To my other GT6 pages.

April 7, 2022

Rear Quarter Lights

In the days before car air conditioning was ubiquitous, drivers had to

rely on ventilation to stay relatively comfortable on hot days.

One of the features of the GT6 cars was a pair of rear quarter lights

that could swing out a few inches at the rear. At speed, this

caused a suction that would effectively exhaust hot air and provide a

positive air flow through the cabin.

The windows are an odd shape that fits between the contours of the rear

wings and the roof line. Mine were pretty dirty, but appeared to

be intact.

Each window has a folding latch at the rear that both secures the window

against its seal when closed, and limits the opening when open.

The chrome frame of the window is in two pieces: The straight vertical

piece at the front edge, and the rest of the frame, which is

curvy. The two pieces are held together by internal steel corner

brackets held to each side by small screws. The screws on the

bottom side were pretty rusted, so I wanted to take the frame apart to

check the brackets. On this window, one of the screws had to be

drilled out. There is a rubber seal between the glass and the

frame all around.

The little "L" bracket at the bottom corner was very corroded. The top one looked new.

I was able to de-rust the bad bracket and even though it was pitted from

the rust, I was able to zinc plate it OK, but I apparently don't have a

good pic of the redone bracket. The old rubber seal for the removed

frame piece was damaged, so I got some 1mm thick neoprene sheet in a

similar durometer. The thickness of the seal was pretty

critical. 1/32" (0.031") material was too loose, but the 1mm

(0.039") was perfect. I sprayed some adhesive on the rubber so it

would stay wrapped around the edge of the glass until I could get the

frame piece on.

I inserted the corner brackets and fastened them loosely to the glass

side with new stainless screws. Then, a smear of Vaseline on the

rubber allowed the frame piece to firmly slide home.

The chrome and glass cleaned up really well. The frame itself is

not magnetic, so it is surely brass, which is a much better base for

chrome than steel is.

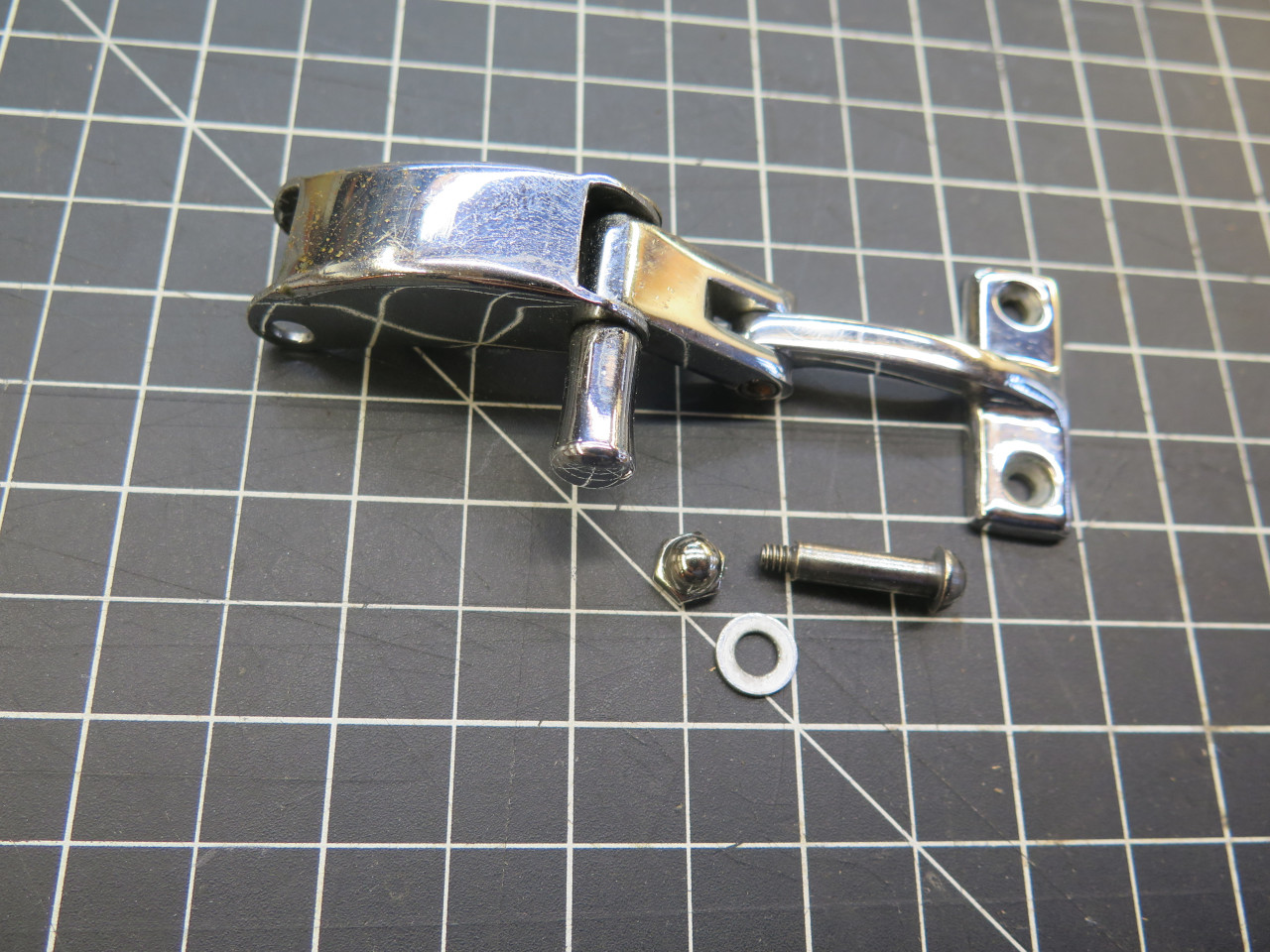

The latch mechanism consists of several pivoting links, pinned

together. I think that large piece is actually polished stainless,

since it has a little different color, and is a little more scuffed up

than the chrome. The other parts I believe are chromed

brass. The hex nut is what I found on the window, but the acorn

nut is the correct part.

With one side done, I turned to the other one. The process

was identical, but the bottom corner bracket was in even worse

shape. I had to drill out all four screws. It got cleaned up

and replated, and miraculously, all of the threaded holes still had

threads good enough to hold the screws.

These puppies are done and on the shelf.

This was a fun one. I was very happy with the condition of the

chrome and glass. It took a day or two, but the cost was only

maybe $10 for the rubber sheet.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages.