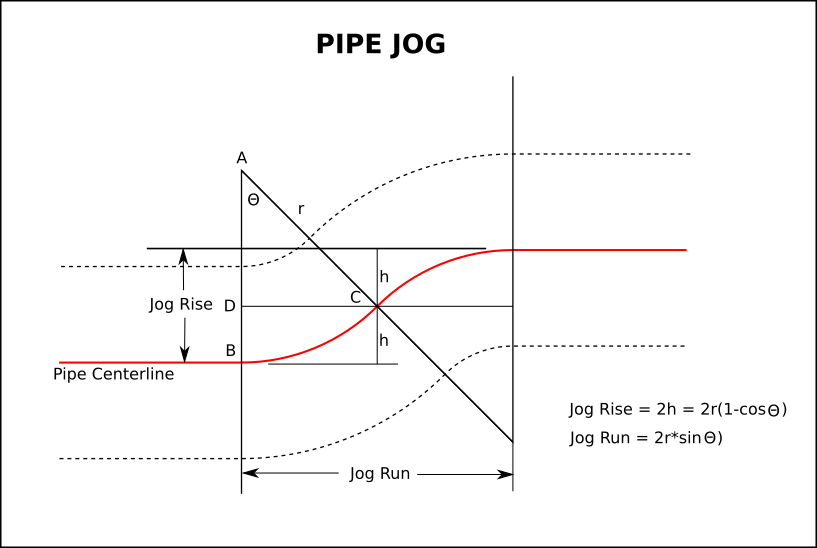

That angle then can be plugged into the Jog Run formula to find the Jog Run.

Or,

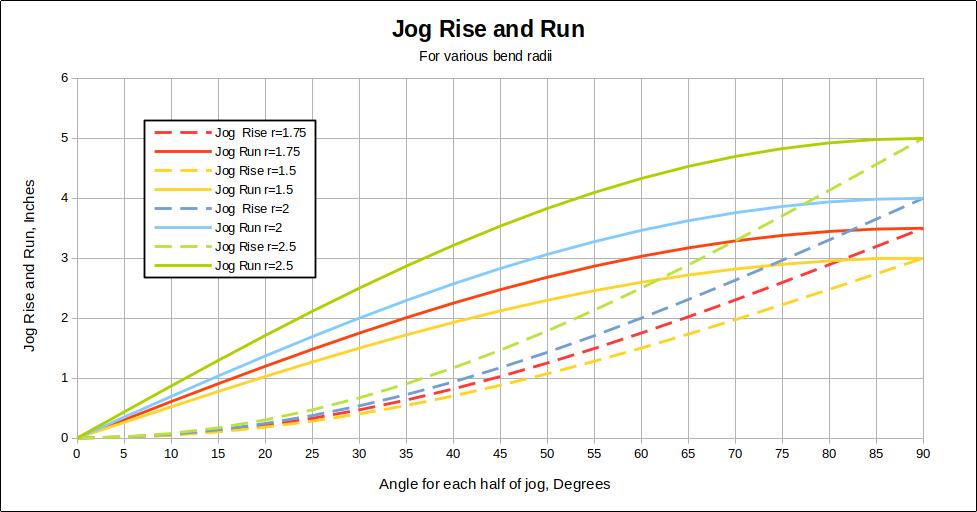

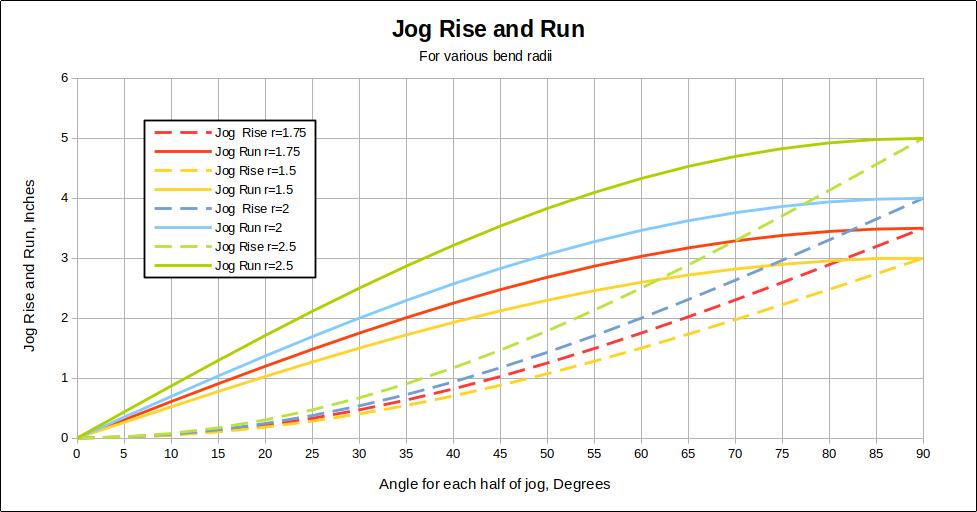

if those sin and arccos things seem a little intimidating, use the

chart below. To use the chart, pick the desired Jog Rise on the

vertical axis. Follow horizontally to the dotted Jog Rise curve

corresponding to the bend radius. Then drop down to find the angle

of arc for each half of the jog. From that point, go vertically

up to the solid Jog Run line for the bend radius, then back to the left

to read the Jog Run.