To my other GT6

pages

February 14, 2021

Bonnet Supports and Hinges

One sort of unique thing about the GT6 and related cars is the way

the entire front clip tilts forward to expose the engine and front

suspension. This is possible because the bonnet, front

wings, wheel wells, and grille area are essentially one welded up

assembly. A pair of curly support tubes hug and are bolted

to the wheel wells, and continue through the front grille to form

part of a pair of hinge contraptions behind the front

bumper. The other halves of the hinges bolt to short

extensions on the front frame cross member. There is also a

smaller tube that spans from port to starboard under the bonnet to

give some support at the center.

My support tubes were all present and in rusty, but otherwise

decent shape.

The frame-side brackets were also in OK shape, except for the

actual pivot point. The forward end of each bracket has a

welded-in sleeve. A tubular distance piece, slightly longer

than the sleeve, slides into the sleeve, and is clamped firmly

between the cheeks of the hinge end of the support tube.

This allows the support tubes to rotate smoothly around the axis

of the sleeves. At least that was the idea. Both

of my brackets had the distance pieces firmly seized in their

sleeves. The only reason the bonnet could still be raised

was that the fasteners were loose.

After a bit of a wrestling match, I did manage to liberate the

distance pieces, but in the process, the ends got pretty chowdered

up. The damage was to the point that they were just about

the same length as the sleeves they had to fit into, so the

necessary clearance was pretty much gone. They are the pair

of smaller tubes in this picture.

I decided to just make a pair of replacement distance pieces to

give a positive clearance.

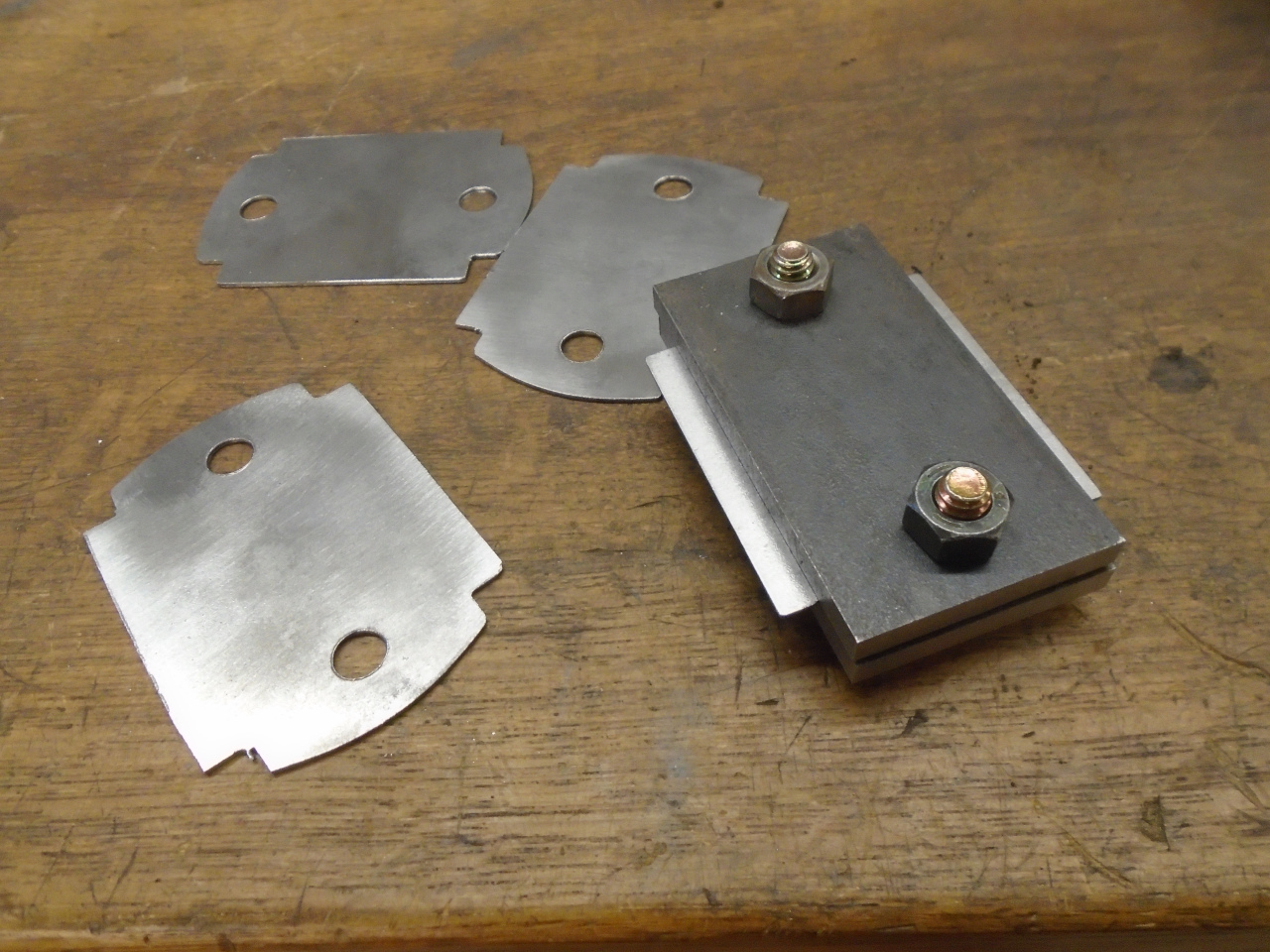

Since the support tubes themselves didn't need any attention other

than cleaning and priming, the only detail left was the clamp

brackets that held the tubes in place. They were rusty, but

looked OK until I blasted them. A couple of the backing

plates had rust-through holes in the middle.

I'm not sure if these are available for sale anywhere, but they

were easy to make.

Priming and test fitting of everything went fine. The

spacers and hardware were plated. These will go on the shelf

until the day they will be reunited with the bonnet.

This was basically an in-fill task, ramping up to the day I can

finally get back out to the garage. It was good for a day or

so's worth of time, and the cost was near zero.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages