To my other GT6 pages.

July 6, 2021

Fetching the Engine

I am blessed to have a three stall garage.

However, considering our two daily drivers, plus my three LBCs, one LBM,

and the clause in our marriage vows where I agreed that no car

will spend the night outside, I'm out of garage space. I do have a

small work bench in the garage, but it's used mostly for parts

storage. So most hands-on work on non-frame and non-body parts

takes place in my basement shop. This worked out just fine, even

with the engine, which I broke down in the garage, and hauled piece-wise

to the basement, the heaviest part being the block at only about 135

pounds.

The trouble comes when it's time to move the rebuilt engine, now

probably around 350 pounds with the stand, back to the garage. I

may not have mentioned the flight of 16 stairs between the two.

I've actually faced this problem before, with the engine on my TR6 restoration, and also with moving some of the heavier stationary power tools down to the shop.

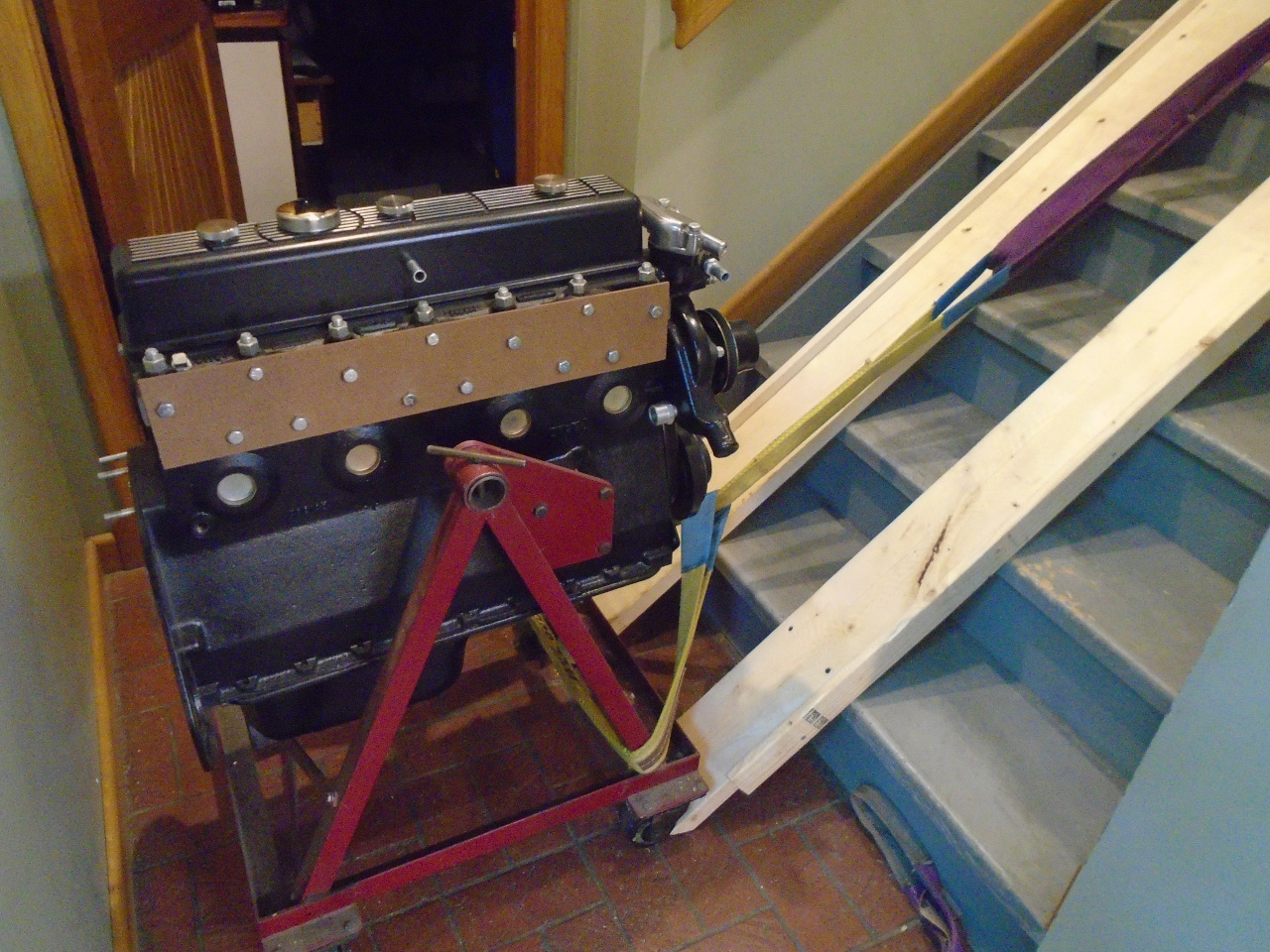

The method I've developed involves building a pair of tracks screwed to

the stair treads, and using either a sled or a wheeled stand to hold the

heavy item. The engine was on a bespoke stand.

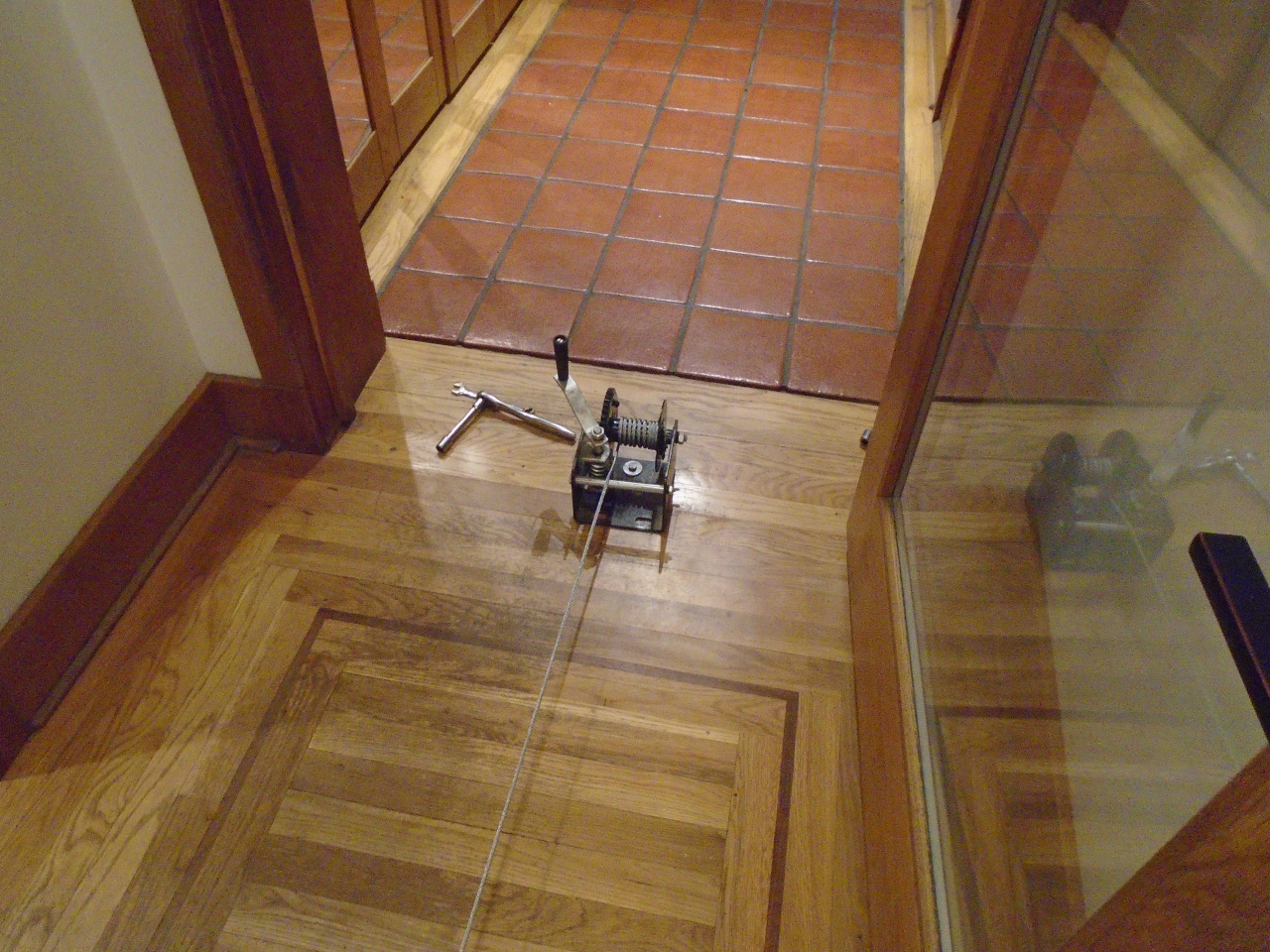

A hand crank operated winch was lag bolted to the floor a ways back from

the top landing of the stairs. I remove the threshold of a

doorway and put the winch there, so the holes are hidden by the

threshold when I'm done.

Finally, it's show time!

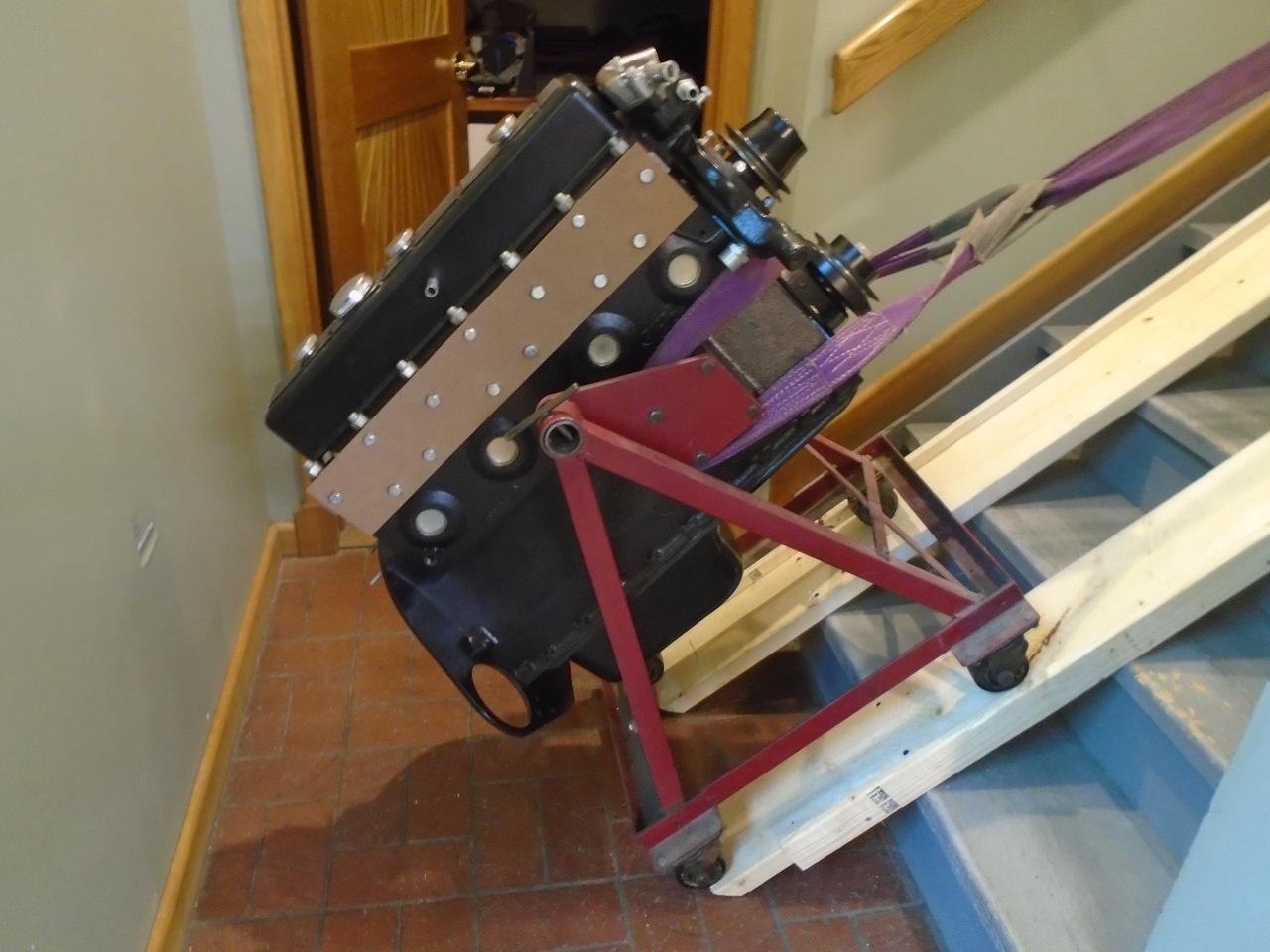

Oops! The low attachment of the pulling strap allowed the

engine/stand assembly to tip backwards and hit the wall. I'm glad

the wall was there, and that it was concrete behind the drywall, to keep

it from falling all the way backwards. Milliseconds after I saw

that tipped engine, I remembered that the exact same thing happened with

the TR6 engine. It was a déjà vu moment. The pic shows the

tipped engine with the strap already re-positioned higher.

Up she goes...

It took nearly an hour to crank it all the way up. I stopped to check everything every foot or so.

When it was finally secure on the main floor, I pushed it aside so I

could remove all of the rigging. The pic looks like one of those

puzzles where you are supposed to find what doesn't belong.

Getting the engine down a couple of steps into the garage was comparatively easy.

My contract says I have to fix this damage before I can do anything else on the car.

This job was sort of nerve wracking. Moving the engine only took

an hour or so, but with setup and tear down, it was a whole day.

Cost was just some of the lumber I had to buy.

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages.