To my other MGA pages

March 27, 2025

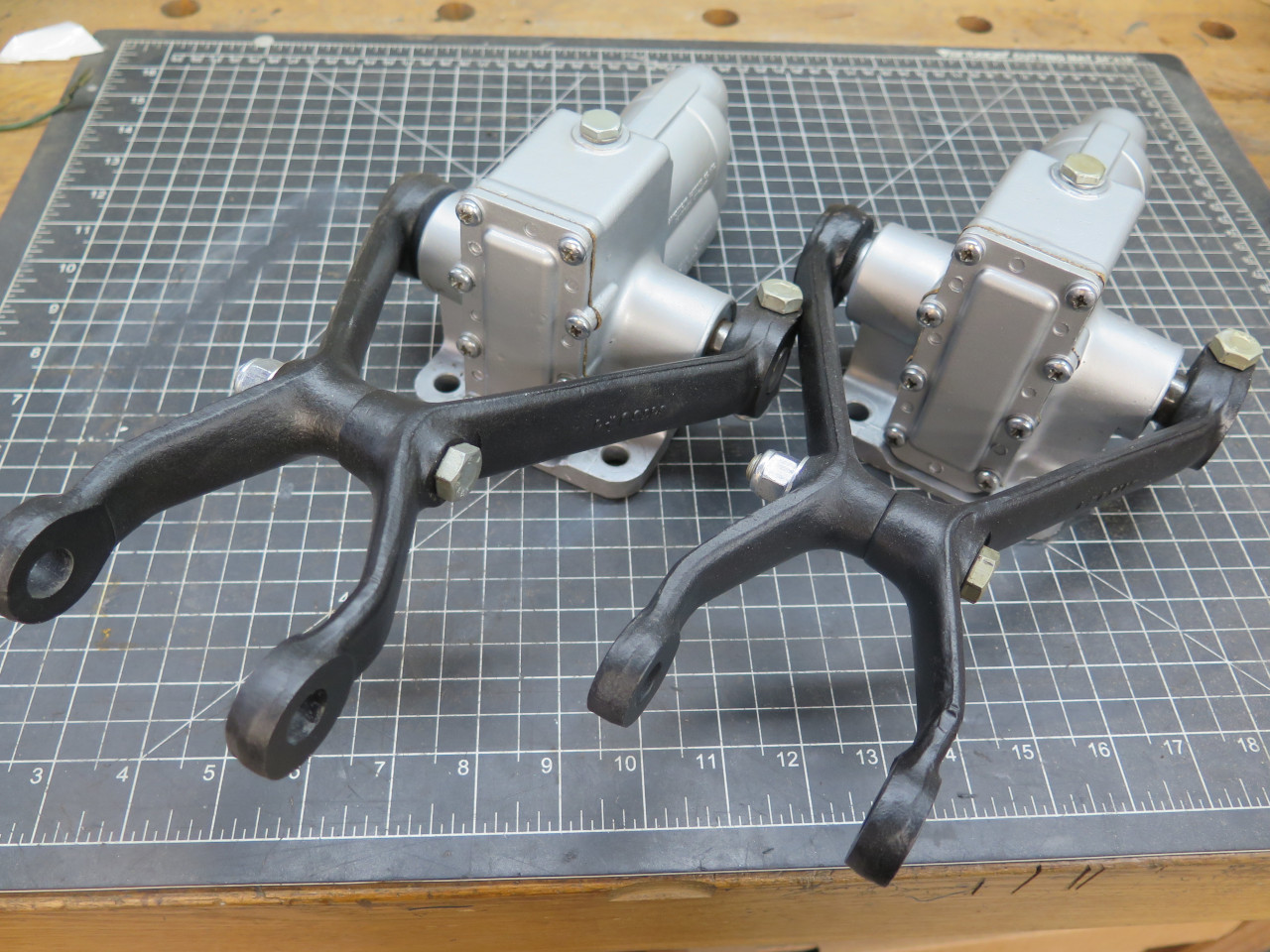

Front Dampers

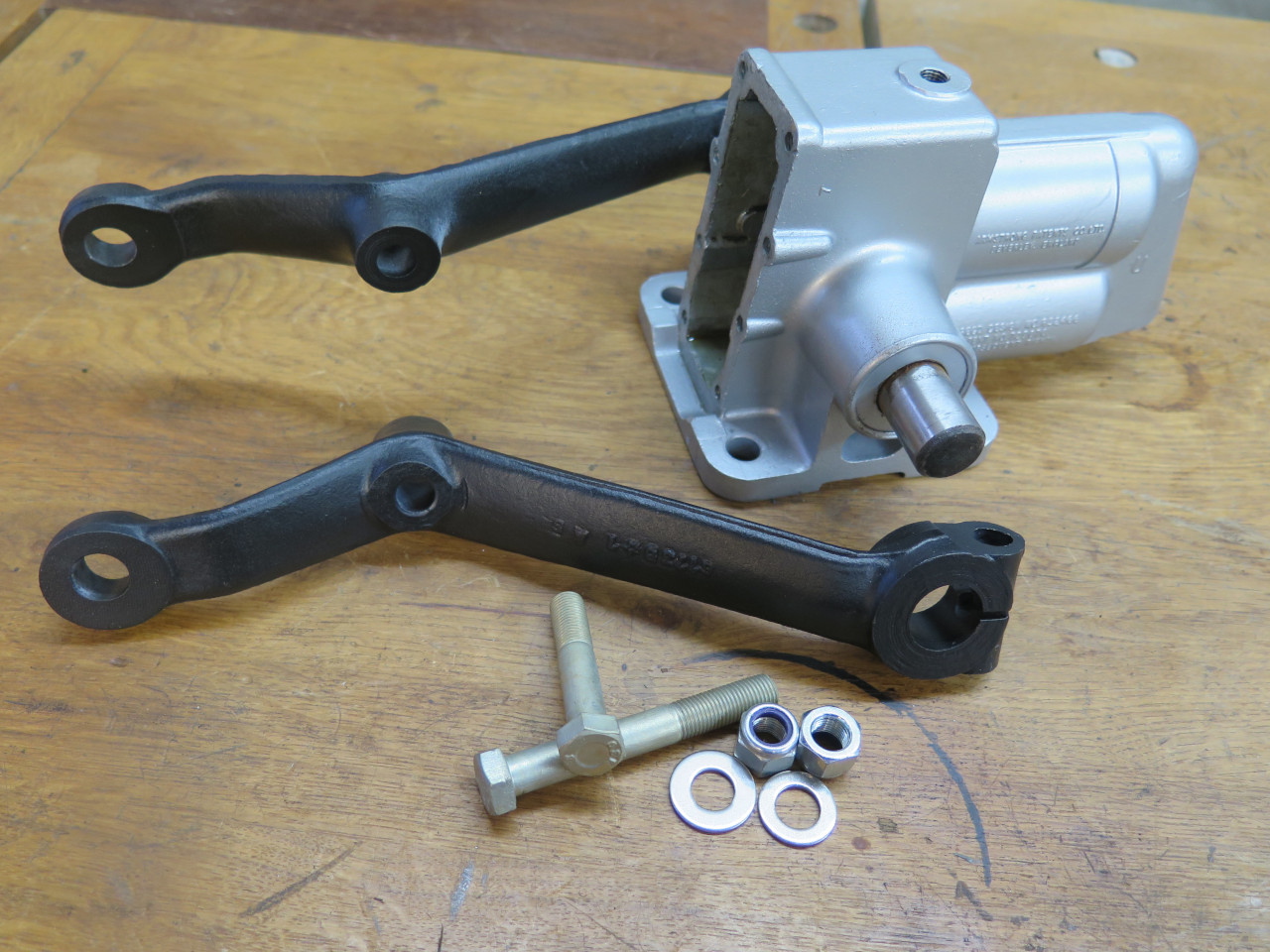

The MGA front suspension is a bit unique in that its damping is provided

at the upper A frame pivot. The damper body is fixed to the

frame, and includes a horizontal shaft whose rotation is damped by a

pair of linked pistons riding in two horizontal bores. Arms fixed

to either end of the shaft form the suspension's upper A arm.

Hydraulic oil is forced back and forth between the cylinders with

rotation of the shaft. Restrictions in the oil passage determine

the amount of damping on bump and rebound.

I knew that I had replaced the dampers on this car in the early 70s, and

that they had probably less than 1000 miles on them before I put the

car in to storage in 1975 or so. So, I hoped they would still be

in reasonable shape. They were pretty dirty, but there was no

evidence of leaking.

I resisted the urge to completely disassemble these units. First,

it isn't easy. Second, there would be a real risk of damaging

something. And third, there didn't seem to be any good reason to

take them apart. So I stifled my natural impulse and limited my

work to easy stuff. One of the arms comes off easily, and makes

cleaning easier. I painted the bodies a nice silver, and the arms a

tasteful satin black. I considered powder coating them, but I

wasn't sure that there wasn't something inside that would be harmed by

the curing temperatures. I'm not sure if the cork cover gasket is

available anywhere, but It was pretty quick to just make one.

The arm hardware got stripped, replated, and chromated.

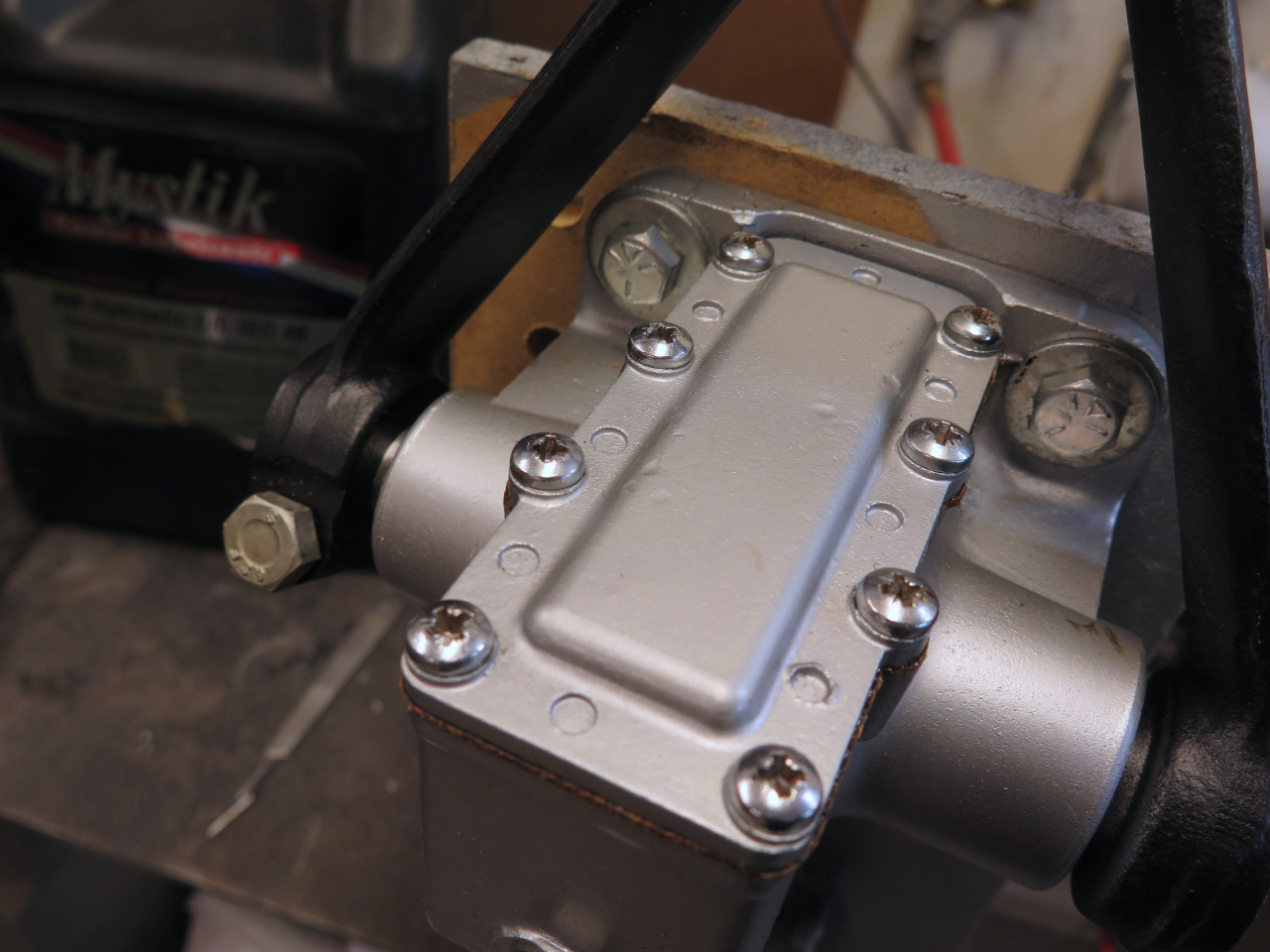

The valving assembly was just cleaned and re-installed as I found it,

but with a fresh O ring seal. In principle, one can adjust the

damping levels by messing with shims, springs, and that little adjusting

nut, but my style of driving doesn't warrant that kind of

distraction. I replated the hex part of the large screw.

Before painting, I had drained the old oil, which still looked very

good. After painting, I put in fresh oil. It was much

quicker and easier to fill the innards with the front cover still off,

and the opening facing up. Dampers are hydraulic devices, so a

hydraulic oil seemed appropriate. This is ISO 46 hydraulic oil,

which is in the range of 20 weight engine oil in terms of

viscosity. As I exercised the arms, the level would drop as the

internals got filled with oil. When I saw stable level and no more

bubbles, I called it full.

Then buttoned up the cover with the home made gasket but original screws.

Ready for Prime Time...

When the frame was ready, these dampers were the first thing to

install. But, in an unusual case of foresight, I realized that

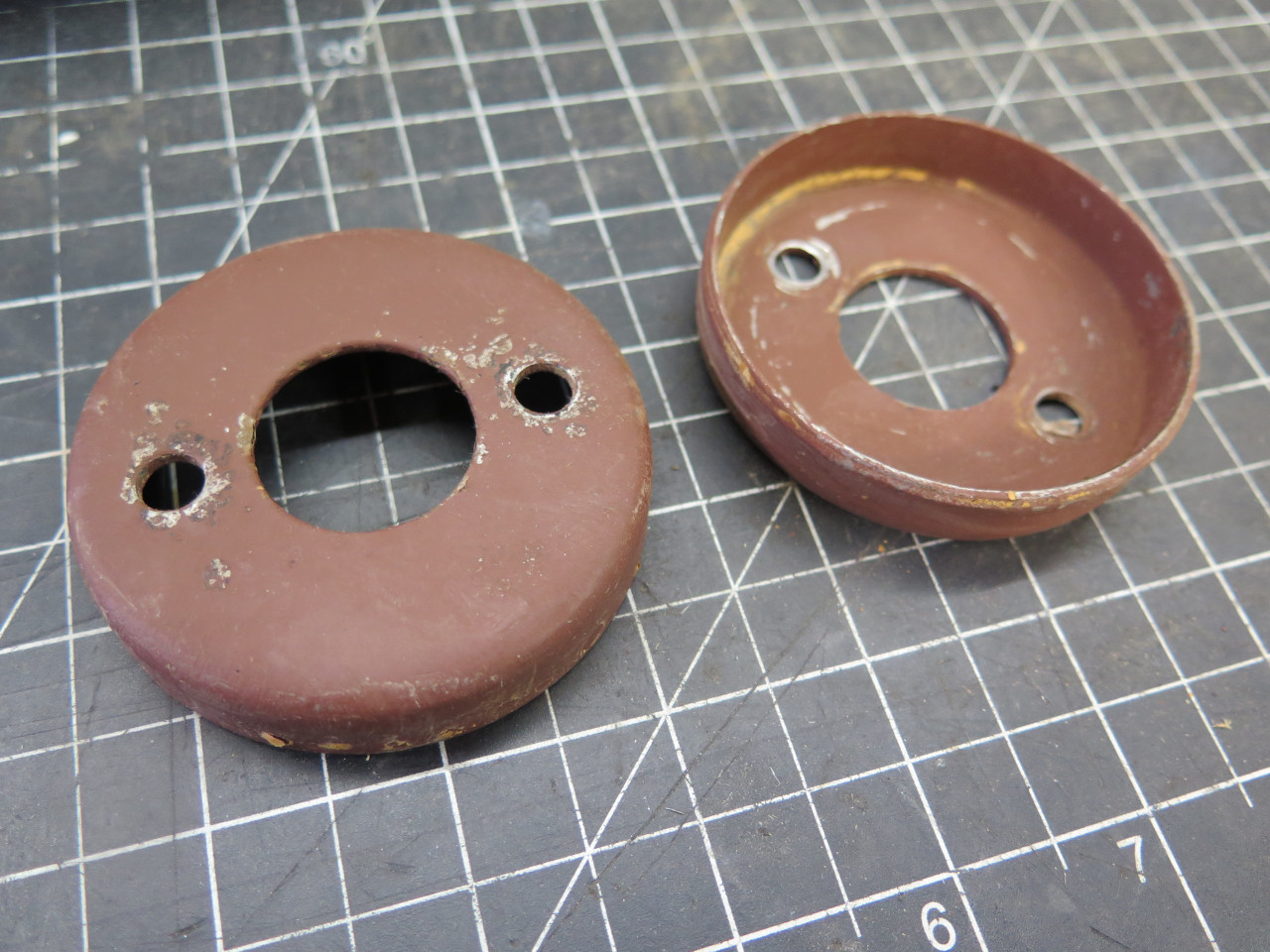

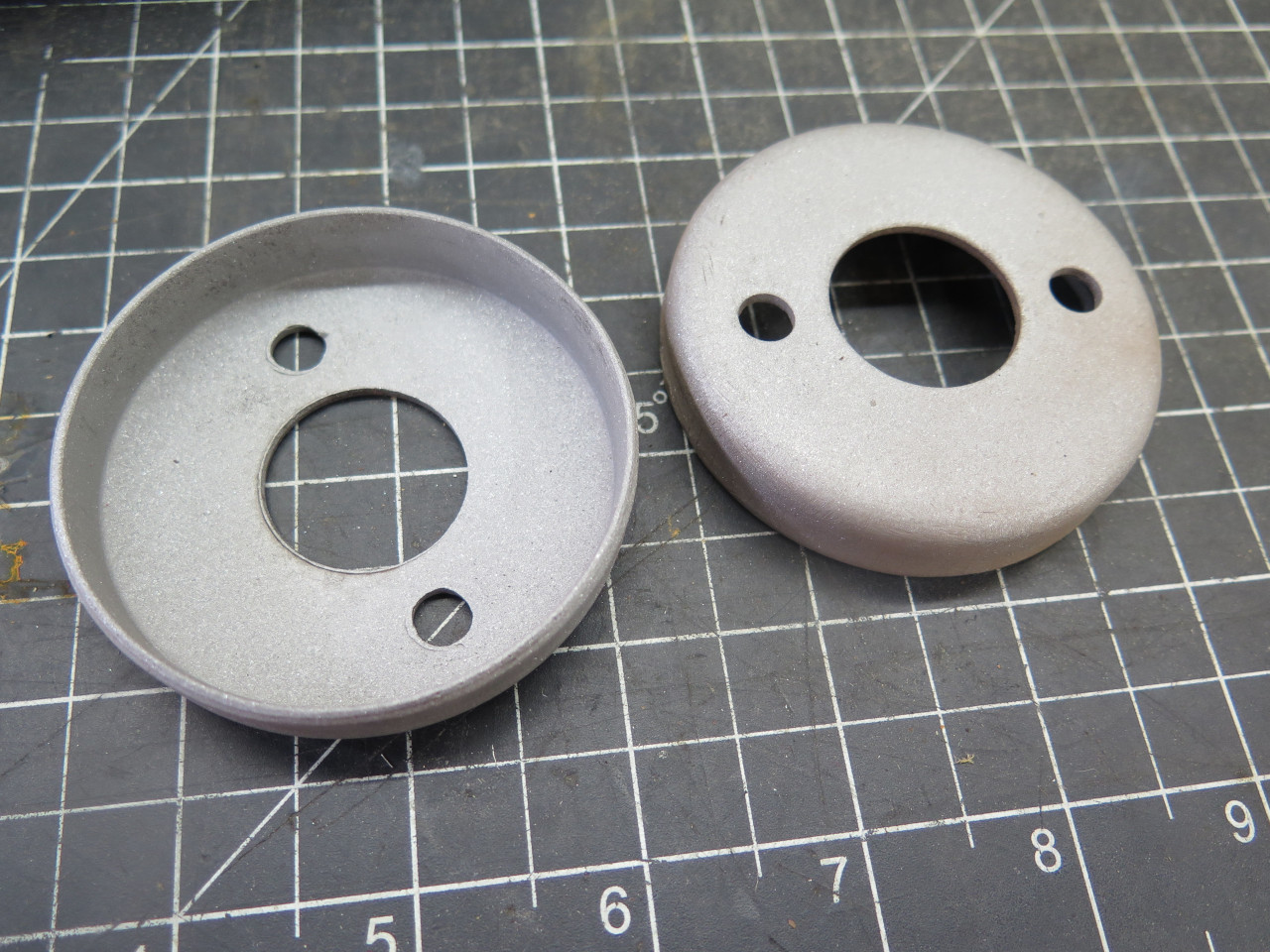

something else had to go in first. The factory apparently called

these little cups "spigots". They help locate and centralize the

top of the road springs. They were blasted and powder coated, and

got new hardware. Anywhere I can, I replace original split lock

washers and nuts with flat washers and lock nuts.

They went home in the spring towers.

I was able to save all of the original damper mounting studs. They

got zinc to protect the steel, and chromate to protect the zinc.

I usually chase threaded holes in the chassis before mounting

anything. Especially after painting with something like POR15,

which can foul threads.

The twins, ready to go to work.

Its forever home...

It feels good to start hanging things back on this car. This was a

pretty simple job, and cheap--no cost other than some consumables.

Comments to Ed at elhollin1@yahoo,com

To my other MGA pages