To my other MGA pages

May 17, 2025

Rear Dampers

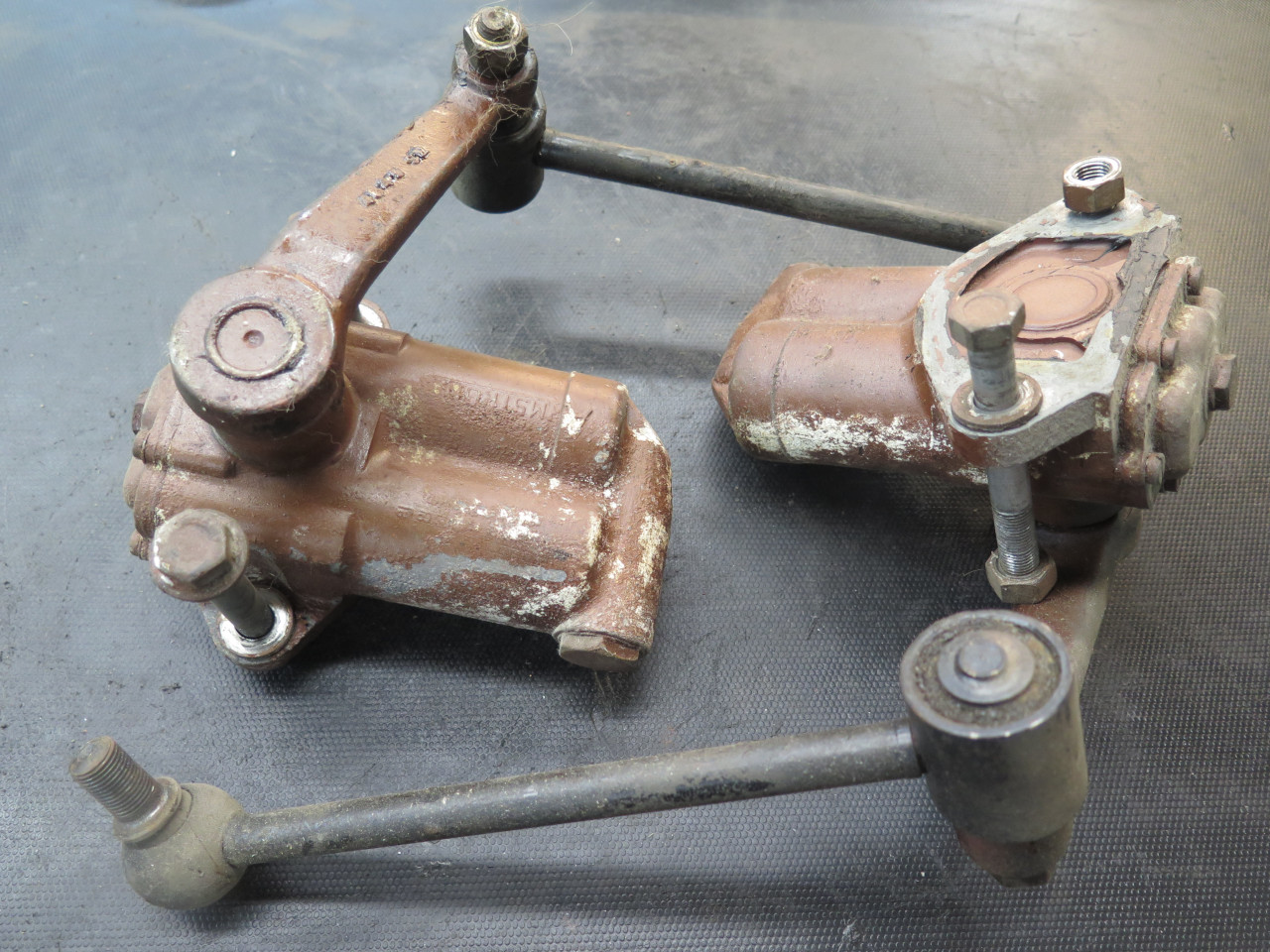

MGA cars, like many of their siblings and cousins, used a pair of

Armstrong lever dampers at the rear. They each consist of a pair

of oil-filled cylinders with pistons running in them. The pistons

are attached to a rocker arm that allows the pistons to move see-saw

fashion in the cylinders. A valve restricts and controls oil

flowing between cylinders. The lever arm of the damper is fixed to

the rocker.

I believe I replaced these dampers in my 70s restoration, and since the

car has been in storage since then, I had hopes that they would still be

in reasonable shape. They didn't look very good, but showed no

signs of leaking.

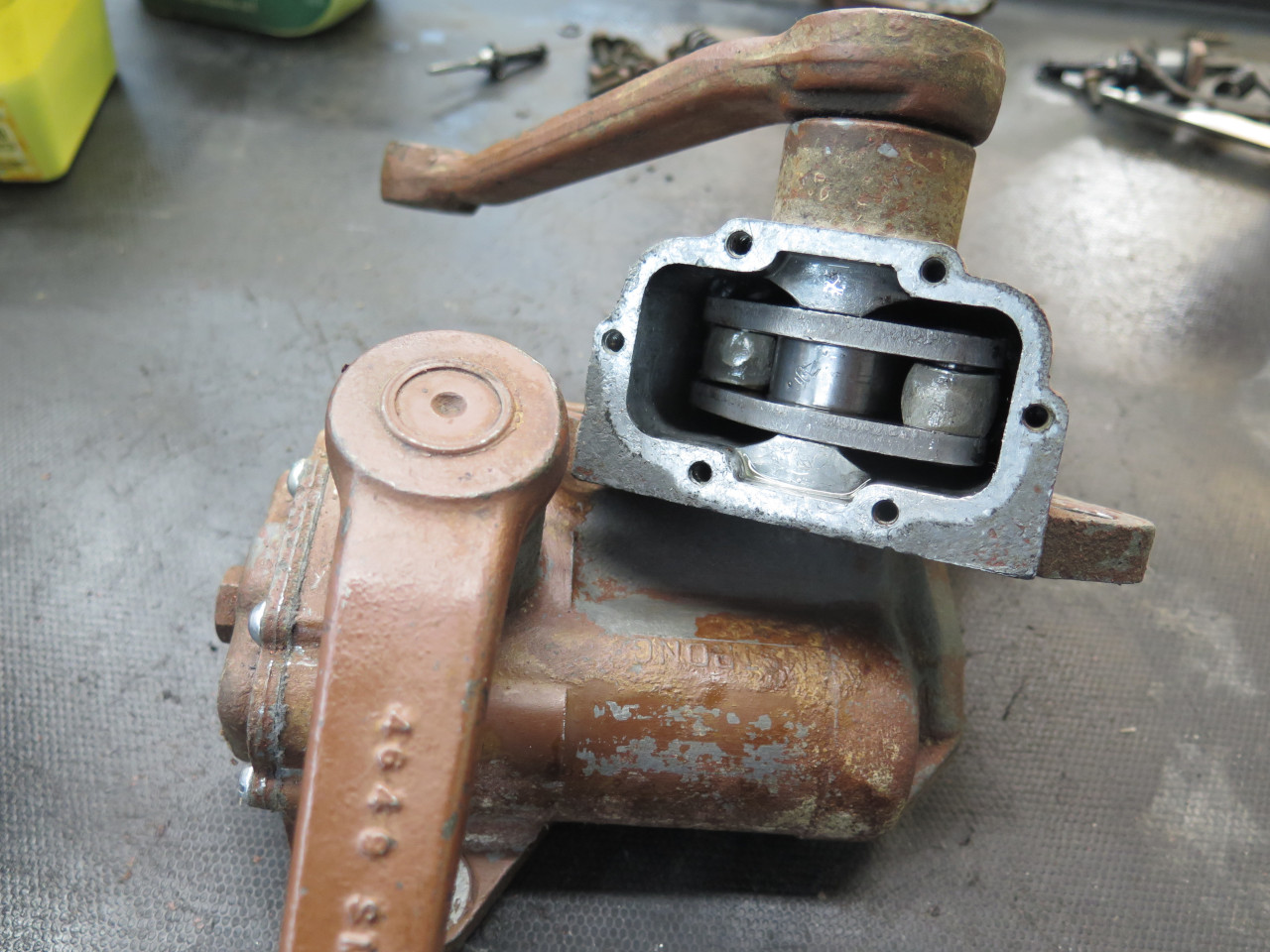

They looked a little dirty inside, so after I removed the top covers, I

emptied out the oil and flushed them with clean hydraulic oil, with the

first few flushes thinned with a little mineral spirits. The

insides looked better after that.

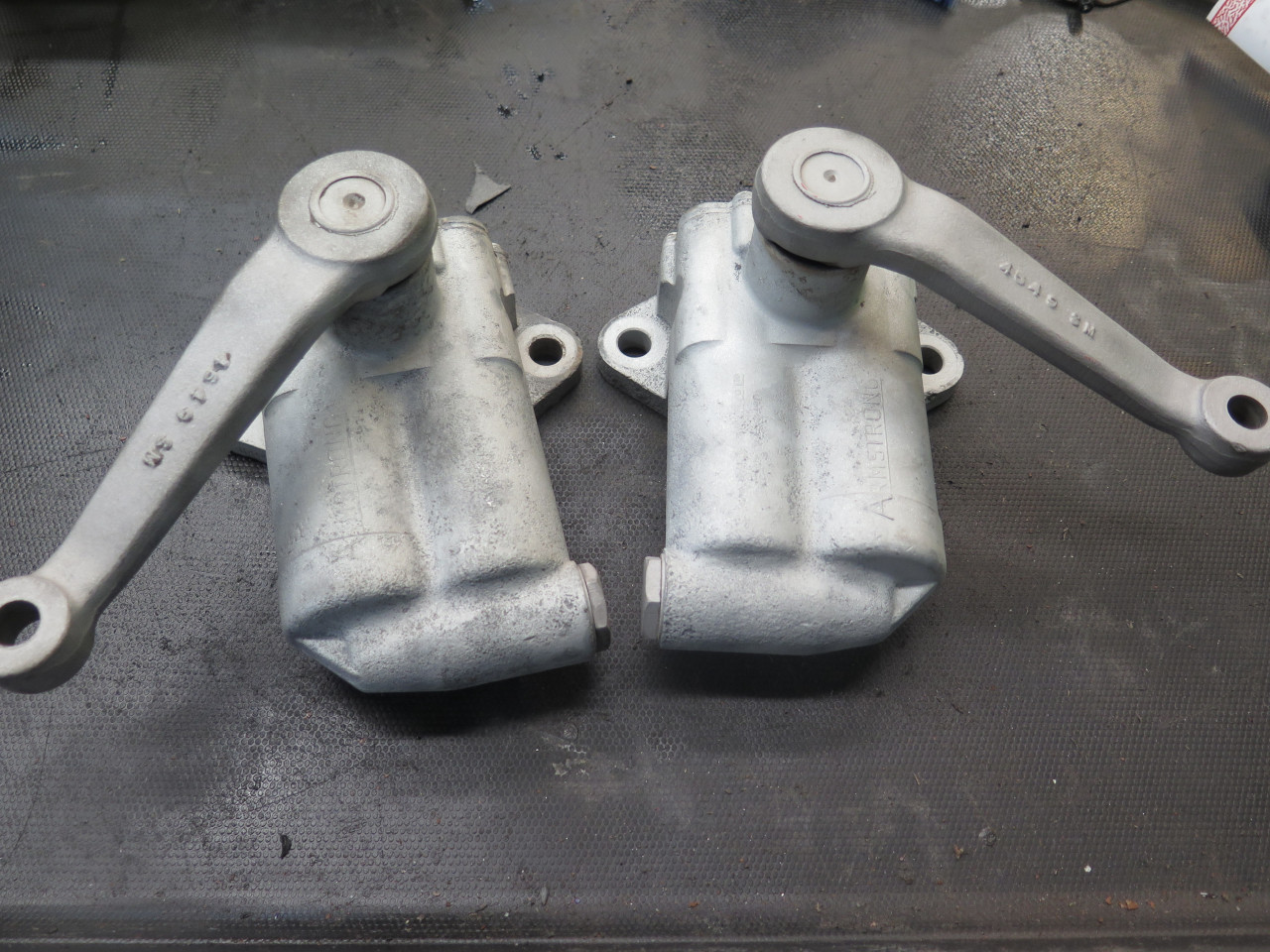

I then blasted them to remove the old paint and corrosion. There

was quite a bit of white zinc corrosion on the bodies that left visible

pitting. It's likely that these were rebuilt units when I bought

them, so the bodies could be pretty elderly.

Since I wasn't sure what materials were inside these and how they would

react to heat, I decided against powder coating, and instead just

painted them.

The valve assembly directs oil through restriction valves. The

amount of restriction for each direction of flow is set primarily by

spring force. The force of the two springs can in principle be

adjusted with that little end nut or shims. Since my style of

driving isn't fine-tuned enough to warrant adjusting damping rates, I'll

just leave them alone.

The valve body has two O rings, the smaller one keeps flows separate,

and the large one just seals the oil from the outside world. The

sizes appear to be -111 for the smaller ring, and -113 or -114 for the

big one. I think I used a 113. The valve body got a

selective zinc plate on its head, and a yellow chromate treatment.

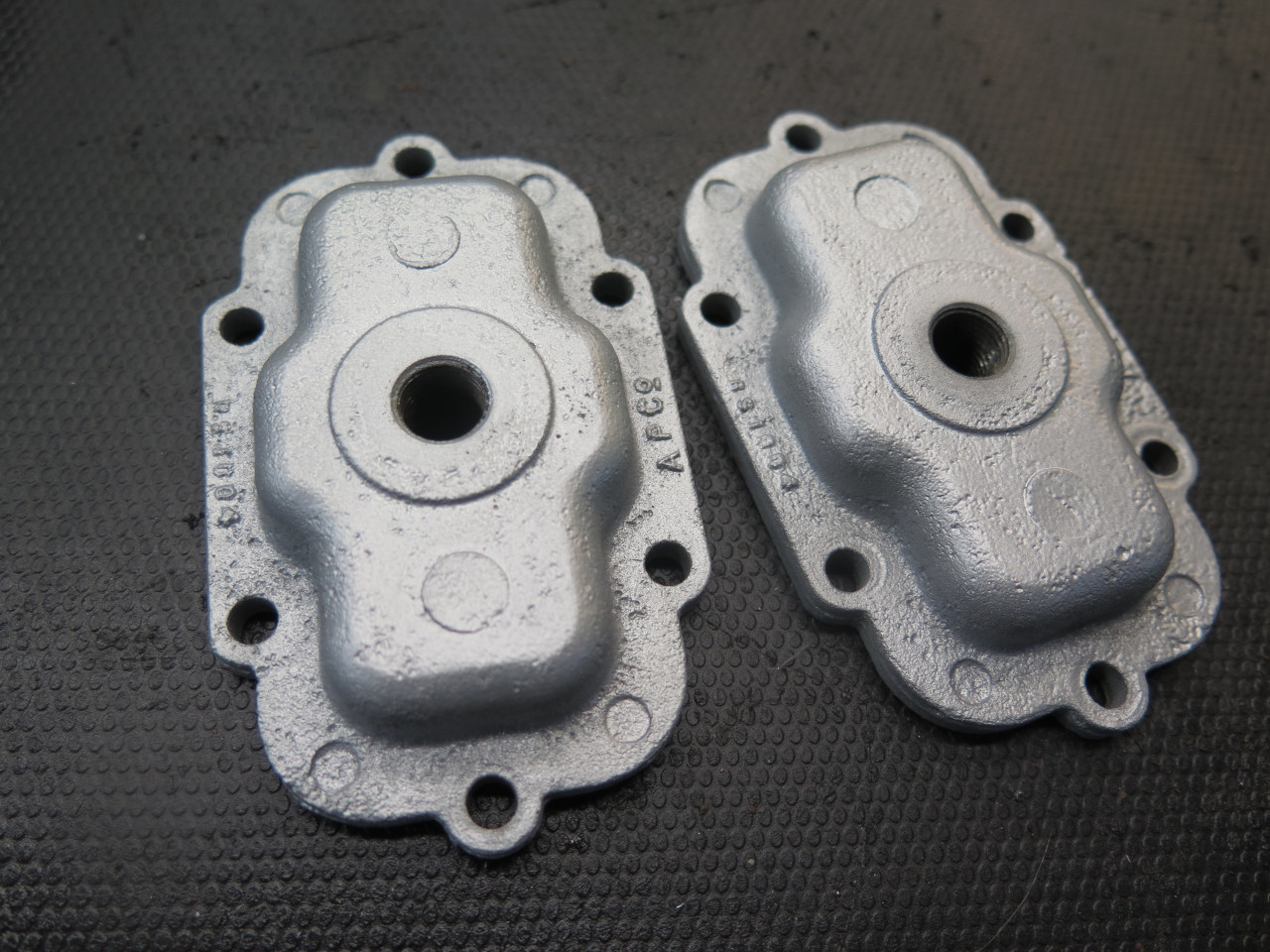

The top covers got powder coated and the sealing surfaces linished

flat. The corrosion pitting bothers me some, but I just hae to

tell myself it doesn't affect function.

The cover screws looked pretty bad, so I decided to replace them.

They looked to be 10-32, but aren't. Then I assumed they were

M5-0.8. They aren't. Finally, I realized that they are 2BA. I

could have ordered some, but by that time, it seemed quicker to just

clean up and re-plate the originals.

The covers had rubber gaskets, but I didn't have any appropriate rubber

material. I knew that Armstrong also often used thin cork for

gaskets, which I did have, so I made a couple of new cork gaskets.

The fill plugs also got plated and freshly annealed aluminum seal

washers.

By that time, I had everything I needed to refill the dampers.

This seemed like a hydraulic application, so I used a good hydraulic oil

that is in the viscosity range of SAE 20 weight oil. Many people

recommend motorcycle fork oil, but since that is also a hydraulic

application, I assume it is actually hydraulic oil, too.

Adding oil and exercising the arm until the action was smooth and there

were no more bubbles, I topped her off, and popped on the cover. I

hung them upside down for a while to try to coax leaks. I failed.

Since this car has been molested before--by me, for one--not too many of

the original fasteners are left on it. By some happenstance, the

damper fasteners were an exception. They had the depressed

circular marking on the heads that are characteristic of British

fasteners of the period. I try to preserve them whenever I find them.

Last up were the damper links. These were surely replaced in my

70s work, and appeared to still be in fine shape. Partly because

of my trust issues with modern aftermarket parts for these cars, I

decided to re-use them.

Ready to go on the car...

While the corrosion pitting on these still makes me sad, I'm pretty

confident that they are in good working order. I'll get over

it.

Cost for this work was essentially zero, just some consumables.

Comments to Ed at elhollin1@yahoo.com

To my other MGA pages