To my other MGA pages

January 25, 2025

Oil Pump

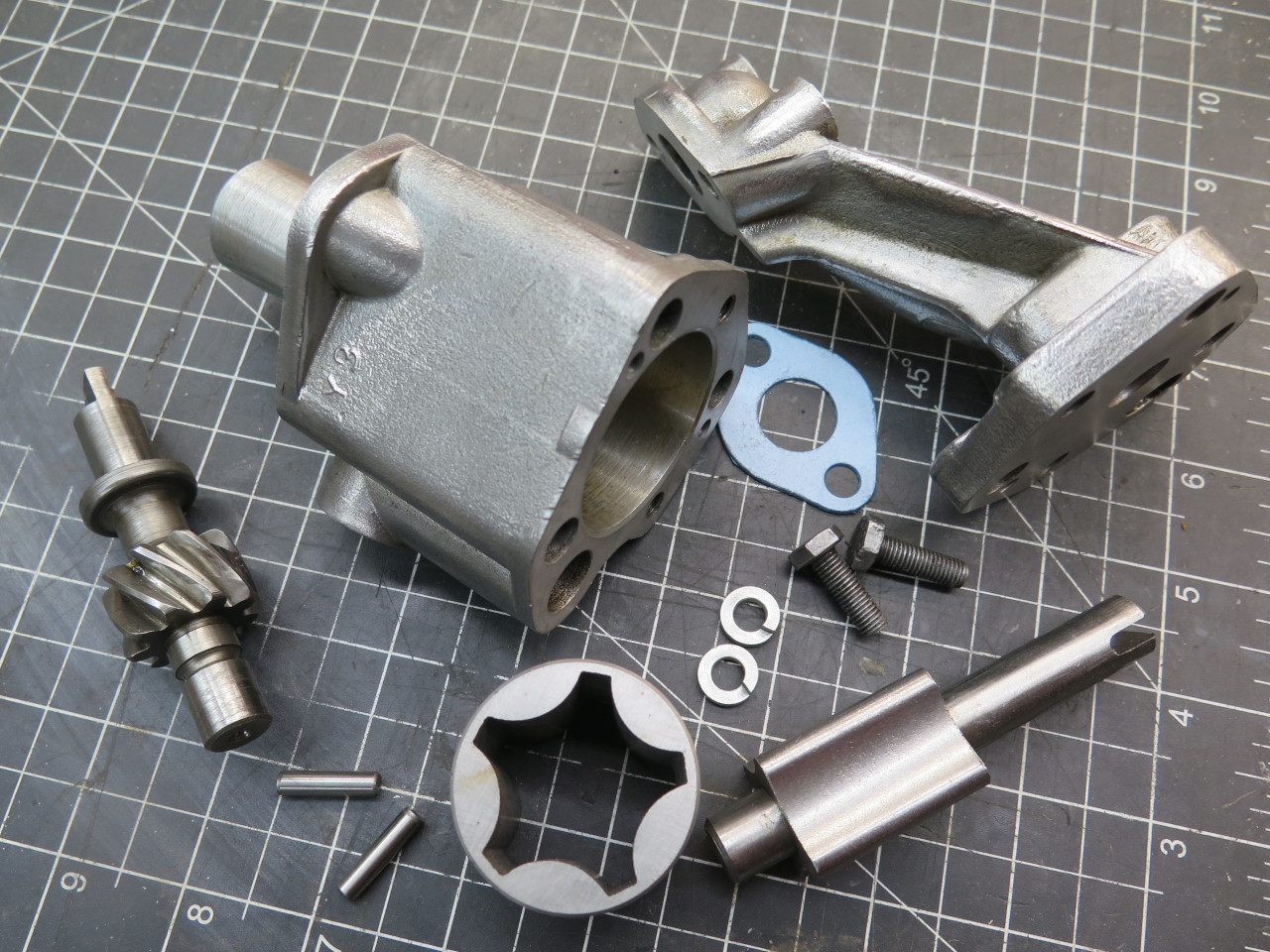

The MGA used a gerotor type oil pump that is ubiquitous in automotive

applications. It's a positive displacement pump that uses a four

lobed inner rotor meshed with a five lobed outer rotor. The

profiles of the rotors are such that the volume between the lobes

expands on one side of the pump, and contracts on the other.

Because the lobes are a very close fit, a suction is created on the

expanding side, and a pressure is created on the contracting side.

The housing is designed to expose the suction to the sump, and the

pressure to the oil distribution system.

My pump appeared to be is OK condition, with no obvious severe wear.

This is the early version of the MGA pump, and seems to be generally out

of favor with many enthusiasts. Reportedly, it's suction side is

relatively restricted, so that under some extreme conditions, including

high revs or hard cornering or braking, flow can be intermittently

interrupted. Since my driving style doesn't include any of those

things, I'm not going to stress about it.

However, since close tolerances are needed for efficient operation, I

want the pump to perform well. There are two measurements that

assess the pumps wear: The end clearance of the rotors, and the

clearance between the two rotors. Both of these should be around

0.005" or less,and both of mine were double that. So I ordered a

new rotor kit.

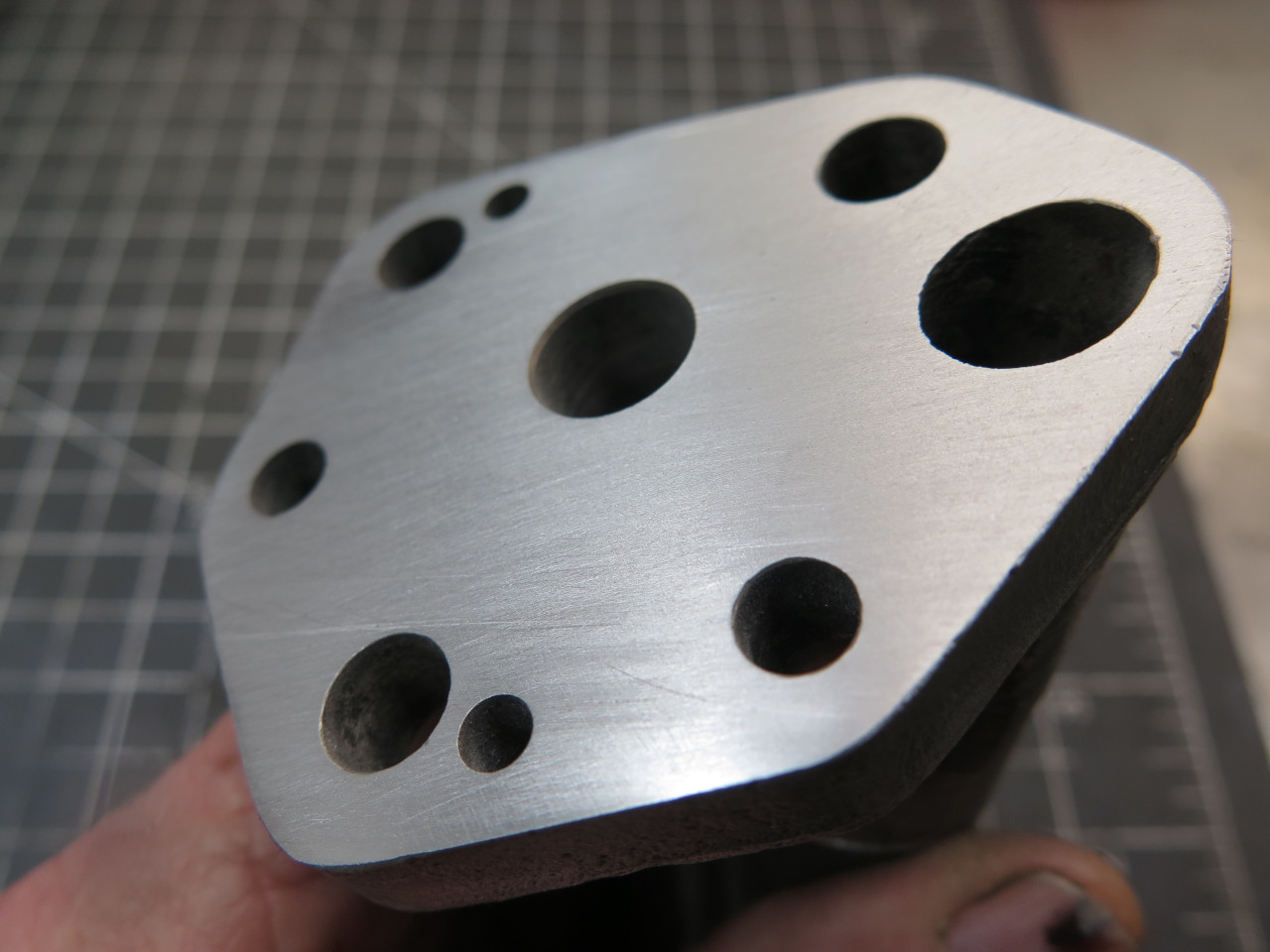

I also linished the body flat, which also tightens up the end clearance.

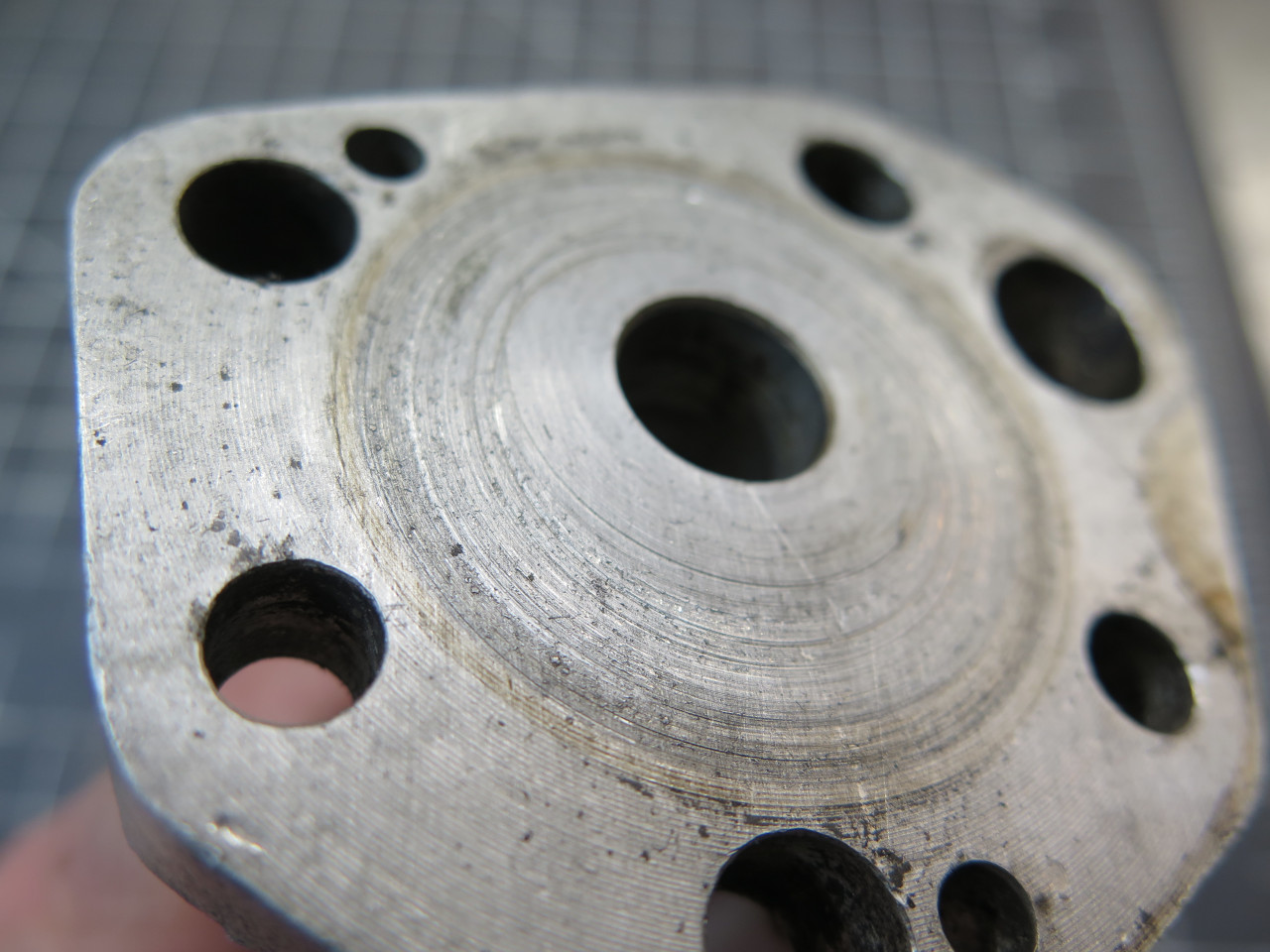

The mating face of the oil pickup assembly had some very noticeable

scoring. It seemed to me that this might have the same bad effect

as a loose end clearance, so I linished that flat, too.

And the lower end of the pickup tube for good measure.

Ready for assembly.

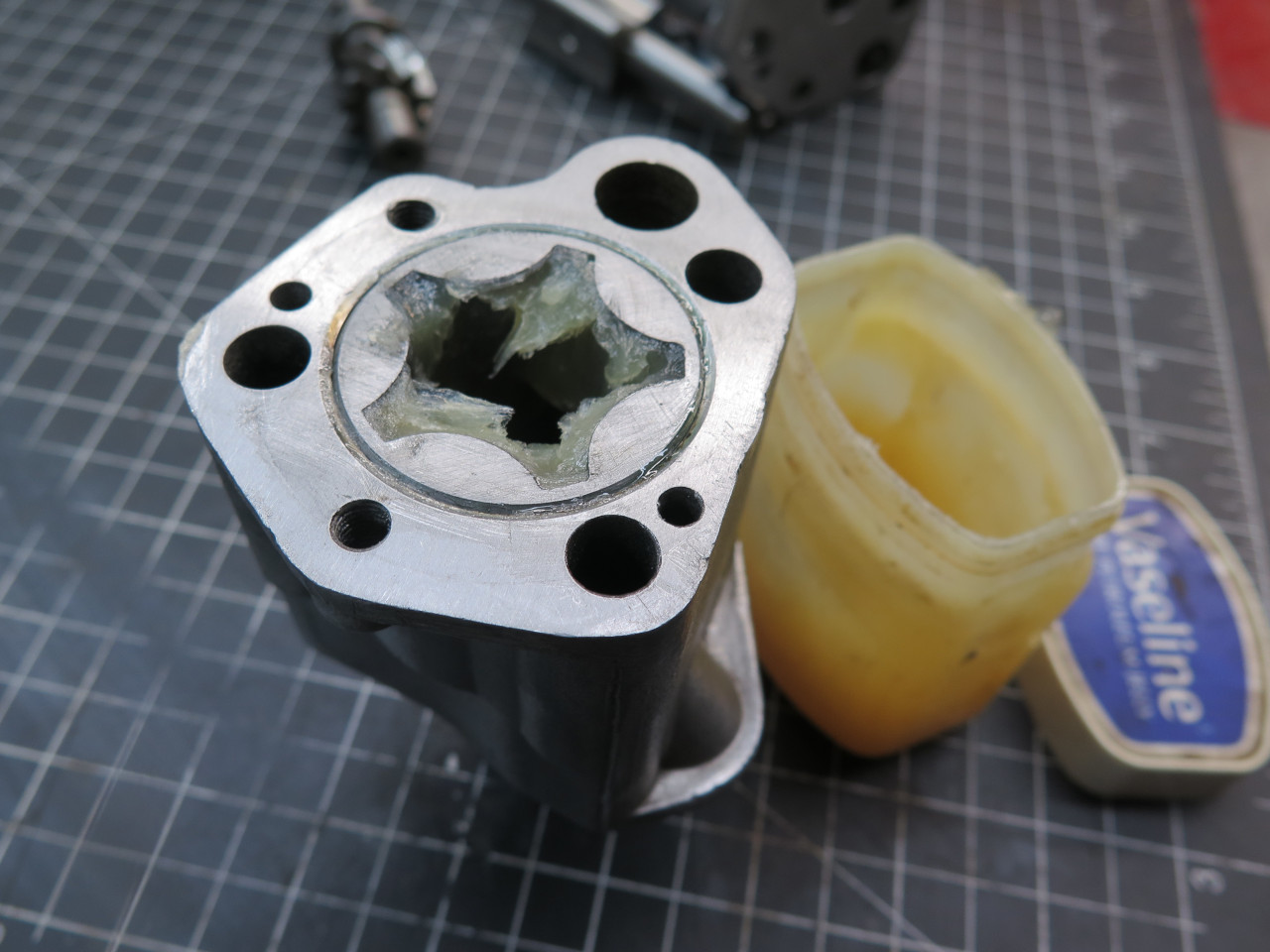

Loading the pump with petroleum jelly purportedly makes it prime quicker. The jelly dissolves in engine oil.

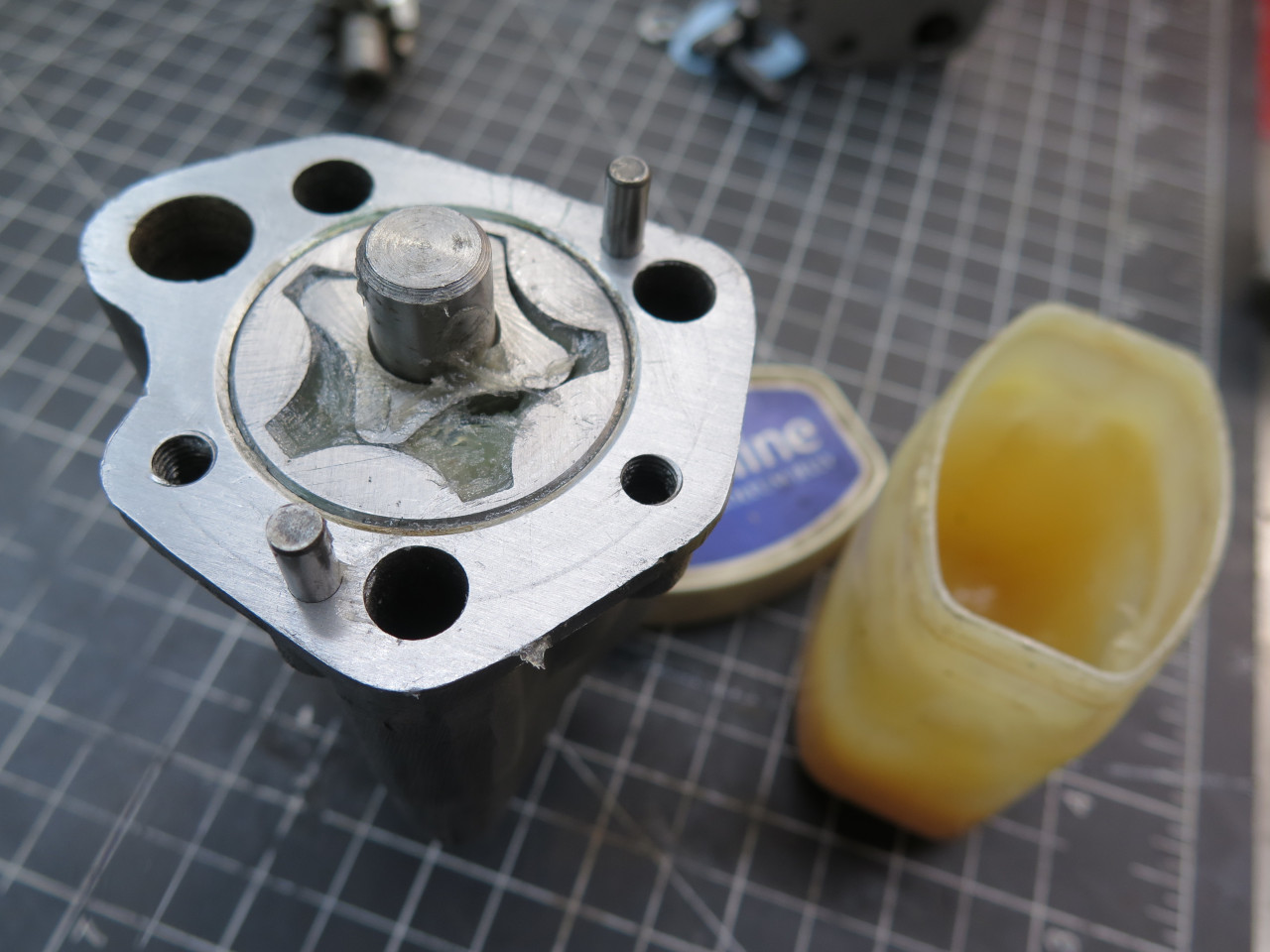

Almost forgot the new locating dowels. The originals didn't survive removal.

Moving parts seem to move smoothly.

Attached the pickup stuff loosely so nothing walks off.

This was a quick little project, but an important one. Cost was around $40 for the rotors and random hardware.

Addendum, February 10, 2024

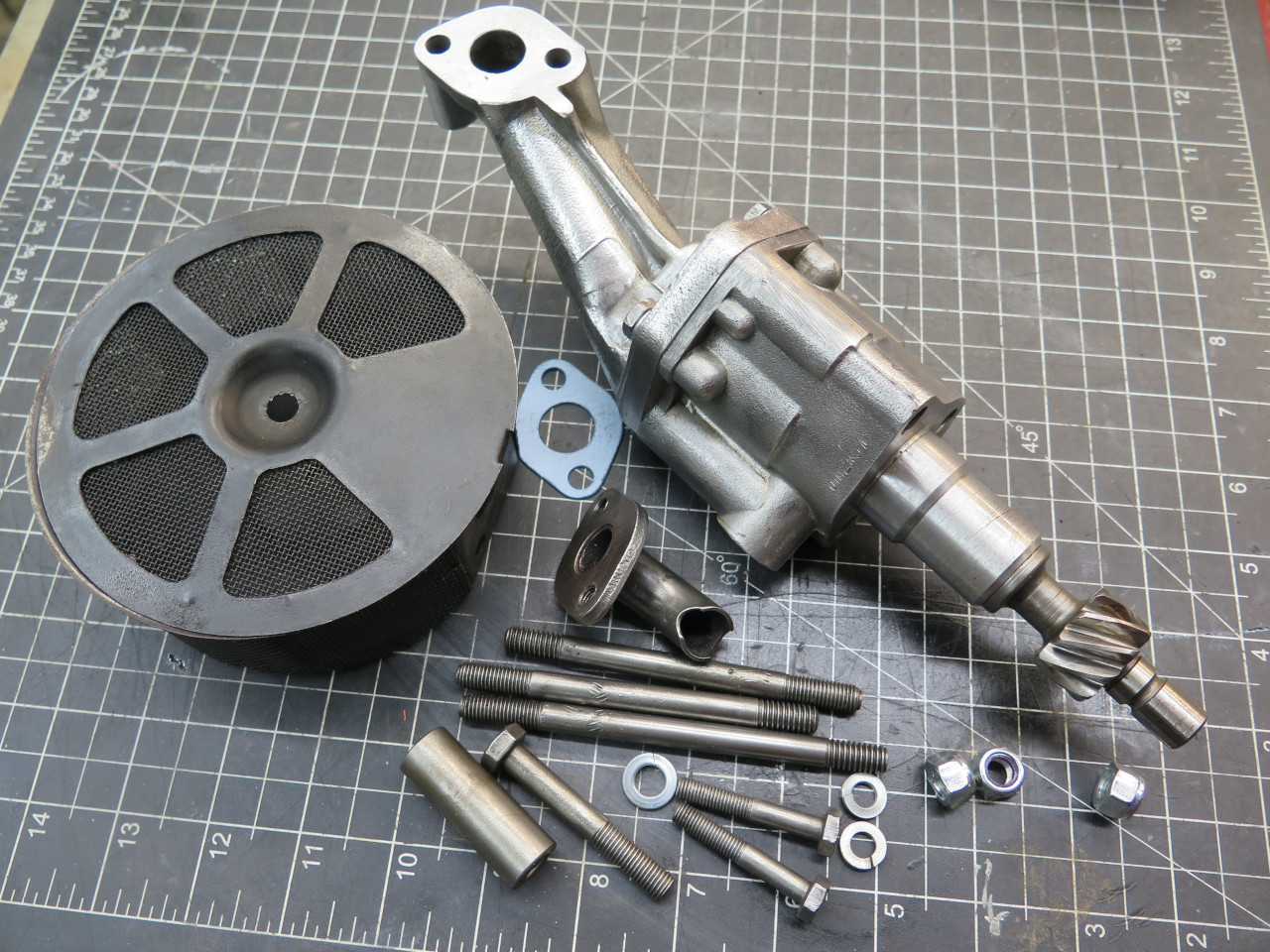

Well, due to some prodding from some online commenters, I reconsidered

my decision to use the stock pickup arrangement. Later pickups are

undeniably a better design, and I found that I could buy the parts

fairly cheaply on eBay.

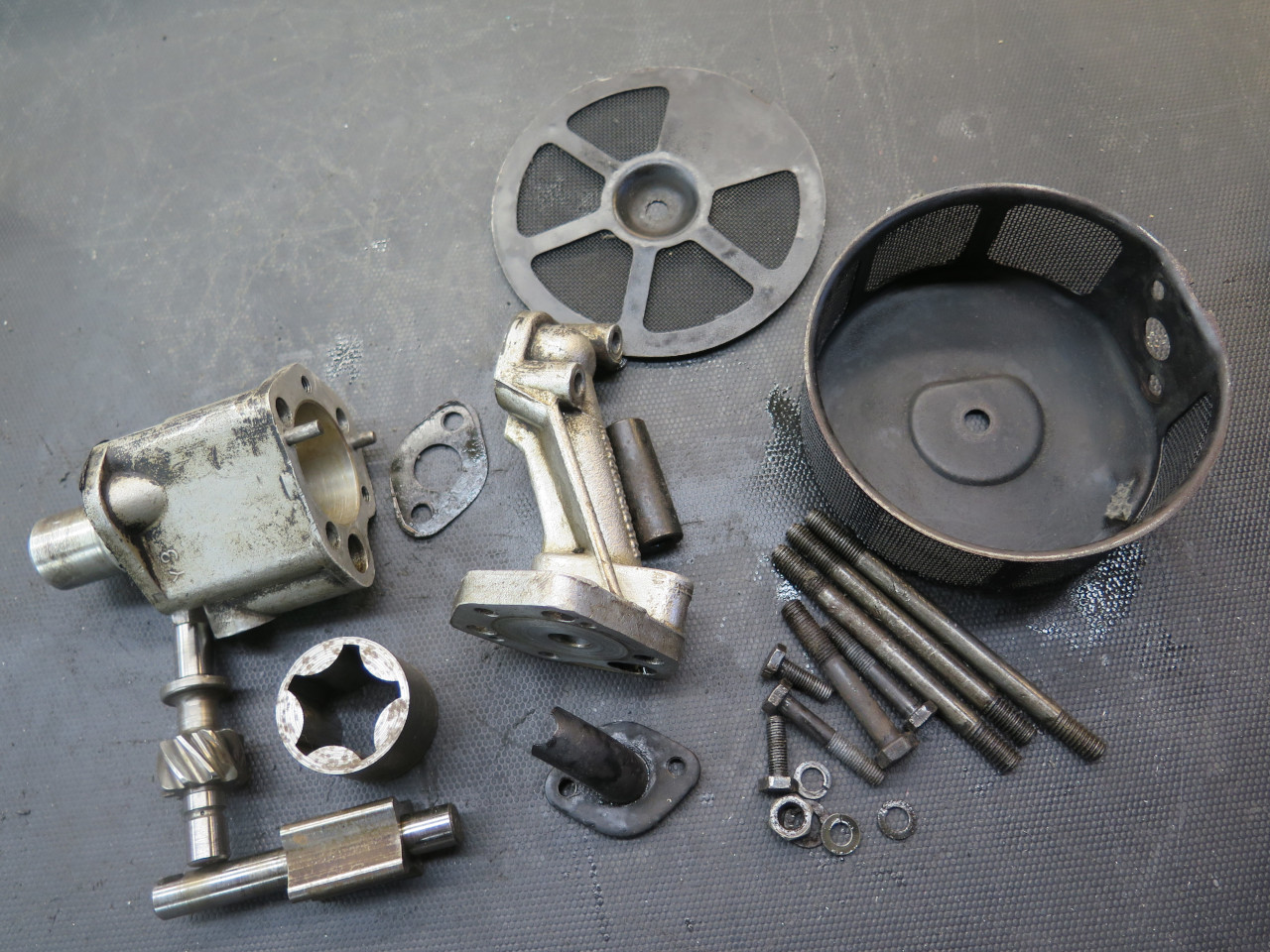

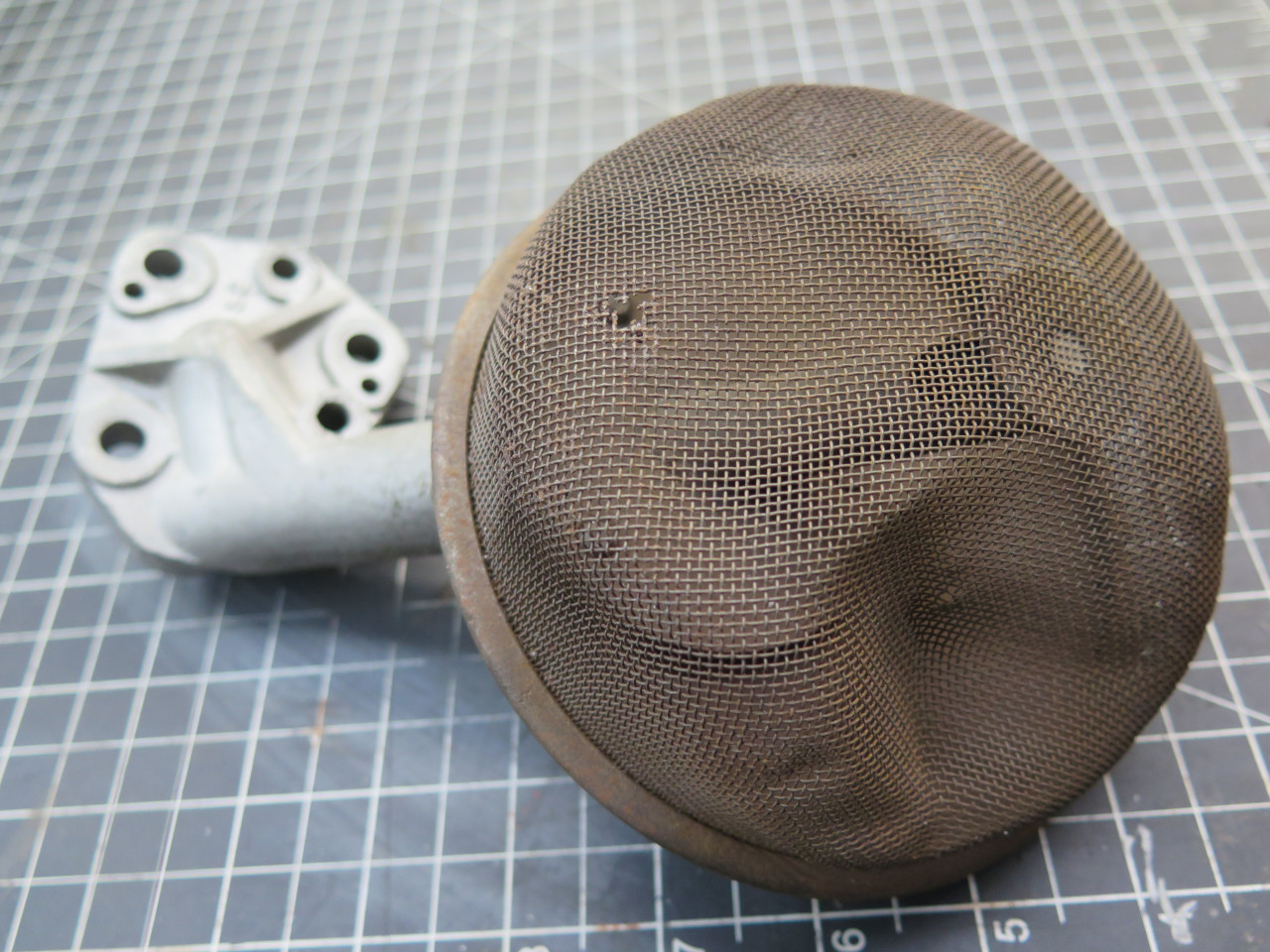

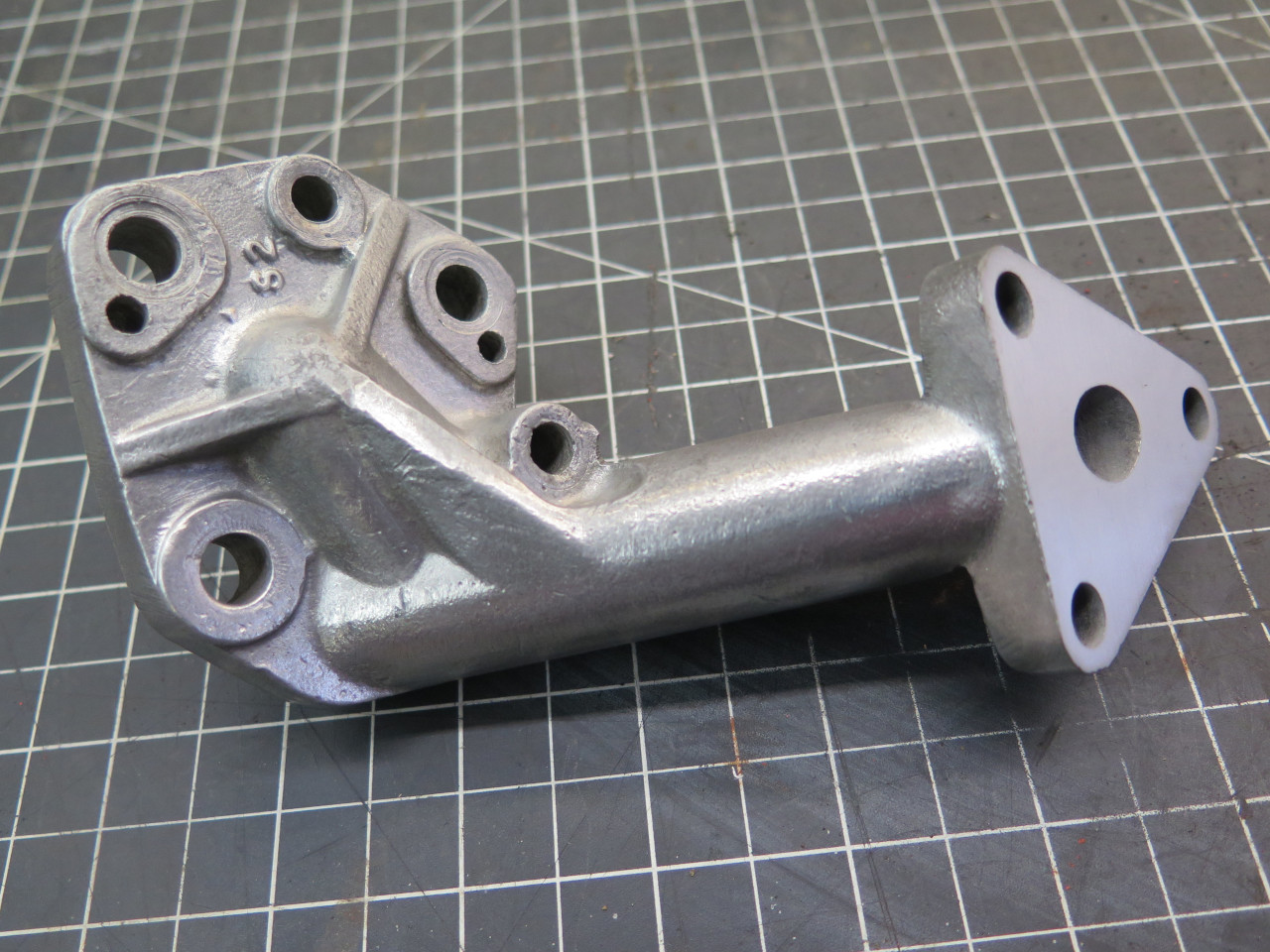

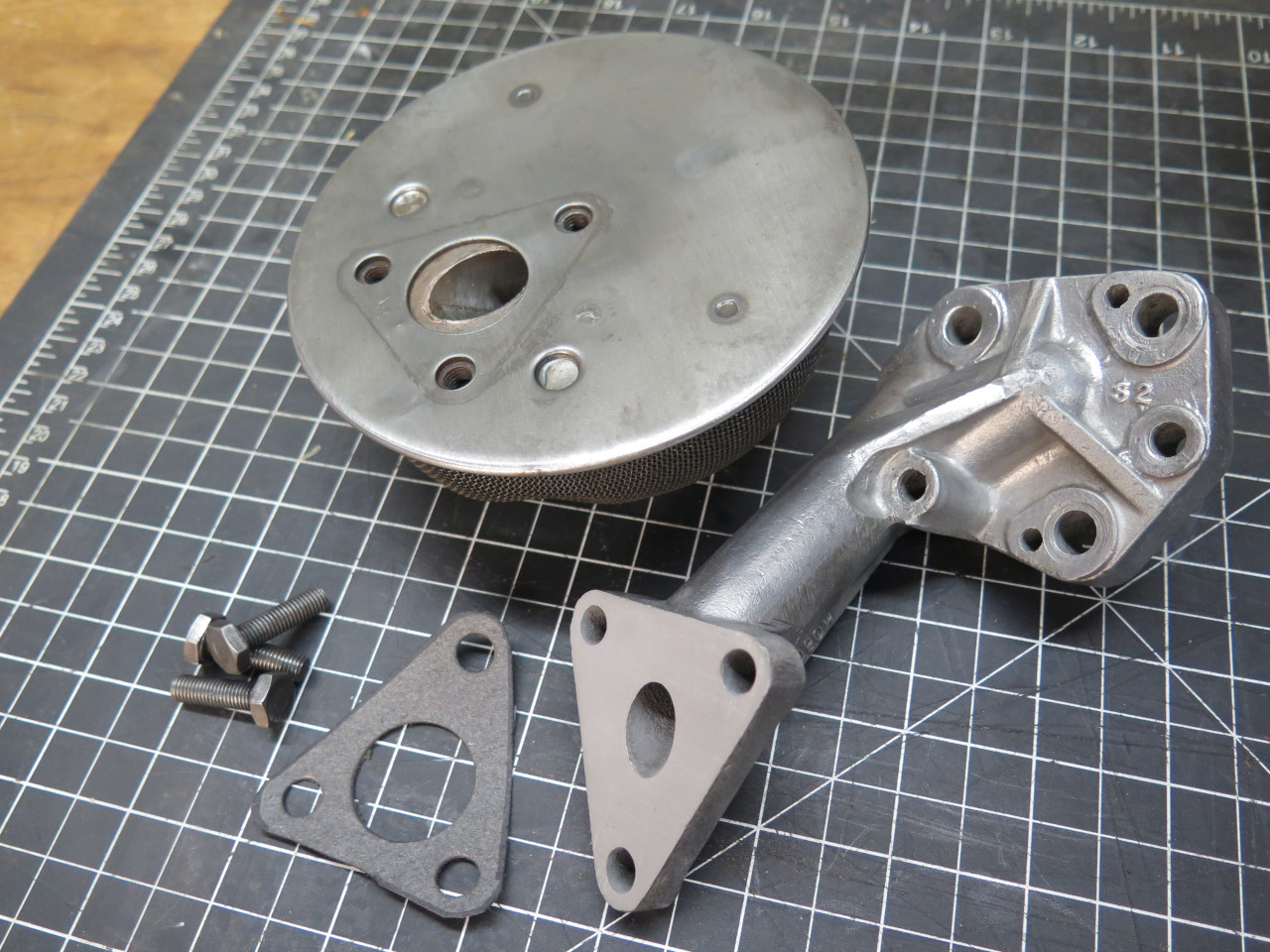

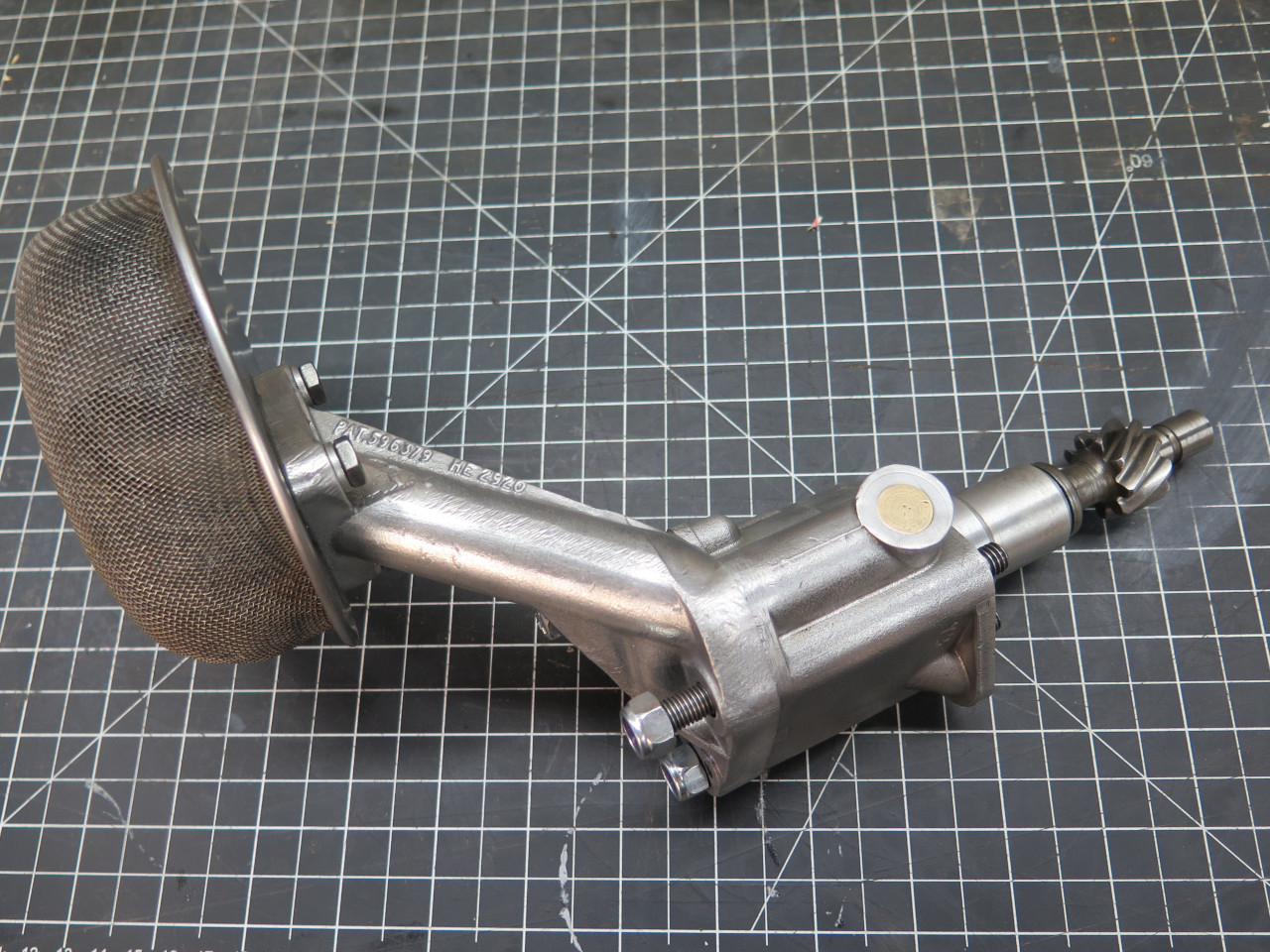

This is what eBay turned up.

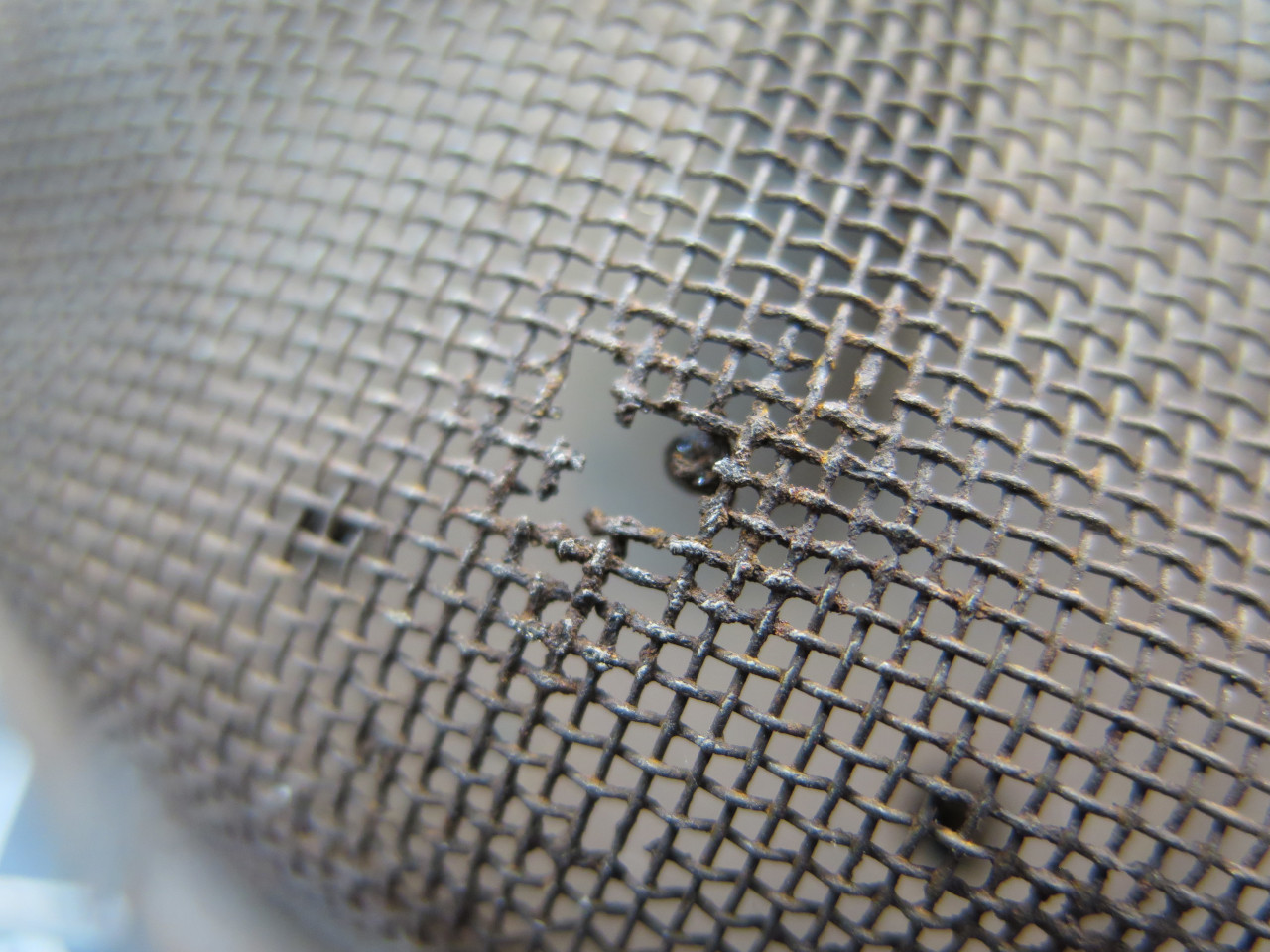

The aluminum casting was fine, and I could fix the dent in the screen,

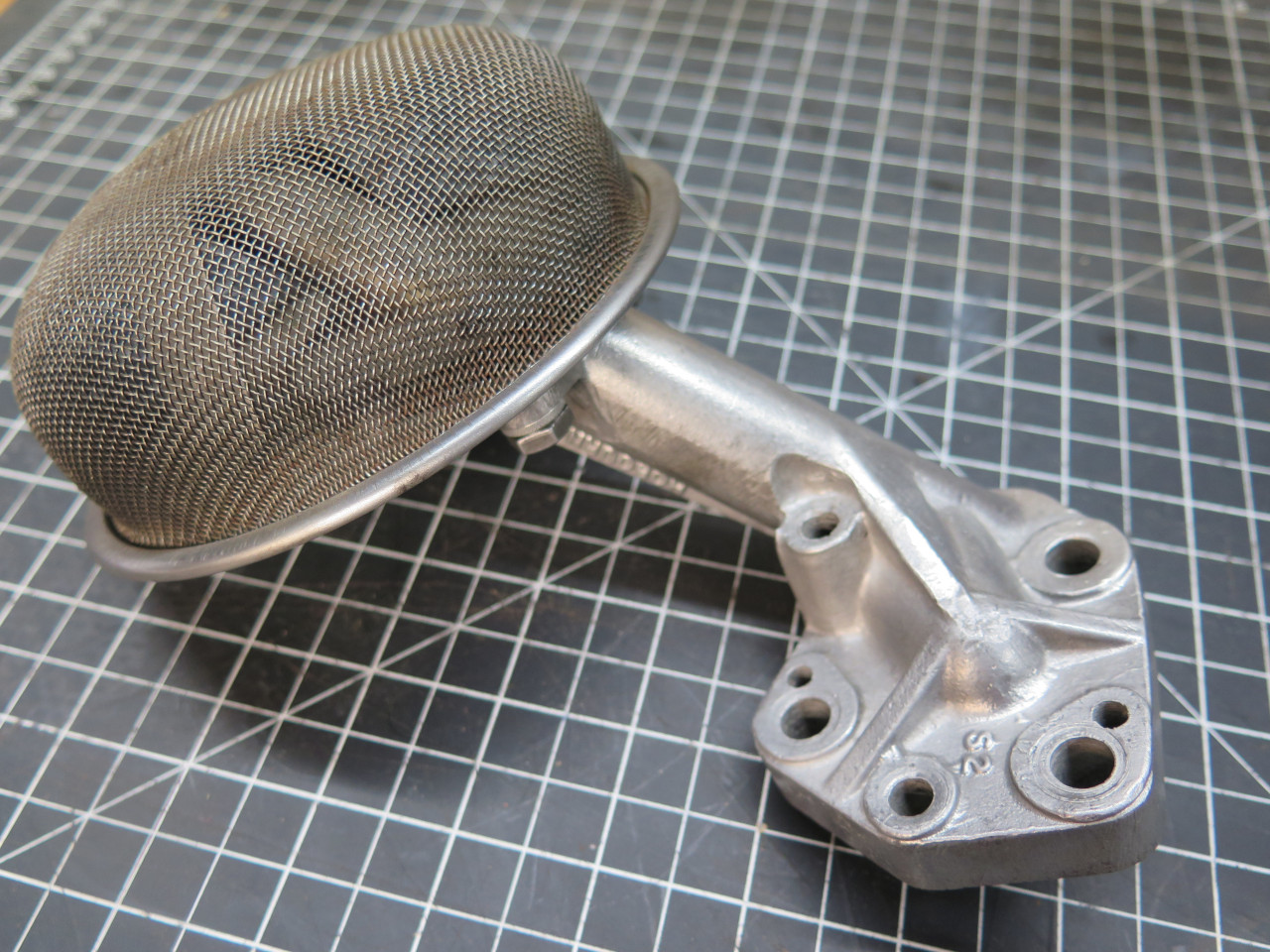

but there were other problems. The screen had holes in it,

apparently from corrosion.

I was actually more worried about the screen shedding bits of corroded

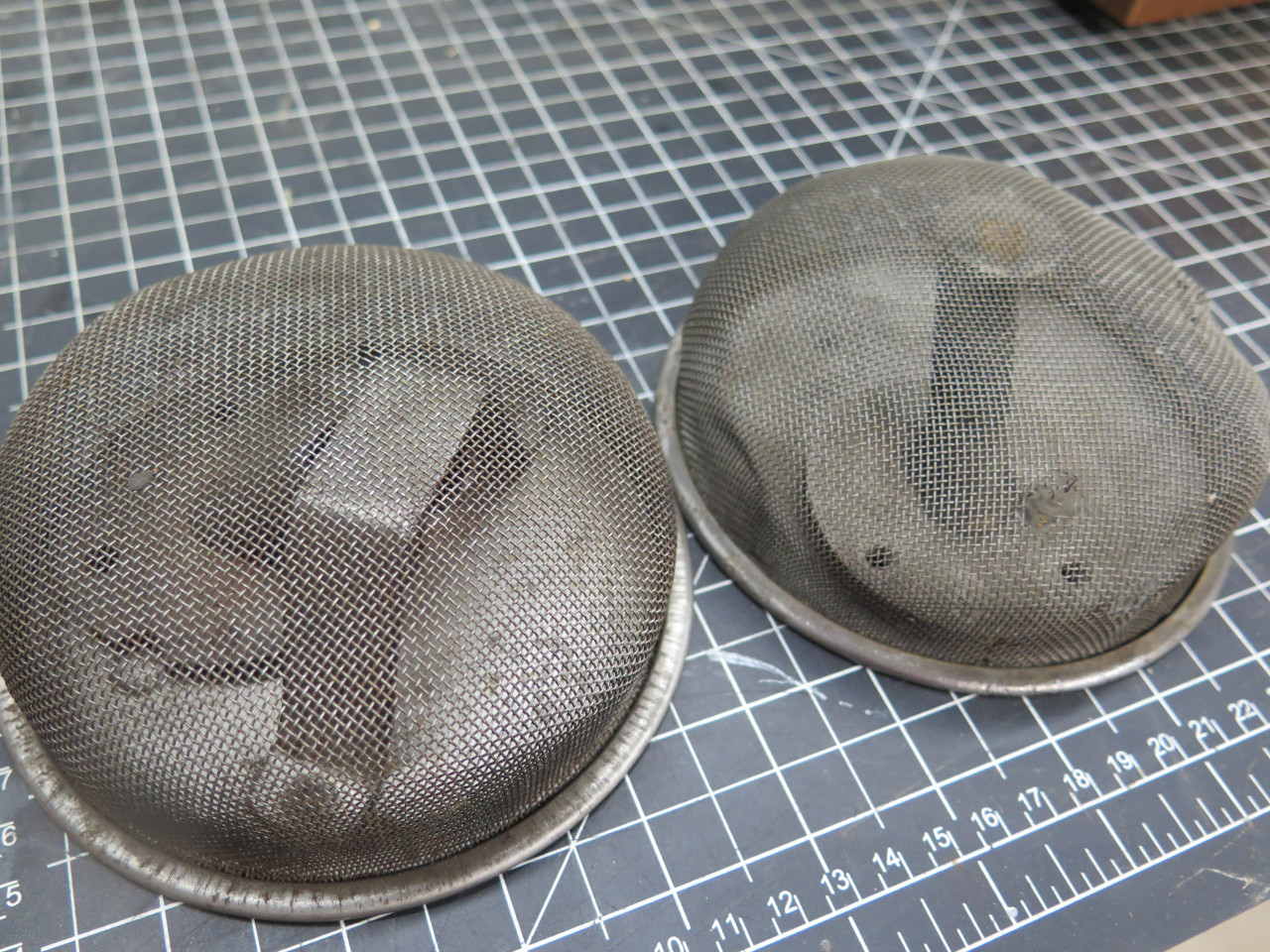

metal than the holes themselves. Back to eBay, where I found a

screen that was much better. The internal construction was a

little different, but it was a direct replacement.

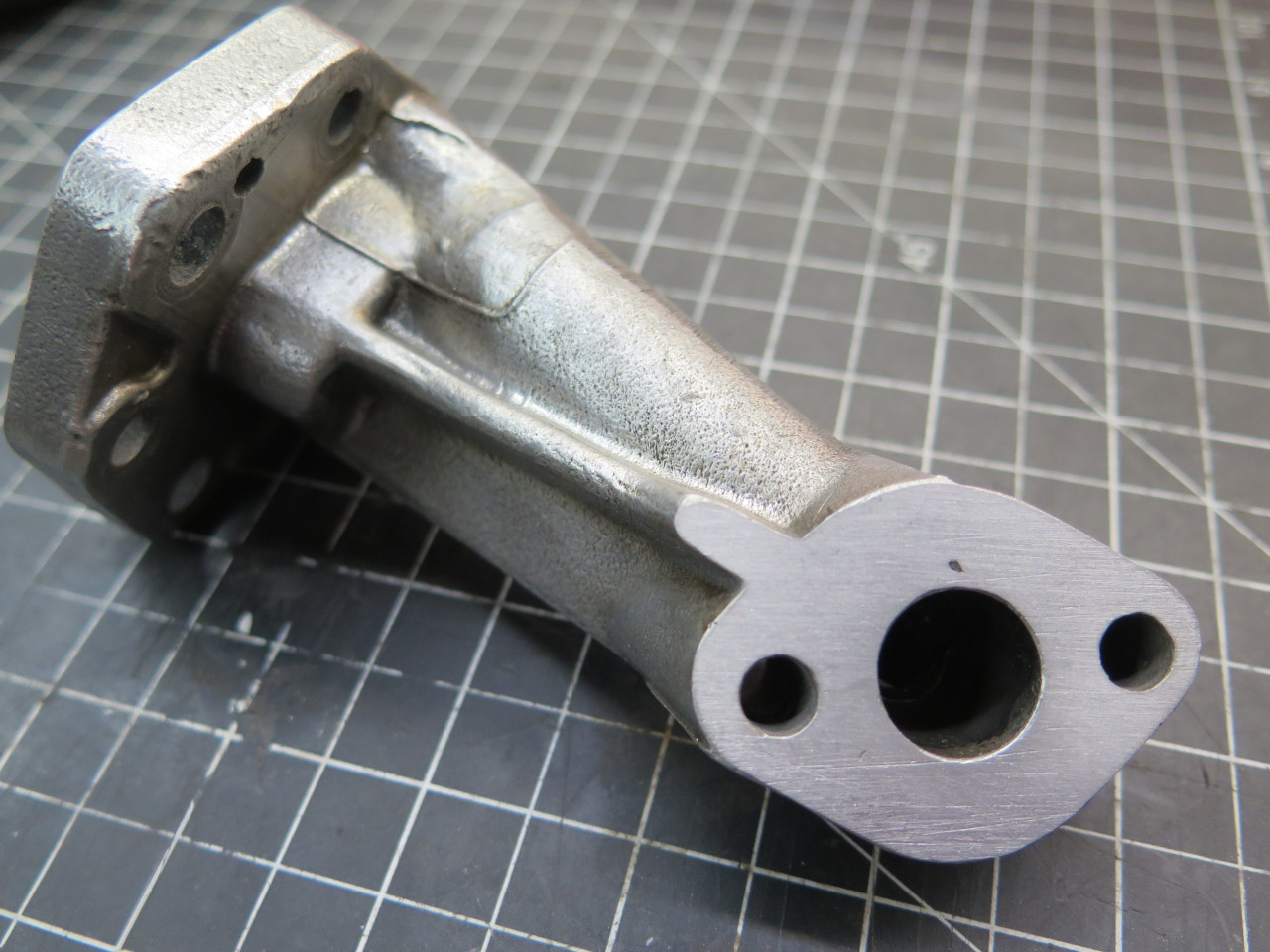

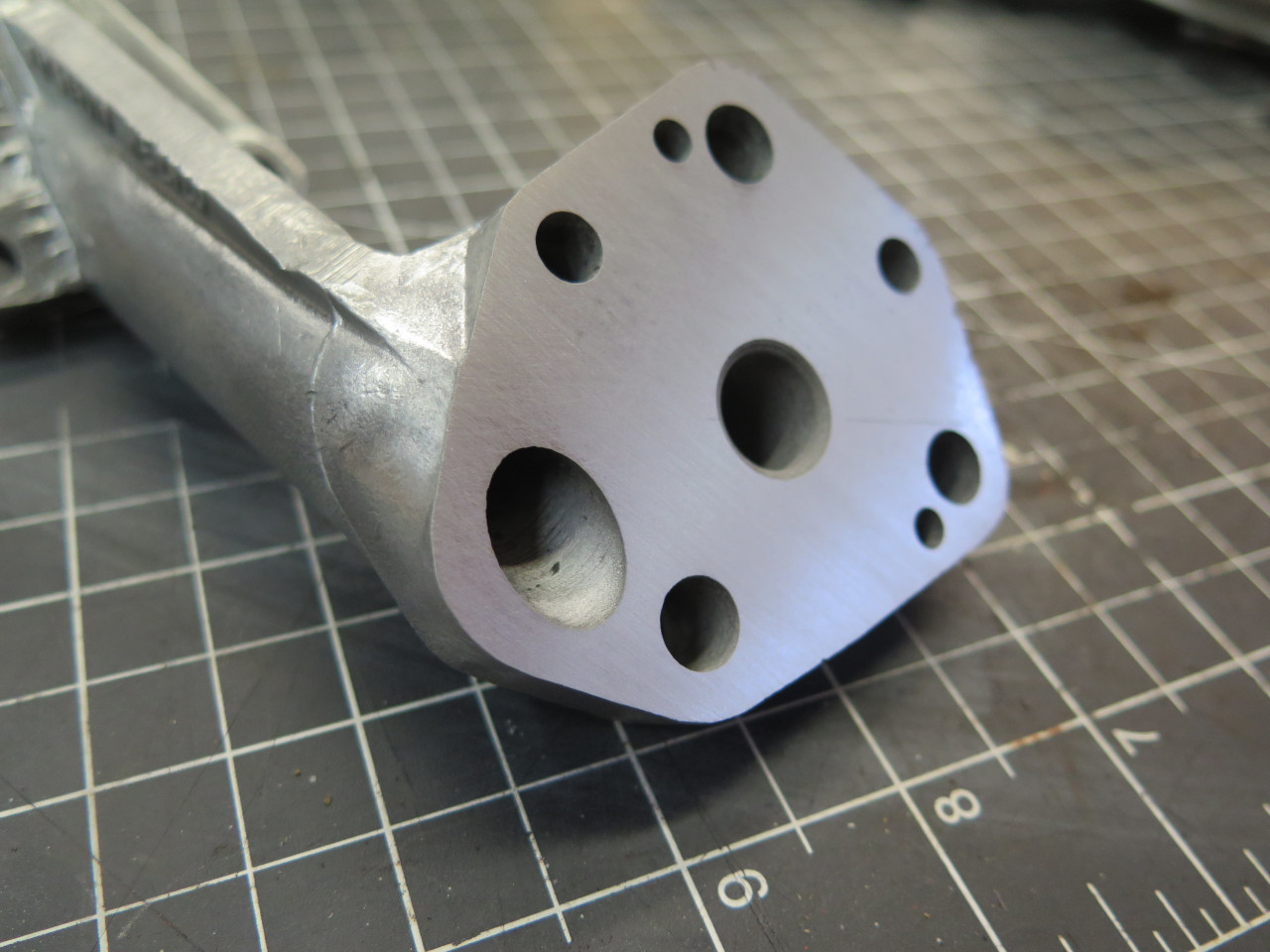

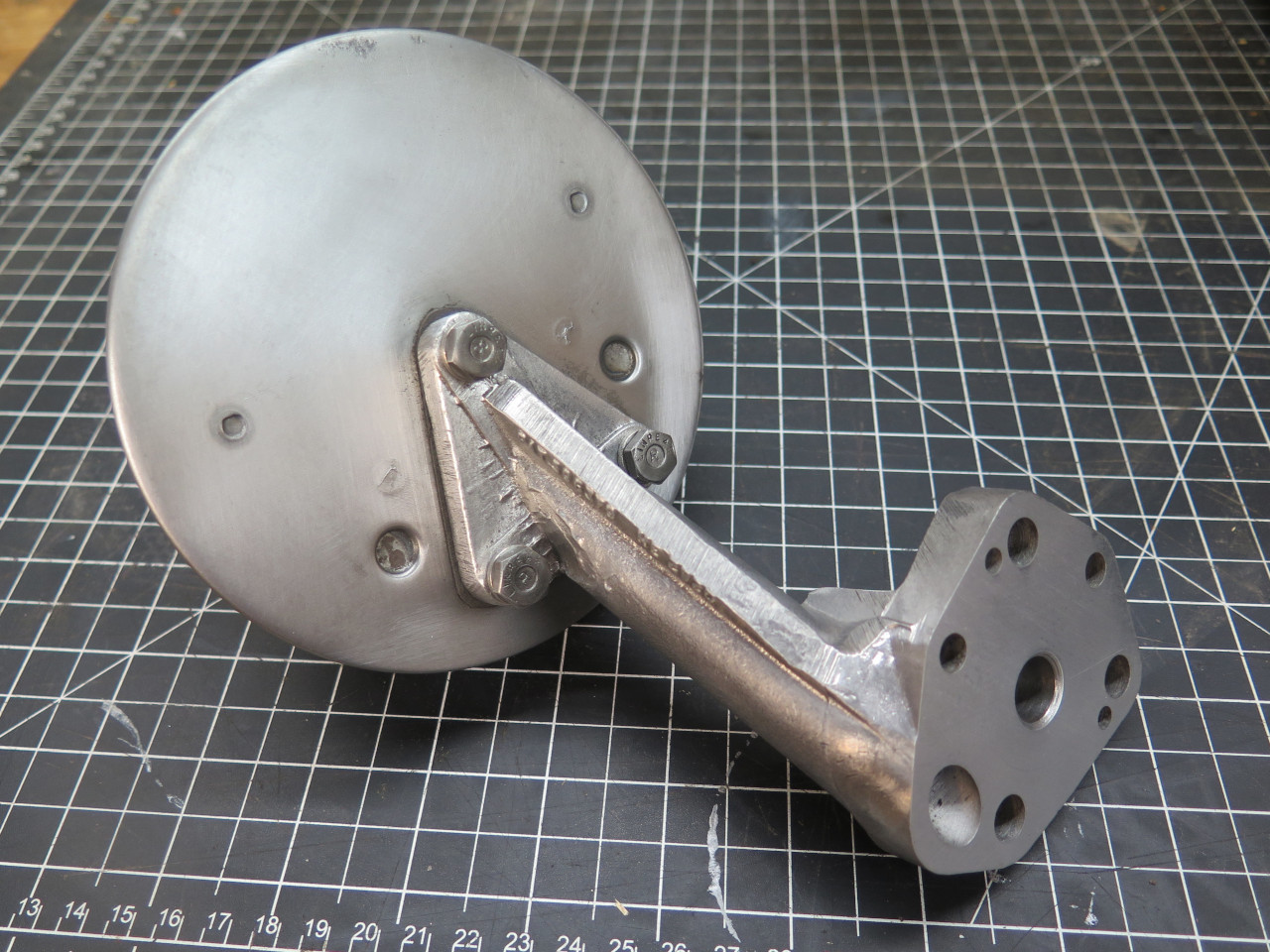

Like the original pickup, the casting had some scoring on the face that

forms the bottom of the pump itself. I linished it flat.

Also cleaned up the surface that mates to the screen.

Ready to go together with homemade gasket. I don't bother to plate fasteners that will essentially be bathed in oil.

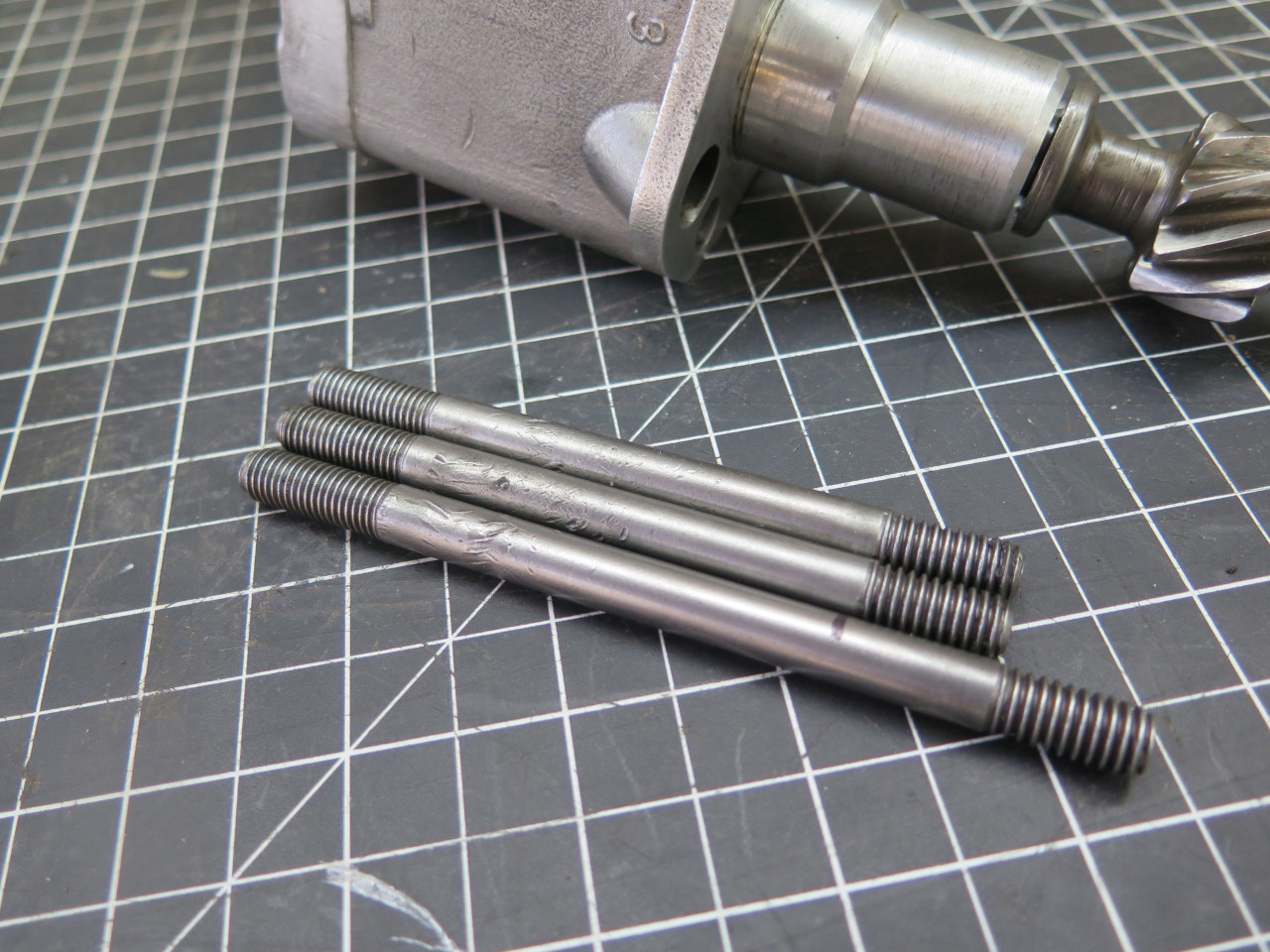

One last thing: One of the mounting studs on the pump using the

original pickup was longer than the others. With the new pickup,

they needed to be all the same. I just extended the threads on one

end, and cut it shorter..

On the shelf with this Dude until final engine assembly.

This little side trip added cost to the project such that it was almost

as much as buying a complete new pump. On the other hand, I am

usually willing to re-use as many original parts as possible, even if

the cost is a little more.

Comments to Ed at elhollin1@yahoo.com

To my other MGA pages