December 12, 2012

Pneumatic Power Drawbar for a Knee Mill

Earlier

this year, I got a new (to me) vertical milling machine. I love

the machine, and learn something every time I use it. One of the

things I learned early on was that I'm not tall enough. The

machine is almost 7-1/2 feet tall, and the drawbar hex is at just short

of seven feet. I can reach the drawbar, but I can't see it at the

same time. Though I've gotten pretty good at getting a wrench on

it by feel, I still have to feel around up there to free and draw up

the collets. I'd seen some examples of power draw bars on the

web, both commercial and home-brew. A DIY power draw bar seemed

like a good project to use the mill for, so I started formulating a

plan.

Most if not all of the DIY and power drawbars I saw were

based on pneumatic impact drivers. Most also used

pneumatic cylinders to lower the driver onto the drawbar hex and to

actuate the driver. I thought the air driver was a great way to

go, but I eventually favored a manual mechanism for lowering and

controlling the impact driver. I wasn't afraid of designing the

pneumatic control, but felt that I'd get a better feel for engagement

with a mechanical linkage. In some ways, the linkage for the manual

approach was more challenging.

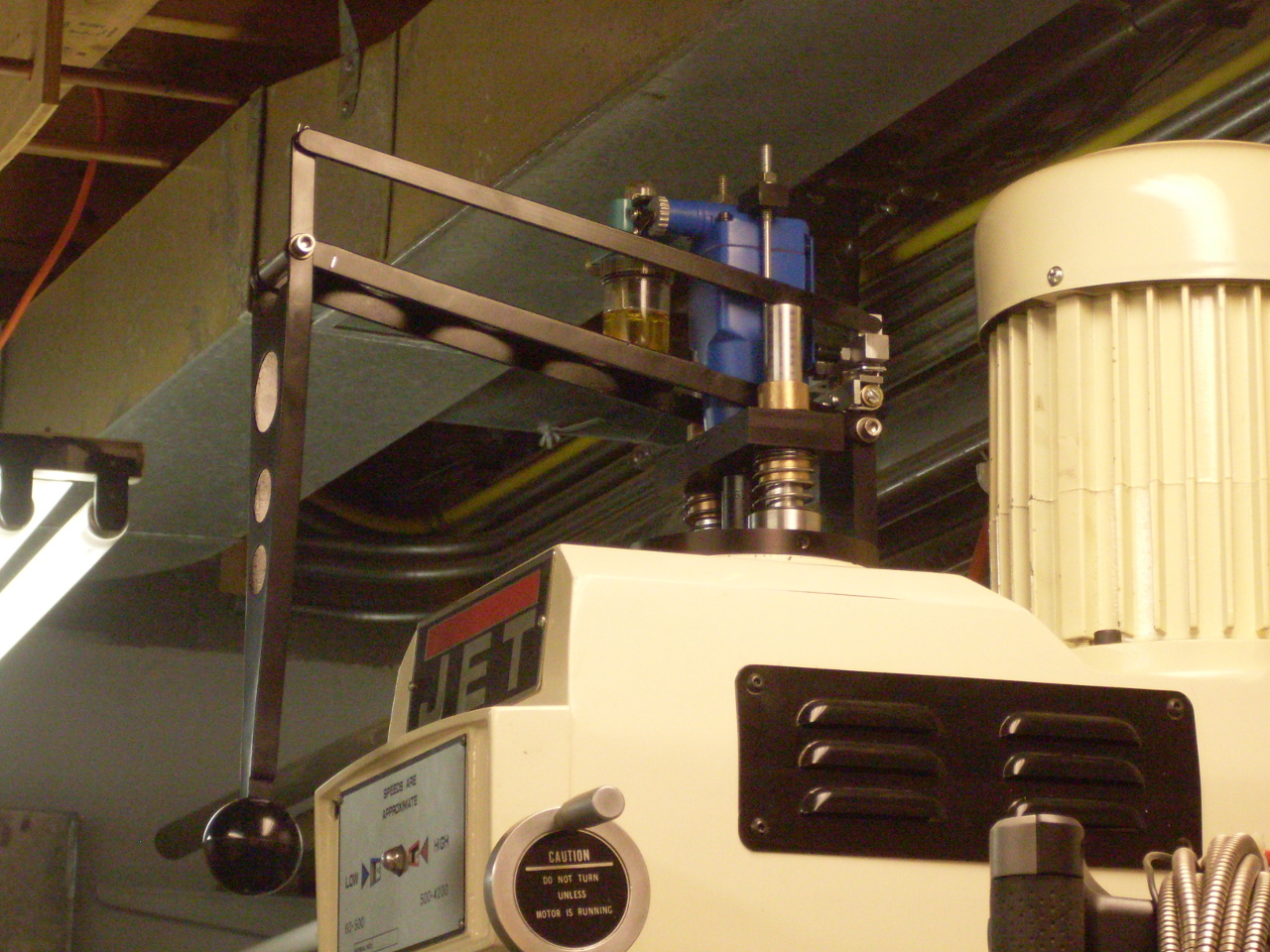

I'll show the finished device in place first so some ofthe later pics will make more sense:

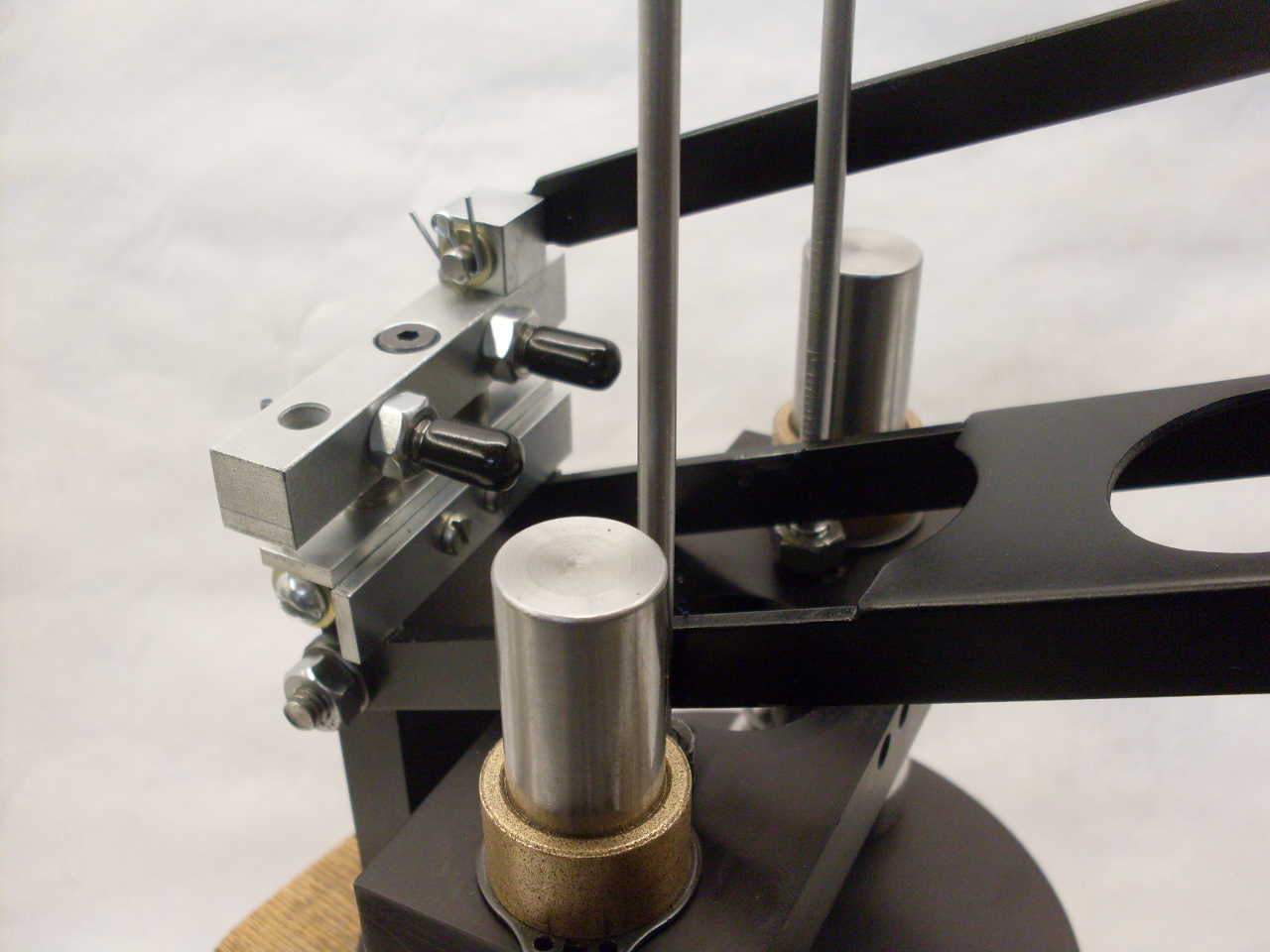

The

power drawbar is actuated using the ball handle that hangs down to a

comfortable height. There is a sort of dual-action parallelogram

linkage that lowers the driver when the ball is pulled straight down,

and actuates it forward or reverse when the ball handle is pushed

forward or pulled back. It is easy to feel the engagement of the

driver with the drawbar hex, and the actuating action is tight and

immediate.

Here's an outline on how it was done.

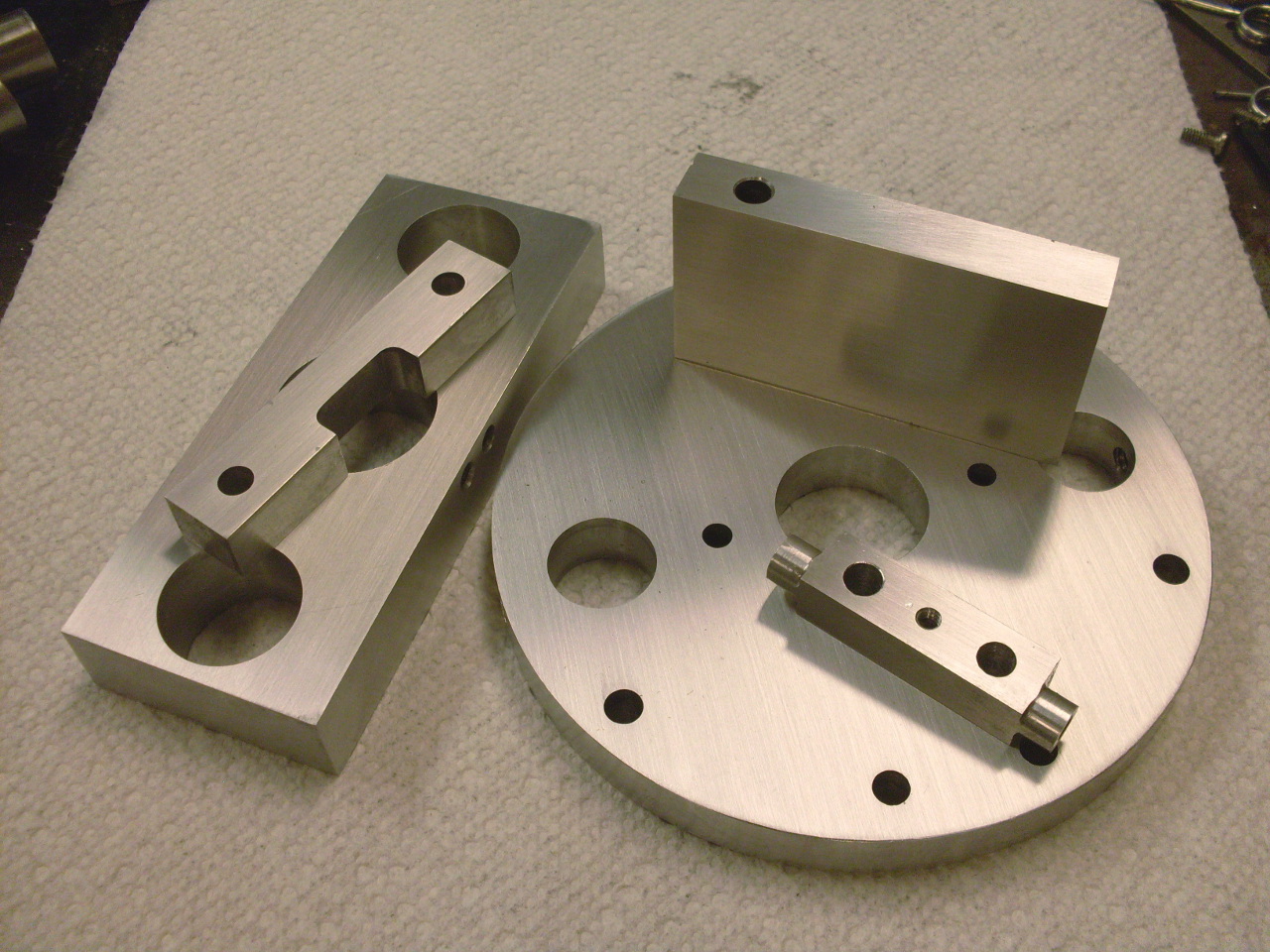

I

roughed out and then finished most of the parts from 1/2" and 3/4" 6061

aluminum. I've been playing around with anodizing lately, so I

also anodized them black.

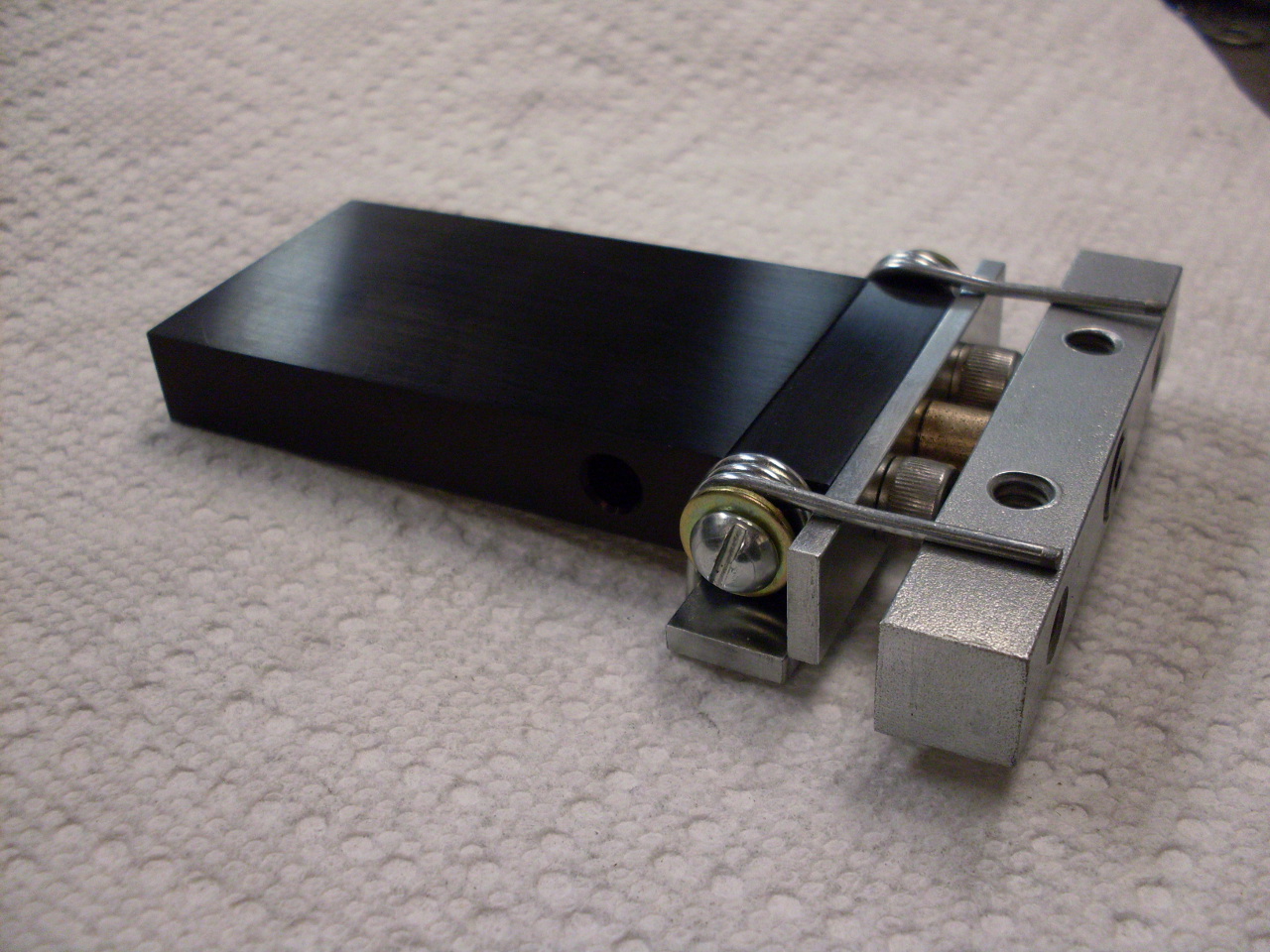

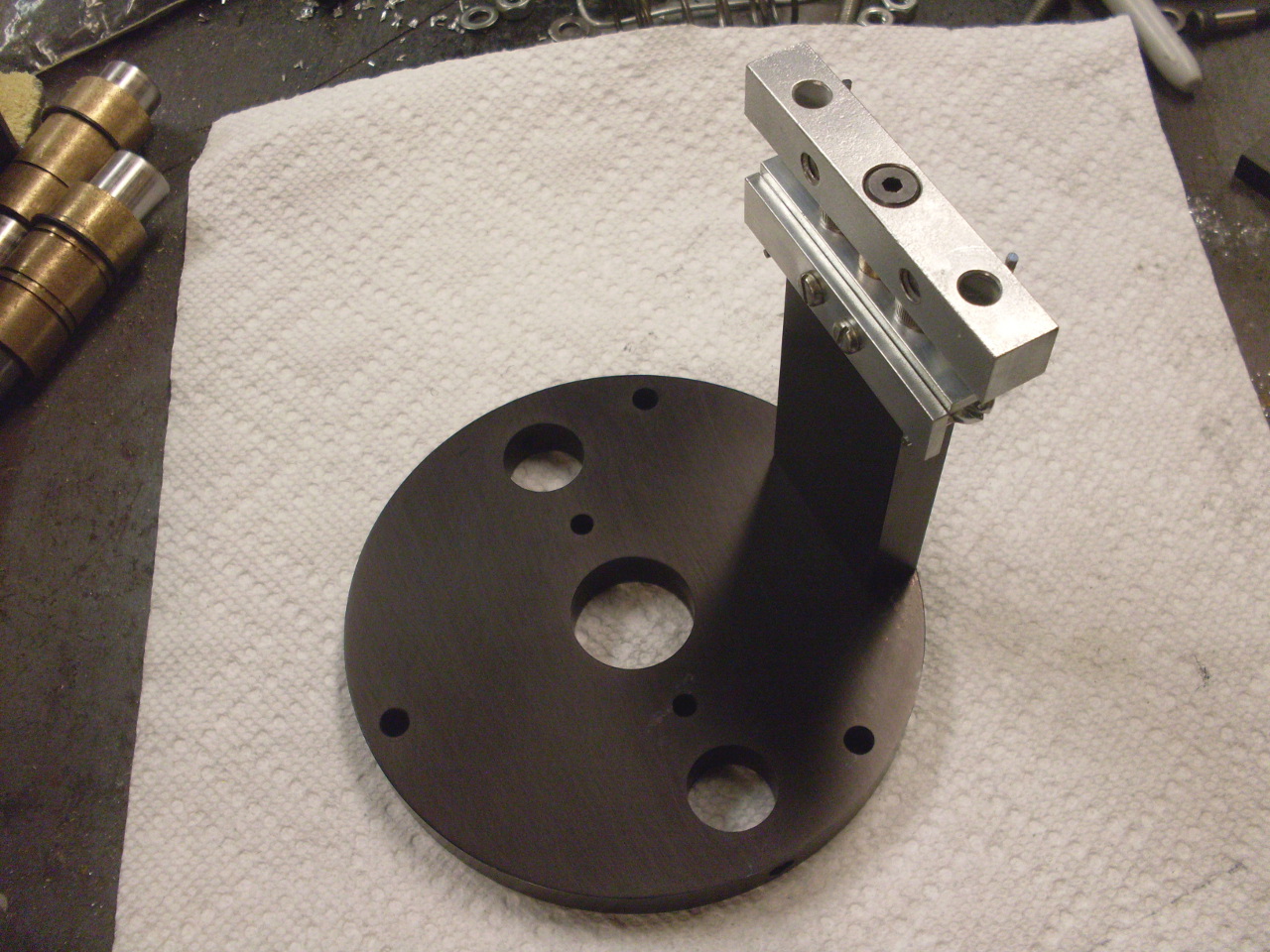

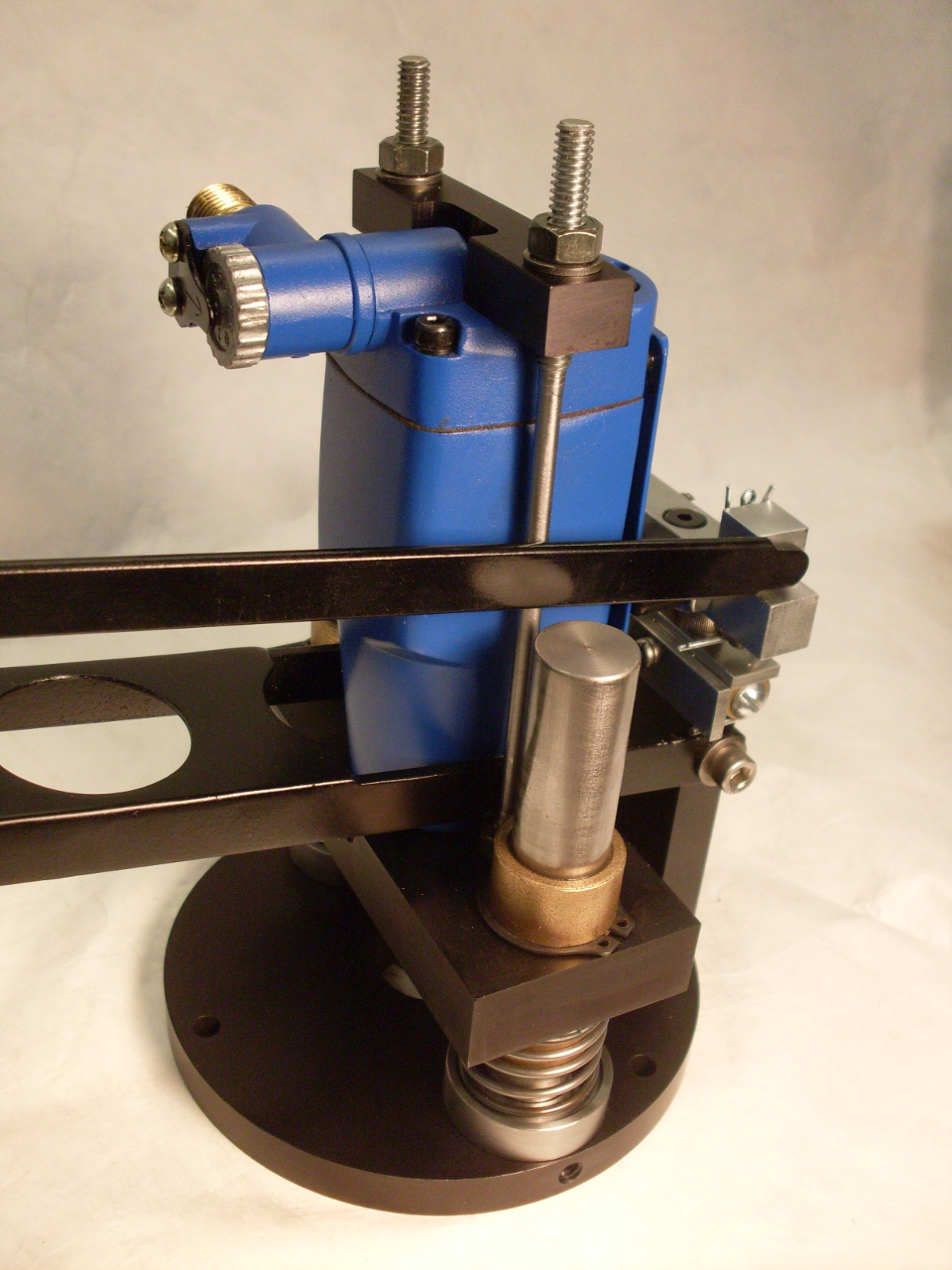

This

is a post at the back of the unit that carries the actuator arm

mechanism. The piece of 1/2" key stock is the actuator arm for

the impact driver and can pivot on a shoulder bolt fixed to the post

assembly. The springs allow it to pivot either way, but return it

to the central position. The two 1/2 x 1/8 steel pieces act as

stops for the springs.

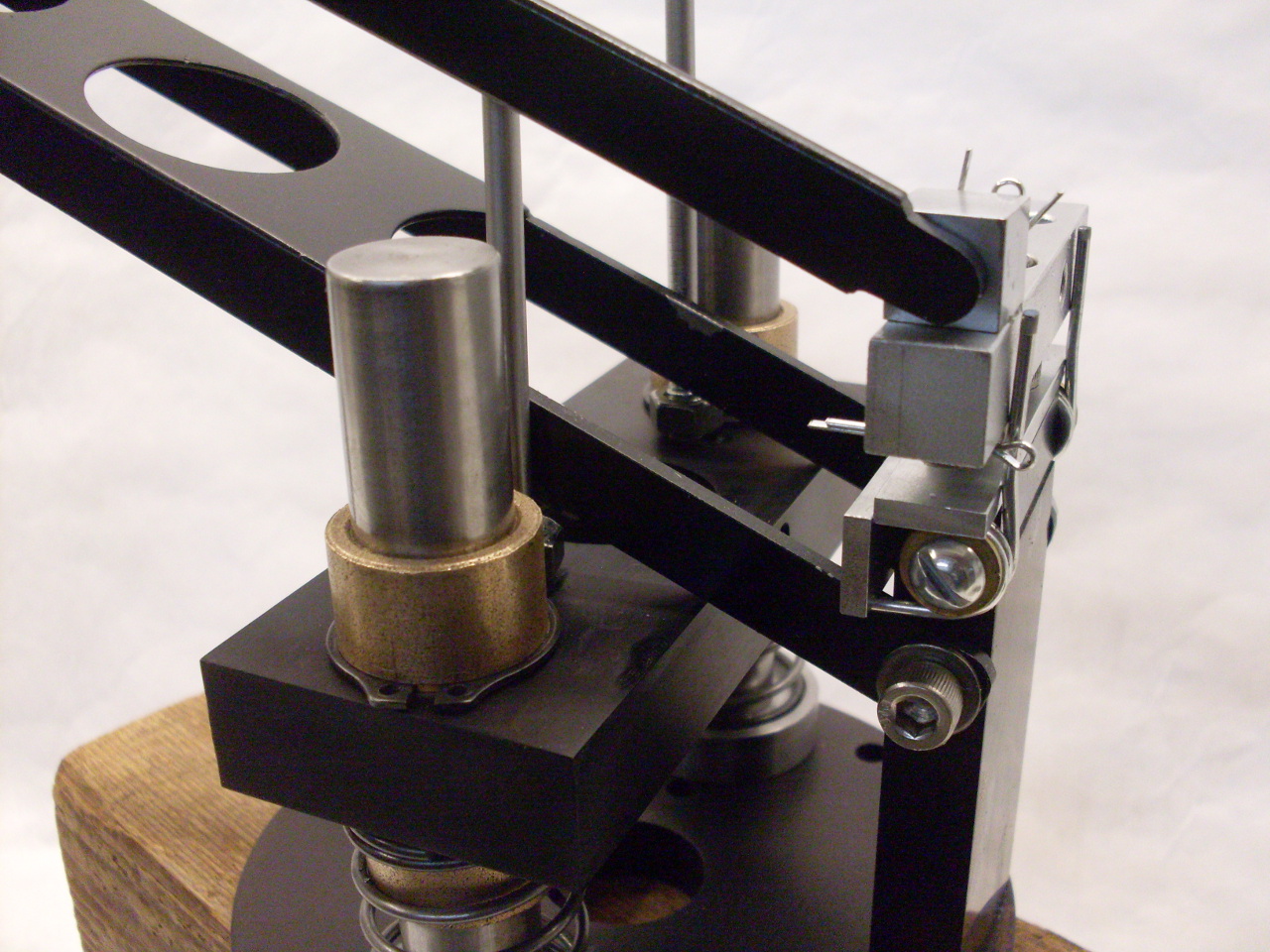

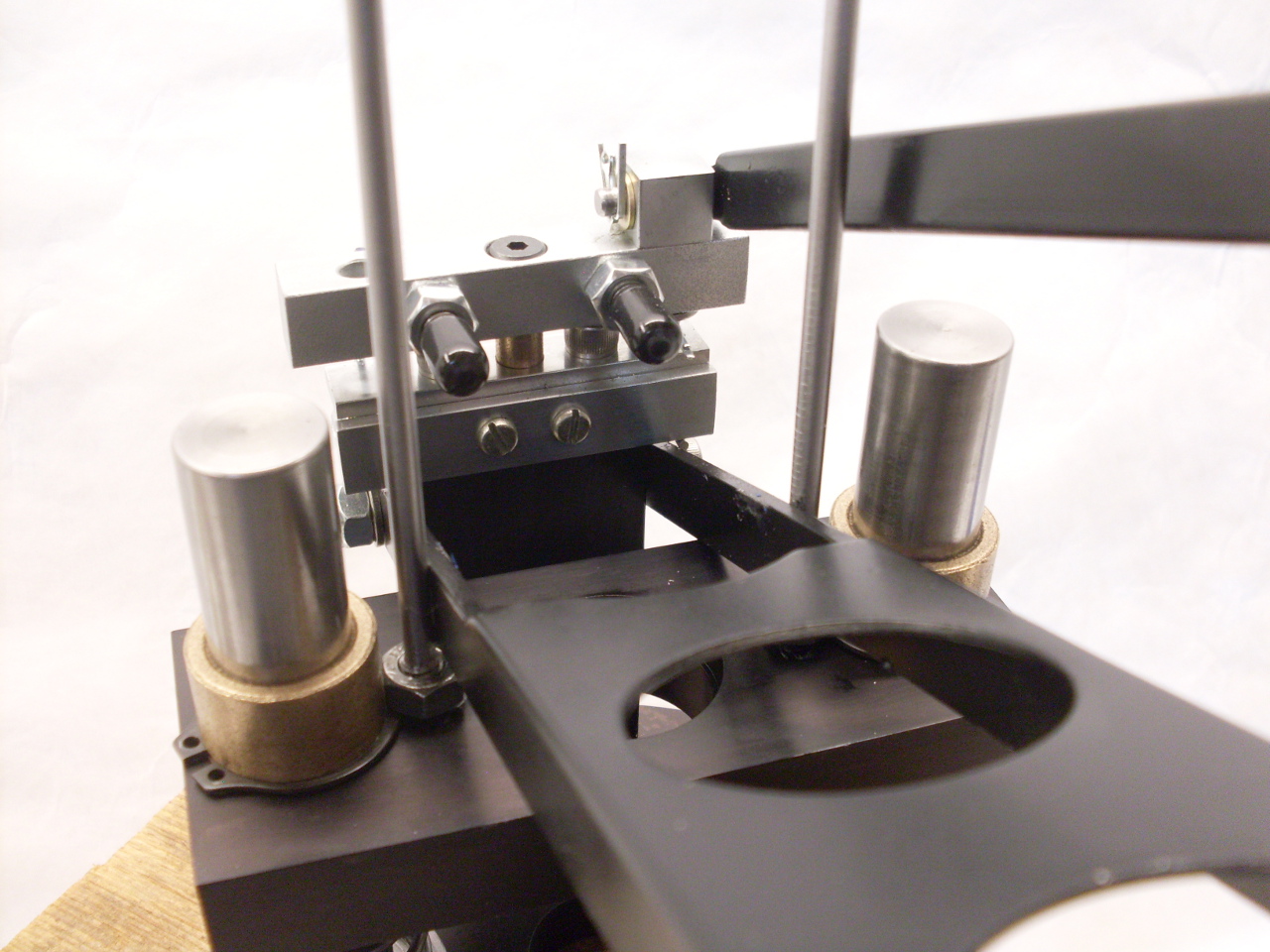

Here is the back post mounted to the base. Two chunks of 3/4" drill rod serve as slides for the impact driver carrier.

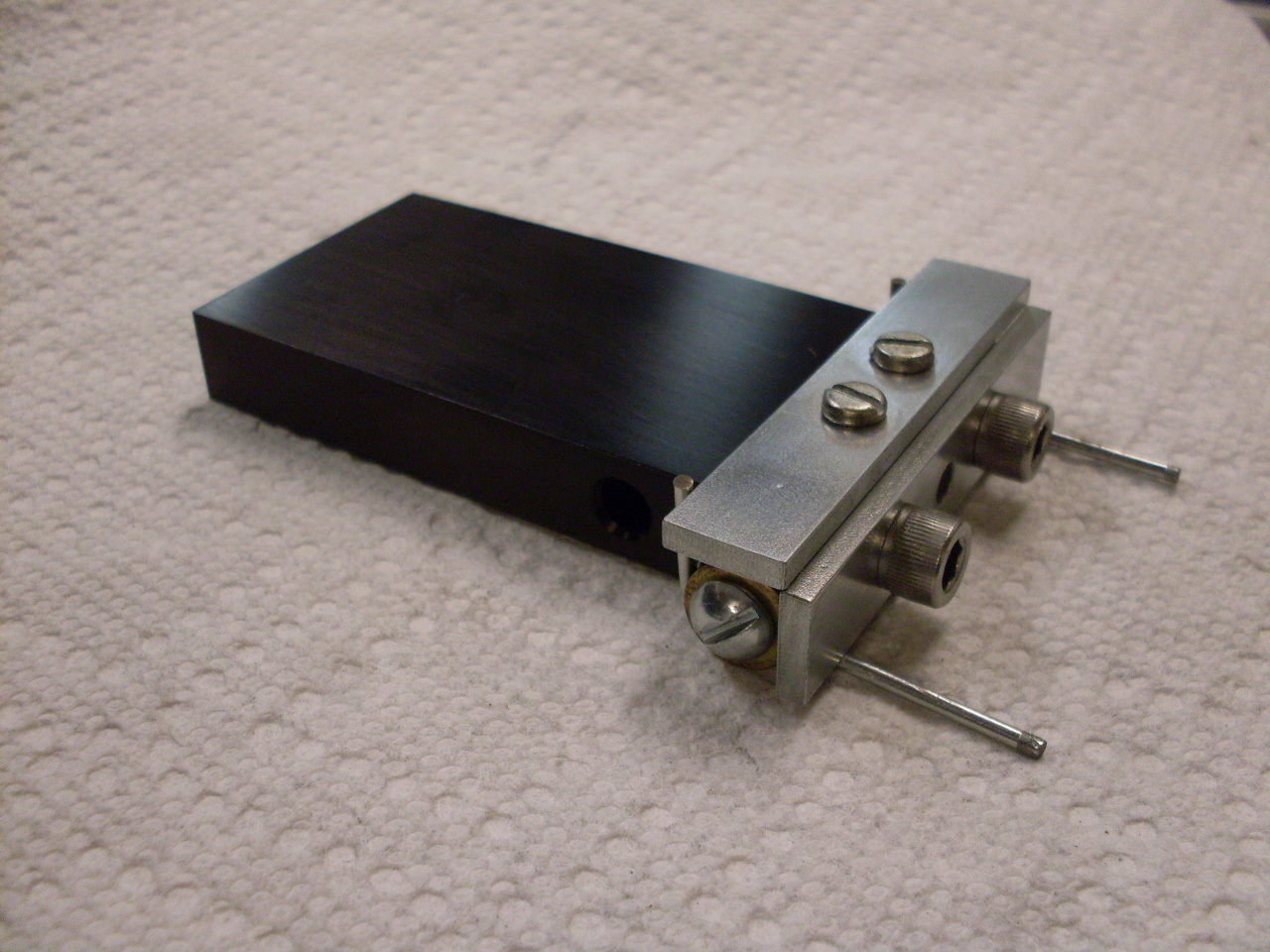

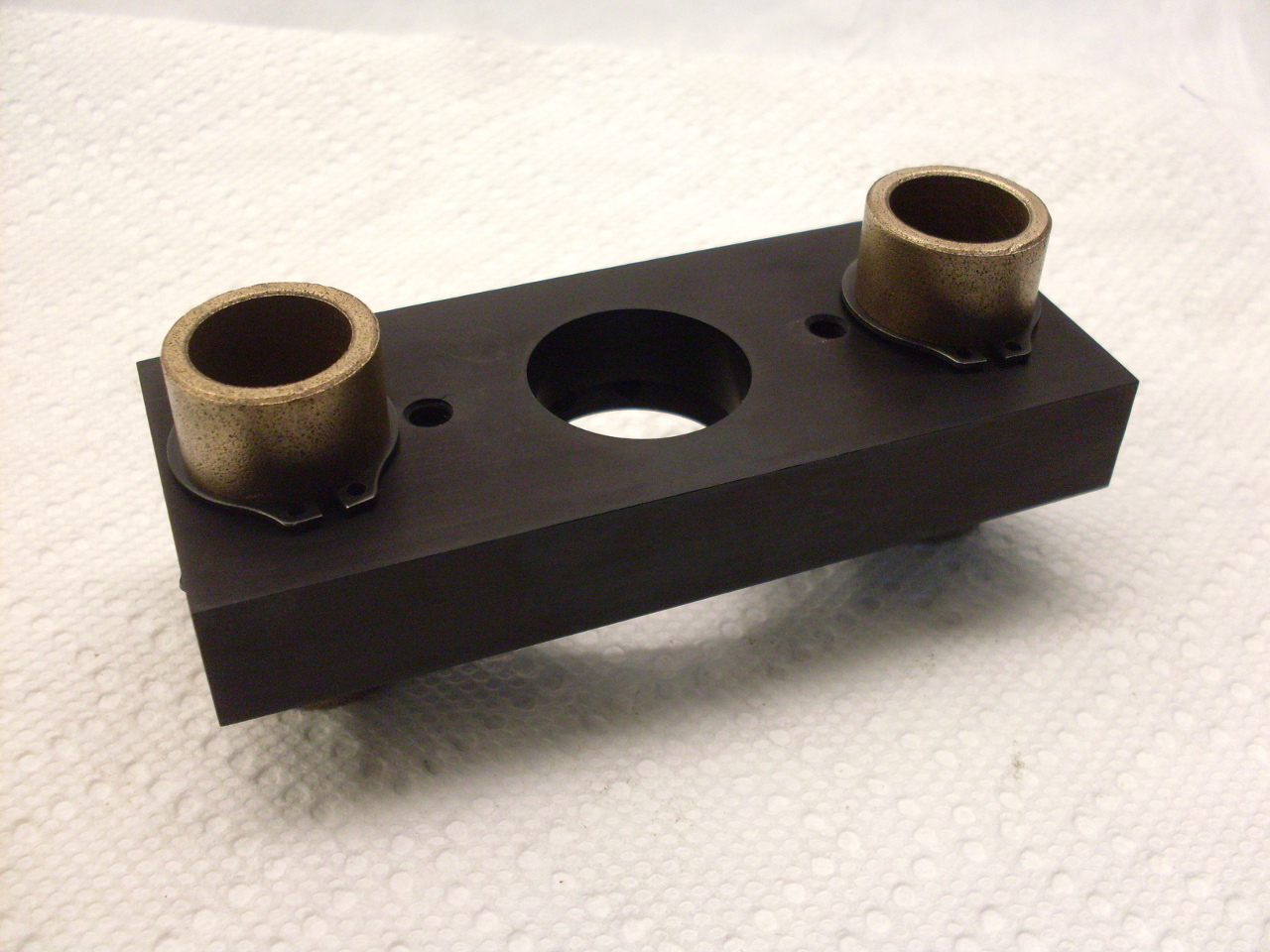

The

driver carrier is a piece of 3/4" aluminum bored to accept two oilite

bushings to ride on the slides. The thin rods are to hold the

driver in the carrier.

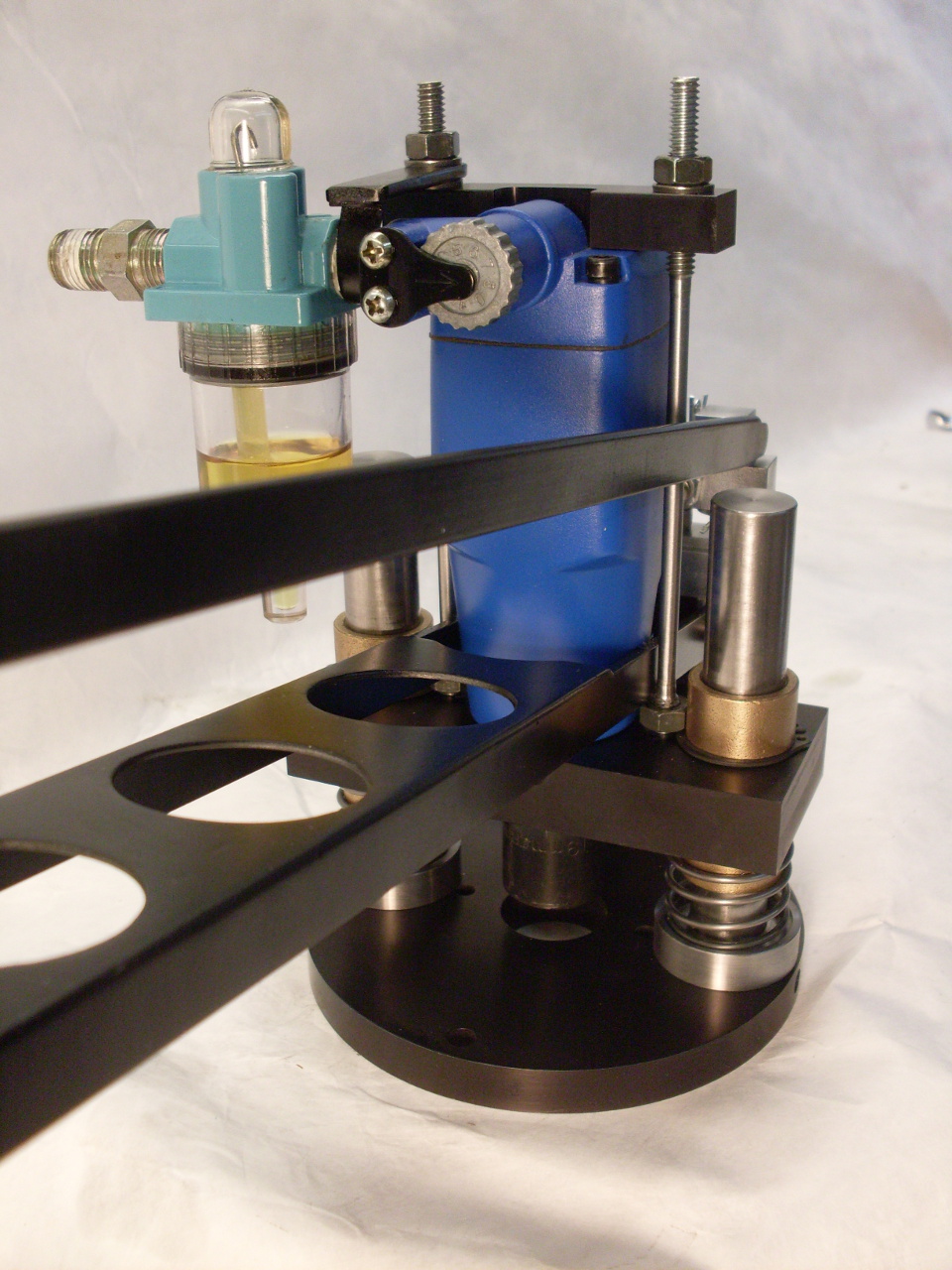

This is part of the control handle and linkage. It is just welded up steel painted black.

The

linkage connects to the actuator arm with that little universal joint.

It's a little hard to see, but the lower arm of the

parallelogram linkage bears on those two hex nuts to push the carrier

down. The little rubber caps are on some adjustable studs, and

push against the actuator paddle on the impact driver.

This is a keeper machined to fit the top of the impact driver.

I added a miniature inline oiler since doing it by hand would be a royal pain.

I

set the built-in "torque adjuster" on the driver to be wide open, and

control torque with a dedicated pressure regulator on the wall behind

the mill. Seems to work great. The only problem now is that

it is now even trickier to do the drawbar by hand, and I've got at

least one leak somewhere on my compressor, so I can't leave it

pressurized all the time, and have to charge it up every time I

want to use the mill.

Comments to: elhollin1@yahoo.com