To my other GT6 pages

March 19, 2023

Hand Brake System

Most cars have a backup braking system variously called a parking

brake, emergency brake, auxiliary brake, or hand brake. While

some folks may make a distinction between these names, the terms are

mostly used pretty much interchangeably. These systems are

typically mechanical, usually on the rear wheels only, and bypass the

hydraulic systems completely. On most British sports cars of this

era, the hand brake was actuated by a hand operated lever on the central

tunnel. The systems provide considerable mechanical advantage.

Having already refurbed my hand brake lever a couple of years ago, I now turned to the rest of the system.

On this GT6, and likely on Spitfires of the same vintage, the hand brake

system can be viewed as consisting of three parts: The brake

lever, the primary cable, and the secondary cable. The lever pulls

on the primary cable, and the primary cable pulls on the secondary

cable, which in turn pulls on the mechanical actuating levers of the

rear drum brakes.

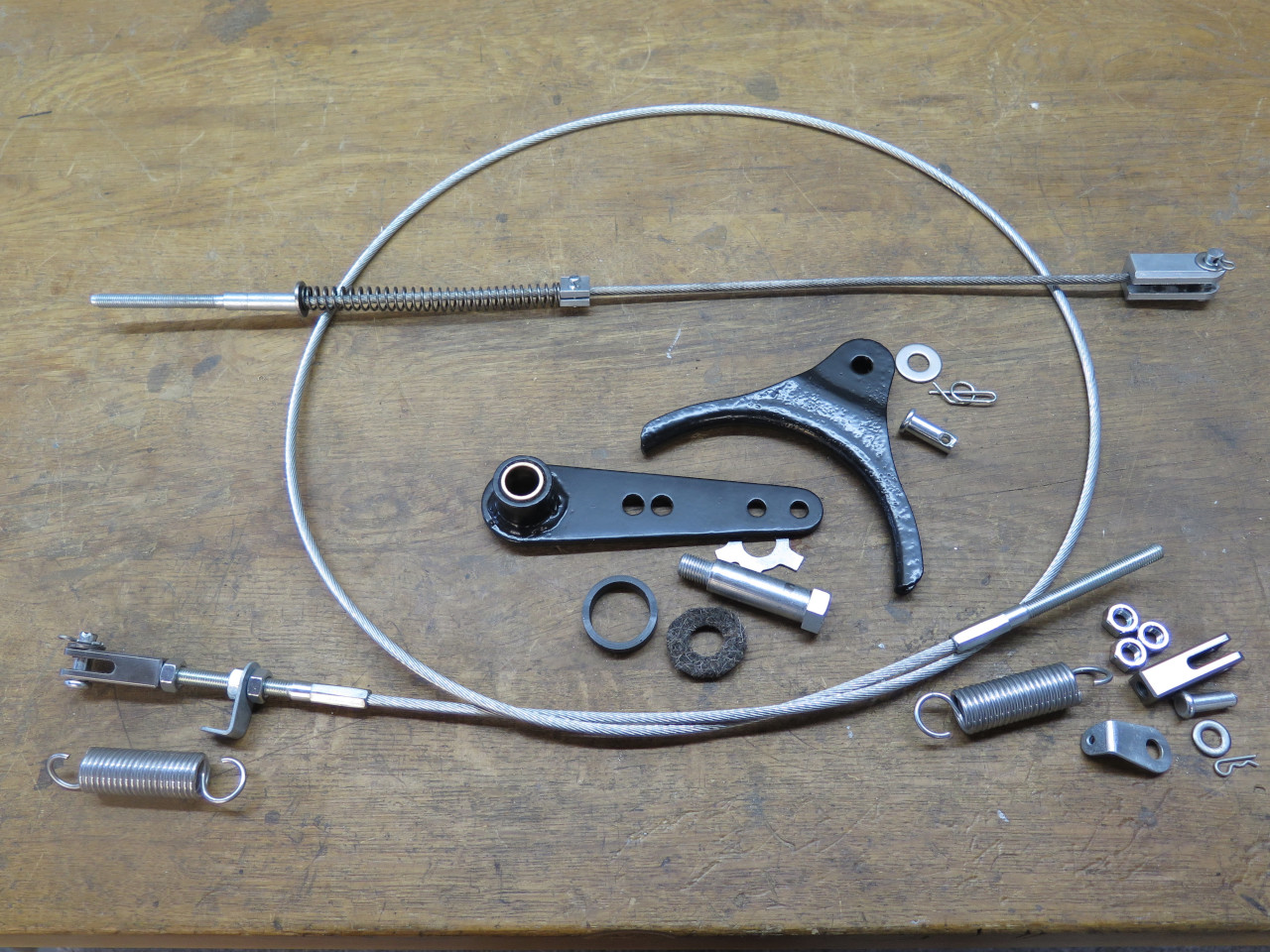

The parts of my brake system were dirty and rusty, and some of them were

broken. The short cable with the spring is the primary cable, the

longer coiled one is the secondary. One of the threaded ends of

the secondary cable broke on disassembly.

The primary cable connects to this "relay lever". The primary

cable is an assembly that includes a spring that pulls the hand brake

lever to its home (down) position. There is a clamp that sets the

preload of the spring.

I thought I could clean up and re-use the primary cable, but the swaged

ends don't permit easy disassembly. But I really wanted to remove

and clean up that spring, so I cut off the clevis. This made

cleanup much easier.

I then made a new, proper clevis that can be removed, but captures the cable end when its clevis pin is in place.

The little clamp that locates the spring never really had a

chance. The screw head twisted off almost as soon as the

screwdriver touched it.

I don't believe anyone sells these clamps, so here is my rendition.

Now, this was admittedly a fair amount of work to save a $10 part, but it was a nice challenge.

Next up was the relay lever. It pivots on a shoulder bolt that

fastens to a bracket on the body. An Oilite bushing tries to keep

it from seizing. The parts cleaned up well, and aside from some

minor rust pitting, they were in good shape. Even the bushing was

still a very nice fit on the shoulder bolt. I attribute this to

the fact that the hand brake never really worked for most of this car's

life, so the lever rarely got pulled.

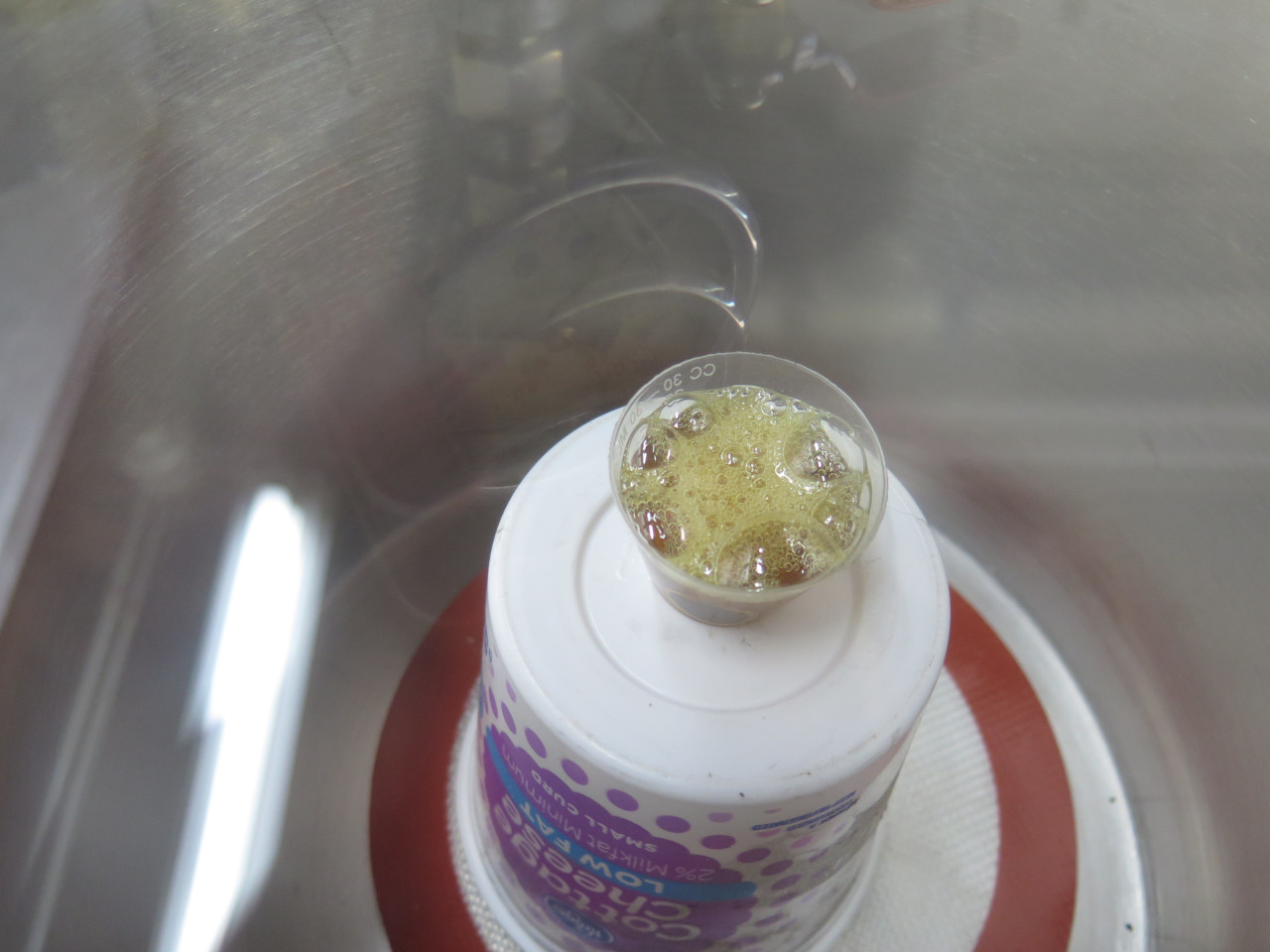

I resolved to re-use the bush, but wanted to re-charge it with

oil. This is typically done by soaking the bushing in SAE 30

weight oil over night. I got a little impatient though, so I stuck

the cup in a vacuum chamber. If any of the tiny passages in the

sintered bush had air in them, this would pull it out. Then by

repressurizing, oil will be sucked back in. There was plenty of

bubbling. Some of this is certainly air that was dissolved in the

oil, but I could definitely see small streams of tiny bubbles coming

directly from the surface of the bushing.

A nice powder coat in the lever, and the bush went back home.

This lever lives in a really inhospitable place, is difficult to access,

and is not on any scheduled maintenance list. In a valiant but

ill-fated attempt to preserve lubrication in this joint, some designer

included another pair of parts. One was a rubber seal that fits

the bottom of the bushing boss, and the other was a felt washer at the

top. Presumably the washer was saturated with oil on assembly, and

this was intended to be the bushing's life-time supply of lubrication.

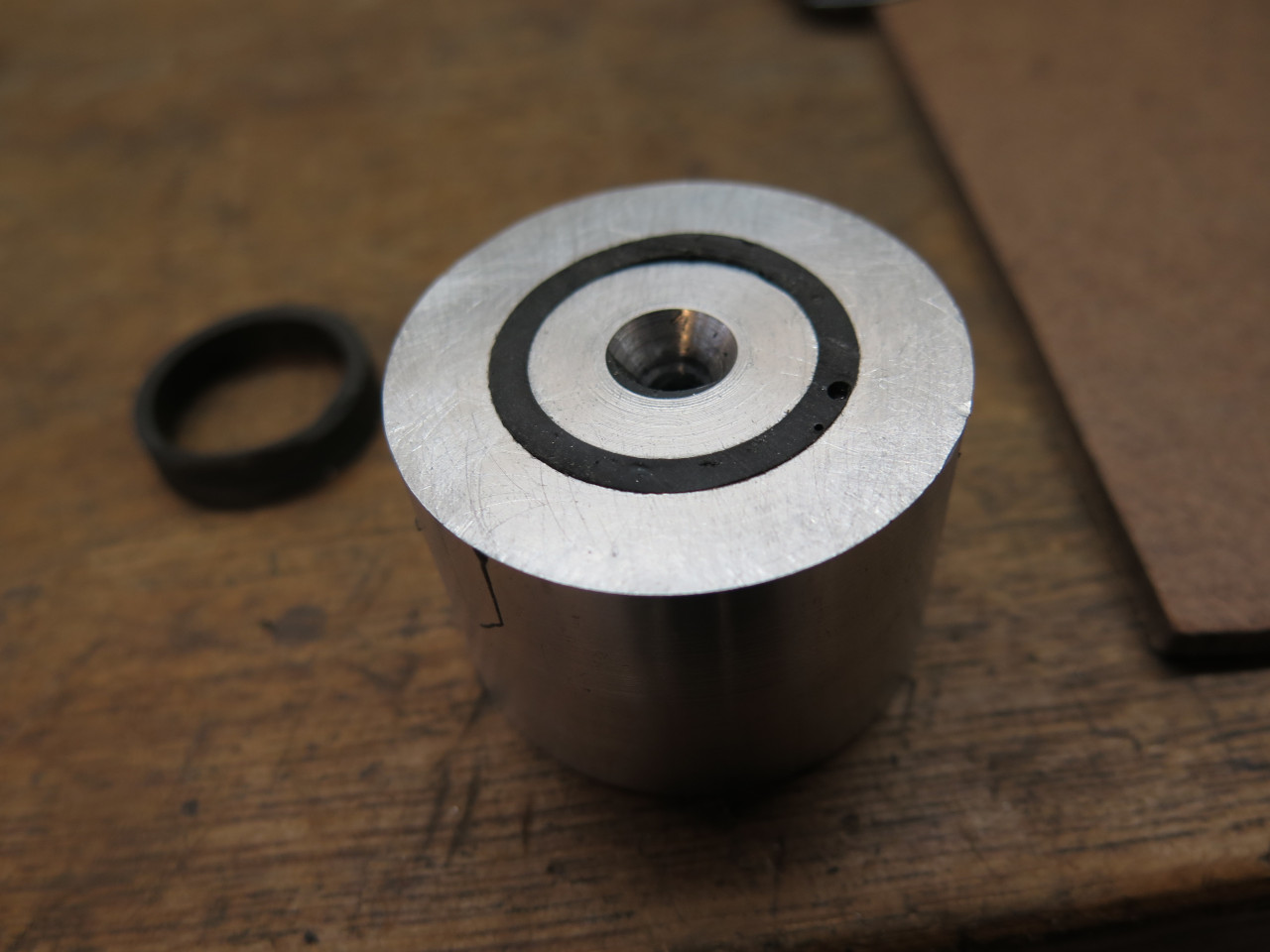

My rubber seal was very hard, misshapen, and dried out. I

understand that these may be available from a UK supplier, but it seemed

a little extreme to order a $2 part from 4000 miles away. A check

of my shop bucket list revealed a desire to cast small rubber parts

some day. Well the day arrived. A simple mold from some

scrap aluminum, pour in some two-part urethane casting rubber, let it

cure, trim, and pop a new seal out of the mold.

My seal has the same ID as the original, but a slightly bigger OD because, you know--upgrade!

As far as the felt seal/oil reservoir, it was totally AWOL, and these seem to not be available anywhere. No problem...

I did order a new secondary cable since mine had a broken end. I

was mistaken in thinking that it would come with the clevises and other

hardware for the ends. I considered cleaning up the original

clevises, but I just couldn't bring myself to do it. The original

bent sheet metal clevis was apparently designed to capture that square

nut in its crotch, which would keep it from turning. Well, that

never works. The square nut spins, making adjustment or

disassembly a great big hassle.

Now these are proper clevises.

The last part was this yoke-like thing. Cooly named a "compensator

sector", the secondary cable threads around the arc so that pulling on

the sector pulls both ends of the cable. It's got some pitting,

but the powder coat should protect it from further corrosion.

So here are all of the parts that will go back into the car.

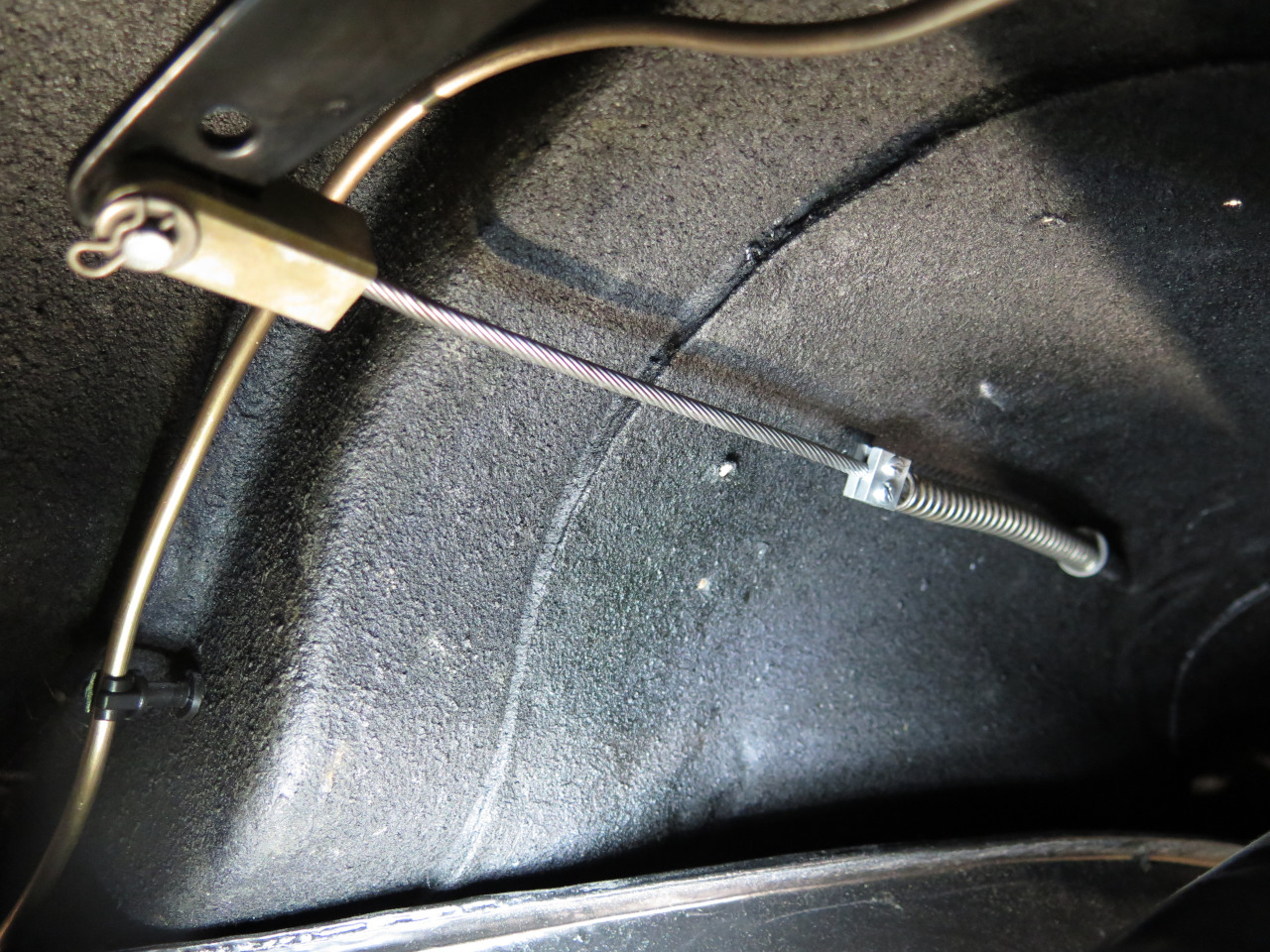

If you ever read or hear that installing the hand brake cables should

really be done with the body off of the frame, believe it. This

was a really disagreeable job. The bracket for the relay lever is

just to the right of the U joint. This is of course after the

exhaust was removed. I eventually had to drop the rear end of the

prop shaft to get enough access.

The relay lever somehow finally went home. I had to re-make the

felt washer with thinner and stiffer felt. The first one was just

too limp to maneuver, especially when saturated with oil.

Installed the refurbed operating lever, and primary cable, then set the spring clamp for some preload.

Then strung the secondary cable. It has to go through a curved

right-angle guide on each side on the way to the brakes. The shop

manual says to load up those guides with grease.

And finally to the rear brakes. Pulling the last clevis into place

took some doing. The springs are from the hardware store, but

have a similar size and spring rate (around 23 lbf/in) as the originals.

I wish I had taken advice I heard and installed these cables while the

body was off the frame. It would have been almost trivial.

Doing it like this was an ordeal.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages