What is the correct O ring for the rocker spindles on a '71 Triumph T100R and similar bikes?

According to my parts book, the rocker spindle O ring on my 71 T100R is

part number 070-3253. I’ve ordered

a few over the years, and since it is sometimes more convenient to buy

from industrial sources rather than from motorcycle parts houses, I

crossed

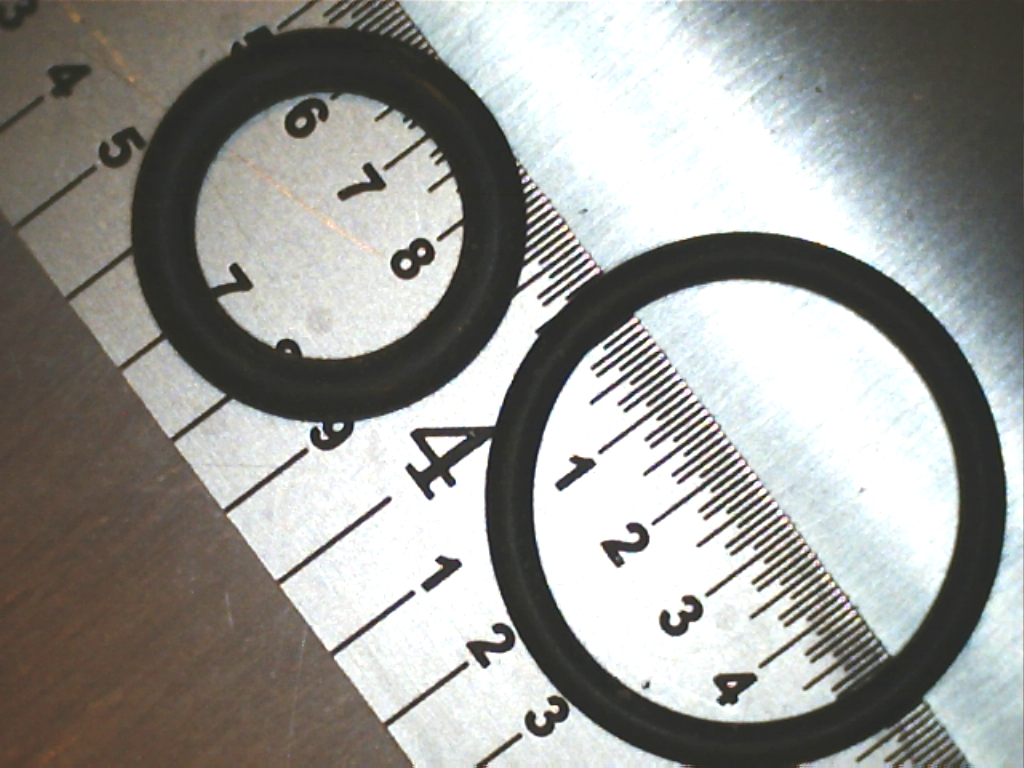

the part to an industrial number. In the top photo at left, the upper

ring is one shipped from any of several British bike parts

suppliers. The lower one is an industry standard “-011” size. The two

appear and measure to be identical. (Click the pics to see them

bigger.)

The nominal dimensions of an -011 O ring are 0.301” ID and 0.070” cross section.

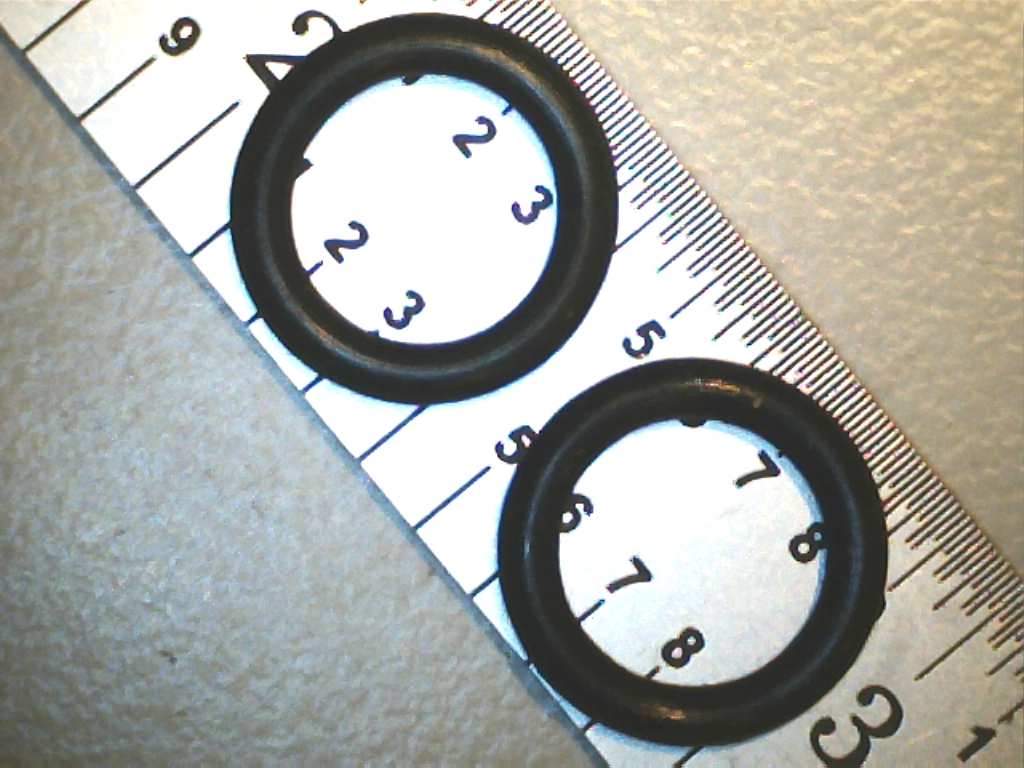

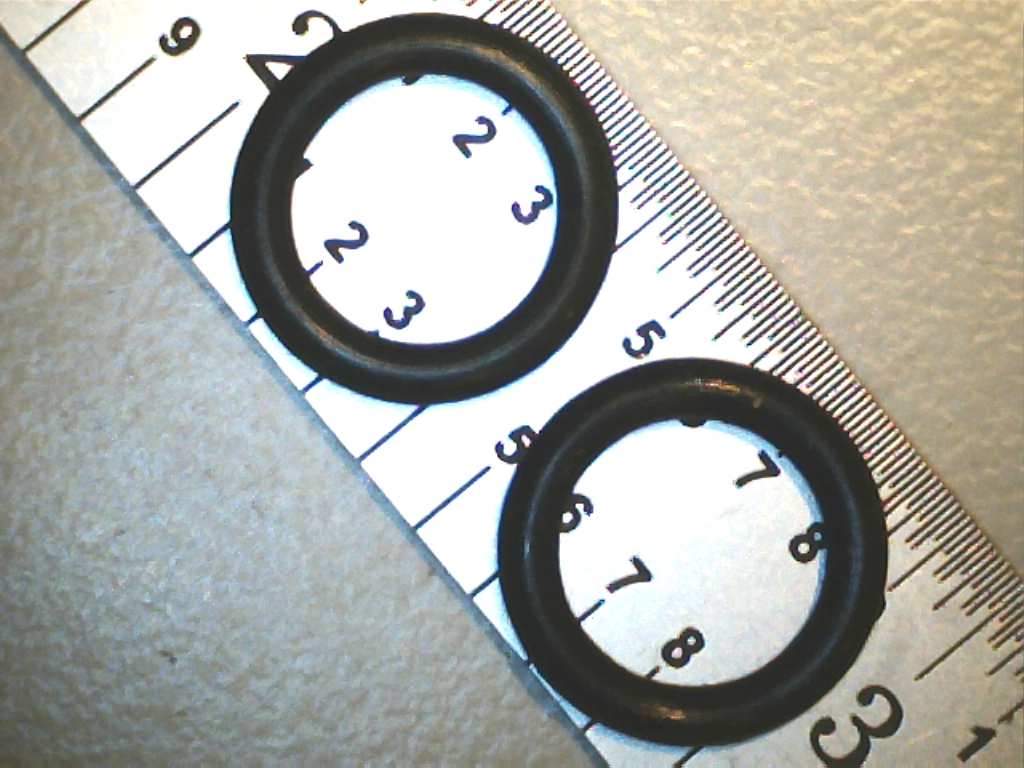

I’ve come to believe that this is not the correct O ring for this application. The first suggestion is the notorious difficulty many if not most people have in installing the O ring without damaging it. The pic below shows a typical damaged ring next to a brand new one. In this case, the shaved off piece was hidden between the shaft and the rocker box bore, so I didn't even know about the damage until I took the spindle out and looked closely at the ring.

More convincingly, some simple arithmetic shows that this ring is not compatible with the O ring groove on the rocker shaft.

The O ring groove on my T100R is about 0.060” wide and 0.037” deep, +/- maybe 0.002”, and it has a root diameter (at the bottom of the groove) of about 0.490”. The first clue that there may be a problem with the -011 ring is that its ID is quite a bit smaller than the bottom of the groove. In fact, an -011 ring will have a “stretch” factor of over 60%, when the general rule for O ring design is to provide something under 10%.

The next warning sign is “gland fill”. The groove (called a “gland” in O-ring speak) in the rocker shaft has a

cross sectional area of 0.060 x 0.037 = 0.0022 in2. The -011 ring has a cross sectional area of π(0.070/2)2 = 0.0038 in2.

Even adding a little

depth to the gland to account for the clearance between the shaft and

the rocker box, the cross section of the ring is bigger than the gross

section of the gland. Industry practice is to fill the gland at around

75%, and never more than 90%.

The next warning sign is “gland fill”. The groove (called a “gland” in O-ring speak) in the rocker shaft has a

cross sectional area of 0.060 x 0.037 = 0.0022 in2. The -011 ring has a cross sectional area of π(0.070/2)2 = 0.0038 in2.

Even adding a little

depth to the gland to account for the clearance between the shaft and

the rocker box, the cross section of the ring is bigger than the gross

section of the gland. Industry practice is to fill the gland at around

75%, and never more than 90%.

I’m an Engineer, but not a Mechanical Engineer. Information about industry practice in O ring gland design was gathered from half a dozen web sites that all agree pretty well.