March 9, 2013

Under Floor Dust Collection

[Click the pics for larger view]

My

wood shop is in the basement of our house, and with very few

exceptions, I consider this ideal. It is heated and air

conditioned 24 x 7 x 365 at no extra cost, I have hot and cold running

water in a shop sink, a full bathroom with a shower, telephone,

internet, and plenty of AC power. I can be in my shop in 15

seconds from anywhere in the house, in my underwear if I want.

From my wife's point of view, there are some

drawbacks--in a

nutshell, they boil down to noise, dust, and odors. While

we've

come to some understandings on these points, she does acknowledge that

it is handy to have me accessible for dire domestic emergencies like,

say, a spider in the sink.

One drawback I see is the

concrete floor. If I ever built a detached shop, and

this isn't likely, I'd have a

crawlspace, or at least a false floor to allow underfloor routing

of AC power and dust collection ducts. The concrete

floor

makes this harder--harder, but not impossible. When I got a

new

table saw ten or so years ago, I tried for a while to make overhead

dust collection ducts work. The ducts were unsightly, always

in

the way, and just generally a hassle. Likewise with the power

cord.

I finally took what many (including me at the time) would

consider an extreme measure: I broke up enough of the

basement

floor to install a dust collection duct and AC power to the table saw.

The job

took a few days, and while a little dirty at times, wasn't all that

hard or complicated. I ended up considering it time and

effort

well worth it.

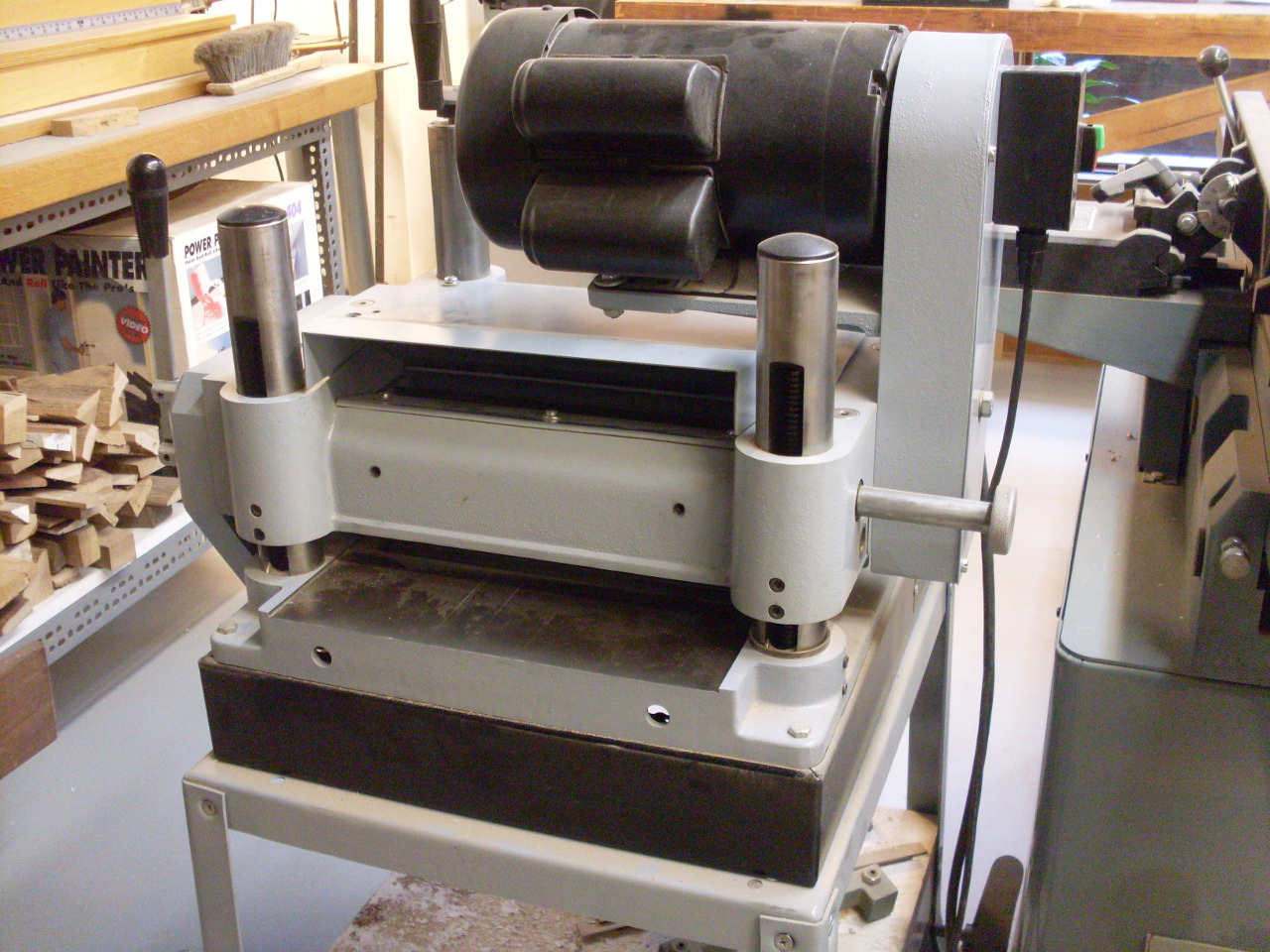

When I got a new Delta RC33 planer (new to me--it's 30 years old [here's a link

to the rebuild of the machine]),

I wanted to put it and my jointer in the middle of the floor.

Since these thing each can put out prodigious

amounts of

wood dust and shavings, they really need good dust collection, and I

decided without hesitation to extend the underfloor system.

The

following is a story about the experience.

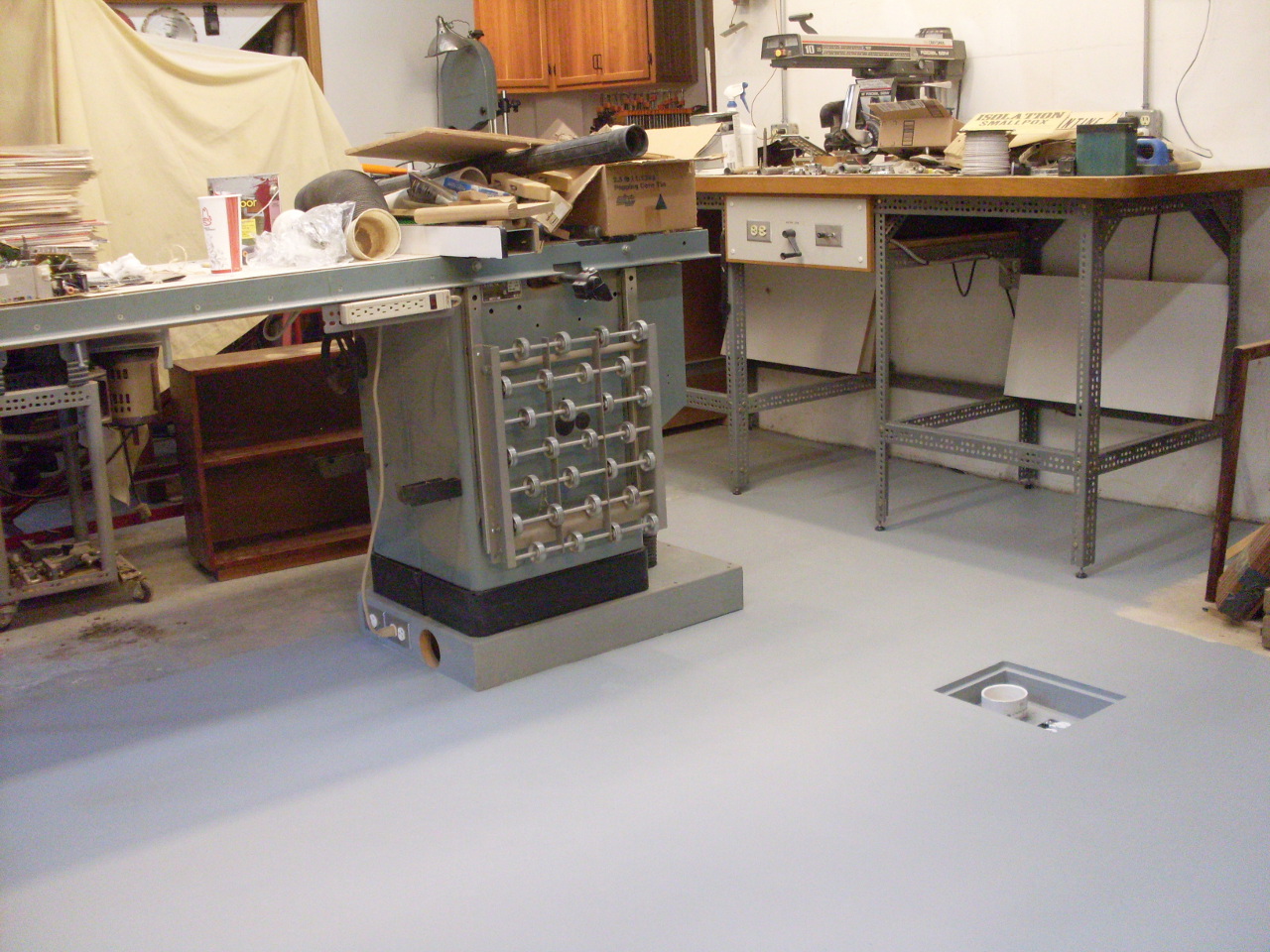

Here is the area

I cleared out to put the planer and jointer. It's about six

feet

from the table saw, which has an underfloor duct that I would tap into.

I marked out on the floor where the concrete would have to be

broken out.

I

broke quite a bit of it out with just a small sledge, but since I

wanted to do the whole thing while my wife was gone for the

weekend, I rented a small jack hammer that finished the rest pretty

quickly.

Here

is where I had to tap into the existing duct and conduits.

One

conduit is for AC power, and the other is for low voltage control wires

to remotely turn the vacuum system on.

Cleaned

up the debris, and leveled the bottom of the trench at the right depth.

The near end of the trench is where the floor access box will

be.

There wasn't a good way to glue the joints of the "Y", so I assembled

them dry with slip couplings and taped them.

Then

ran the conduits. I used a double box for the AC so I could

plug

in both the jointer and the planer, and a single box for the control

circuit.

I

set the duct and boxes in concrete that would form the floor of the

access box, then set an angle iron frame to form a lip for a cover for

the access box. I backfilled the trench

part way with

gravel and some rubble from the demolition...

...and then poured concrete to the floor level. I got to this

point in a single two-day weekend.

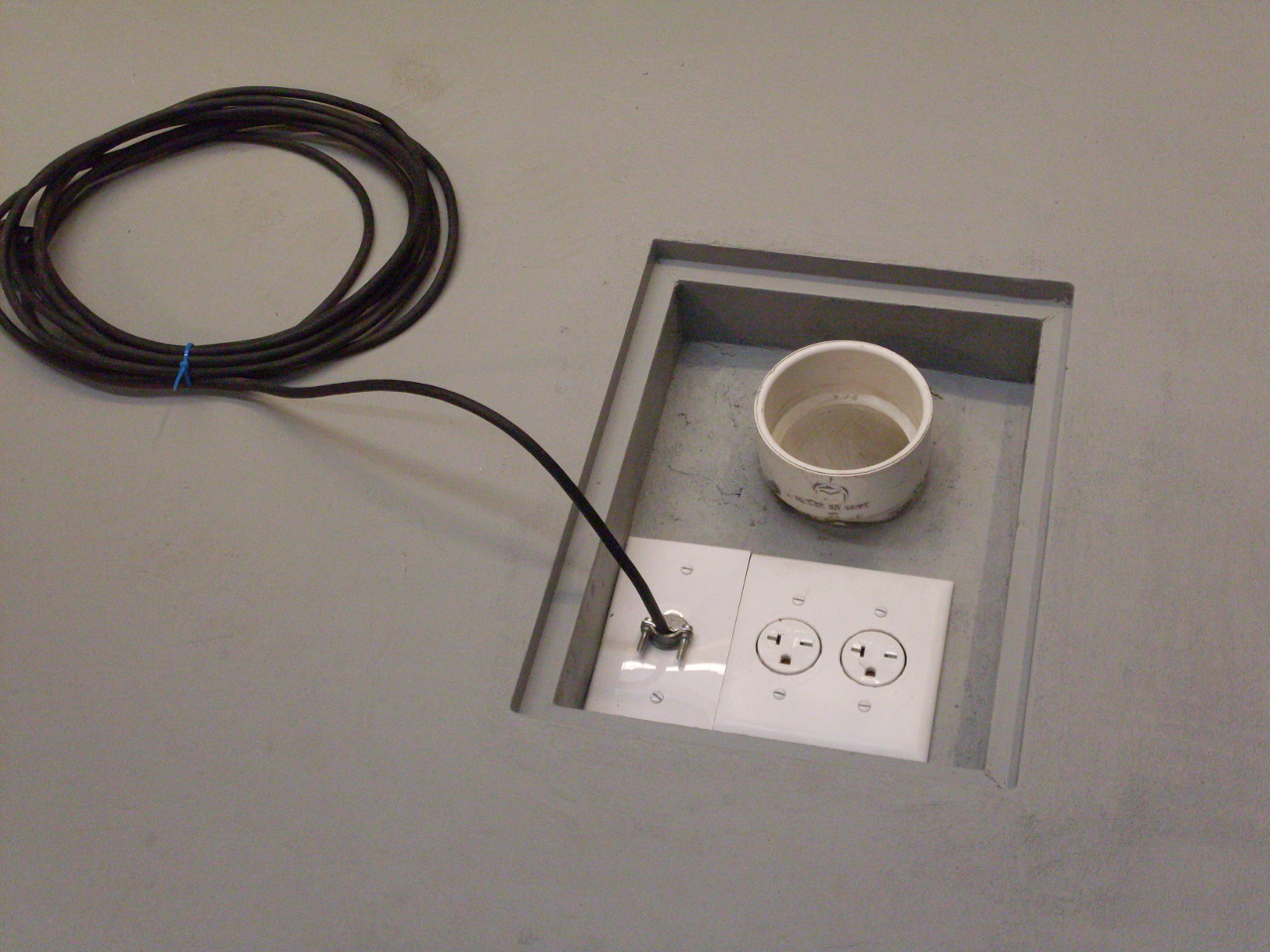

Installed two 20 amp, 220 volt recepticles. They are wired in

parallel on the same circuit.

Decided to paint the entire floor while I was at it.

Added

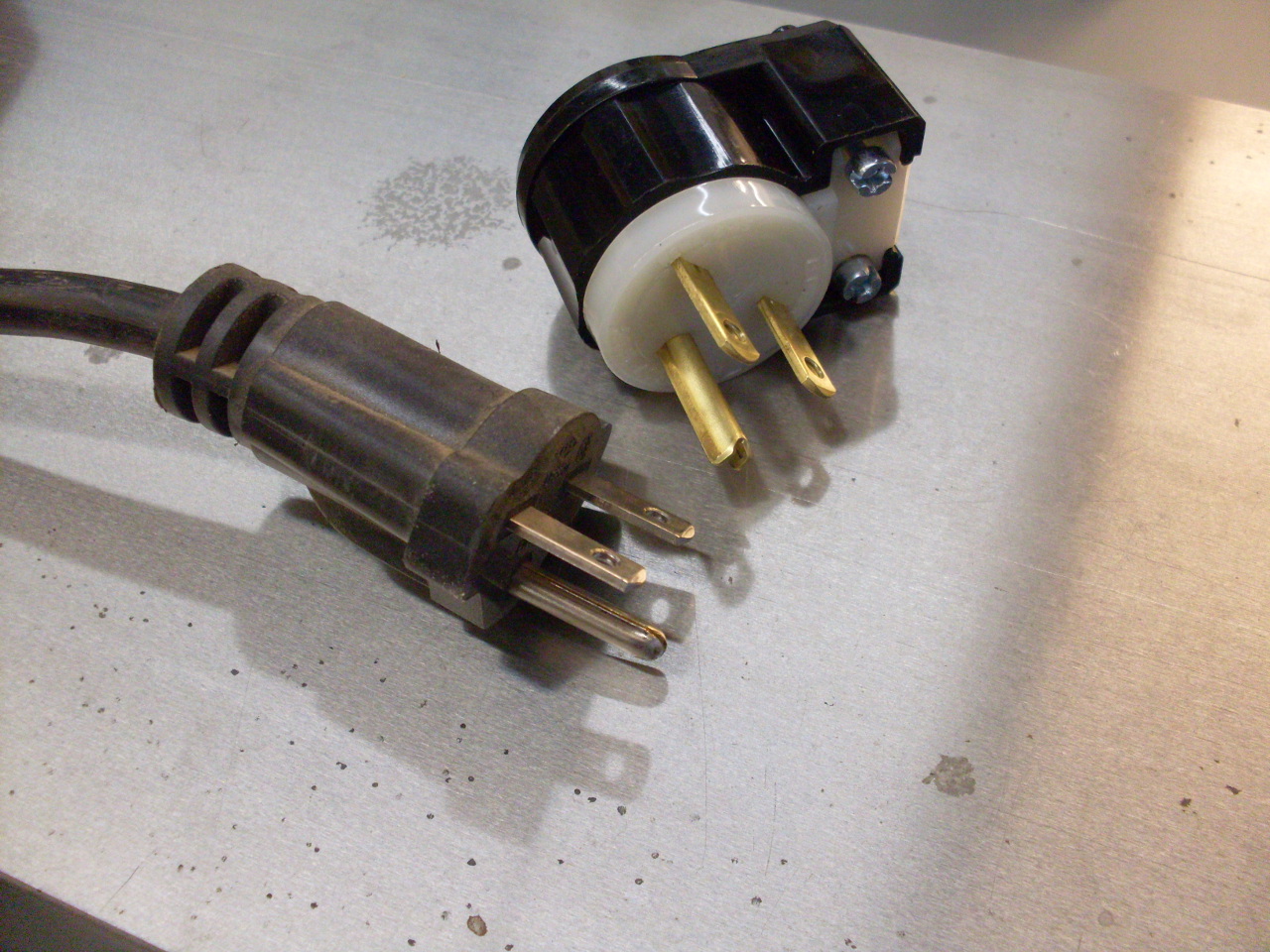

cover plates and a floor cover for the access box. There

wasn't

clearance for the power plugs on the machines, so I swapped them out

for right angle ones.

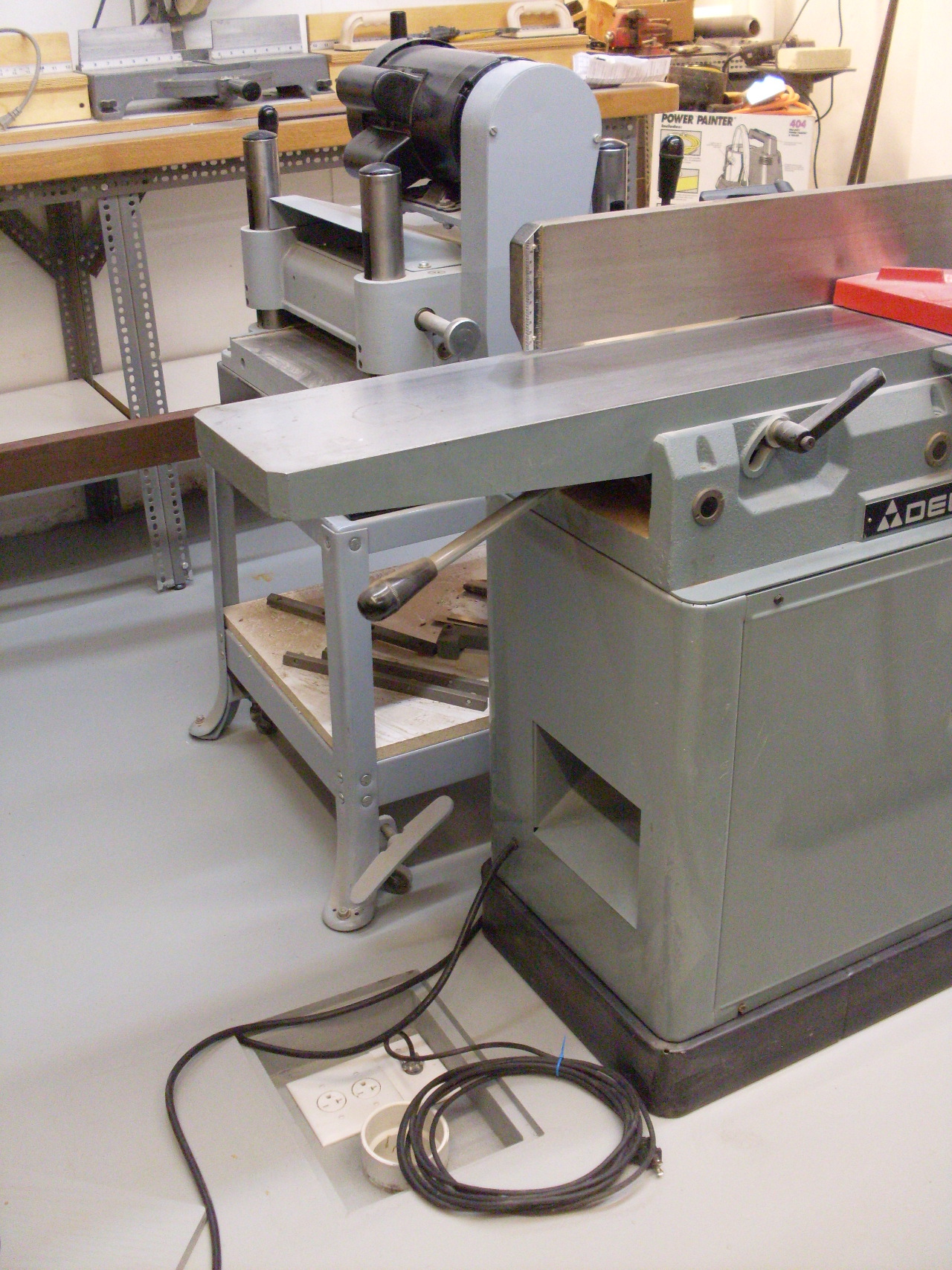

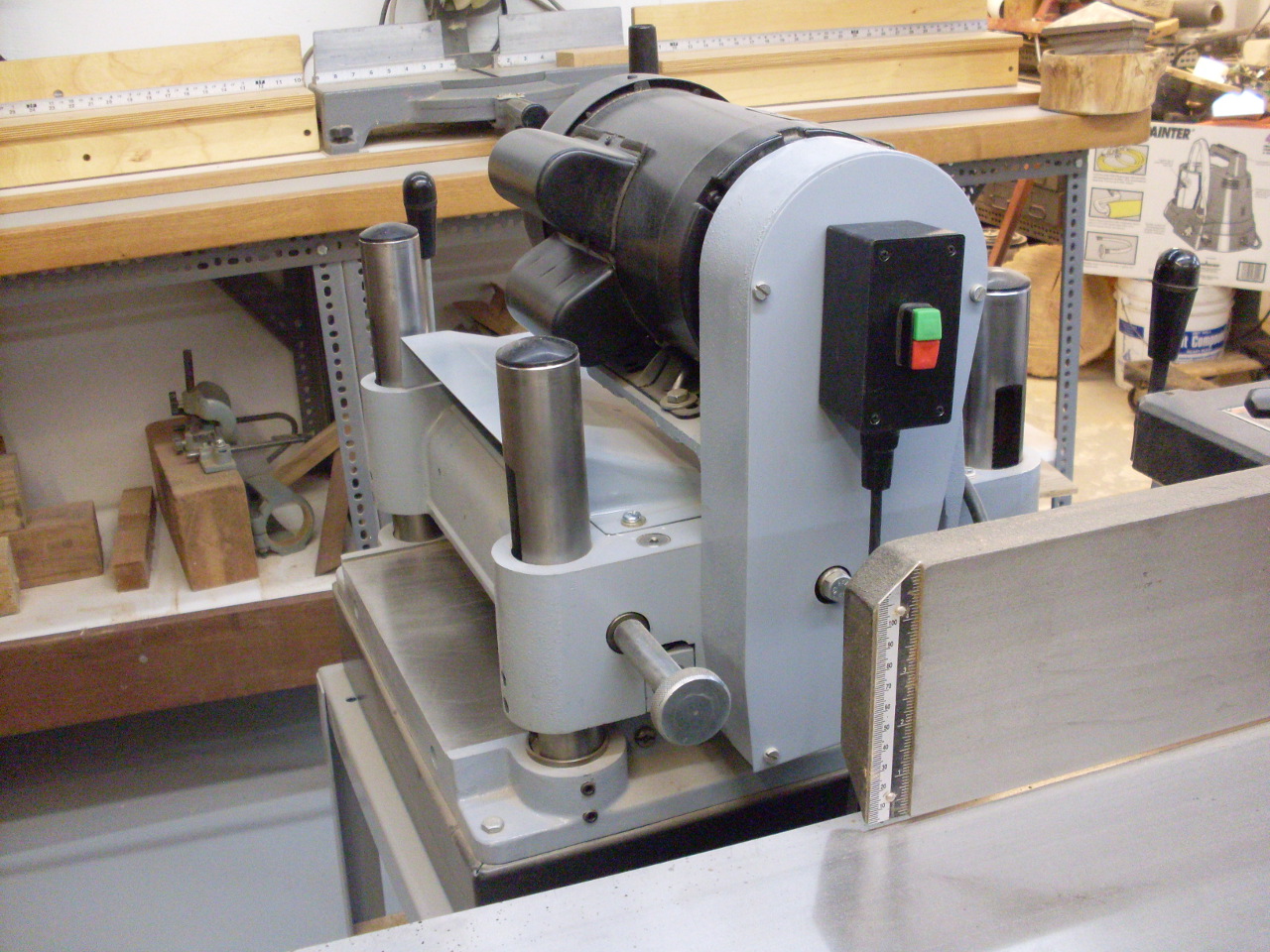

Moved

the machines into place. I had to move the power cord of the

jointer so it exited on the chute end of the machine.

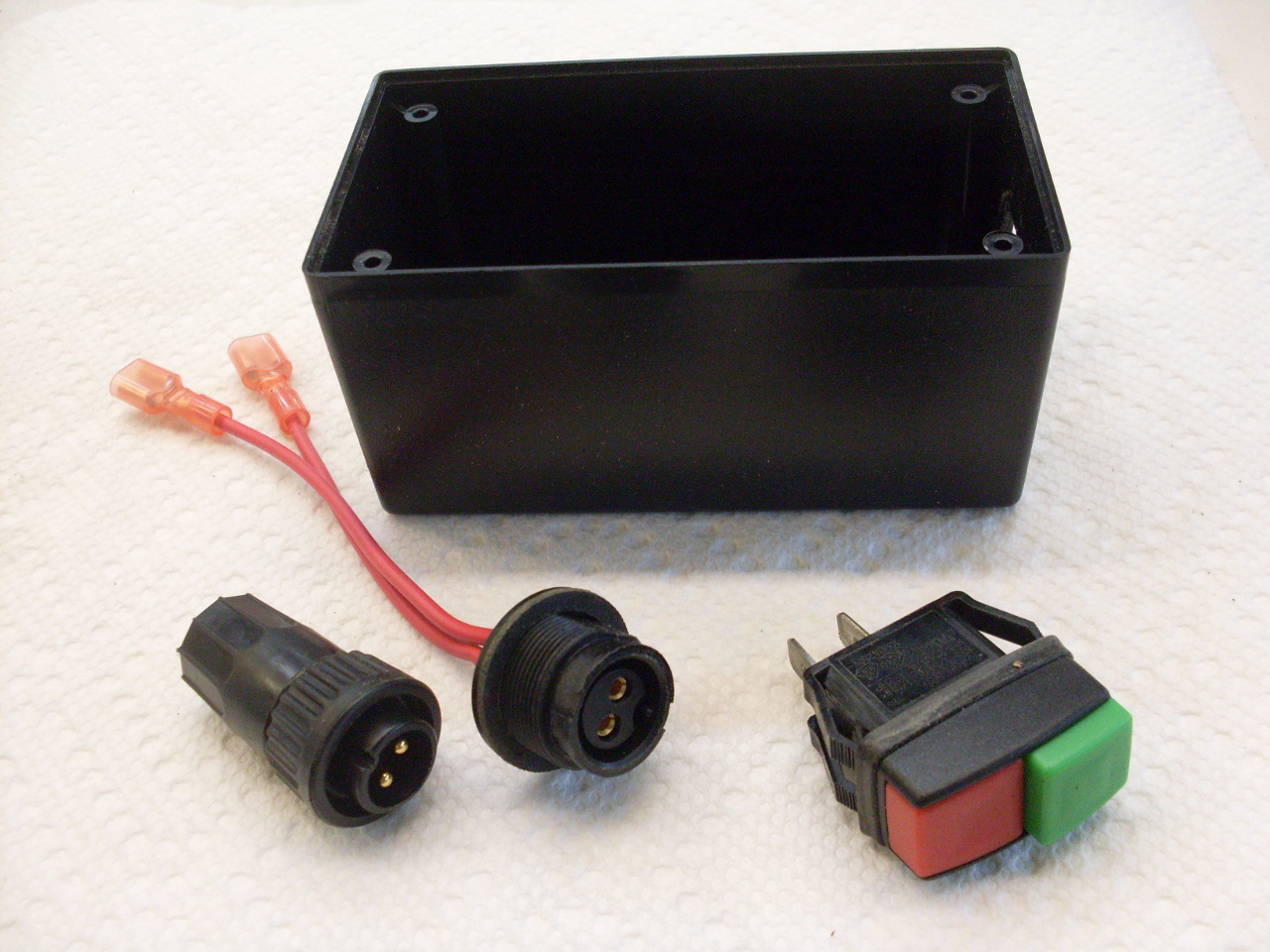

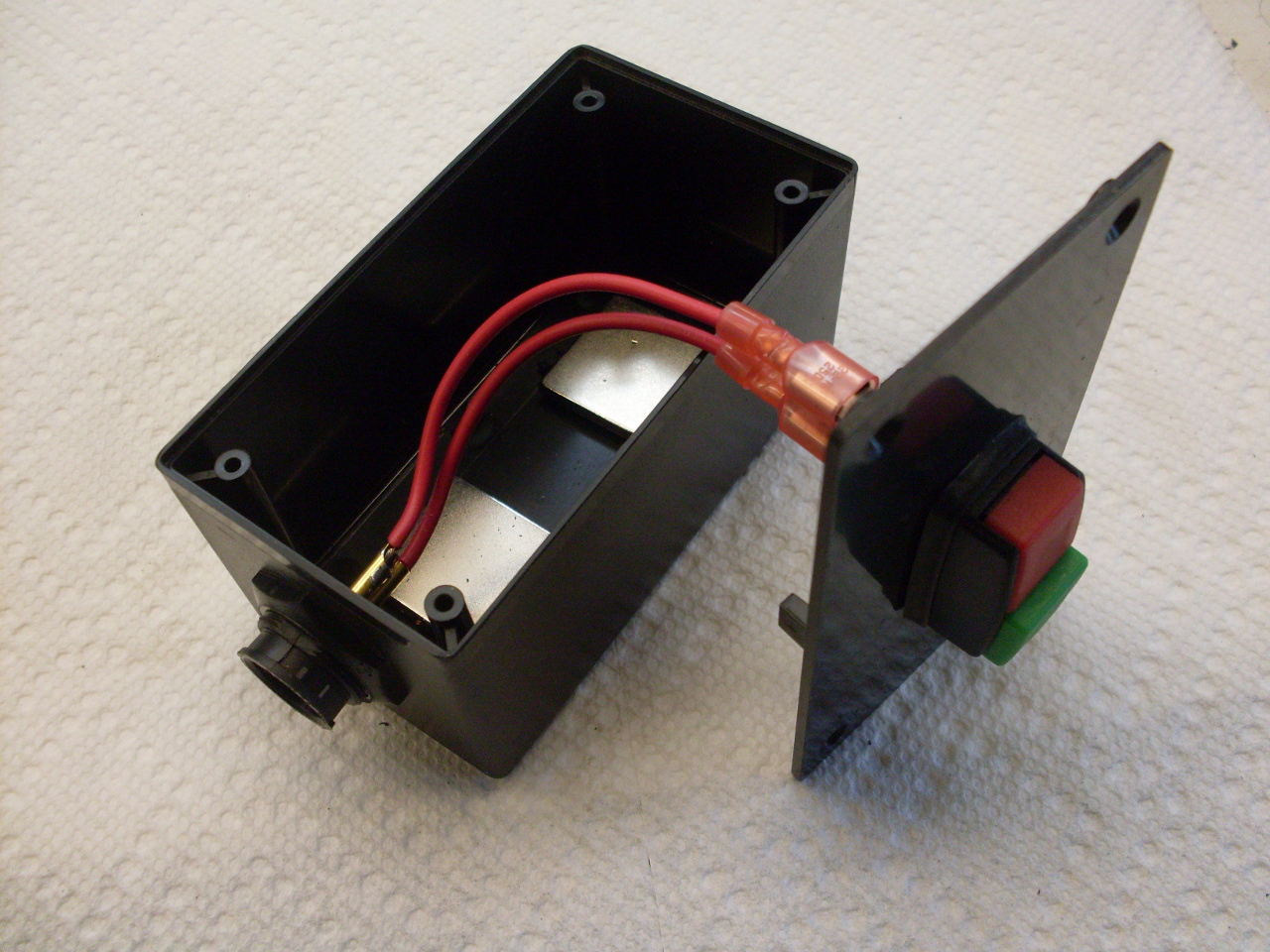

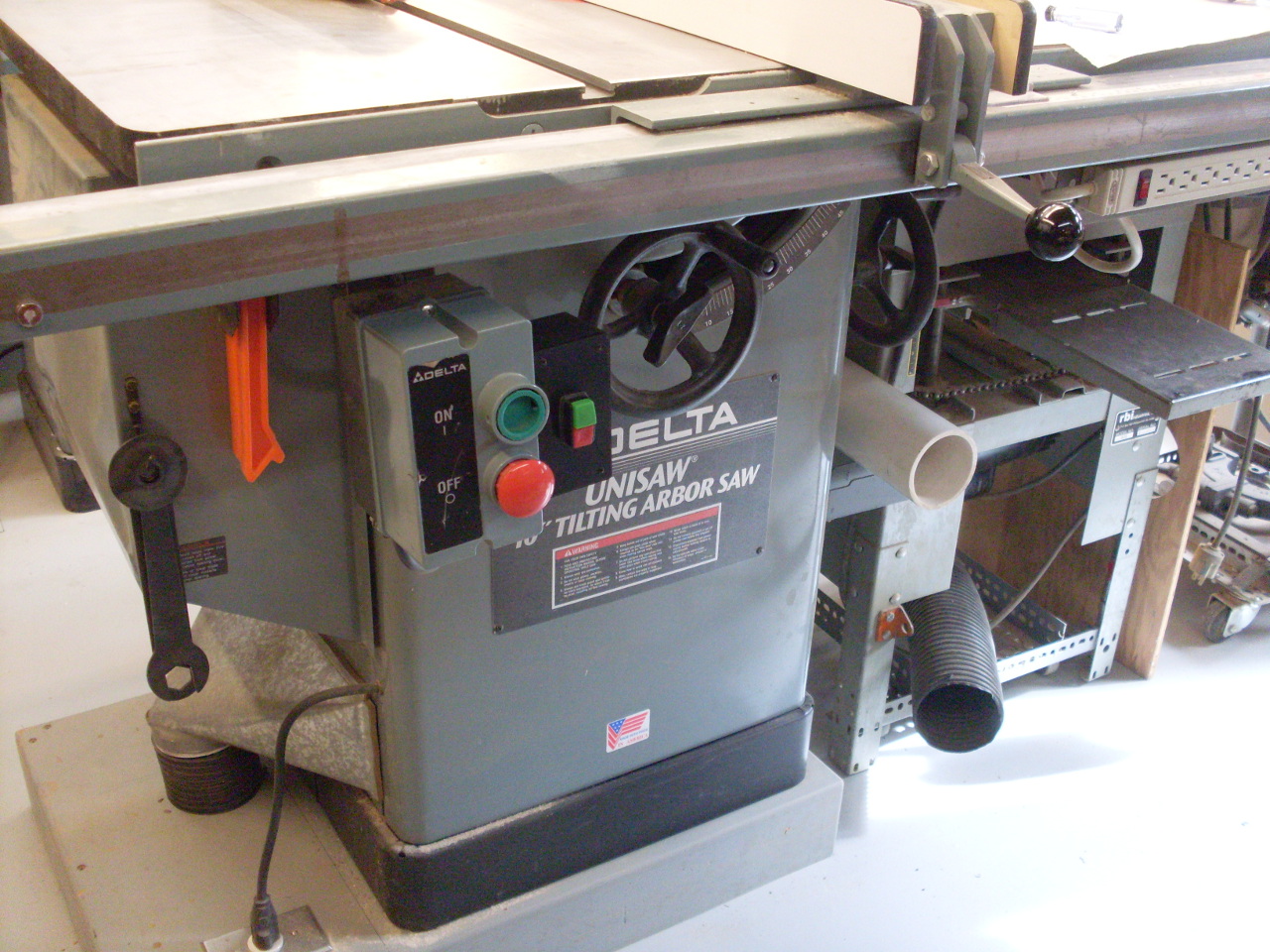

I

made some little control boxes to turn the collection system on and

off. I had a switch on a far wall before. This will

be

better. The box on the planer has magnets inside so it just

sticks to the belt guard. The one on the table saw is

attached to

the existing control box with nylon hardware.

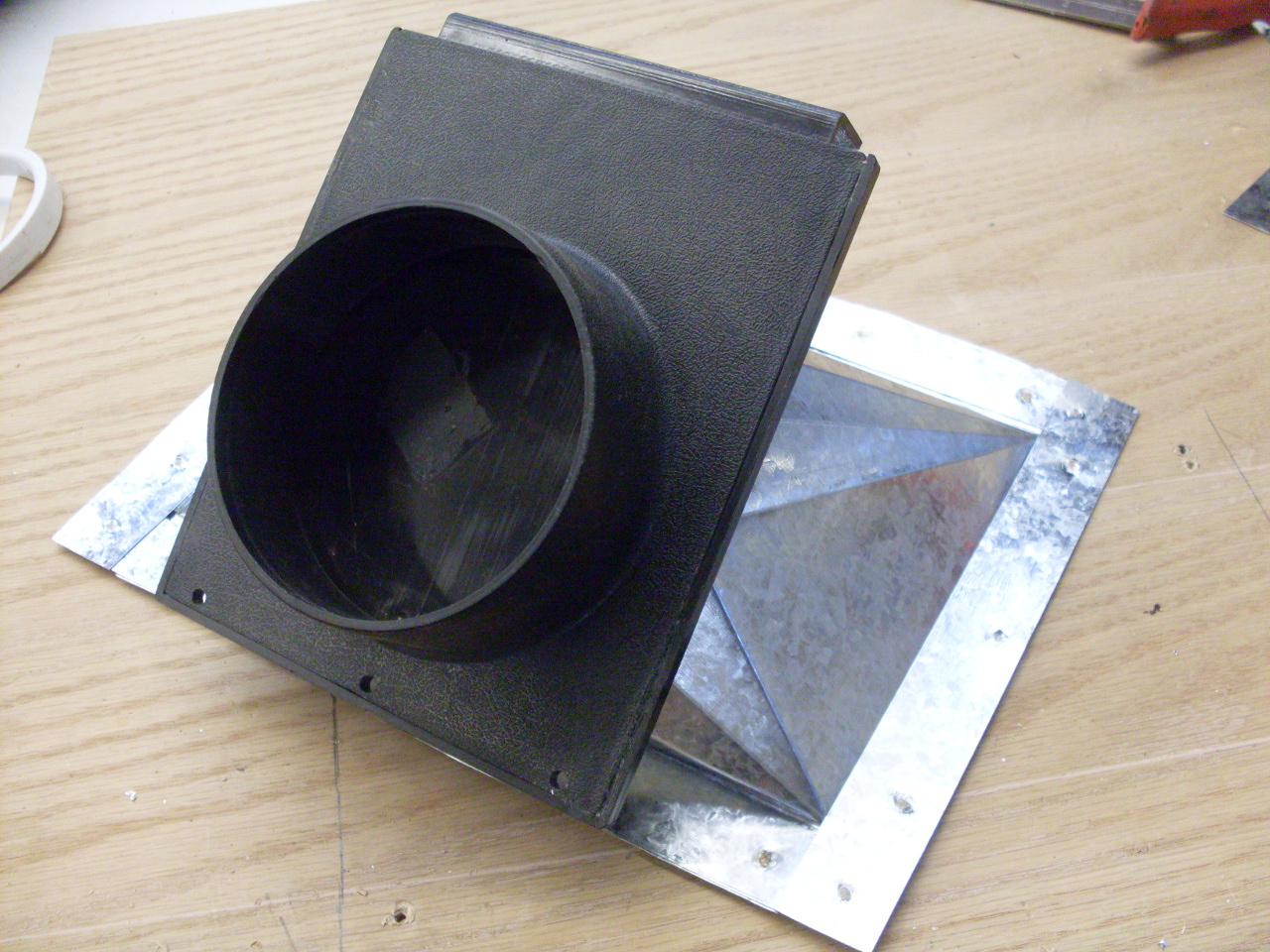

This

is the custom duct transition I made for the table saw years ago.

Normally there are little clips that hold it tighter against

the

cabinet. The transition for the jointer is obviously

different.

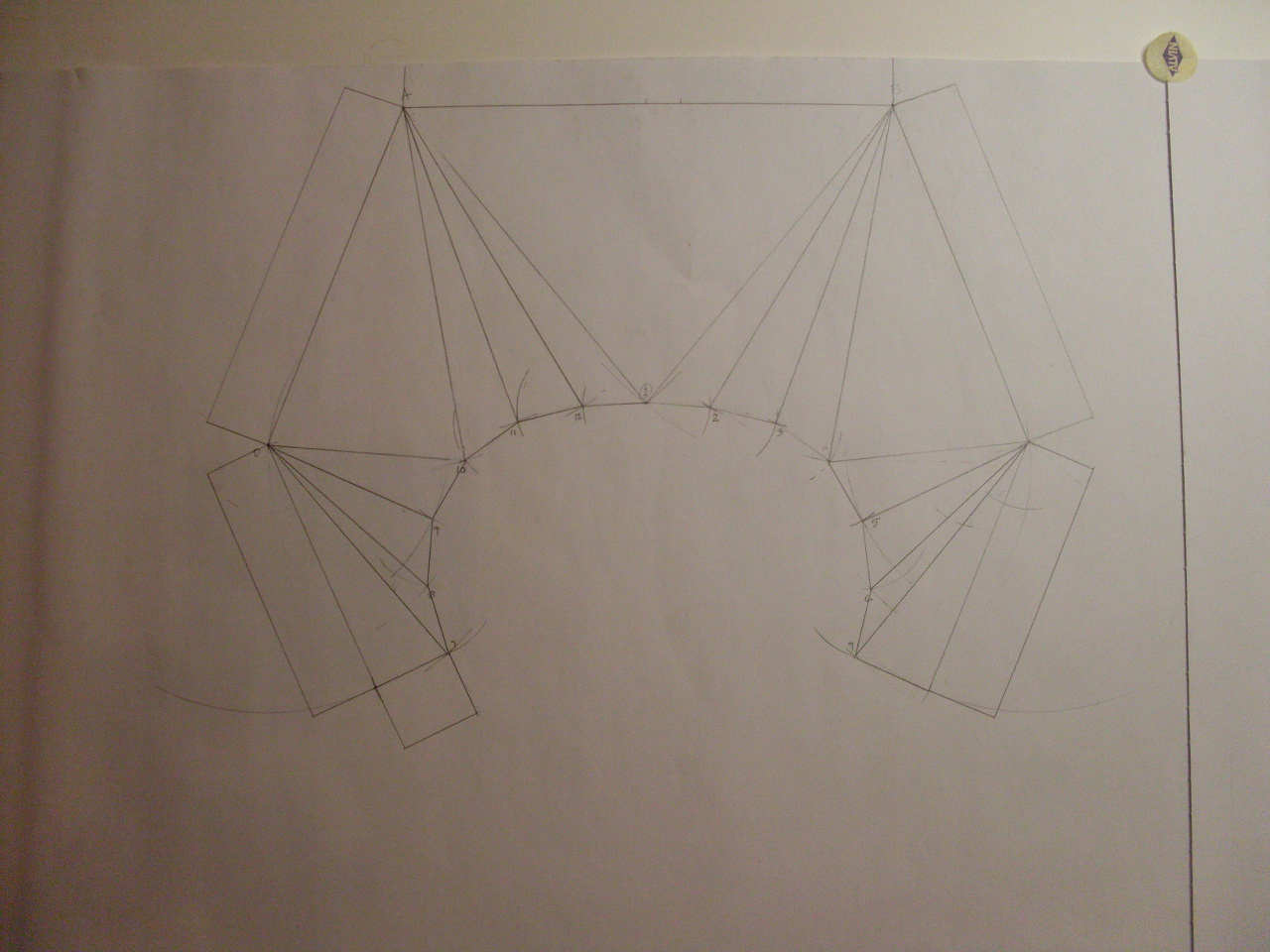

For

some reason, I still remember how to do sheet metal transition design

from drafting class in highschool. It's a skill that's come

in

handy a number of times.

Since

the table saw, jointer, and planer are all on the same duct, I have to

have a way to block individual machines. I had a few blast

gates

around from my previous overhead system. I modified one

slightly

to use here.

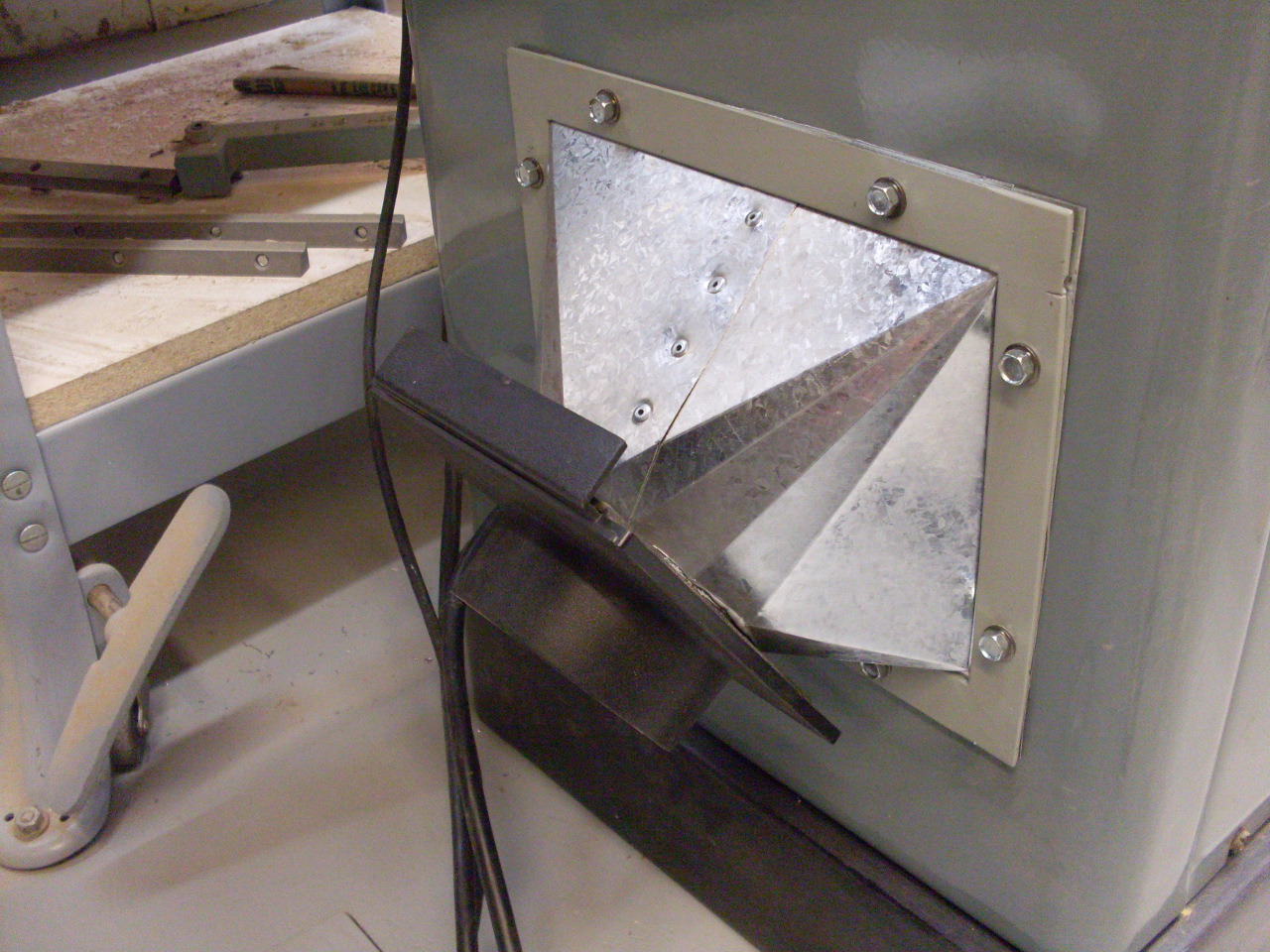

The jointer is hooked up. The planer goes on the other

branch.

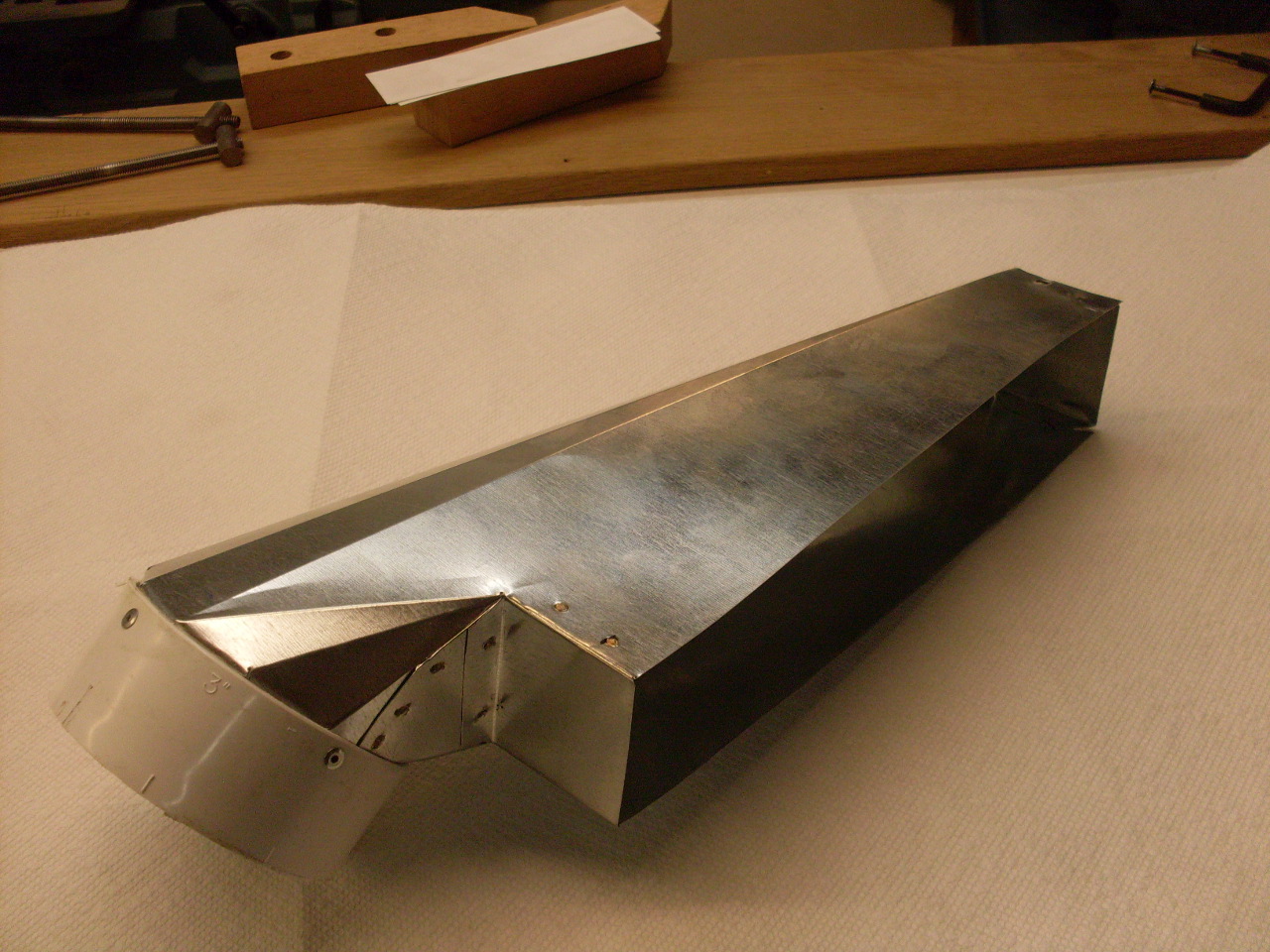

The dust chute exit on the planer is very clodse to a standard 2-1/4 x

12 rectangular duct size, and it's pretty common to just use a standard

sheet metal register boot to transition to a round outlet to one side

or the other.

That was

my first plan, but all my usual sources only had transitions to 6"

round duct, and by the time I put a reducer on it to 4", it made the

angle for the flex hose kind of awkward, and the whole

setup was looking pretty kludgy. I decided it wasn't

that much work to make the transition, so I sketched out something that

would work. It would be a transition from 2-1/4 x 12

rectangular to 4" round on the right side, but the round outlet would

be facing 45 degrees down to help the hose connection.

The layout of this

transition was a lot more complicated that the one for the jointer

because it is asymmetrical. A paper pattern ensures that the

drafting was correct.

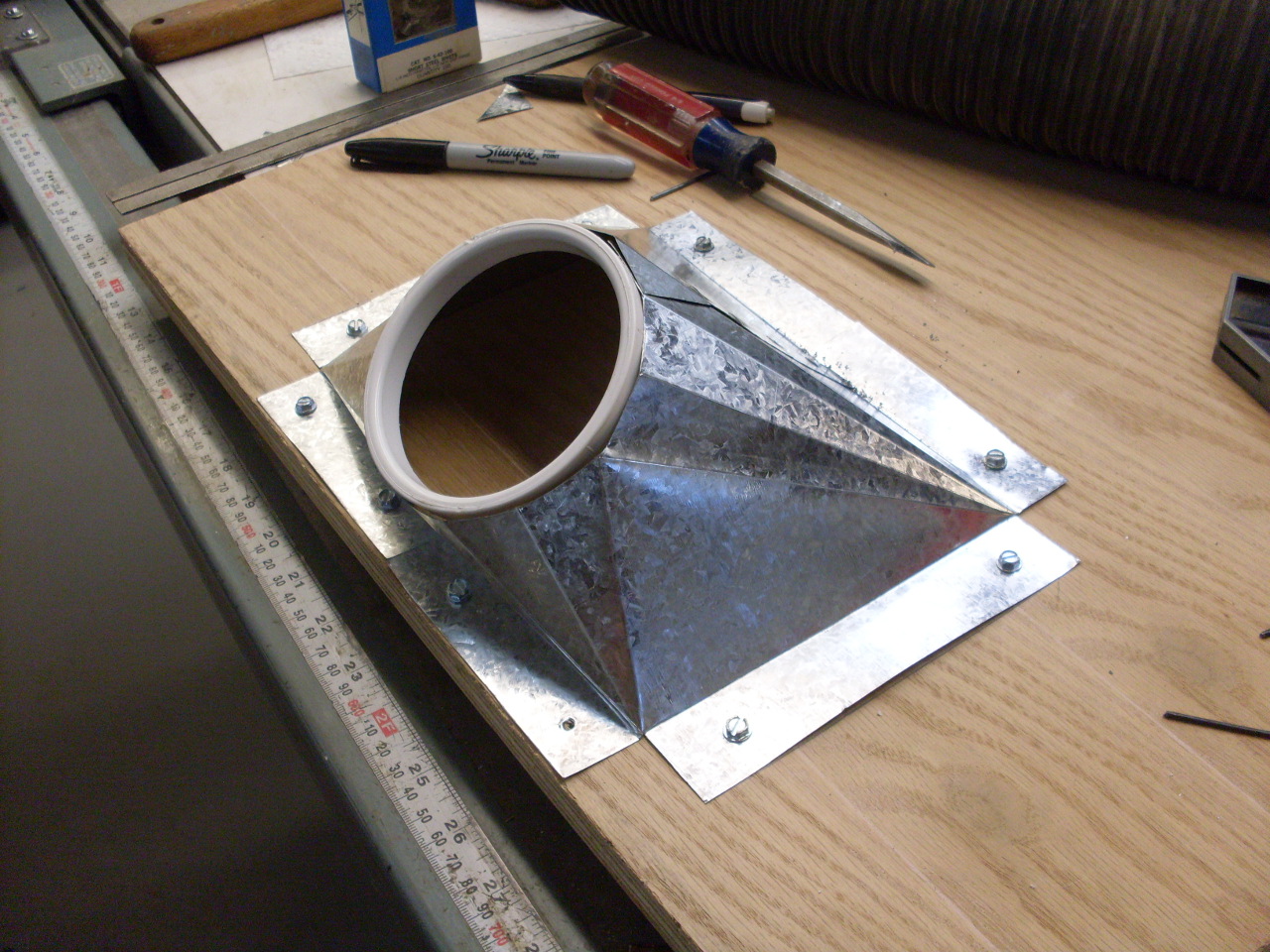

Then transfer to som

thin galvanized sheet, cut it out, and fold it like the paper pattern.

It is hard to visualize without a paper model that some of

the folds have to be reverse. I cut the end off a PVC fitting

and fitted it to the round outl;et to serve as the attachment point for

the flex hose.

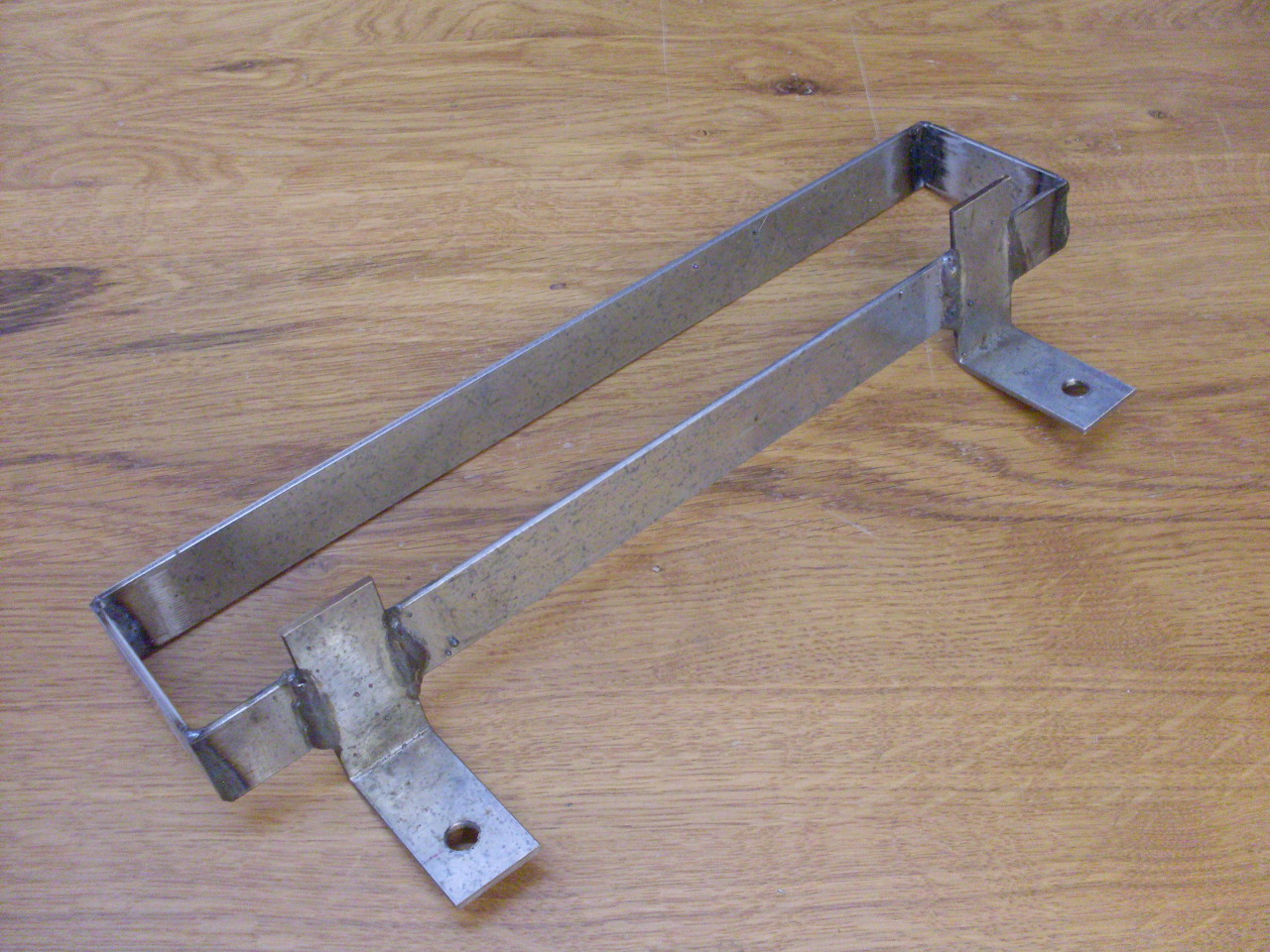

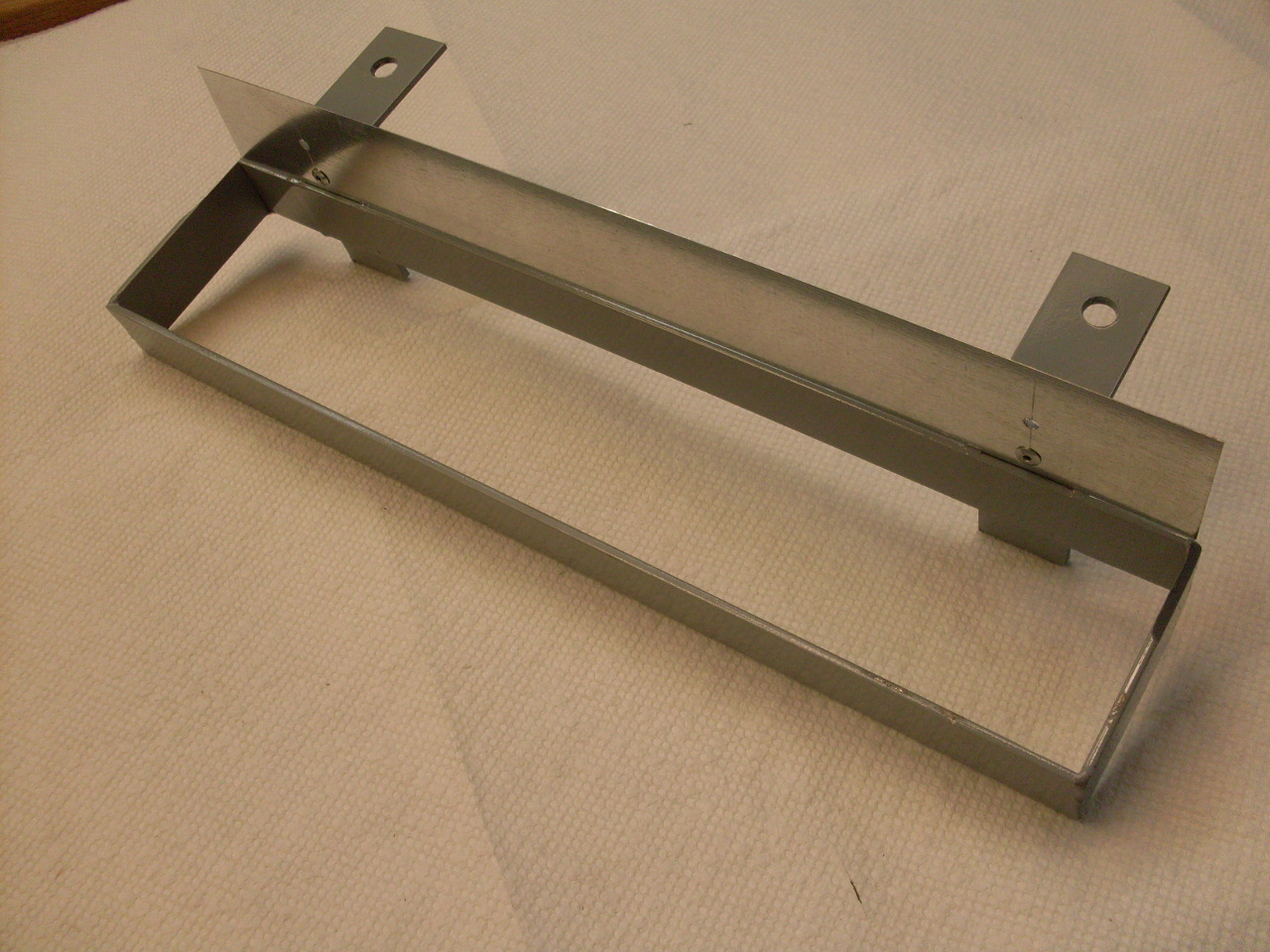

This is the metal frame

to attach the transition to the planer using the existing holes.

One sort of background rule I have for adding accessories to

machines, especially old ones, is to not make any

irreversible changes like drilling holes or welding if at all possible.

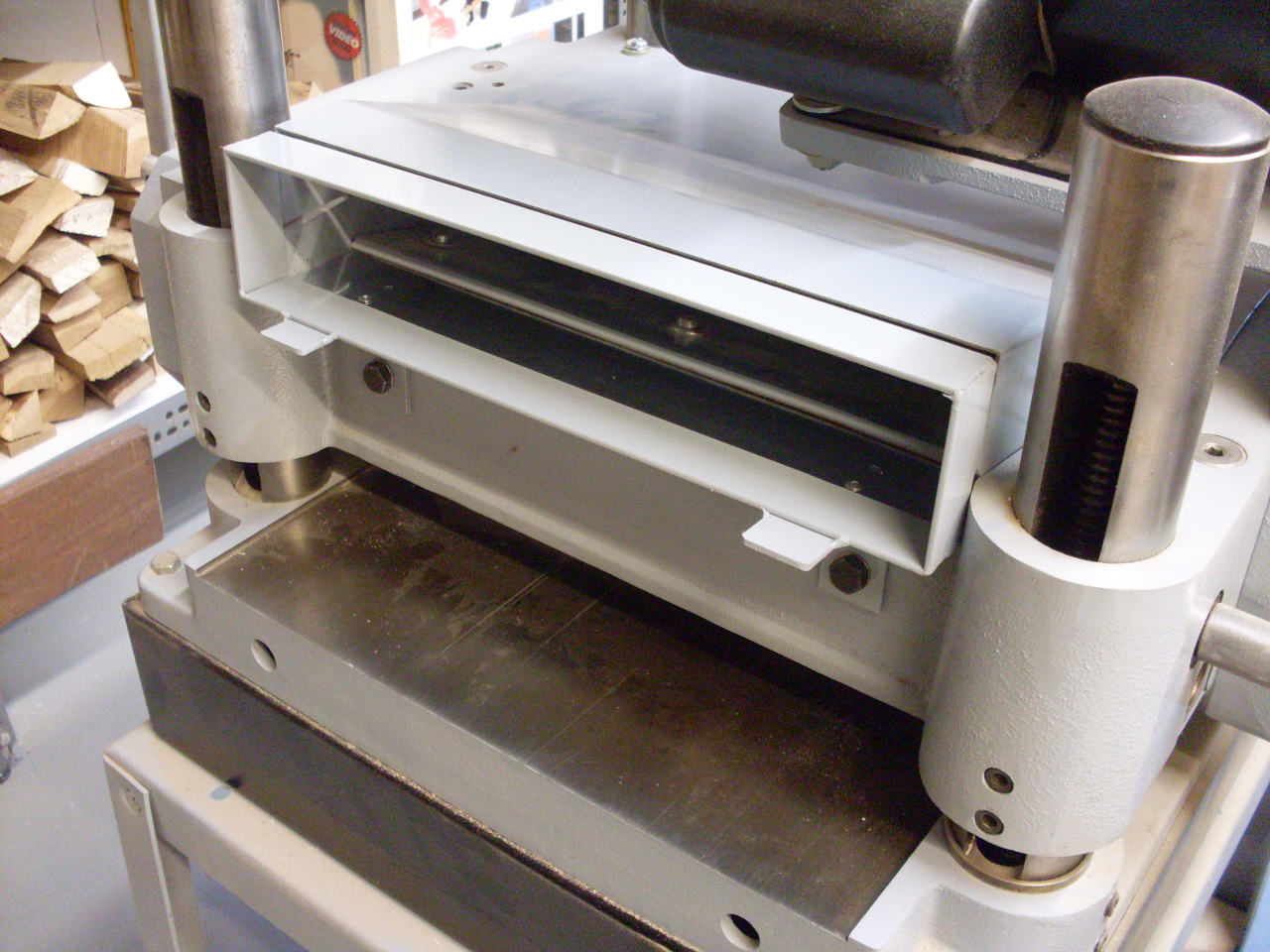

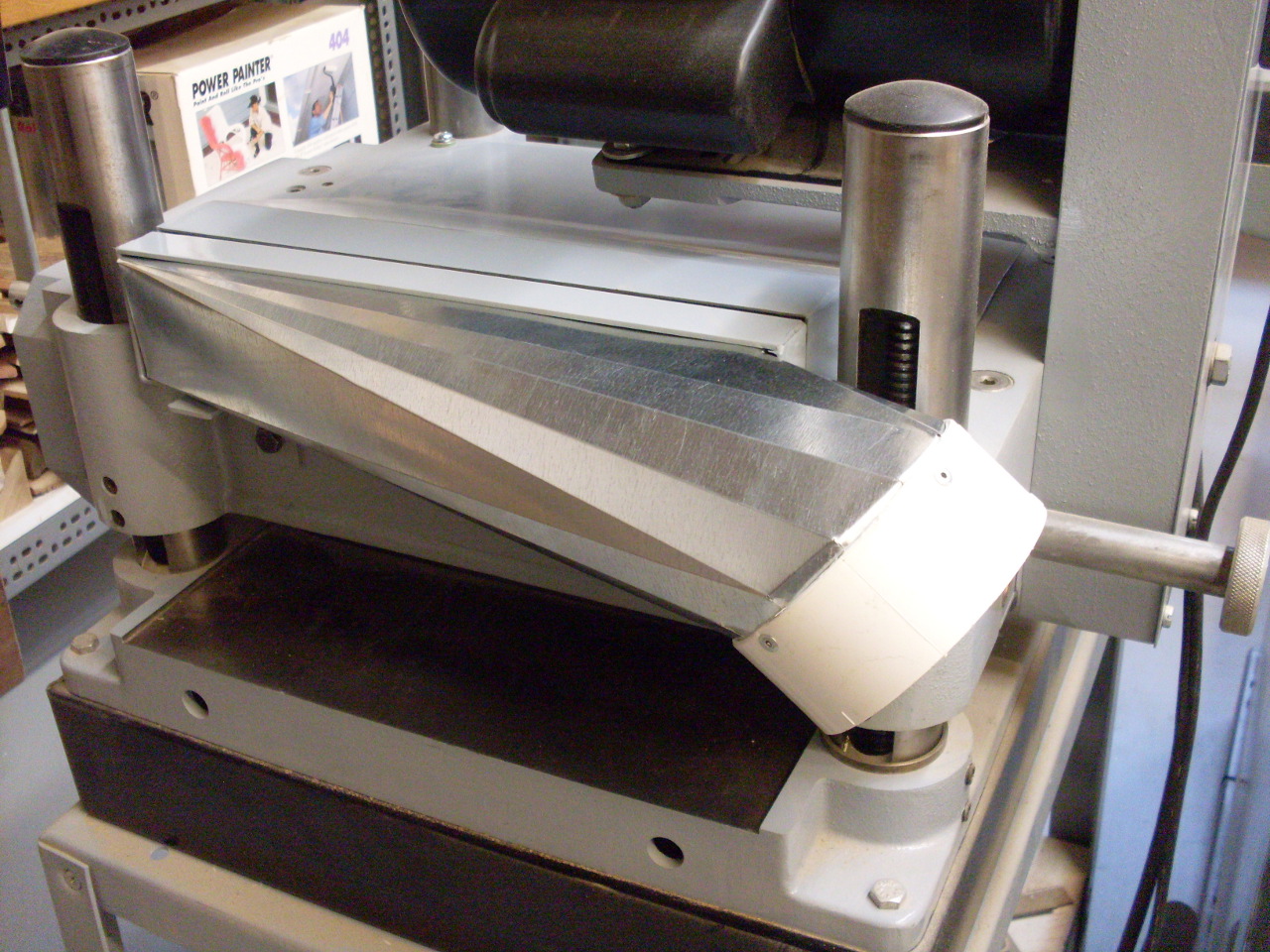

The last pic is a trial fitup of the components.

I had to rivet a little

piece of sheet metal to the frame to serve as the bottom of

the exit duct from the planer, then riveted the transition to the

frame. Some foam weatherstripping tape seals the joints.

Here is the planer all

hooked up to the in-floor system through a blast gate.

Comments to: elhollin1@yahoo.com