To my other GT6

pages.

November 13, 2020

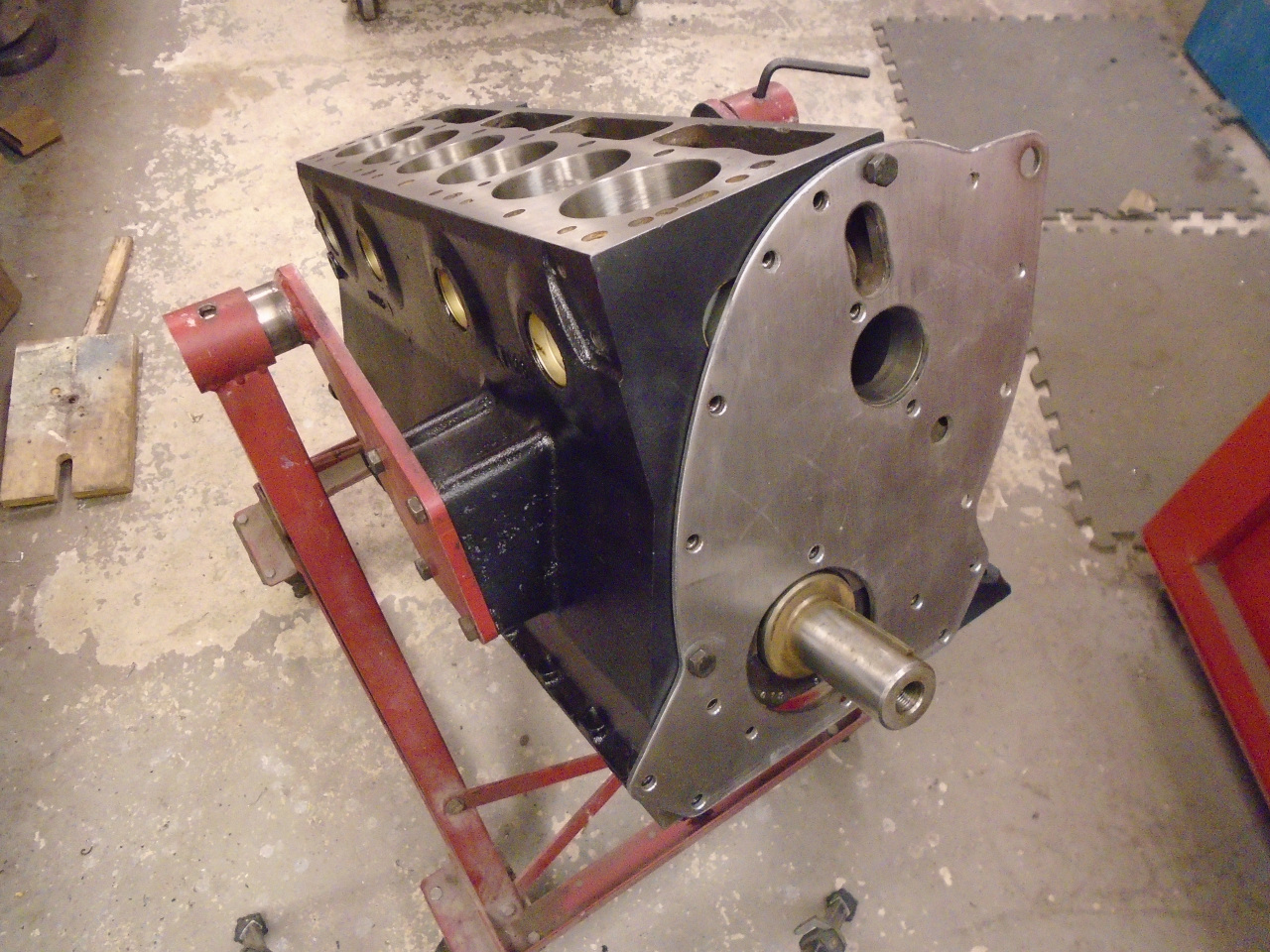

Front Engine Plate & Camshaft

The triumph six cylinder engines have flat plates that close off

the front and rear of the block. The front plate also locates the

camshaft, and carries the timing gear cover with its front

crankshaft seal. The rear plate is heavier, at a little over

1/4" thick, while the front one is just under 3/16". My

plates were greasy, with remnants of gaskets and sealer, but not

really any rust.

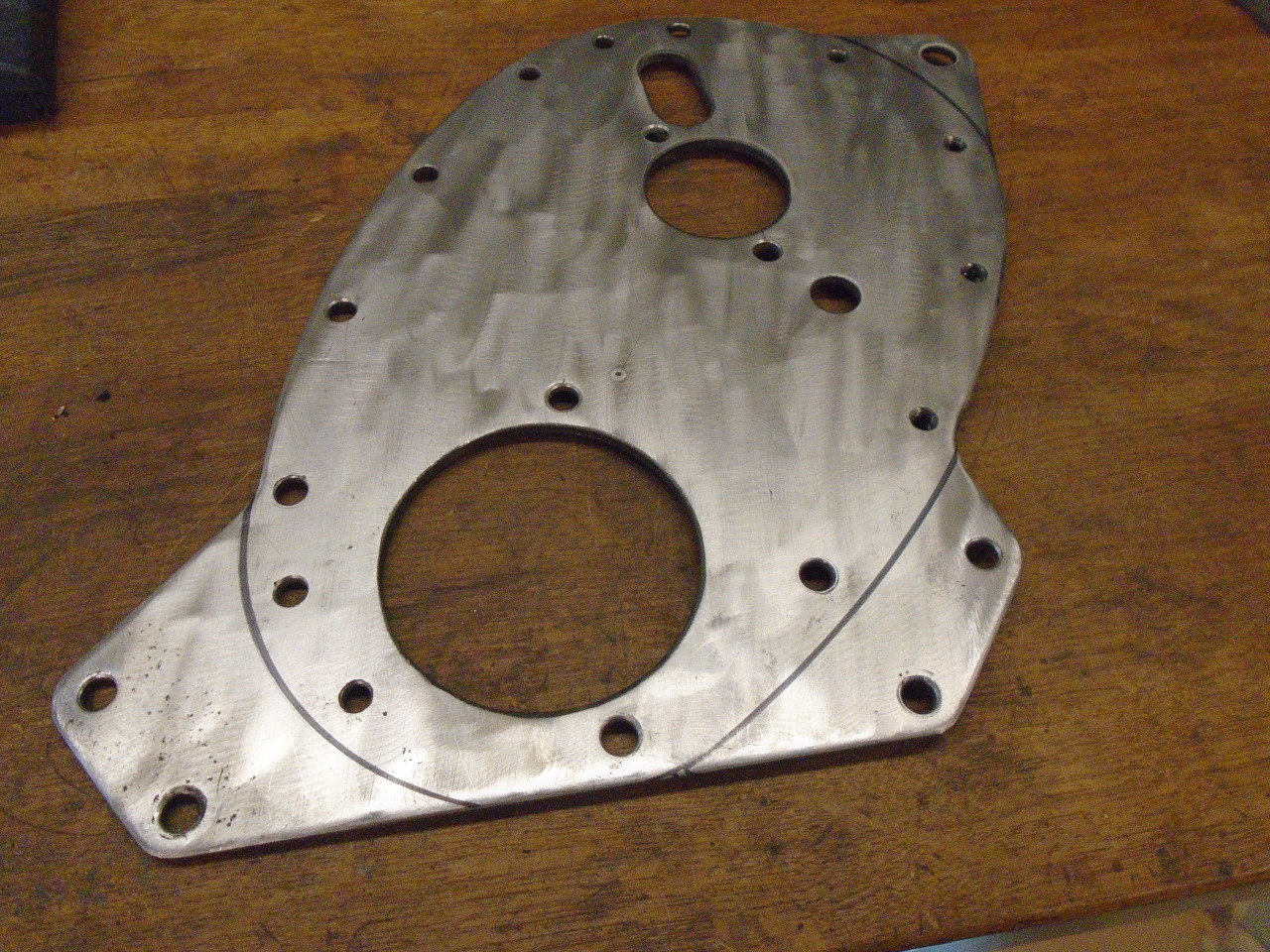

The front plate has what I consider a design flaw that I wanted to

fix. The plate extends out beyond the side of the block on

the left side of the engine, as does the timing cover. The

timing cover is attached only to the front plate in that area, by

the use of short 5/16-24 slotted head machine screws. The

thin plate can only offer less than four threads for the

fasteners. That makes these holes prone to stripping.

This is almost certainly why the designers specified the slotted

head screws for these locations--so it would be harder to

overtorque them. The factory torque specs for those slotted

screws is less than half that for the hex head screws that go into

the block, and is only to maintain 4 ft-lb after a "settling

period", whatever that means.

This suggests to me that not only are these threaded holes prone

to strip, the joint is prone to leak in this area.

My solution (though I'm guessing not an original idea) was to

enhance the threaded hole by welding nuts on the backside.

The nuts were welded on with a bolt installed, so that the new and

old threads would be not only concentric, but continuous. I

also marked the outline of the block and the timing cover on the

plate so I could mask for powder coating. The parts exposed

to the environment will be coated, but the inside, and the gasket

sealing surfaces will not.

I realized after powder coating the plate, that there was one more

location with the short threads. Luckily, it wasn't in the

coated area.

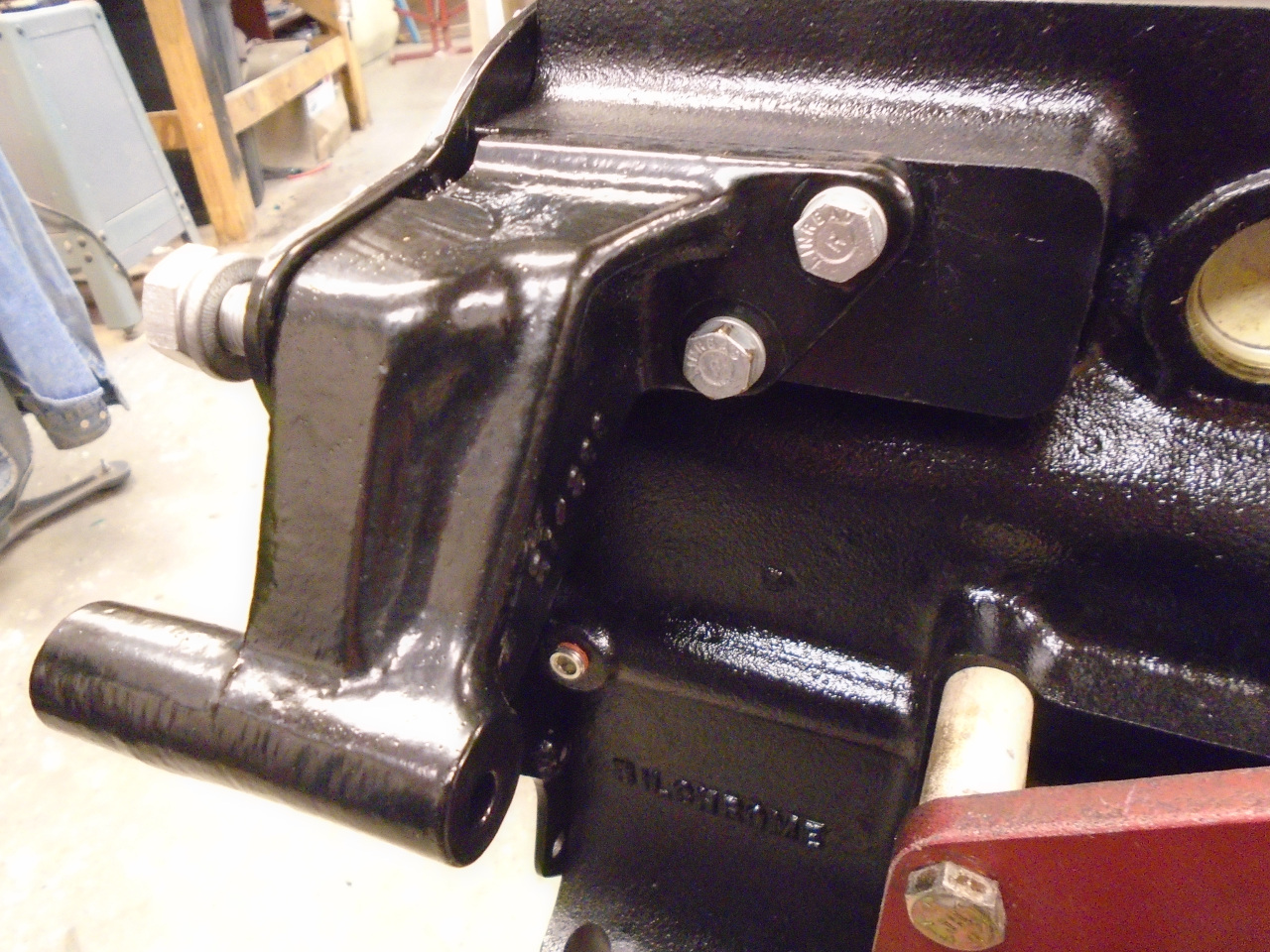

While trial fitting the modified plate, I realized that the welded

nuts interfered with the alternator bracket. The bracket did

have a small recess to accommodate an original fastener protruding

slightly, but I had to enlarge it considerably. Also, I had

to carve a little gullet in one of he webs for the adjacent

fastener.

Then powder coated the bracket and refreshed the fasteners.

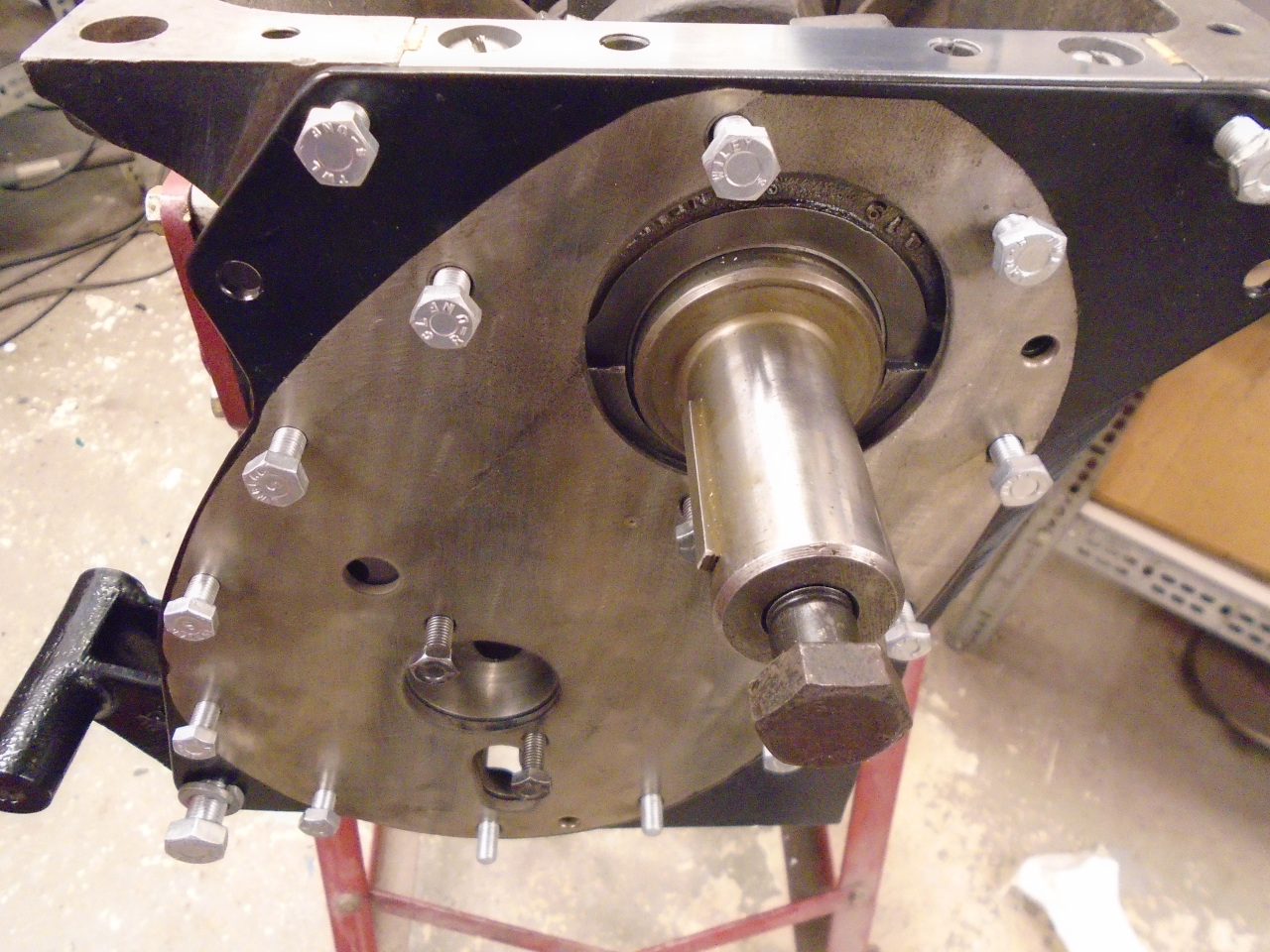

Another test fit showed everything OK. Note that the engine

is upside down in many of the following pics.

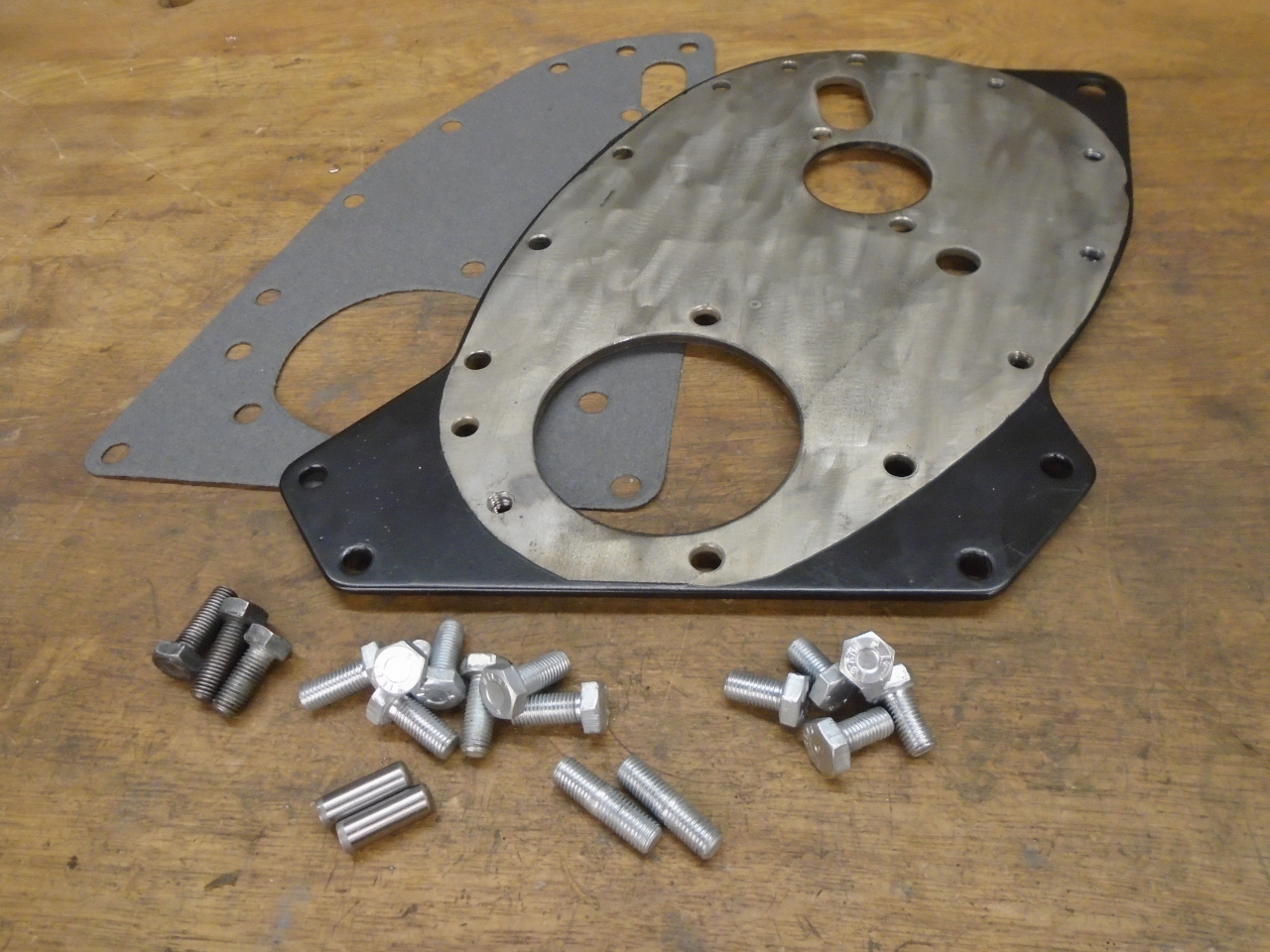

So, gathered together all the pieces and parts. The

fasteners are all original except for the ones that go in the

modified holes. I borrowed those from my stash of British

hardware. They are now 5/8" long instead of the original

3/8", and they are hex head. The three darker bolts at the

left live inside the timing cover, so they don't need to be

plated.

Shoved in new locating dowels. The originals didn't suffer

the removal process well.

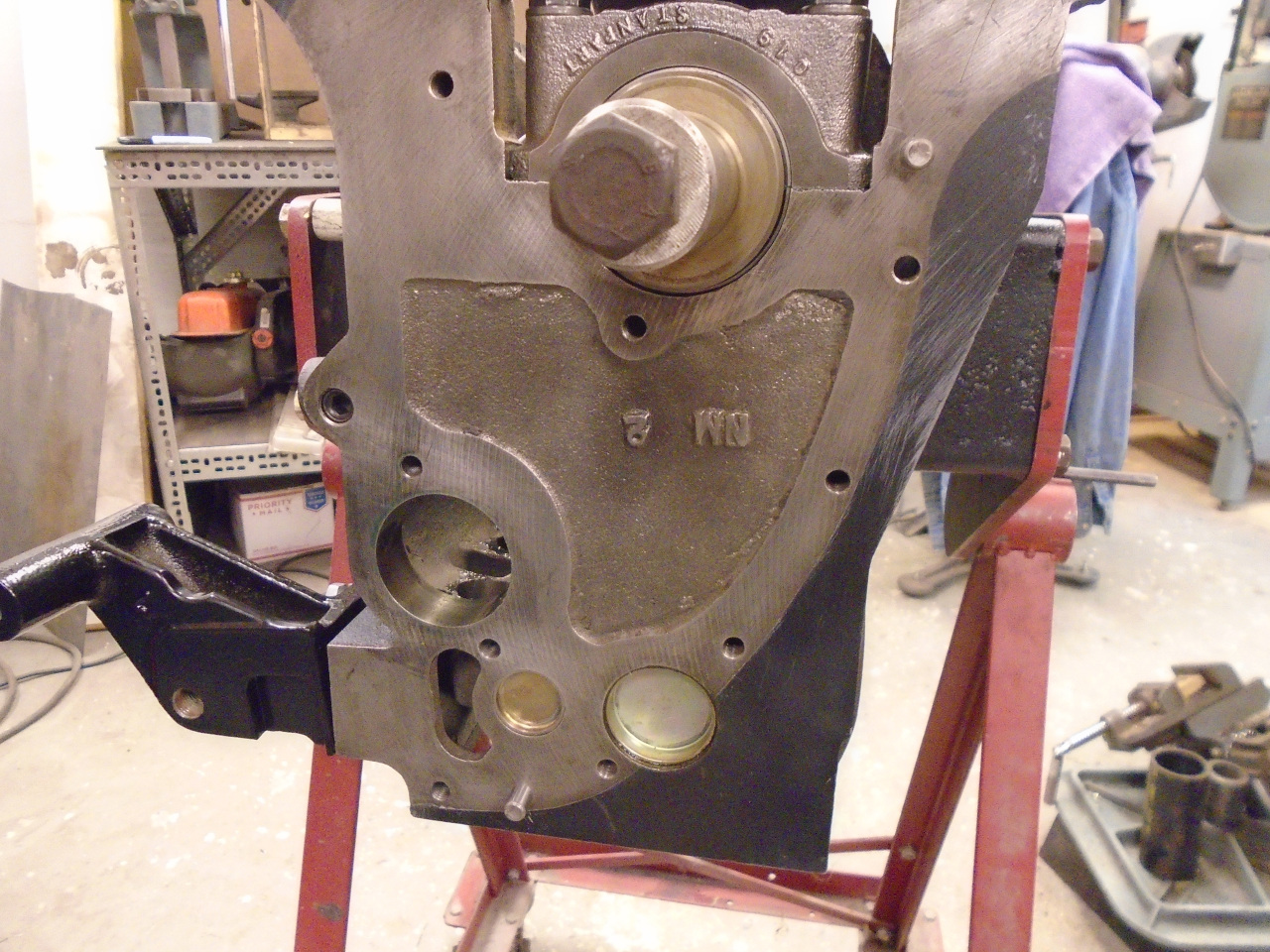

Applied the gasket with a good sealer, and added the plate.

The fasteners that go into the block are all tightened enough to

keep the joint compressed.

At this point, I was ready for the camshaft. There was

nothing apparent wrong with my original cam, but I was looking for

something a little more interesting. I put a GP2 cam in my

TR6, and like it a lot. To get some variety, this is a BP270

cam from BPNW.

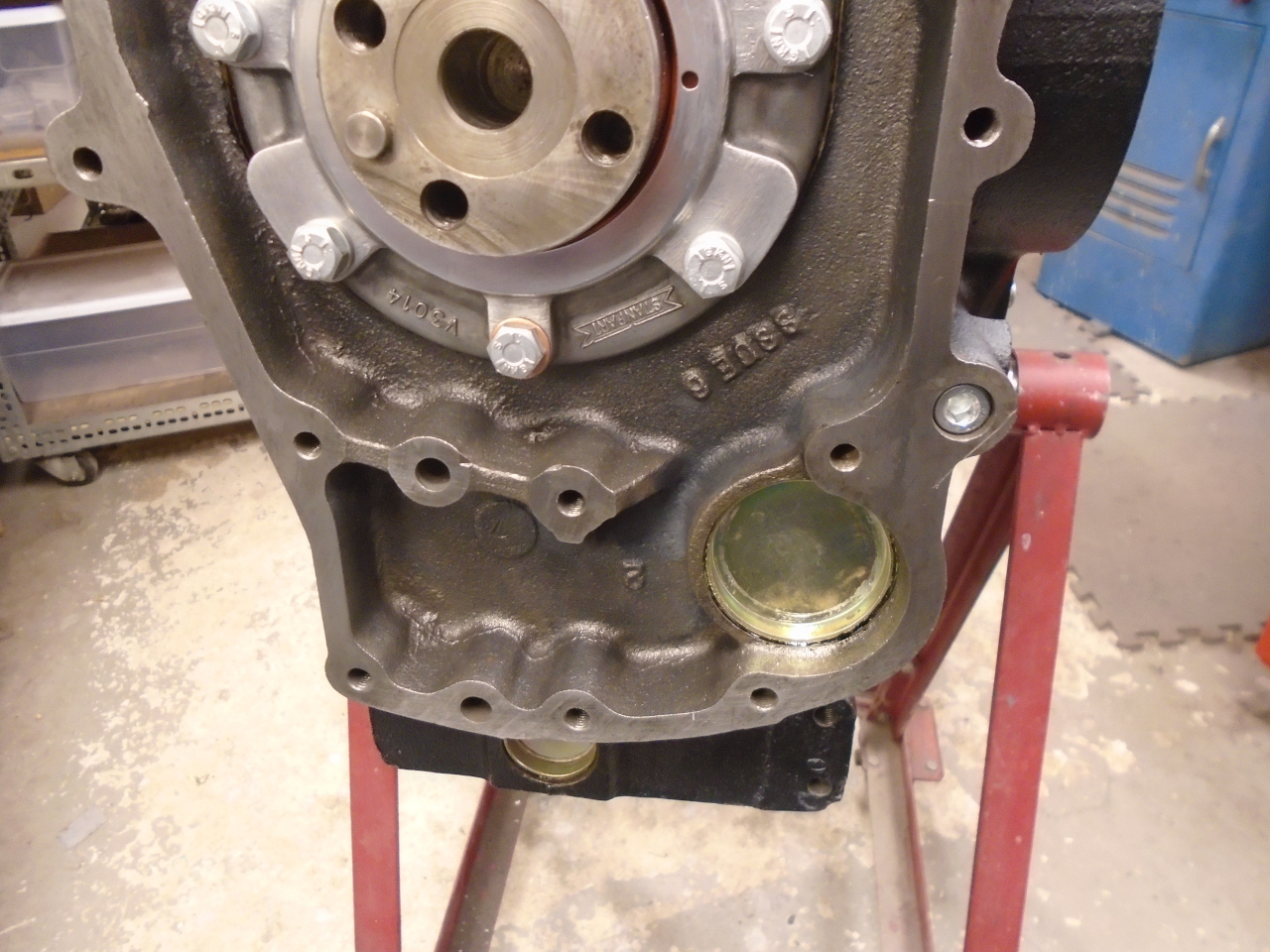

The cam went home without incident. With the keeper plate

torqued down, the cam turns smoothly.

At the rear of the engine, the cam bearing is exposed. This

opening gets closed off with a plug.

This engine seems to be moving pretty quickly now. Should

have it buttoned up soon.

Comments to Ed at elhollin1@yahoo.com

To my other GT6

pages.