To my other GT6

pages.

November 24, 2020

Cam Timing

Since the crankshaft determines the positions of the pistons, and

the camshaft determines the positions of the valves, there has to

be a very specific relationship between the crankshaft and the

camshaft rotations to synchronize the four-stroke

choreography. On the GT6 engine, the two shafts are coupled

by a timing chain running on sprockets on each shaft.

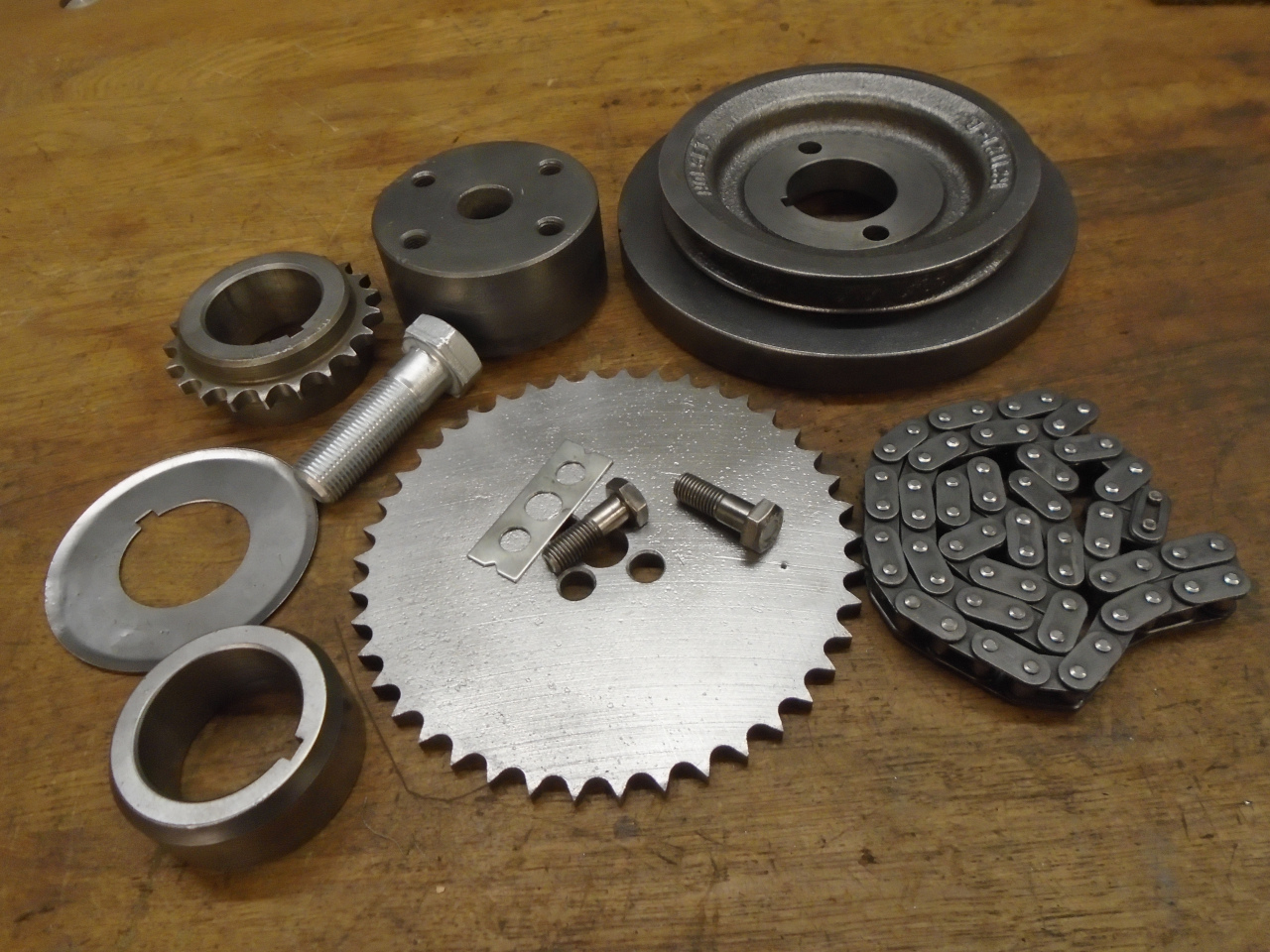

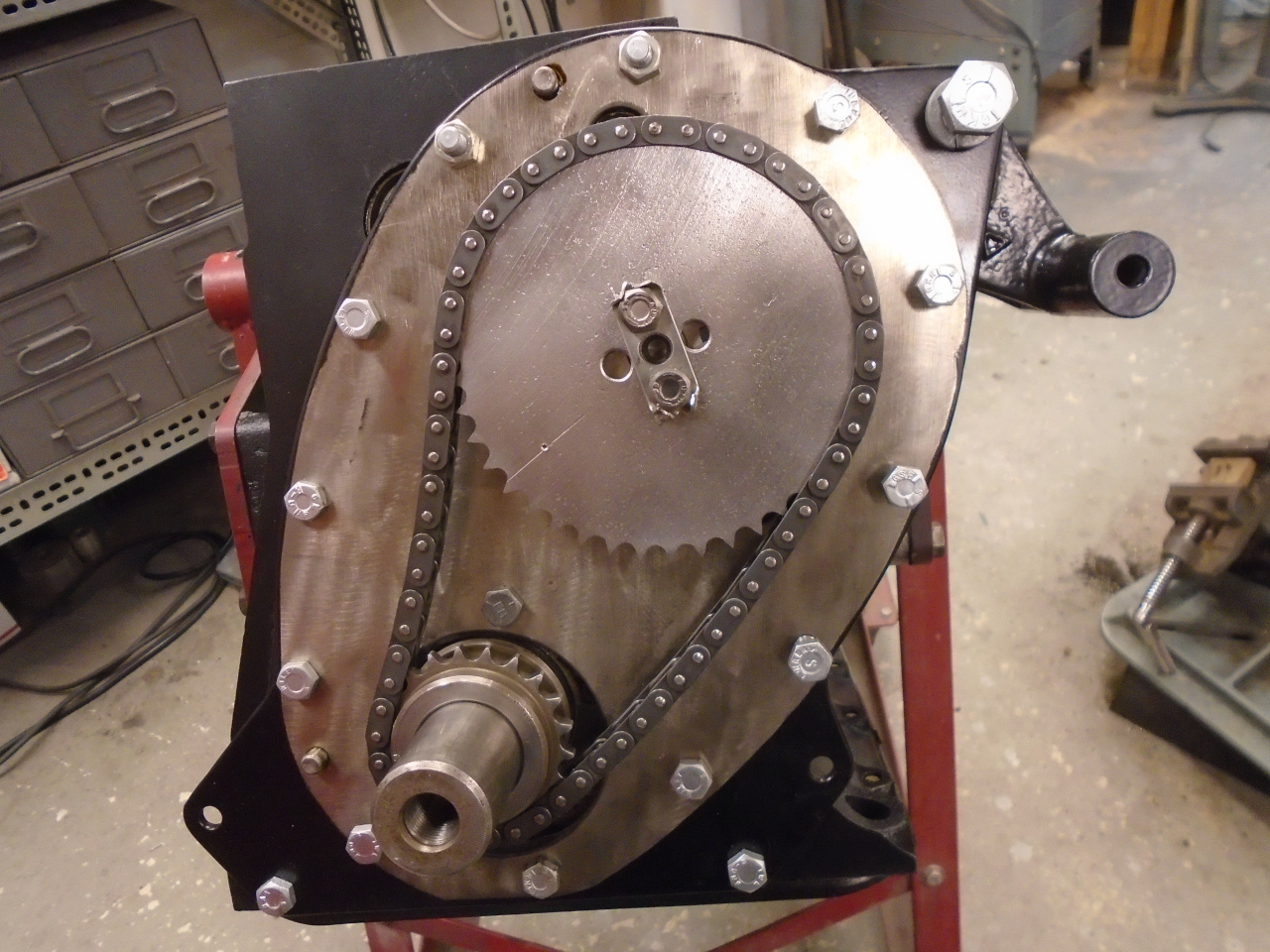

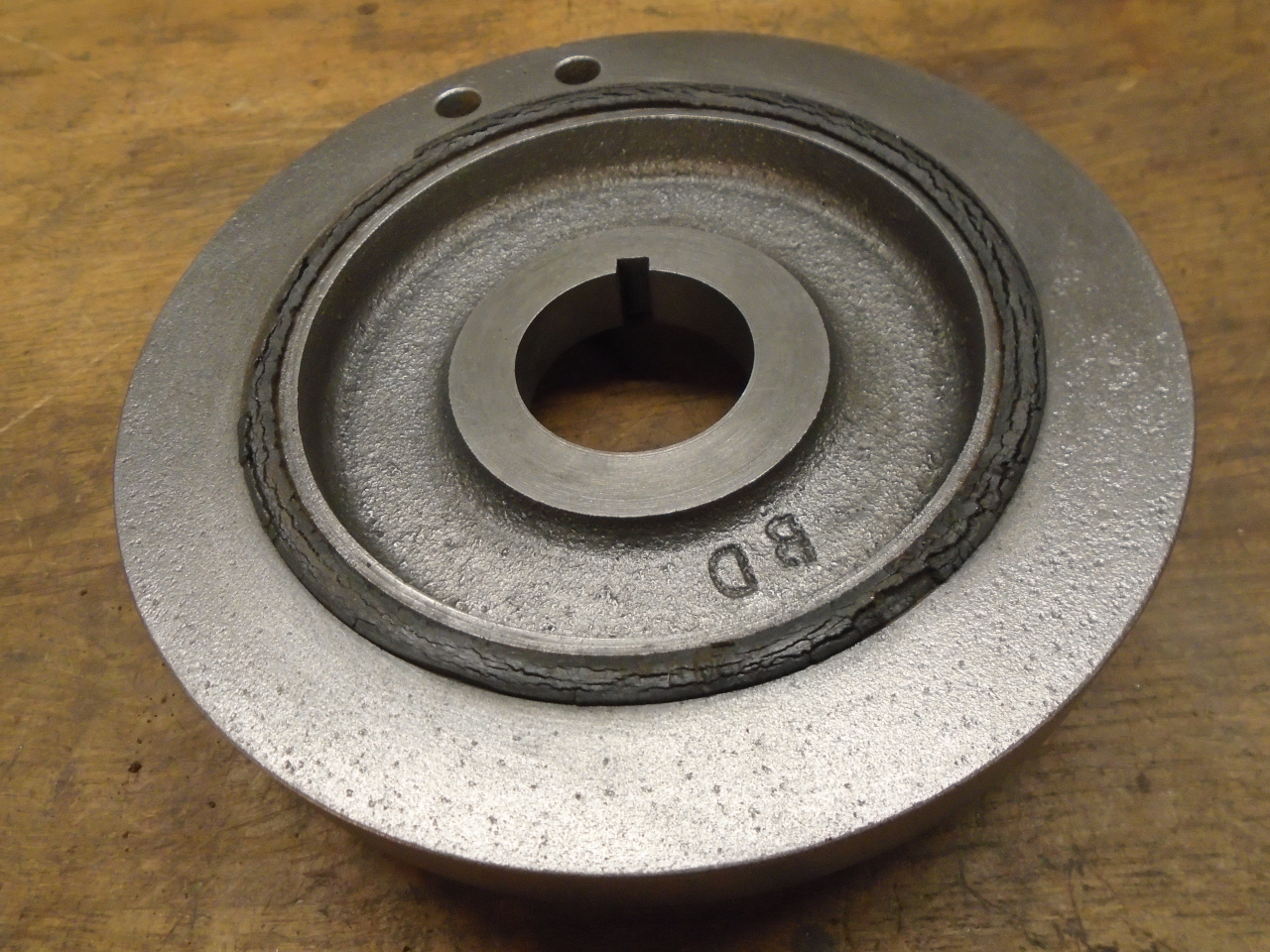

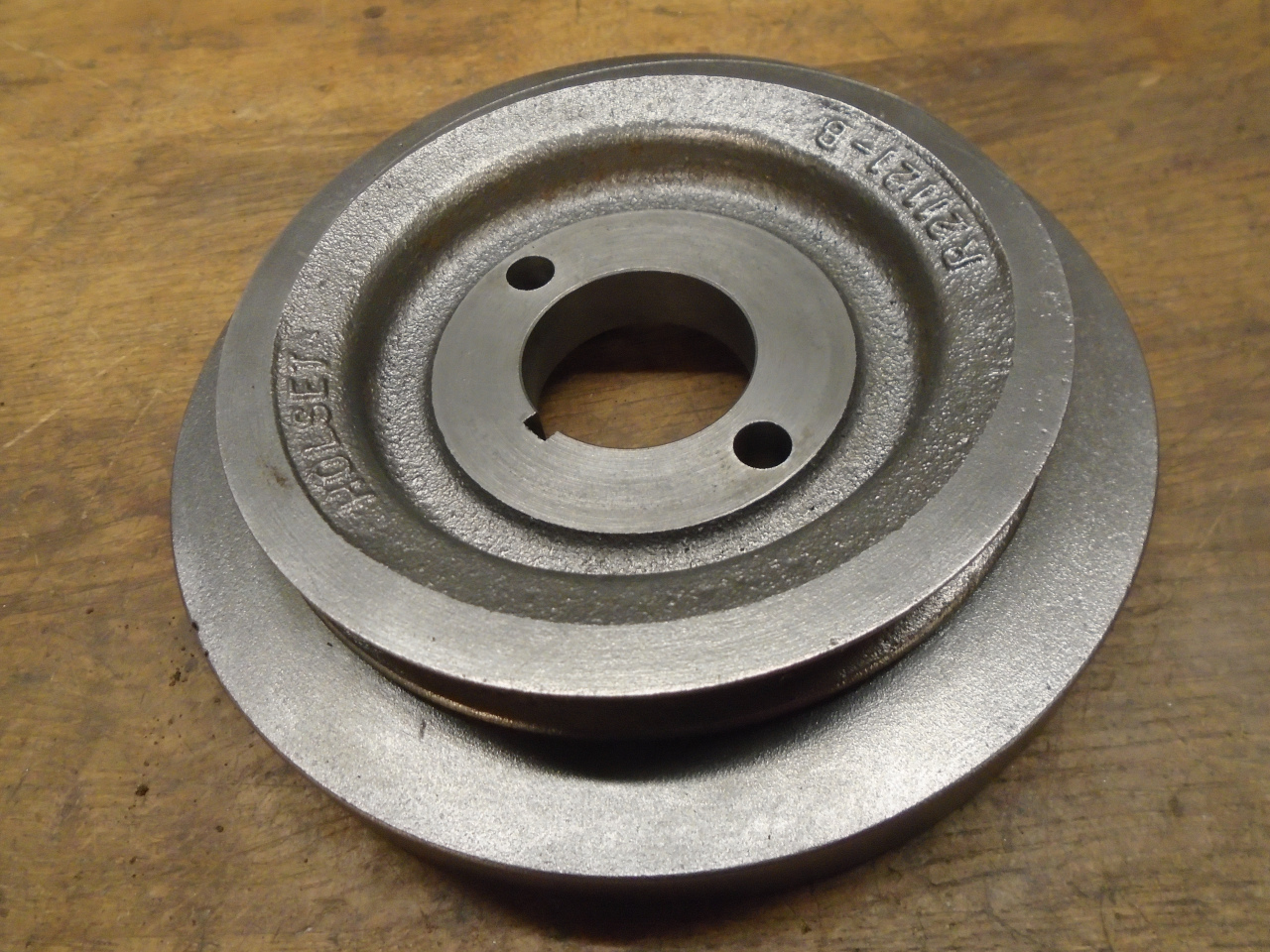

After some cleanup, these are the sprockets, chain, and some other

nearby parts. The sprockets and chain were replaced in my

earlier rebuild, so are close to 30 years old, but still young in

terms of miles. They show little or no sign of wear, so I'll

re-use them.

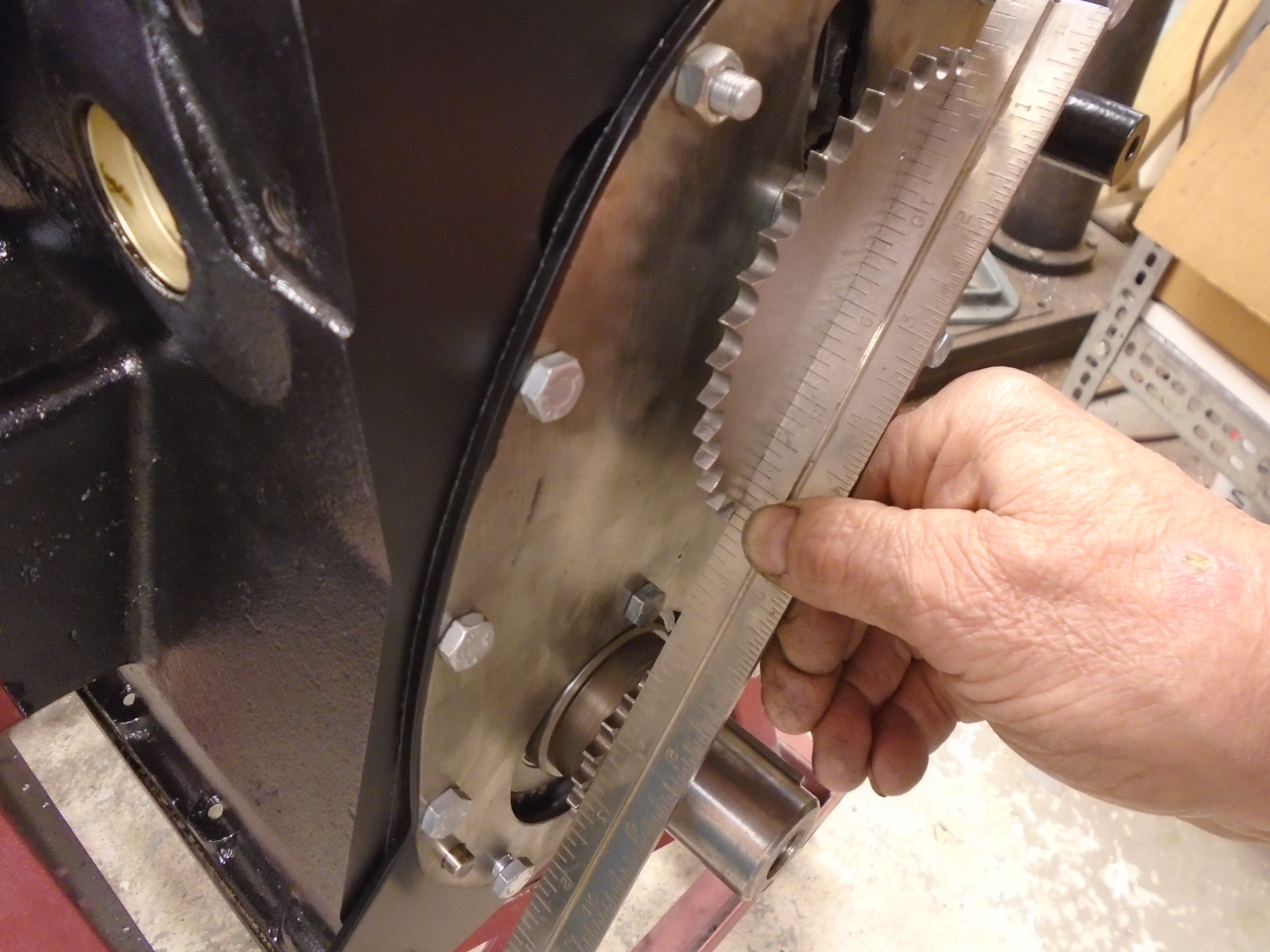

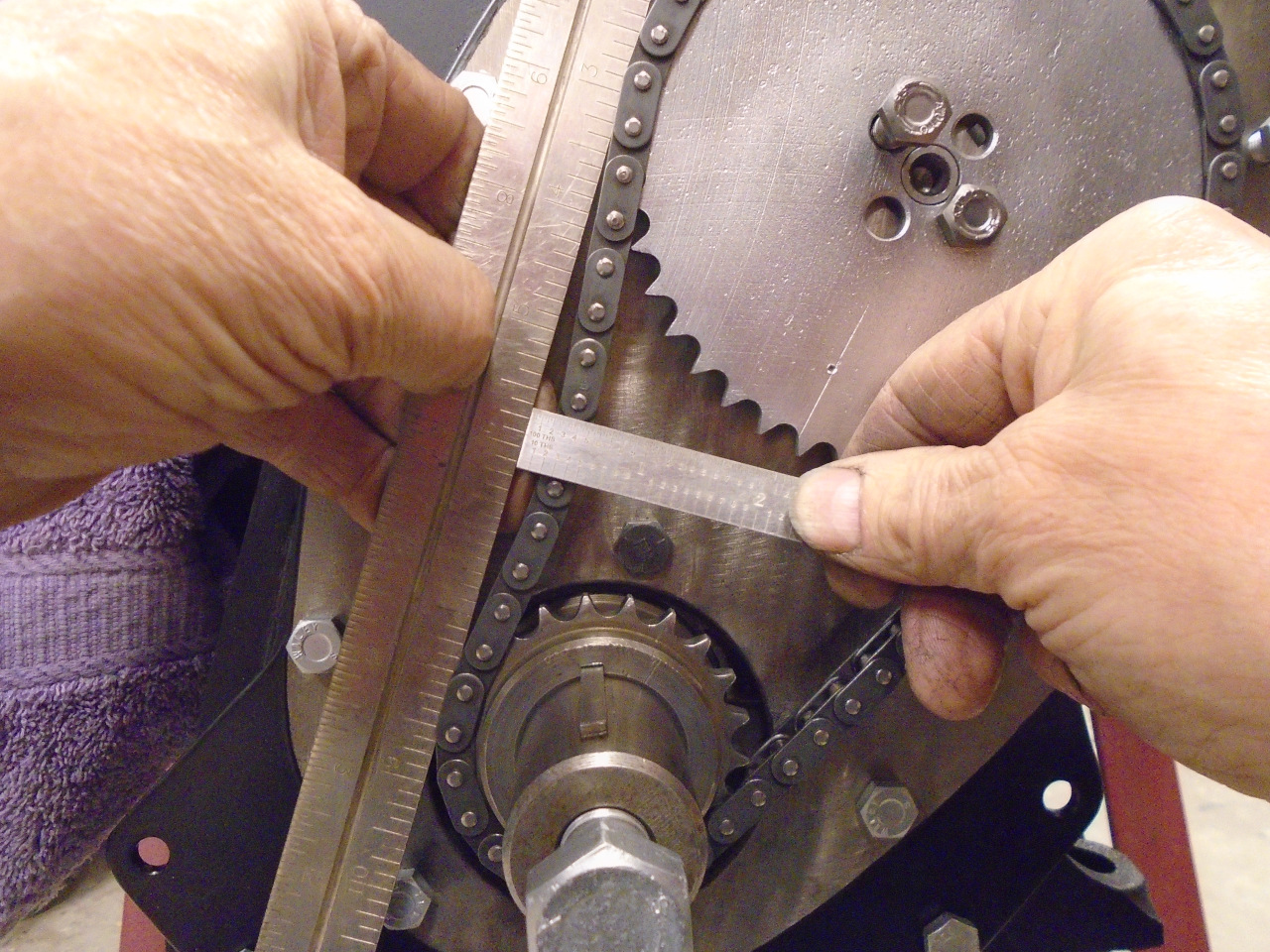

For long chain life, the sprockets need to be aligned to be

co-planar. This can be adjusted by using shims under the

crankshaft sprocket, but I didn't need any.

Chain stretch is measured by the gap between the slack side of the

chain, and a straight edge. The factory workshop manual

allows 0.4", but I had less than half that.

So, to set the cam timing, we need two datum points: For the

crankshaft, it is Top Dead Center (TDC) of the #1 (front) piston,

and for the camshaft, the position of the #1 or #6 cam

lobes. Since pistons #1 and #6 share the same TDC, it's the

cam, which rotates half a turn for each full turn of the crank,

that determines which one is on the compression/power or the

exhaust/intake stroke.

The stock GT6 cam and many of the popular replacements are

"symmetrical" cams. This means that for each cylinder, the

max lift points of the intake and exhaust valves are set to

"straddle" TDC for that cylinder. That is, the number of

crank degrees between max exhaust lift and TDC is the same as the

number of degrees between TDC and max intake lift. So a

common method for symmetrical cams is to set the cam so that the

#1 (or #6) intake and exhaust lifters are at equal lift (intake

rising, and exhaust falling), set the crank at TDC, and install

the chain to hold that relationship.

However, my new BP270 cam from BPNW is not symmetric. Max

inlet and exhaust lift points are not to be centered around TDC,

and the opening and closing ramps are not the same, so another

method of timing is necessary. It is actually simpler.

For this cam, the data sheet instructs to set the cam such that

the #1 intake lifter is at max lift, set the crank to 112 degrees

After TDC, and install the chain.

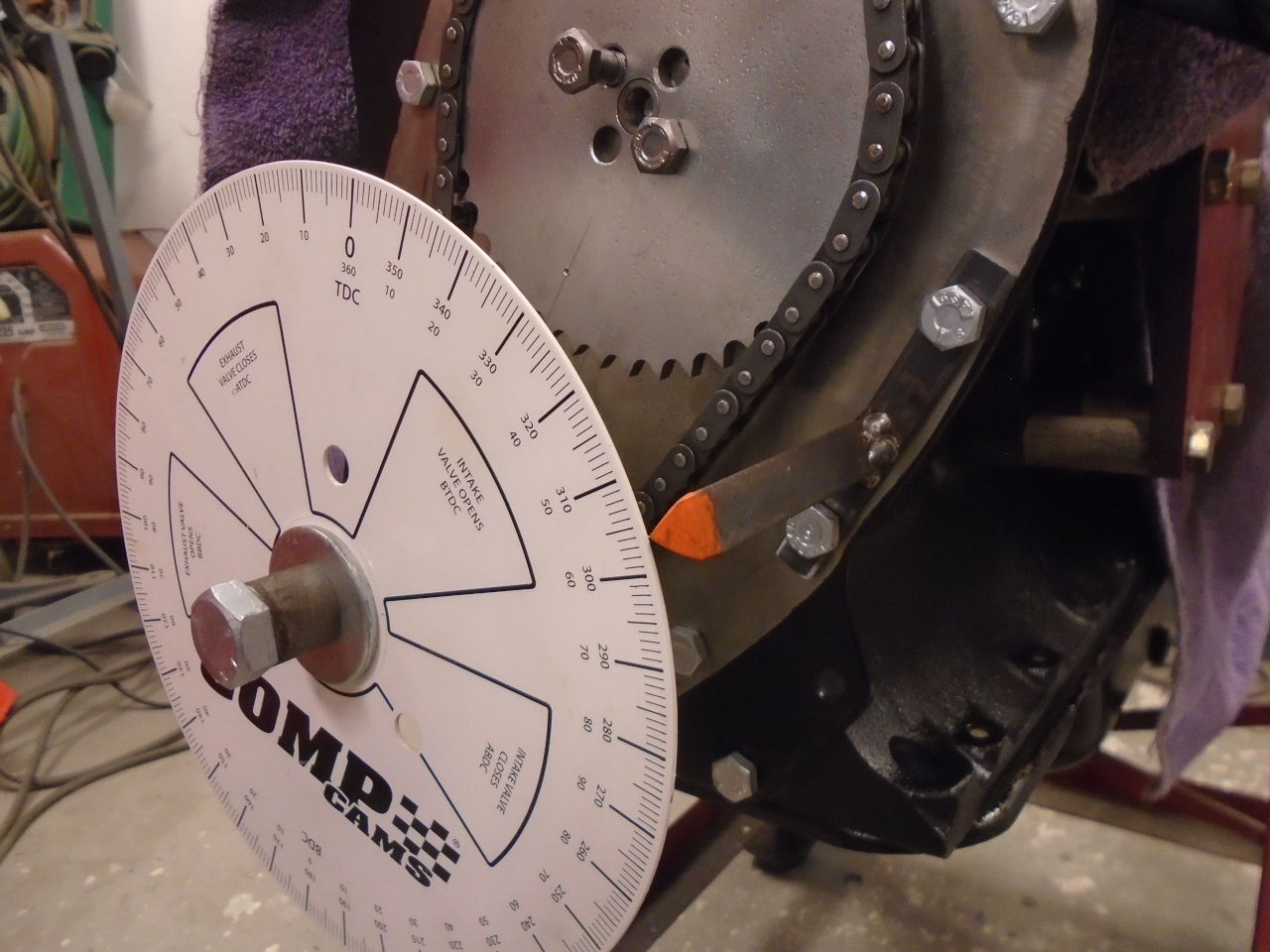

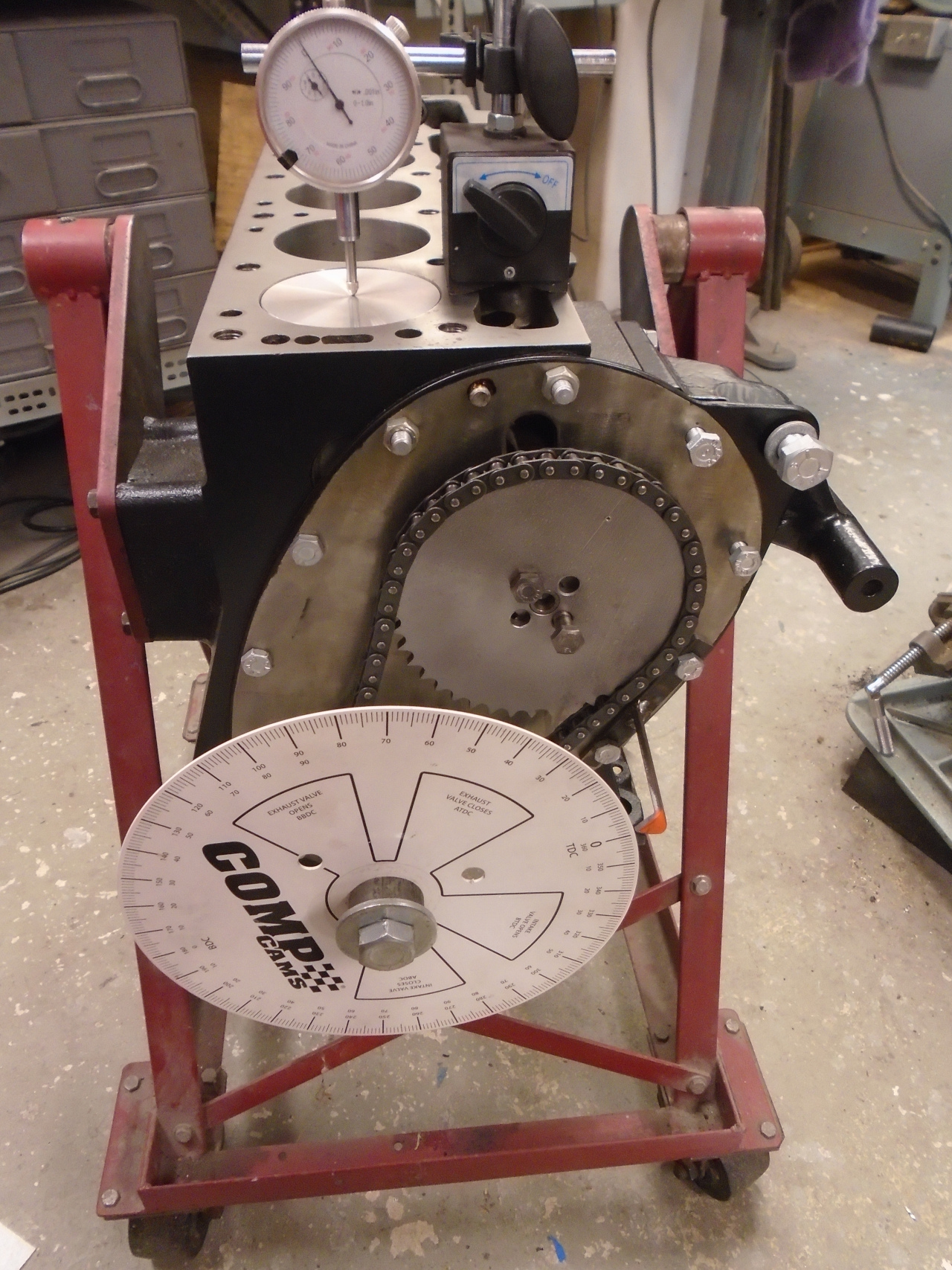

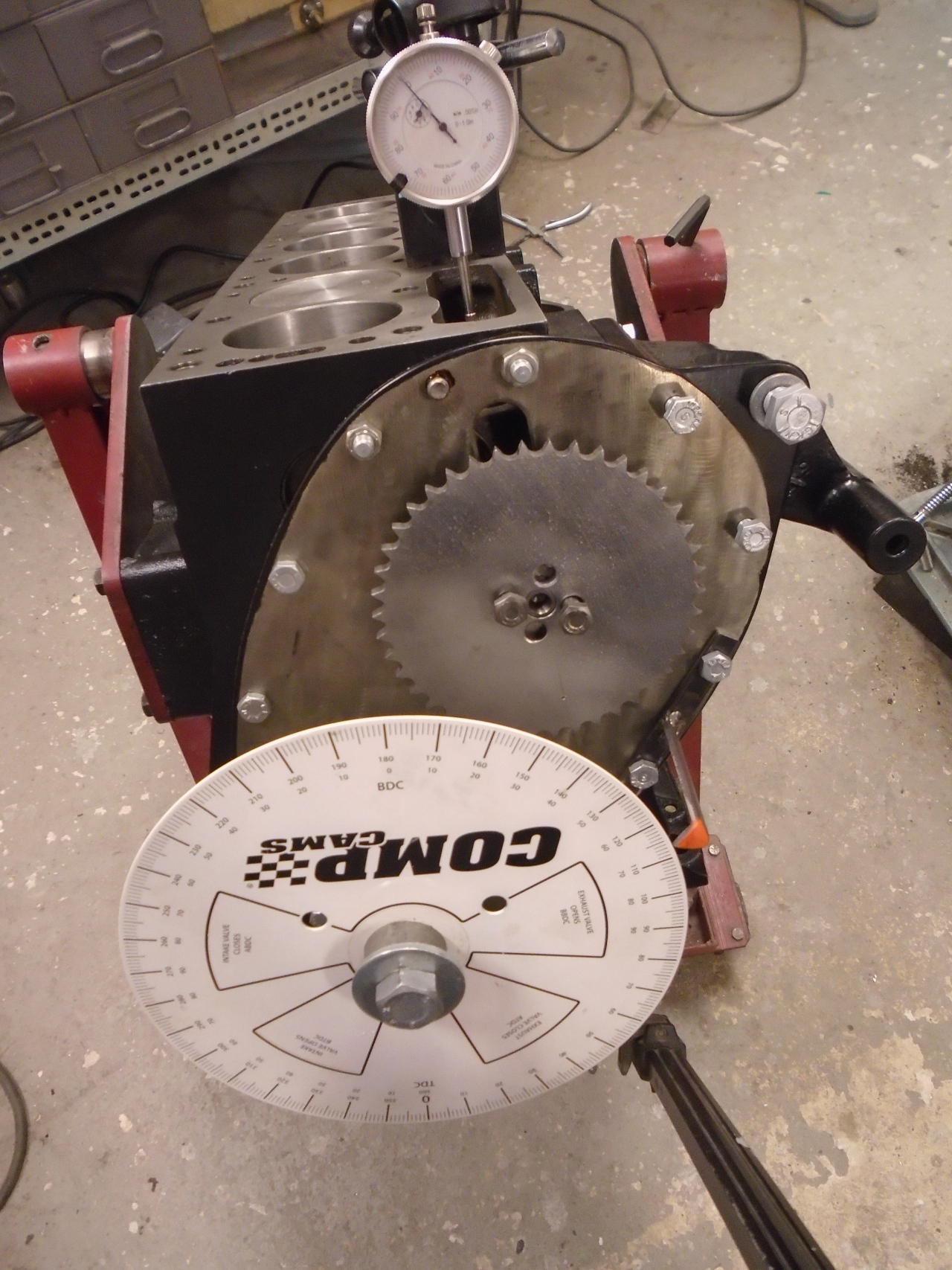

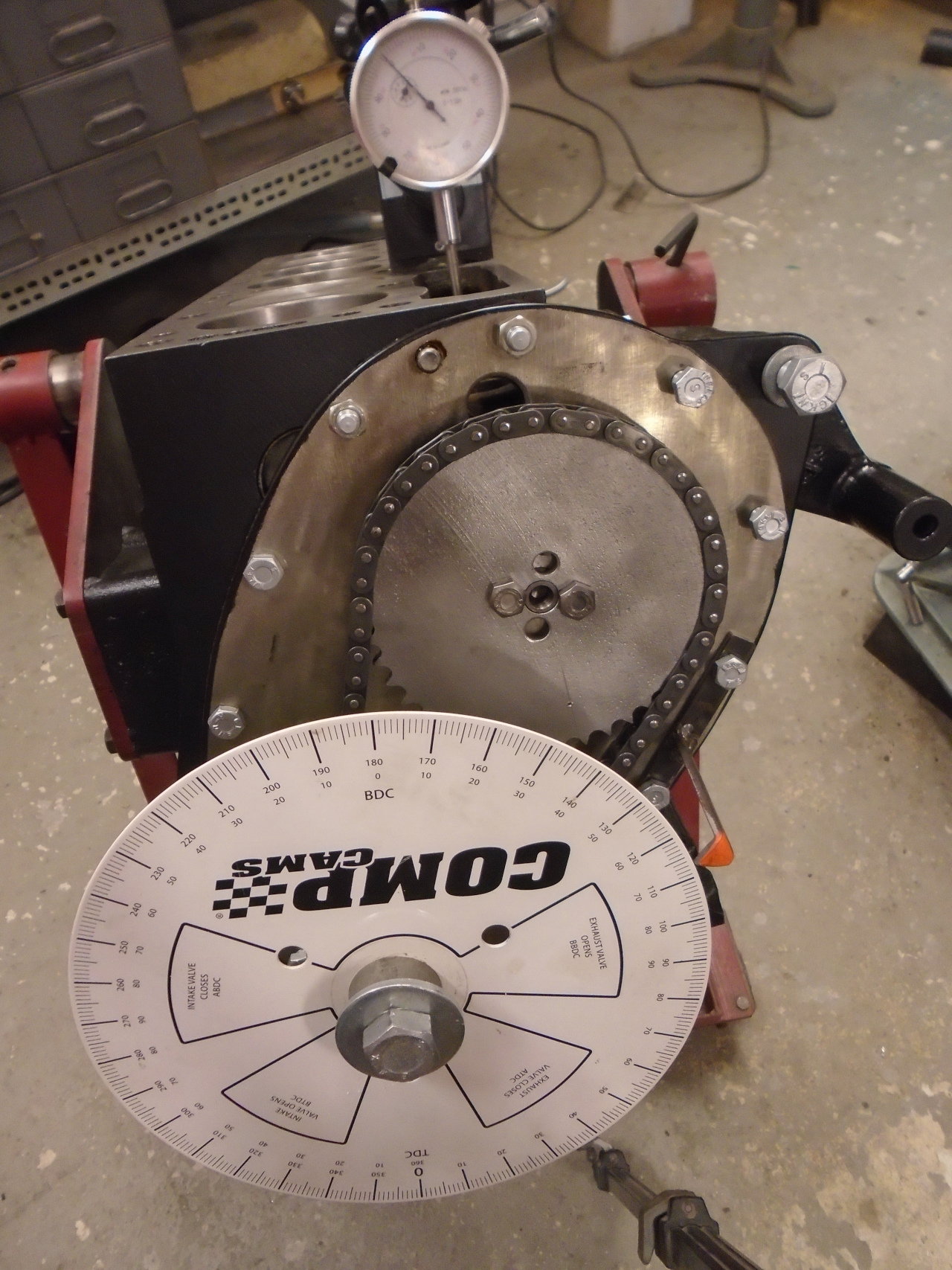

Obviously, some way of measuring degrees of rotation on the crank

is necessary. This is a generic degree wheel, with a simple

pointer bolted to the block. The wheel is set at an

arbitrary position to start.

A dial indicator is used to find TDC. Since motion of the

piston is very insensitive to crank rotation near TDC, one way to

do this accurately is to pick a piston position around 1/2" below

TDC on the rising side, and note the indicator reading and the

degree wheel reading. Rotate the crank clockwise (facing the

front of the engine), past TDC, until the indicator reading is the

same as before, but on the falling side, and again note the degree

wheel reading. TDC will be halfway between the two degree

wheel readings. Set the crank there, loosen the degree

wheel, set it at 0 degrees (TDC), and tighten it. The pic

shows doing this with the chain installed, but it normally would

be done without the chain.

To measure cam lobe position, I made this little slug to fit in

the back of one of the lifters.

With the lifter installed for the #1 intake valve, the dial

indicator was moved to measure lobe lift, and the cam rotated to

maximum lift.

The crank was then rotated clockwise to 112 degrees ATDC, and the

chain was installed.

A word about how close you can get to the specified setting:

The cam sprocket has 42 teeth, which puts them about 8.6 degrees

apart. So the error from some intended setting could be as

much as 4.3 degrees. To the crank, which turns twice as

fast, this error would be 8.6 degrees. On the positive side,

Triumph engineers included two pairs of mounting holes on the cam

sprocket 90 degrees apart. This 90 degres represents 10.5

teeth on the sprocket, so that by moving to the alternate pair of

mounting holes, the sprocket effectively advances 1/2 a tooth, or

4.3 degrees. This has the effect of cutting the potential

error in half, which brings us back to 4.3 degrees at the

crank. Fortunately, small errors in cam timing don't usually

make a huge difference in performance. Even so, some tuners

will intentionally set cam timing a few degrees off either way,

depending on what they are trying to optimize. The error in

my installation was pretty small--maybe a degree or so advanced.

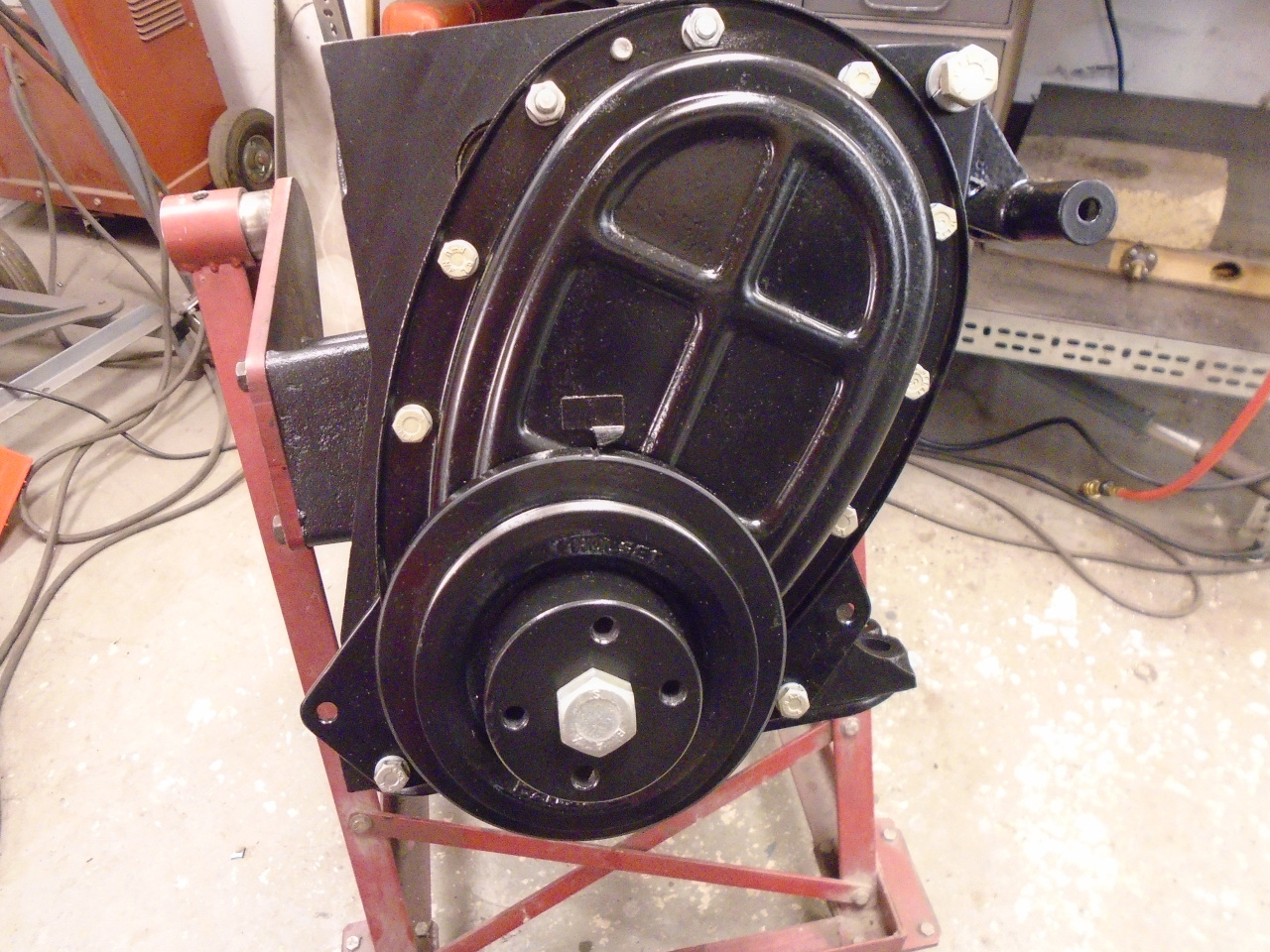

So, with all the brain work wrapped up, it was nice to turn to

something less taxing. The timing cover was pretty rusty,

with some remnants of paint, but it cleaned up and powder coated

pretty well.

The tensioner was well scored, so I installed a new one, along

with a new oil seal.

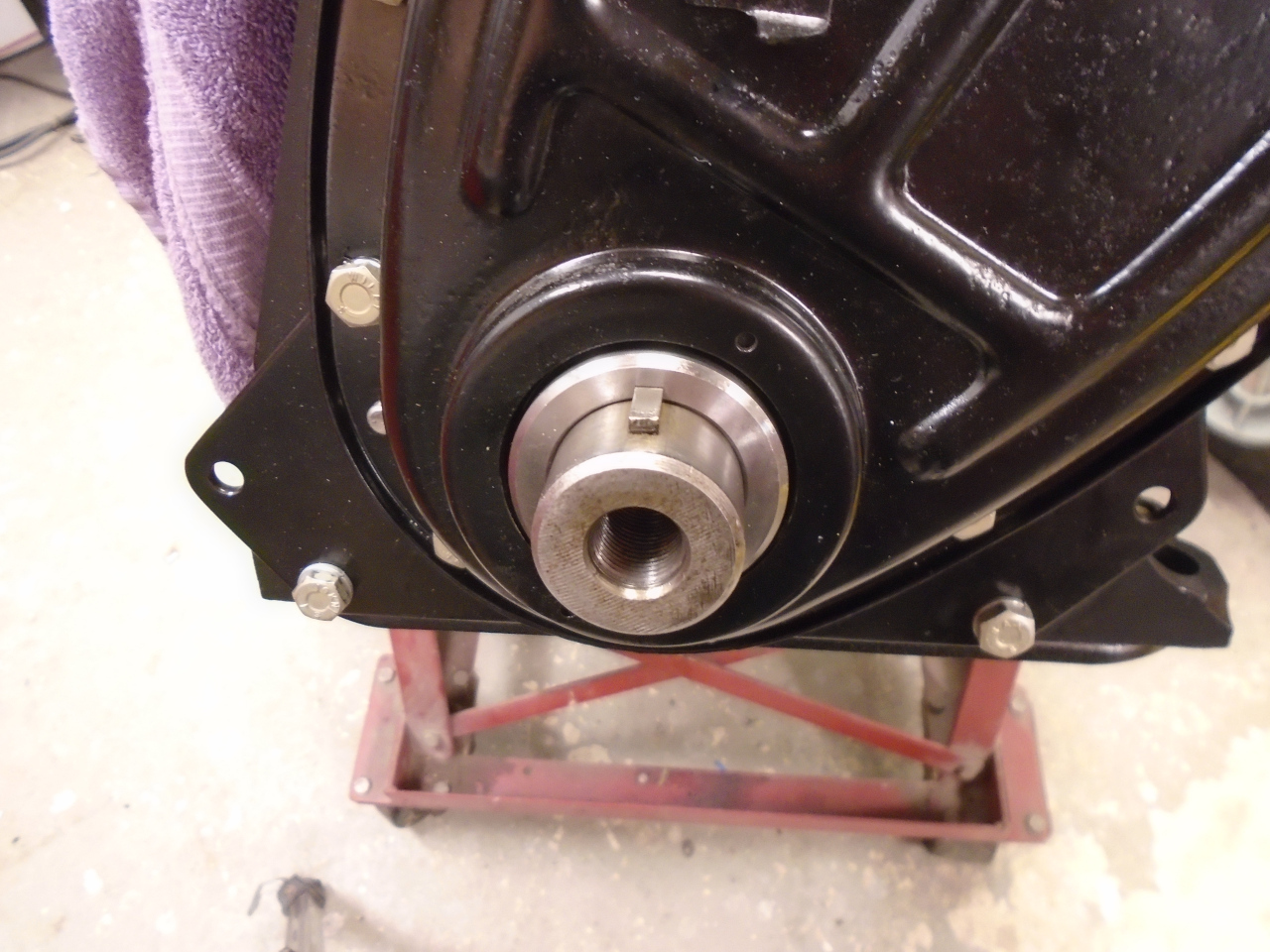

While thinking about stuff at the front of the engine, I dug out

the harmonic damper. Though appropriately crusty on the

outside, the damper appeared to be intact, with no detectable play

between the outer ring and the hub. I'm not a subscriber to

the notion that some deterioration of the exposed rubber is an

indication of damper failure. That rubber on the surface is

exposed to a lot of things bad for rubber--mainly oxygen, ozone,

moisture and various noxious hydrocarbons. The rubber inside the

damper that actually dos the work is not exposed to these

things.

Beyond this, my skeptical nature frets about some aftermarket

parts or "rebuilding" outfits. A harmonic damper is part of

a tuned system, and though deceptively simple, there is a lot of

science inside. So, barring any evidence of slipping or

other damage or degradation, I don't have reservations using ths

original damper.

The front seal sleeve showed a slight groove where the seal

rubbed. Since the sleeve is almost symmetrical, I just

flipped it over, which gave a fresh surface for the new

seal. I did enlarge the chamfer on the leading edge to match

the one on the other end, to help it slide into the seal.

All buttoned up. I'd checked it before, but note that with

the engine at TDC, the indication on the damper is correct.

I'll probably run an electric radiator fan, so that fan mounting

hub may go away.

This was one of the more expensive parts of the project--about

$400 for the cam and lifters, but was good for a few enjoyable

afternoons in the shop.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages.