To my other GT6 pages.

January 15, 2022

Fuel Filler

One of the little iconic features of the earlier GT6 cars is the fuel

filler cap. Rather than trying to obscure the filler by meekly

hiding it behind a door blended into the body lines, Michelotti chose to

make it a bold design statement. A beefy cast filler cap sits

fully exposed, prominently and proudly at the rear, reminiscent of some

race cars.

Though the filler looks pretty much the same over all of the round-tail

years, there were actually a number of variants. Some had magnetic

caps, some had a latch, and some had both.

My filler was of the magnetic variety. It was apparently only used

for a year or so and, as I found out, is relatively rare. My

filler was dirty and crusty, but all there.

A couple of small roll pins act as the hinge between the cap and

body of the filler. The rubber seal has a small flange that is

captured behind the magnet, but can easily be pried out.

I really wanted to get that magnet out for proper cleaning, but it was

fixed in the cap with some unknown glue. I thought heat might

soften the glue, but I didn't want to damage the magnet with heat.

The magnet looks to be a ceramic type, and a little research showed

that ceramic magnets can take pretty high heat. So, I tried a soak

in the oven at 250 ºF, well below the danger temp for the magnet.

This was enough, and the glue released the magnet. There was

actually a steel ring between the magnet and the cap body. Both

joints were glued.

A small aside here. Before I took anything apart, I was assessing

what the materials of the components were. The cap was bright, yet

not really chrome-like. It seemed too dense to be aluminum. I

checked it with a magnet, and it seemed to be magnetic. I assumed

this might be due to the internal magnet, but after I removed the ring

magnet, the cap was still slightly magnetic. This confused me for a

while, because I assumed that the cap was a die-cast zinc alloy, which

would not be magnetic. It finally dawned on me that the zinc cap

must be nickel plated. This would account for the very slightly

yellowish color, and the magnetic properties. Case closed.

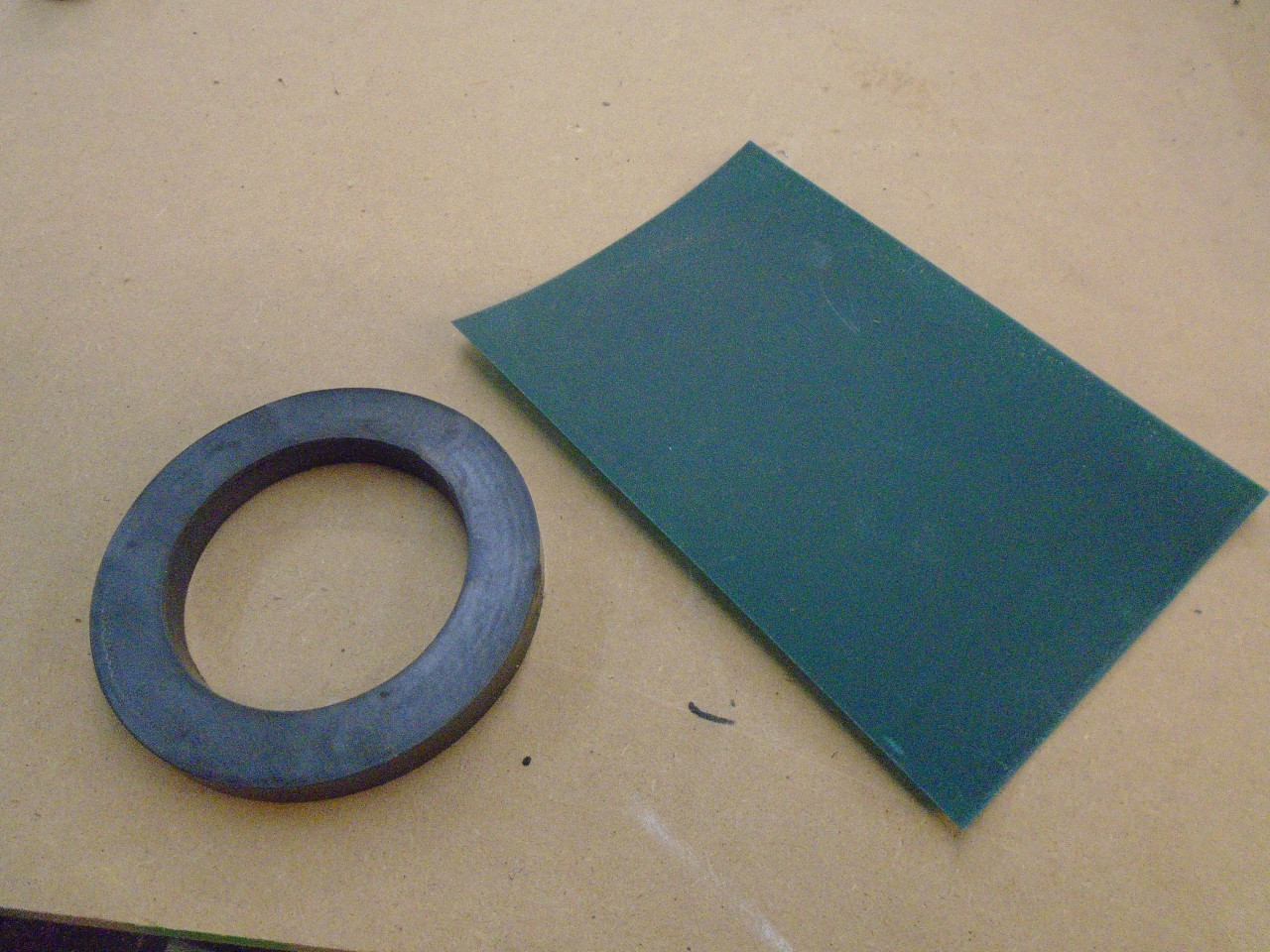

I was a little curious about the ring magnet. The green sheet

below is a special material that responds to magnetic fields. It

clearly shows that the magnet ring contains eight magnetic poles.

Though the sheet doesn't show it, the magnetic areas would certainly be

arranged as alternating North and South poles. This explains the

presence of the steel ring. The steel bridges the pole pairs on

the backside of the magnet, effectively yielding a ring of horseshoe

magnets, which is stronger than individual poles.

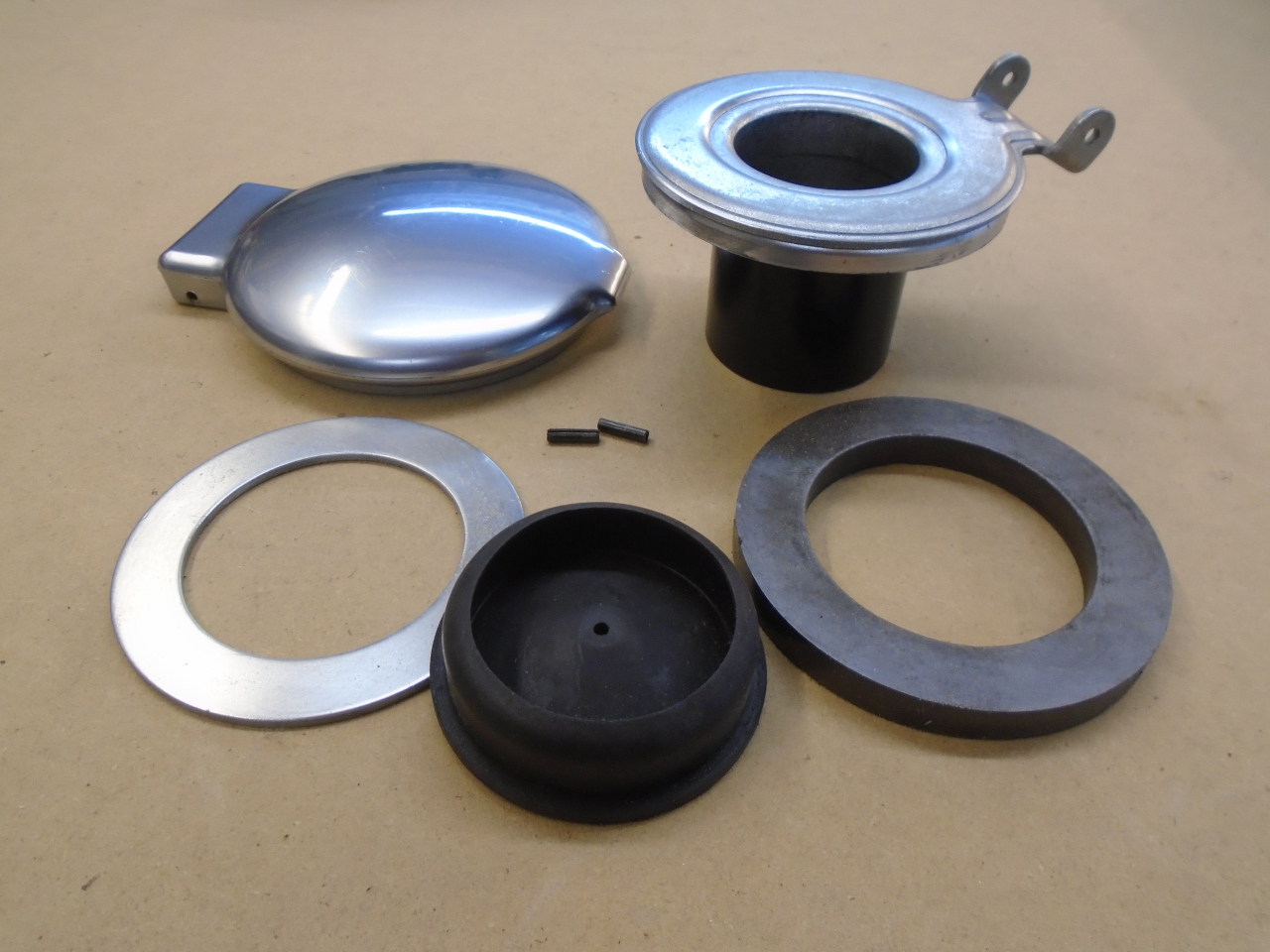

So here are all of the parts cleaned up. The steel ring and the

face of the filler neck were re-plated. The stem of the filler

neck was powder coated.

This brought me to that rubber seal. The seal was in OK condition,

but was over 50 years old, and seemed a little stiff to me. I

wasn't confident about how well it could seal. So, I ordered a

replacement. The seal I received was clearly the wrong one. I

did some research and couldn't find anyone supplying the seal I

needed. I posted a query on one of the Triumph forums. It was

acknowledged there that my seal probably wasn't available anywhere.

It was at this point that the seal became sort of a science

project. I thought there might be a chemical way of rejuvenating

rubber. Some Google research turned up a few leads, but one was

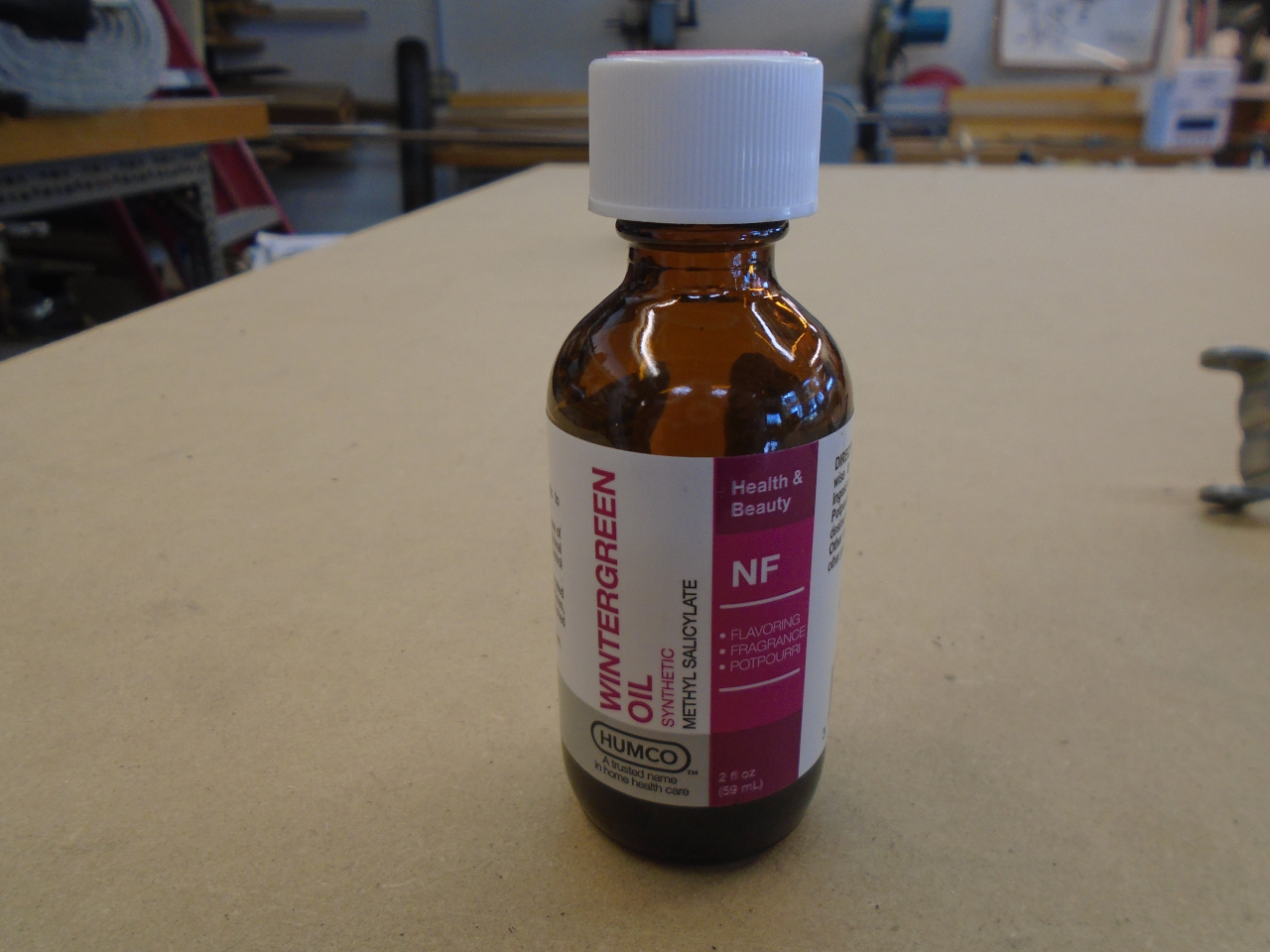

the recurring references to methyl salicylate. Now, I love the

Internet as much as many people do, but one of it's crowning

achievements today is that it has become the worlds largest echo chamber

for utterly bogus information. So, I followed the lead, but went

to some more reliable resources. I checked a few scholarly

articles, which reinforced the idea. I found a few commercial

products that were sold to refresh rubber rollers and platens in

industrial settings. A common ingredient among them was methyl

salicylate. That was good enough for me--I ordered some.

A common name for methyl salicylate is Oil of Wintergreen, and it smells

exactly like Wintergreen Lifesavers. However, in anything other

than very dilute form, it is toxic, and can even be absorbed through he

skin.

Being sort of tech-savvy, I wanted to somehow monitor the process so I

could tell if the treatment was doing anything to the rubber. I

don't have a good way of directly measuring rubber durometer, and

measuring precise physical dimensions of a squishy material is not

easy. I finally decided to monitor the weight of the seal.

If something was going into the rubber, I should be able to see weight

changes. I did two runs, one with the seal immersed in full

strength methyl salicylate, and a second one with 25% methyl salicylate

in isopropyl alcohol, as recommended in one of the sources. Here

are the results:

The first immersion was one hour, with periodic weight checks. The

seal gained about 15% in weight, and the rubber seemed to feel a little

softer. Then, to see if the weight gain would persist, I left the

seal exposed to room air for most of a day. Over the next 18

hours or so, the seal lost about 2.7 of those percentage points.

The seal was then immersed in the diluted solution for about four hours,

where it gained additional weight up to about 26% over the starting

weight. Over the next 20 hours or so, the weight settled back to

about 20% over starting weight. The weight didn't change

appreciably at all over the final four hours. At this point, the

seal definitely felt softer.

I decided to leave well enough alone at this point. The solution

was turning a little yellow, which suggested to me that it was

dissolving or breaking down the rubber or some component of it. It

seemed logical that overdoing this treatment could damage the seal.

I don't know what the prognosis is for the seal. The improvement

may not be permanent, or even long term. I'll try to remember to check

it again at install time.

Now, back to the real world...

I epoxied the steel ring and magnet back in place. I did a way better job centering the magnet than the factory did.

Then slid the flange of the seal back under the steel ring.

I somehow managed to not lose the little roll pins, which went back in place.

On the shelf with this puppy.

This was one of those projects that didn't really cost anything, and

didn't really take that long, but involved a lot of thought and

research. A side benefit is that even now, several days later, my

shop still smells like candy.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages.