To my other MGA pages

July 20, 2024

Body Rotisserie

Like my two previous LBC retirement projects, this will be a "Frame Off" restoration. (Shouldn't it really be "Body Off?)

First thing to do, at least on a roadster, is brace the door

openings. The doors actually fit pretty good before I started this

exercise, and I wanted top preserve that. The internal sill

construction is pretty strong when in good shape, but I thought it was a

worthwhile precaution anyway.

After disconnecting or removing everything I could think of that bridged

the body and frame, and removing all the body fasteners, I thought I

was ready. I started by gently lifting one side with a floor

jack. I put 1/2" spacers under each mounting point until the body

was a couple of inches above the frame. I had to remove the fuel

tank, since the filler neck was interfering with the lift.

All seemed well, so I proceeded to prepare for the body removal.

I'm using an engine hoist type crane as a sky hook, so I built a

makeshift wood lifting frame to interface the single lift point to the

body. It essentially takes and cancels all of the horizontal

forces so that the body only sees vertical lifting force.

And up she went...

Moved the chassis to its home for the next few months...

...and set the body on some temporary dollies to make it easier to move around.

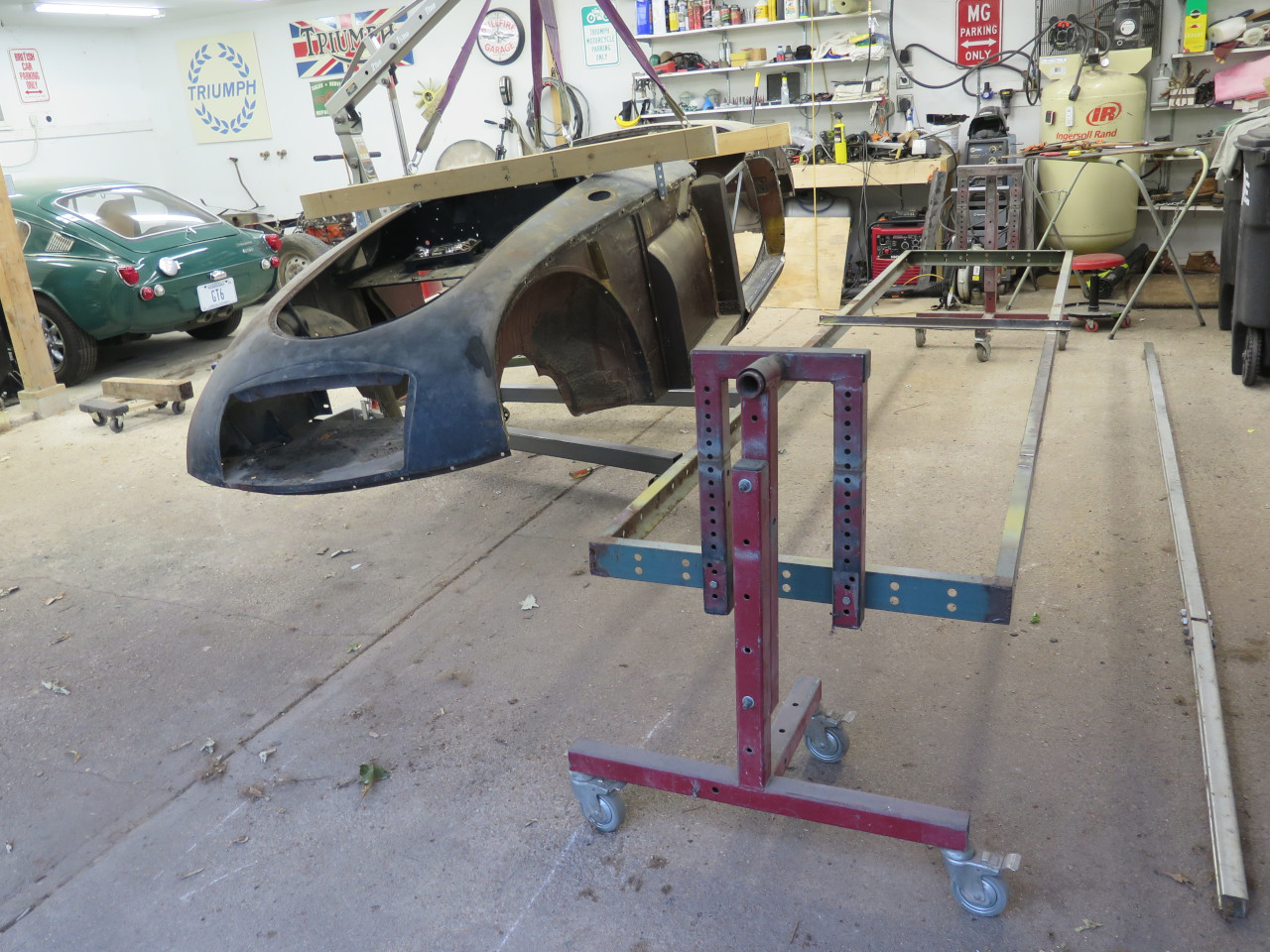

As with my previous cars, I'll put the body on a rotisserie to simplify

access. My rotisserie has a platform that serves as a surrogate

frame for the body to rest on. While on the rotisserie, the body

is firmly supported at most of the same points its used to. This

is the platform and the standards that it mounts to. They used to

be a nice uniform color.

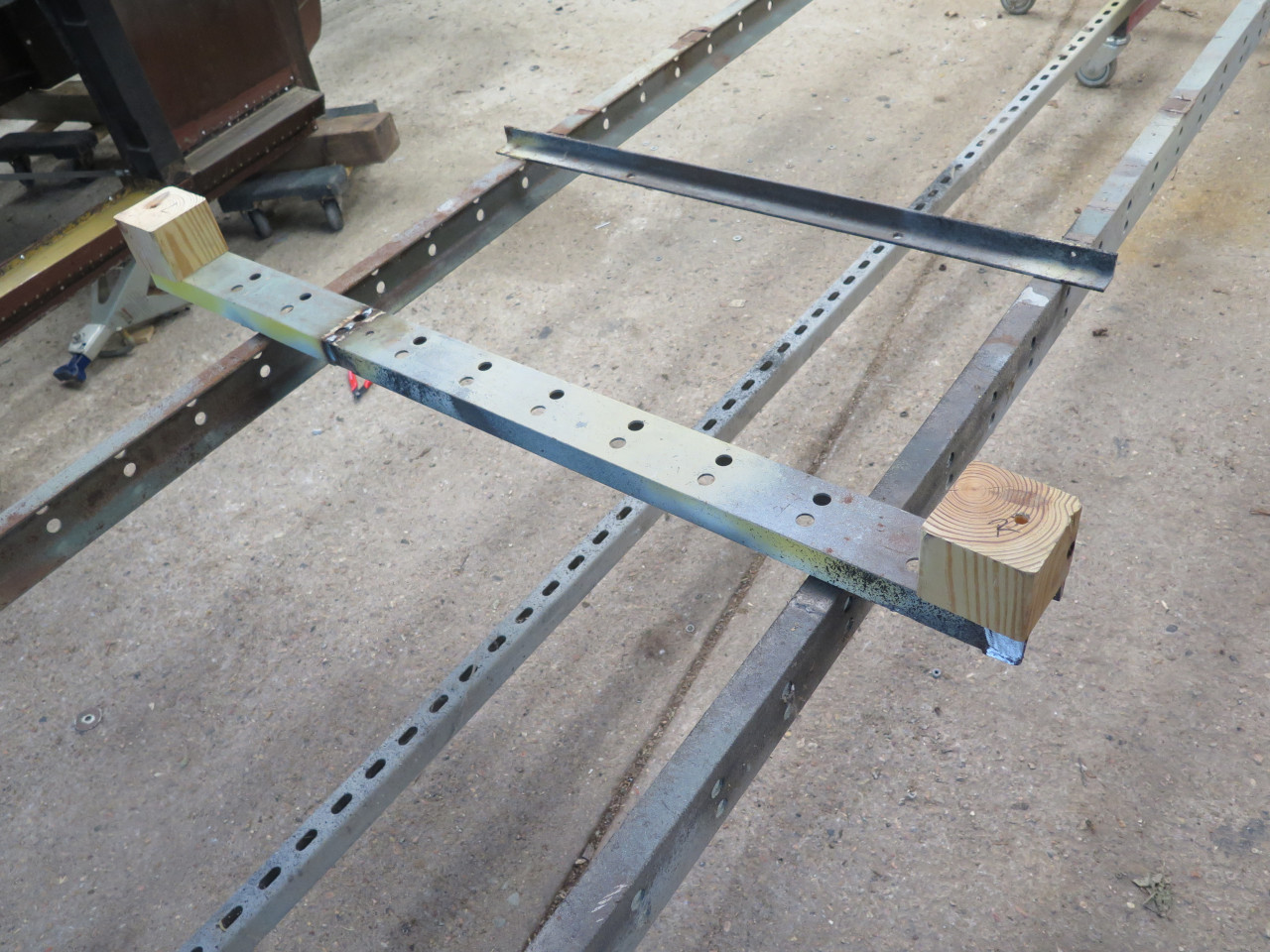

The platform of course has to be adapted to provide mounting points for

the body. I made a crossmember to fit the mounting brackets in the

cabin area. I use wood spacers so that I can remove them one at a

time to blast or paint under them. The crossbar won't get welded

to the platform until the body is in position.

Lifting onto the rotisserie...

After the body is positioned correctly and the main crossmember is

welded to the platform, the other supports, adapted from previous

supports, are fitted and welded in. They have wooden spacers too.

All secure, and she tilts.

However, the sills fouled the stretcher bar of the rotisserie, so the

body would't rotate 360 degrees. This was anticipated, and I just

has to raise the adjustable standards by four inches.

The next problem was that the rotating assembly was very bottom heavy,

so it was quite a chore to rotate it. I had misjudged the center

of gravity because I neglected to account for the weight of the

platform. Another adjustment, and all was good. I want it to

be slightly bottom heavy, but not too hard to turn.

The rotation is also a requirement for another reason. My home

manager allows me to work on my cars in the garage during the day, but

neither of our daily drivers is permitted to spend the night

outside. It was in our wedding vows. Space is tight, but

tipped up sideways, there's room.

After all this preparation, it will be nice to finally do some metal work.

Comments to Ed at elhollin1@yahoo.com

To my other MGA pages