to powder coat it. I wasn't

sure if the entire pump would be harmed by the heat, so the rest of the

pump just got conventional paint.

So, here are the parts for the pump, ready to go back together. The bolts and fittings are replated original.

One

thing on the gaskets in the picture above. I didn't know if a

gasket would come with the pump, so I ordered one. Well, a gasket

did come with the pump, and comparing it with the one I ordered, I was

obvious that they were very different in thickness. Now, this

might normally be a trivial matter, but maybe not with a pump like

this.

The

efficiecy of a centrifugal pump depends on a number of factors,

one of which is the clearance between the impeller and its housing.

Minimum clearance supports maximum efficiency, and the gasket

under the pump flange affects the clearance between the impeller vanes

and the housing. Since pumps and housings are not matched sets,

suppliers have to assemble their pumps to provide generous clearances,

and this might be the reason behind the thick gasket that came

with the pump. It's possible that the effect of gasket thickness

is below the noise floor for pump efficiency, but I tried the

pump with the thinner gasket, and there was no rubbing, so that's the

one I used.

Last thing to do was to tend to the thermostat housing that goes on top of the pump.

A little cosmetic attention made it look better.

Now, on the shelf with this puppy.

Not a lot of time invested in this one, and only about $60 for the pump.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages.