To my other GT6 pages

April 23, 2021

Clutch & Flywheel

The flywheel on a car can be thought of as an energy storage device or a

filter. It absorbs the energy from the crank and damps the

pulsations from the individual cylinders. It can give up some of

the stored energy when needed, like when starting out from a stop, when

the engine torque is low. One downside of a flywheel in this

application is that its inertia resists rotational speed changes, so it

can hamper acceleration.

The energy storage and the resistance to acceleration are two sides of

the same coin, and it's possible to trade off one for the other.

The original flywheel design is a compromise that the engineers thought

would satisfy most typical drivers. However, tweaking the flywheel

is a popular modification to tailor a car's response to a particular

driver. This virtually always means lightening the flywheel.

A lighter flywheel spins up quicker, and hinders acceleration less, but

overdoing it can make a car a little trickier to start from a

stop.

Now it's true that lightening any rotating part of the power train will

have a similar effect, but the fortuitous part of flywheel lightening

(as opposed to, say, the rear hubs or brake drums) is that the effect is

effectively multiplied by the gearbox and differential.

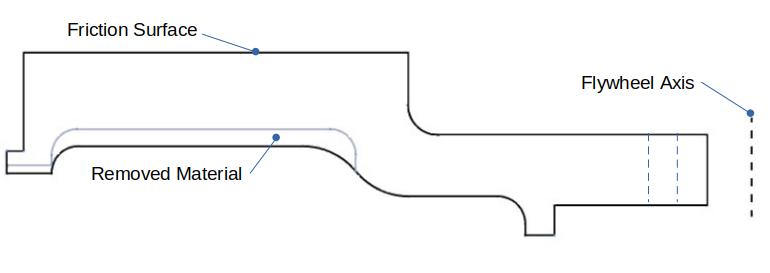

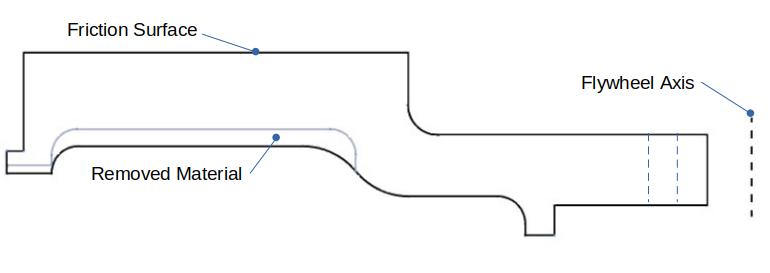

One other wrinkle involved with lightening rotating parts is that it

matters a lot where the weight is removed. Material removed form

the periphery of a rotating object will have much more effect then

material removed near the axis. This is because it is the "moment

of inertia" (MI) of a rotating body that resists acceleration, and MI

depends on the mass and the distance from the rotation axis.

Anyone suffering from an unhealthy desire so see a more mathematical

explanation of MI and how flywheel lightening can affect performance of a

car can take a peek here.

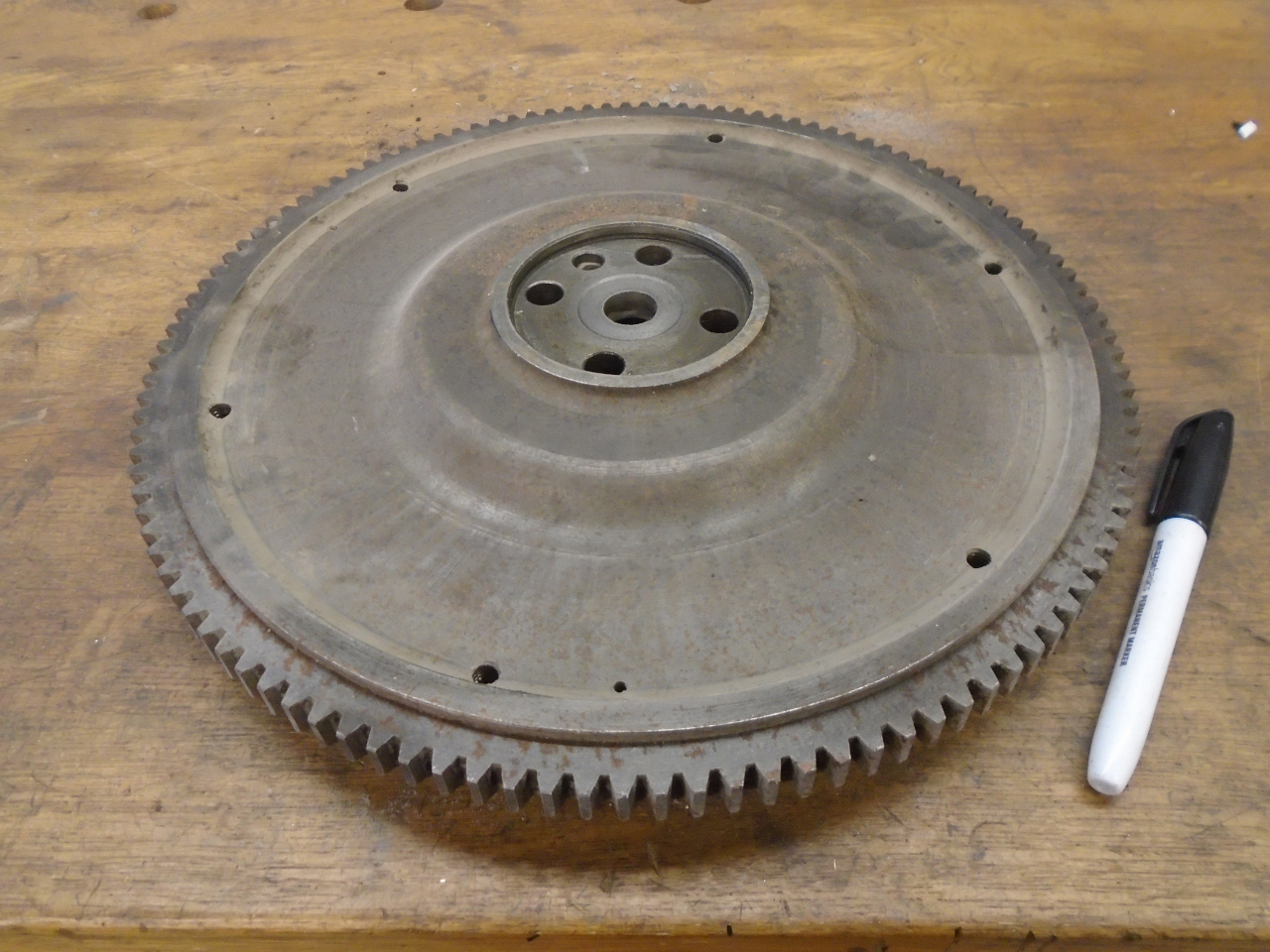

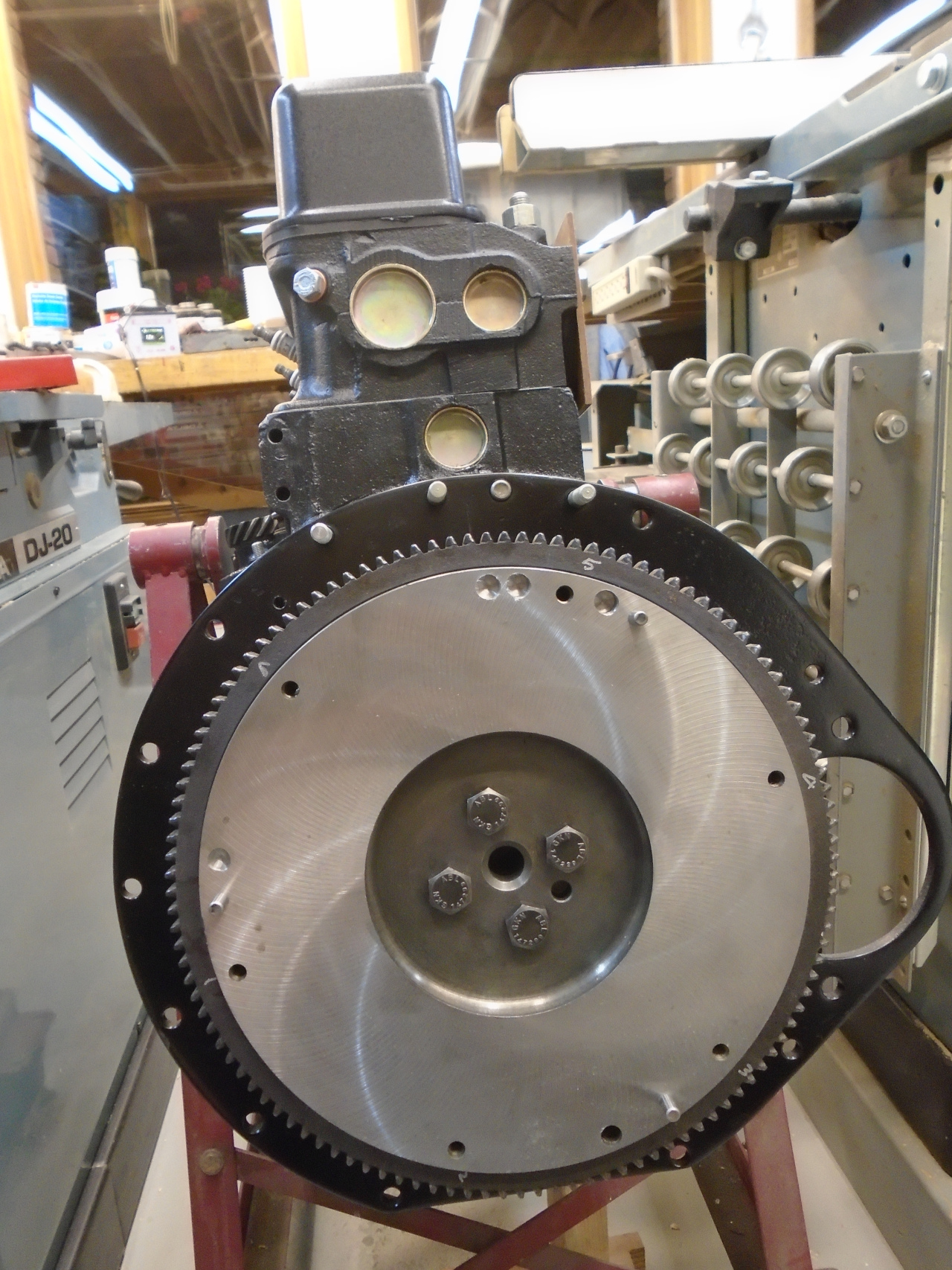

Typical flywheels also include one of the clutch friction surfaces, so

they wear. My flywheel was plenty dirty and stained, but the

friction surface showed little actual wear. I probably had it

surfaced shortly before I put the car away decades ago. Though I

know this engine has lead a pretty sheltered life, I inspected the

flywheel pretty carefully for any signs of cracks or other distress.

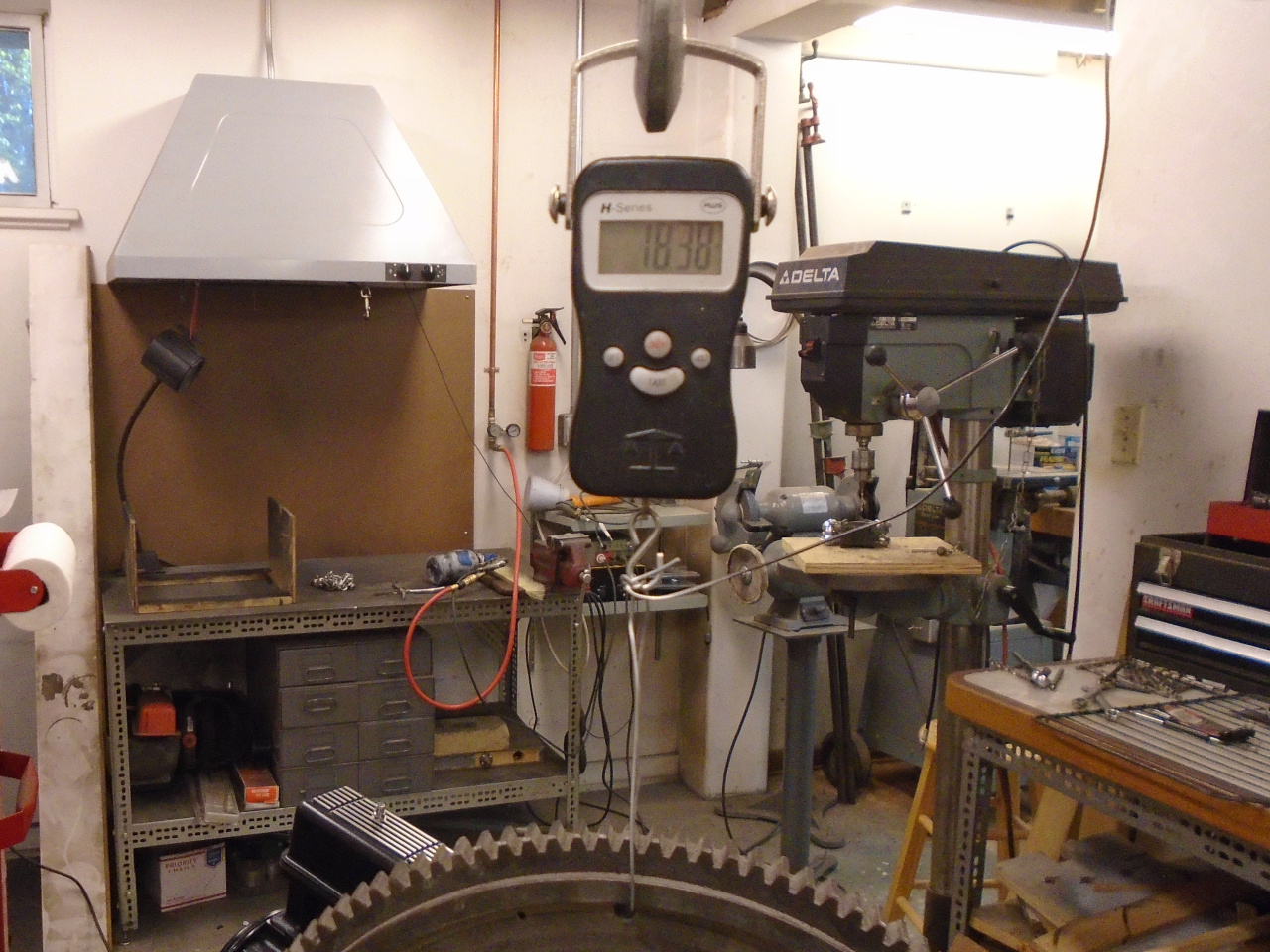

Mainly looking for some modest acceleration benefits, I decided to look

into lightening the flywheel, so first I weighed it. It came in at

a little over 18 pounds, which surprised me. I was surprised

because I did similar work on my TR6 engine, and it started out at over

27 pounds (which I lightened to about 22). So the stock GT6

flywheel was already significantly lighter than my lightened TR6

flywheel.

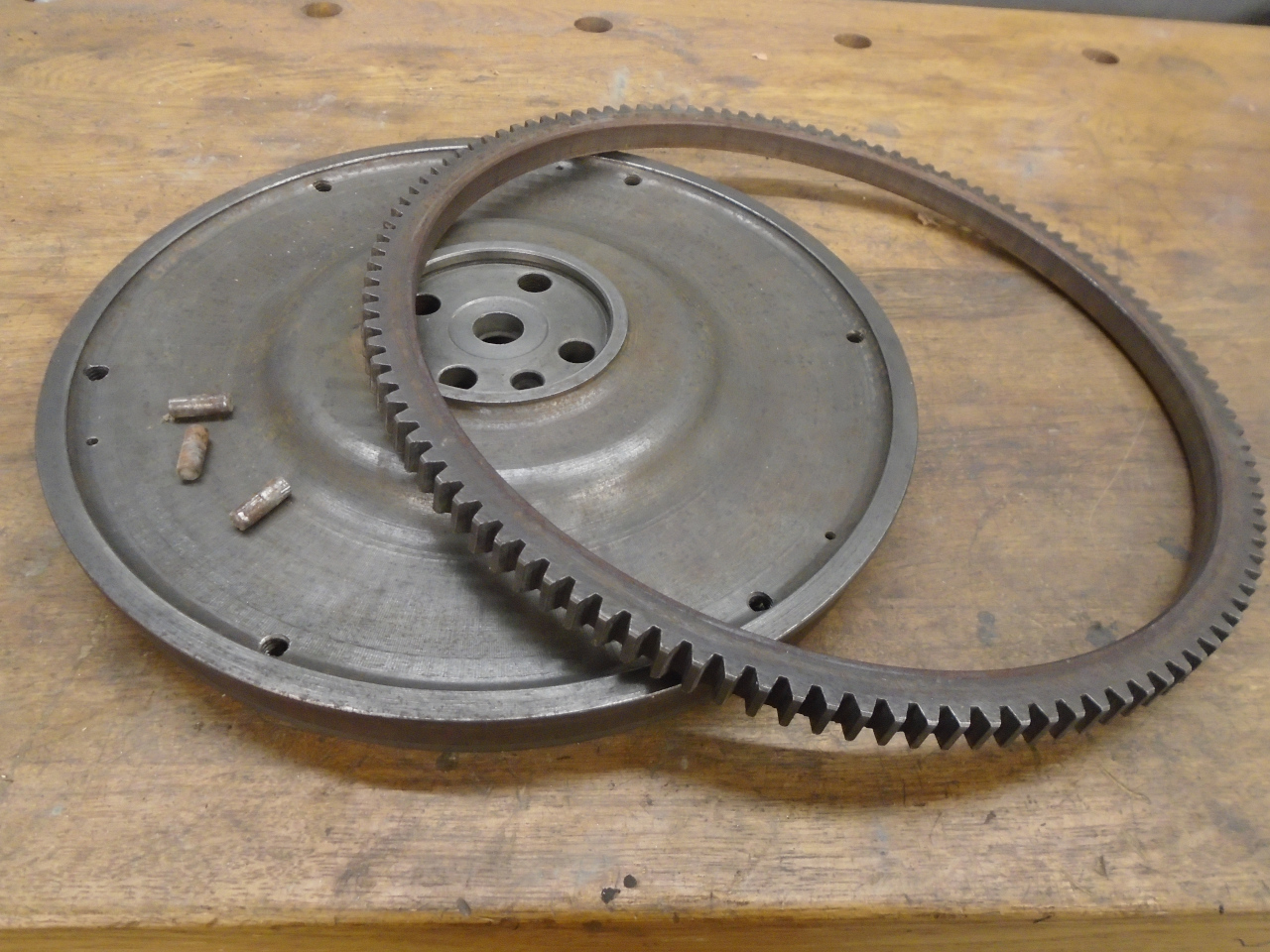

I still wanted to take a little weight off, though, so I forged

ahead. Even with the ring gear off, the wheel was just a little

too big for my smallish lathe, so I had to do the material removal on a

milling machine.

I developed a plan for what to remove where, based mainly on the

recommendations of a few knowledgeable people. Removal was

actually pretty modest, and the final weight, including ring gear was a

little over 16 pounds, so only about two pounds were removed, or a

little over 11%. Some people have been way more aggressive in

chopping out metal, but this was my more cautious approach. It is

not a recommendation.

I then sent the flywheel out to be resurfaced and balanced. I had quite a

bit of trouble finding a shop that had arbors small enough to fit the

bore of the flywheel.

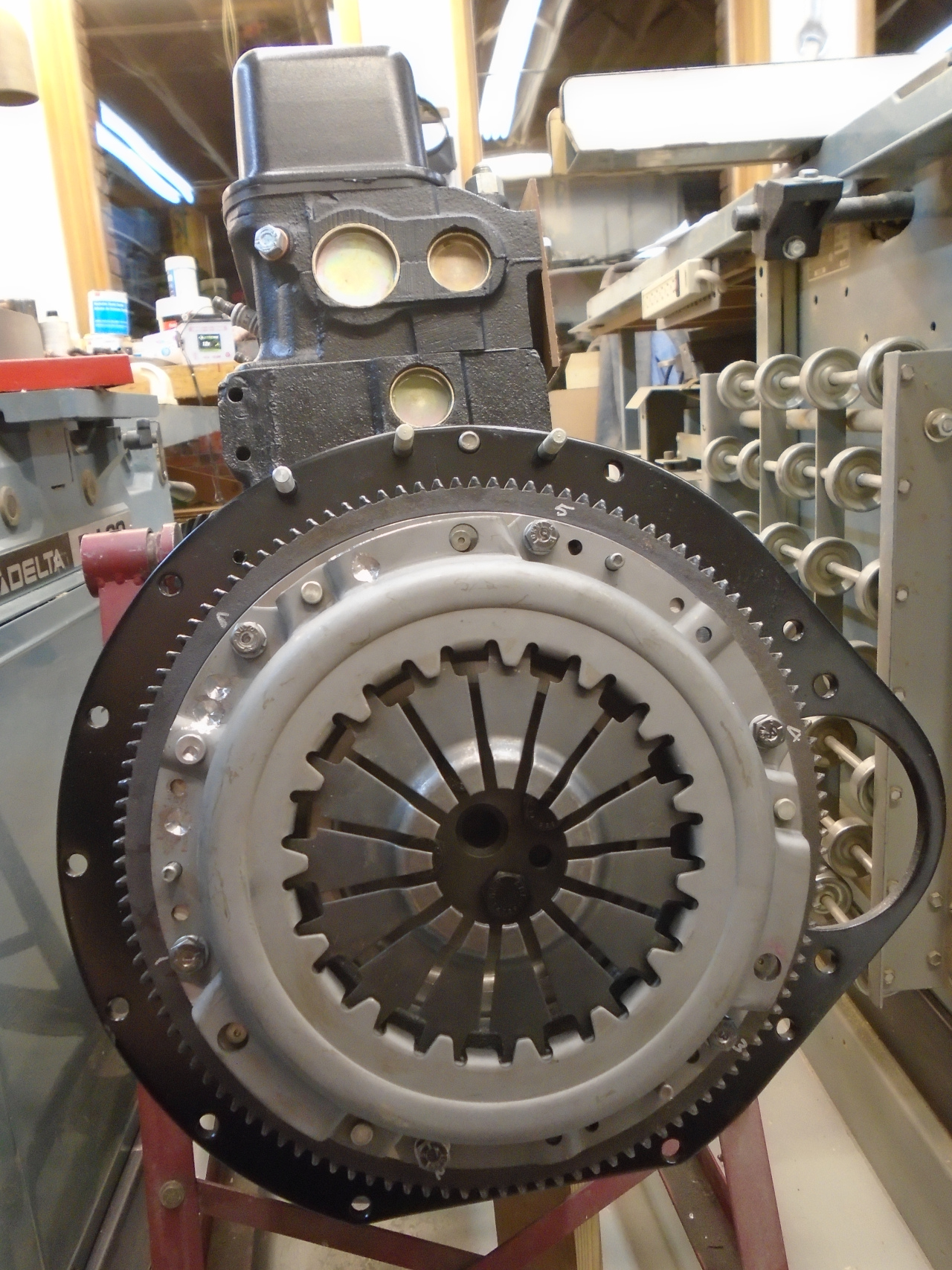

Then, even though my clutch didn't have much mileage on it, I got a new

one. It turns out that the new clutch is a couple of pounds

lighter than the old one, so the assembly is now about 15% (4.2 pounds)

lighter than I found it.

I mounted the flywheel and clutch on the engine, mainly so they wouldn't

get lost. I'll take them off to lighten the load when I have to

take the engine up a flight of stairs to the garage.

I consider this the end of the engine work. Back to the body...

Comments to Ed at elhollin1@yahoo.com

To my other GT6 pages