To my other MGA pages

May 29, 2025

Frame Closure Panels

The MGA frame includes a beefy "goal post" structure that supports the

firewall and cowl, and delineates the passenger and engine

compartments. There are heavy diagonal braces to the front and

rear of the bridge. The rear braces are actually in the passenger

compartment, and the factory provided triangular aluminum panels to

close off the space under them.

In my 70s restoration, I found these panels largely corroded away.

I was able to save most of the leading edges of the panels, but just

riveted on thin aluminum to replace the rest.

This time around, I decided to just make new panels. This isn't

exactly trivial though, because the front edges are actually formed to

partially wrap around a vertical bracket welded to the bridge upright,

and have a tapered jog.

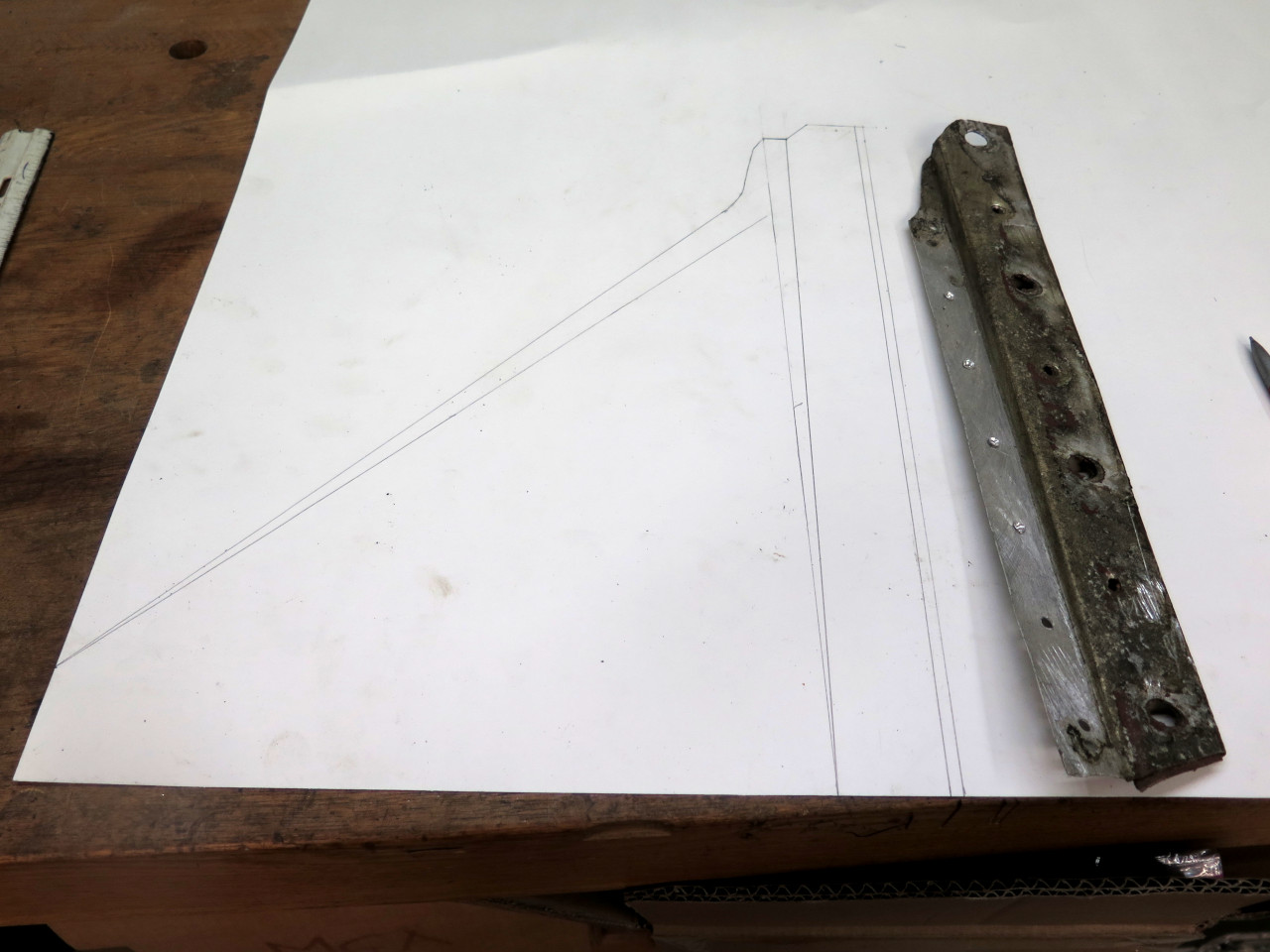

Between the remnants of the old panels and measurements from the car, I

was able to determine the necessary original size and shape. I

later found some online drawings that confirmed that I was pretty darn

close.

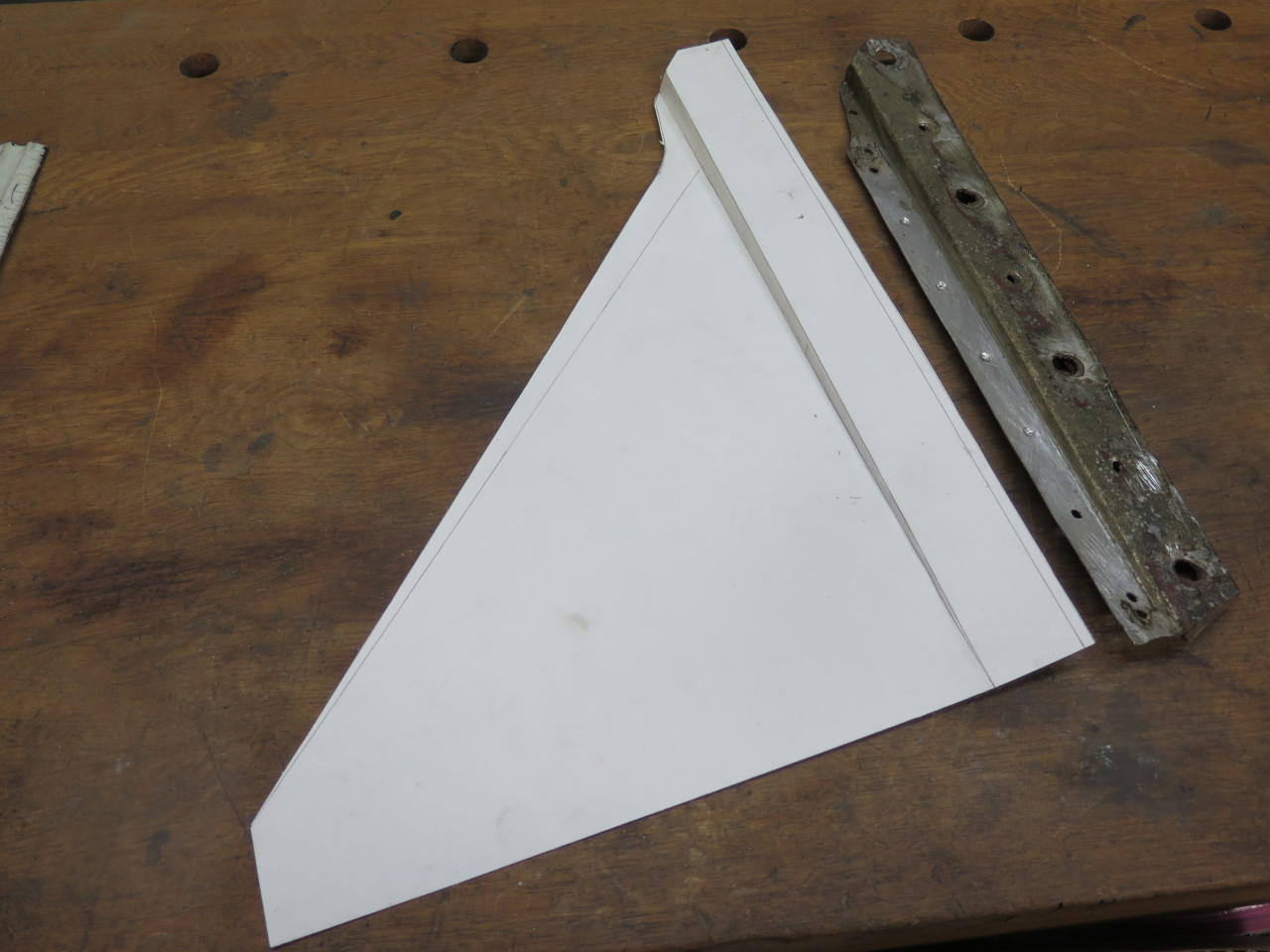

I made a heavy paper pattern that fit the car pretty well.

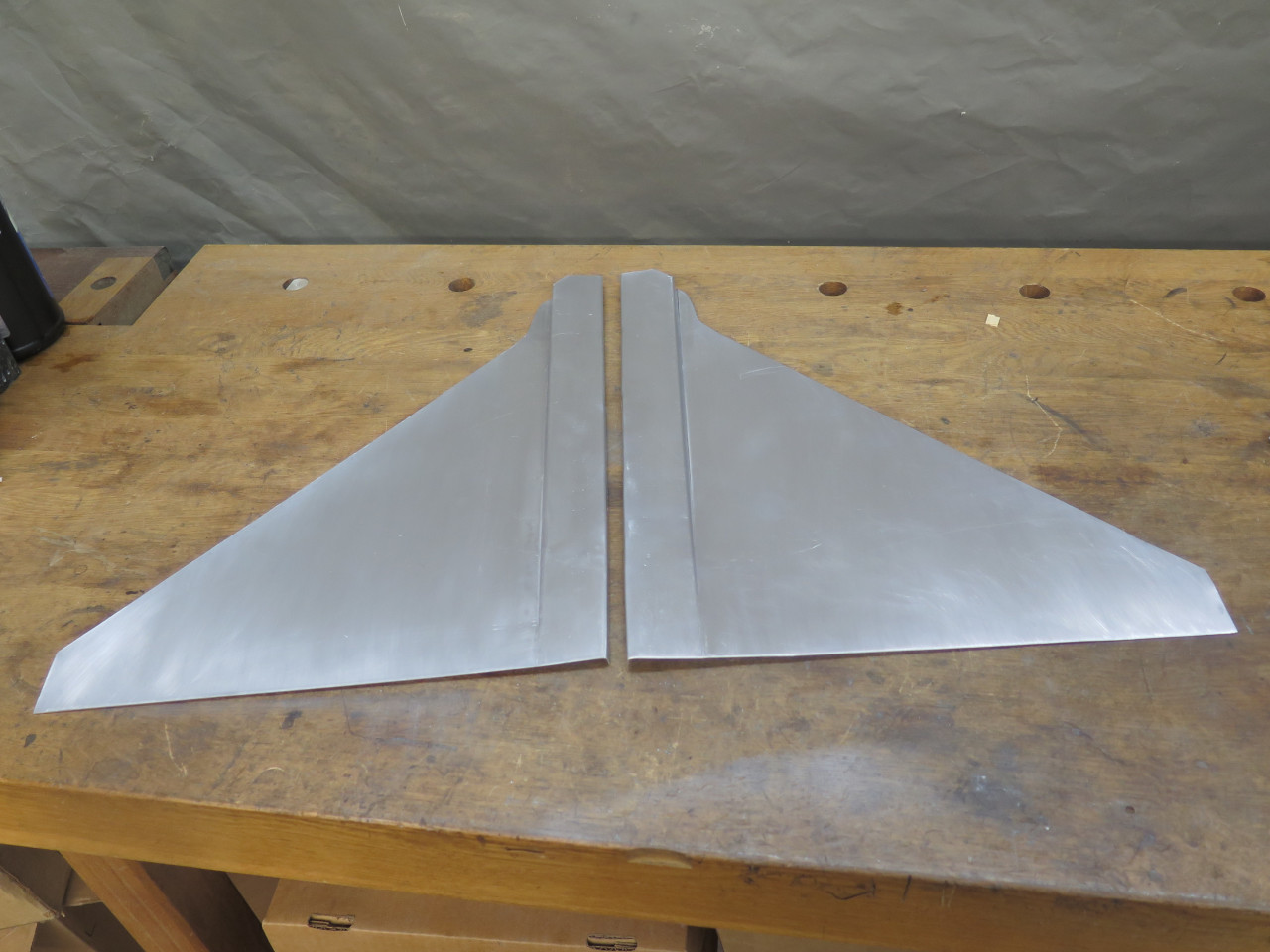

Then transferred the flat pattern to some actual aluminum. The

original panels measured at about 0.035", and the new material was

0.040", so, you know--upgrade!

Straight bends in sheet this thin is normally not much of a problem, but

while my brake has no trouble with a single bend, it can't really do

another one that is too close to the first one, such as in this

piece. So, for these panels the second bend was done with a hand

bender.

There are five holes in the leading edge of the panel--three small ones

to mount the panel, and four large ones for body fasteners to pass

through. To help align the panel holes with those in the frame

member, I used the old tape trick.

This was enough to hang the panel to mark for the other holes. I

put the five original screws in their holes in the diagonal rail, then

hung he panel from the front edge. A little hammer tap at each

screw location put a mark on the backside as a guide for drilling.

There are also some holes along the bottom. These were apparently

just to hold sealing strip, since there were no corresponding holes in

the frame rail.

Speaking of the sealing strip, it's pretty well known that the original

design used felt at many places on these cars, including on these

panels. This seems to me a questionable application for a material

that wicks and holds water so well. I tested a small piece of

felt, and found that it sucked up and retained seven times its dry

weight of water, and was still pretty damp the next day. Many

pictures I've seen of old original panels seemed to have the most

corrosion on the bottom edge, where road splash could get to the seal.

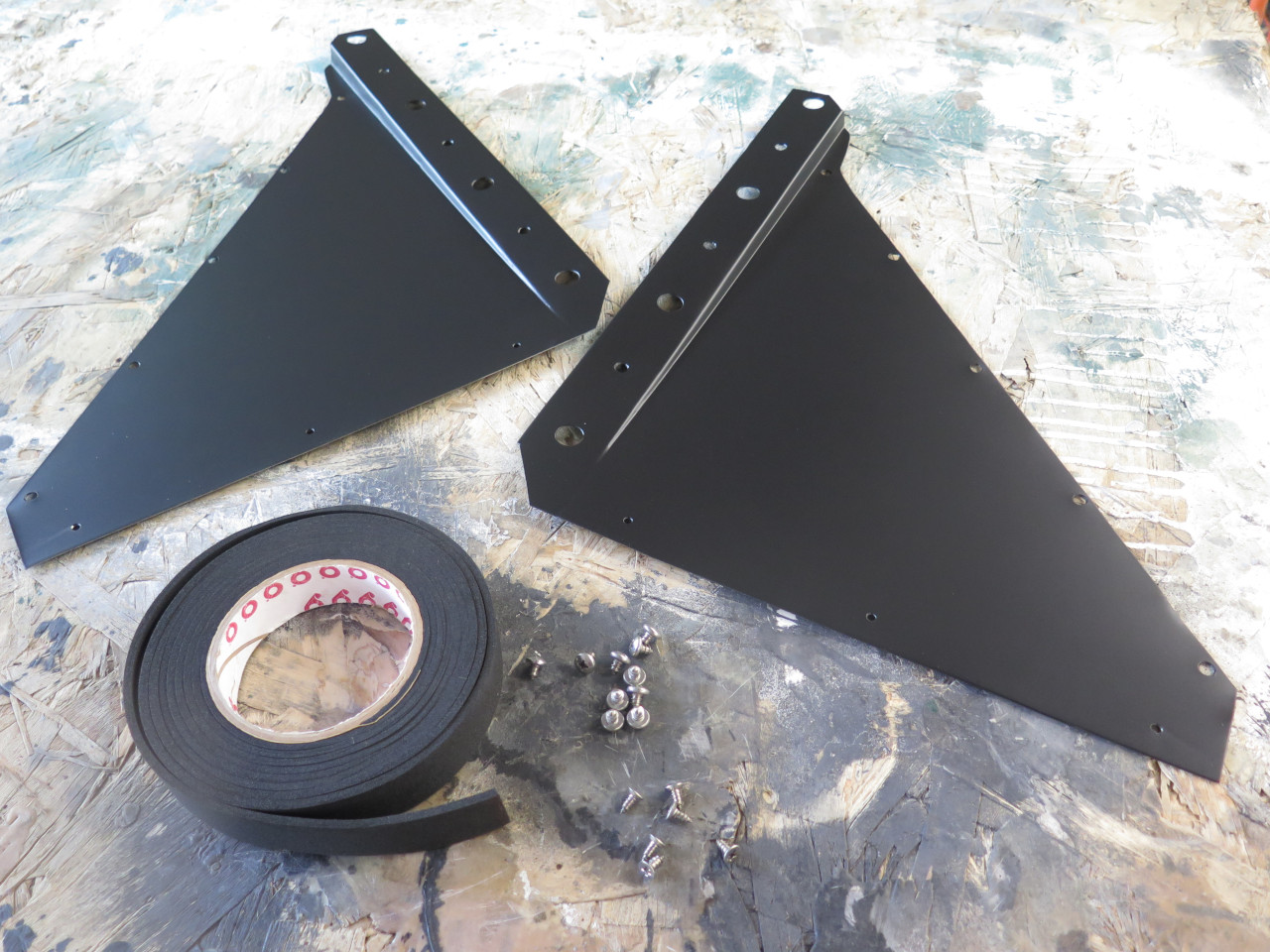

In the end, I decided to use what I believe to be a more suitable

material. This is a closed cell weather resistant EPDM foam with

dimensions similar to those of the original felt.

I painted the panels. I believe they were natural color originally, but it's my car. Also got new stainless screws.

Cut the foam and punched holes for the screws or rivets.

Test fit seemed OK, but I did notice a couple of things.

First, the factory apparently didn't use a sealing strip for the front

edge of the panel. This seemed like a strange omission. I

considered putting a strip of foam there, but in an act of concession to

the original designers, I instead just put a bead of strip caulk on the

leading edge, where the panel wraps around the frame bracket.

The second thing I noticed was a gap at the bottom edge of the panel

where it meets the vertical bracket. The bracket is proud of the

frame there, and a single layer of foam wasn't thick enough to fill that

void. A short strip of foam glued there fixed that right up.

Finished up the other side. All done.

This addition to the frame somehow makes it look more, I don't know,

substantial, I guess. It was a fun project with few big

challenges. Cost was maybe $20 for the foam and fasteners. I

think I had everything else on hand.

Comments to Ed at elhollin1@yahoo.com

To my other MGA pages