To my other GT6

pages.

November 12, 2020

Rear Main Seal

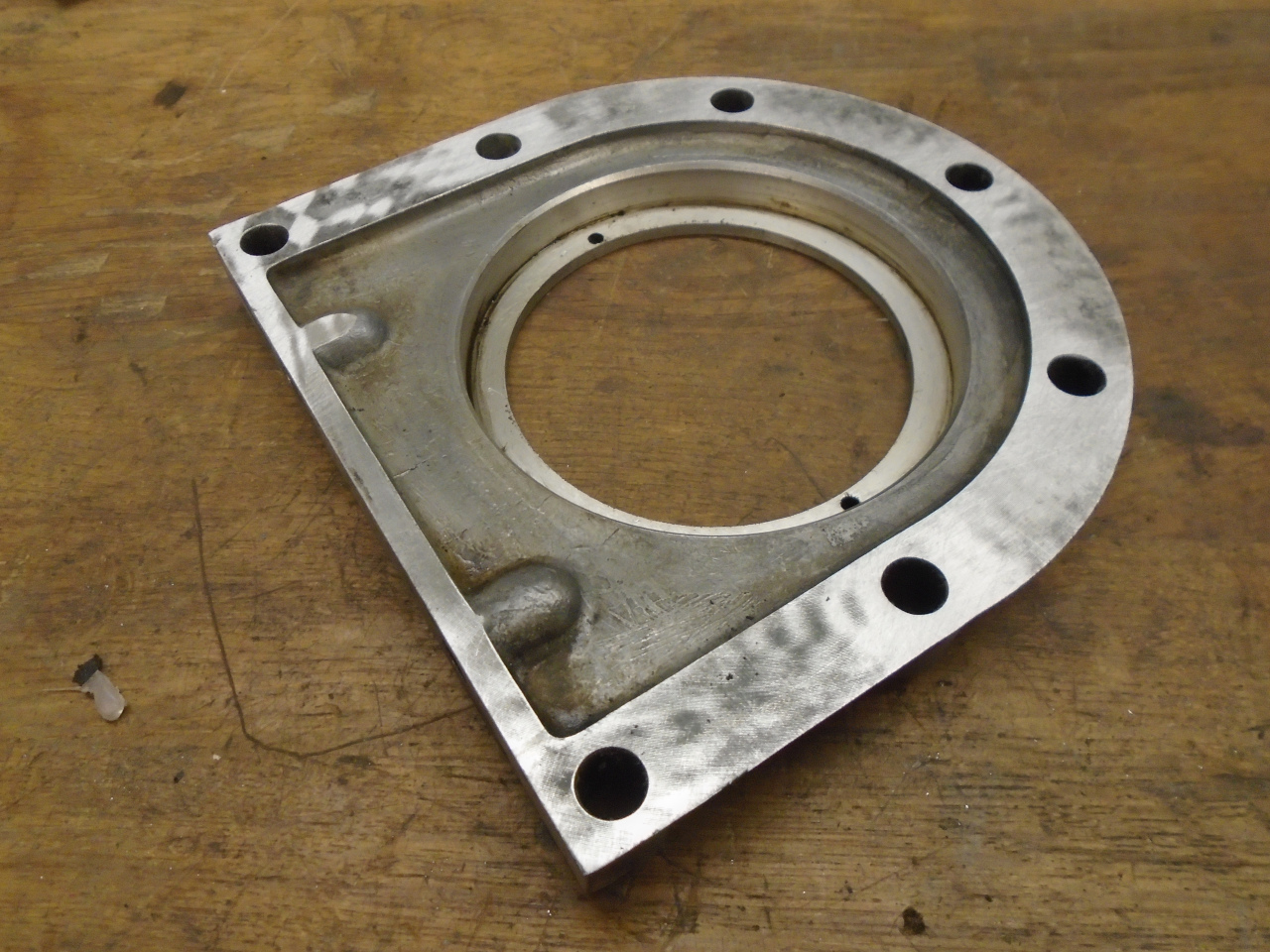

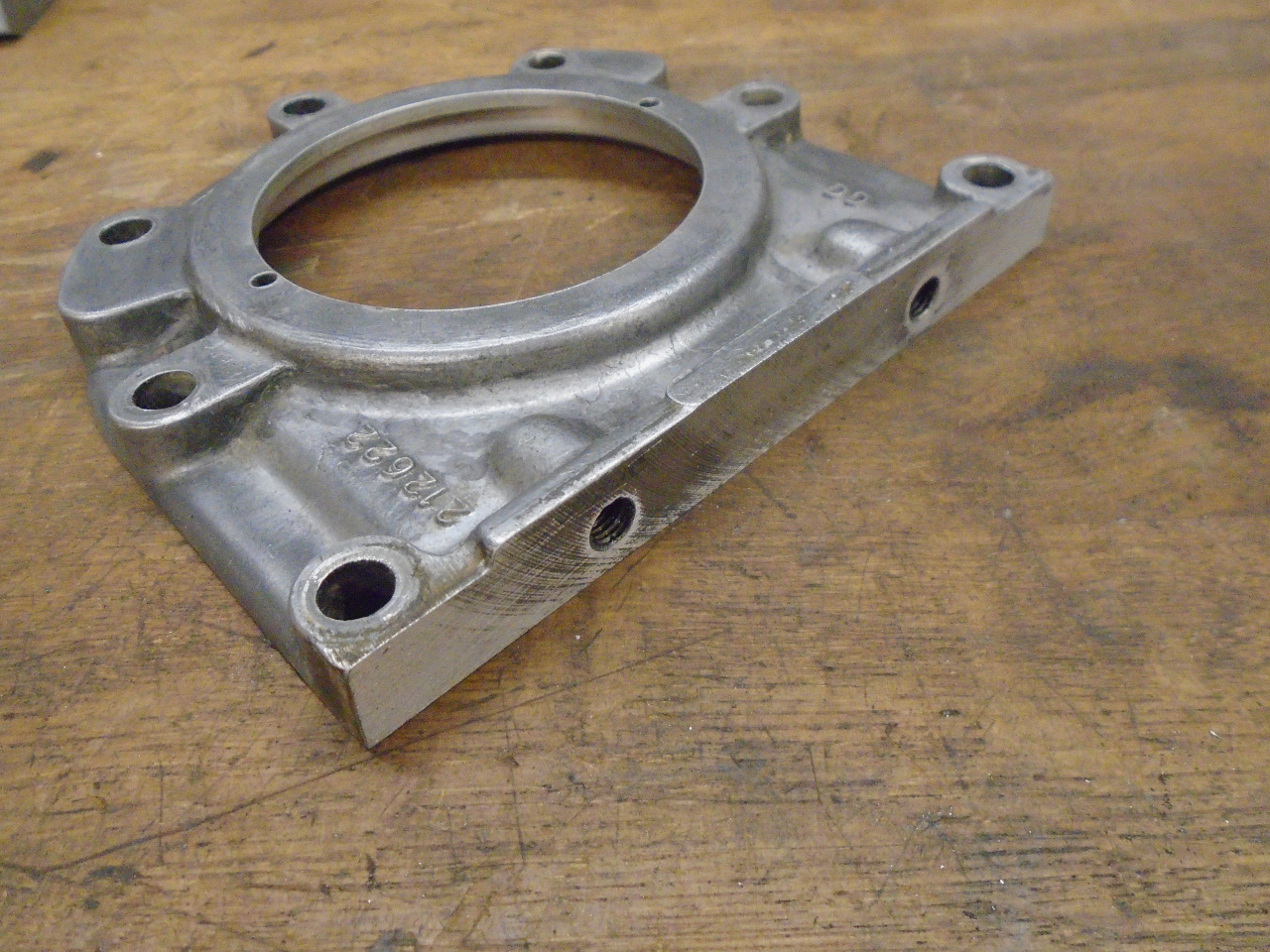

The Triumph six cylinder engines had a main crankshaft seal housed

in an aluminum casting at the rear of the crank case. The

housing also bridges the gap in the sump mounting flange, and

accepts two of the sump fasteners. The machined mating

surfaces of my seal housing after 50 years weren't all that flat.

A little linishing quickly fixed that. I considered

installing some inserts in the threaded holes for the sump

attachment, but these don't really seem to present the problems

that the ones in the sealing block at the other end of the engine

do. I assume it's because the aluminum of the seal housing

is a much stronger material than the zinc alloy of the sealing

block.

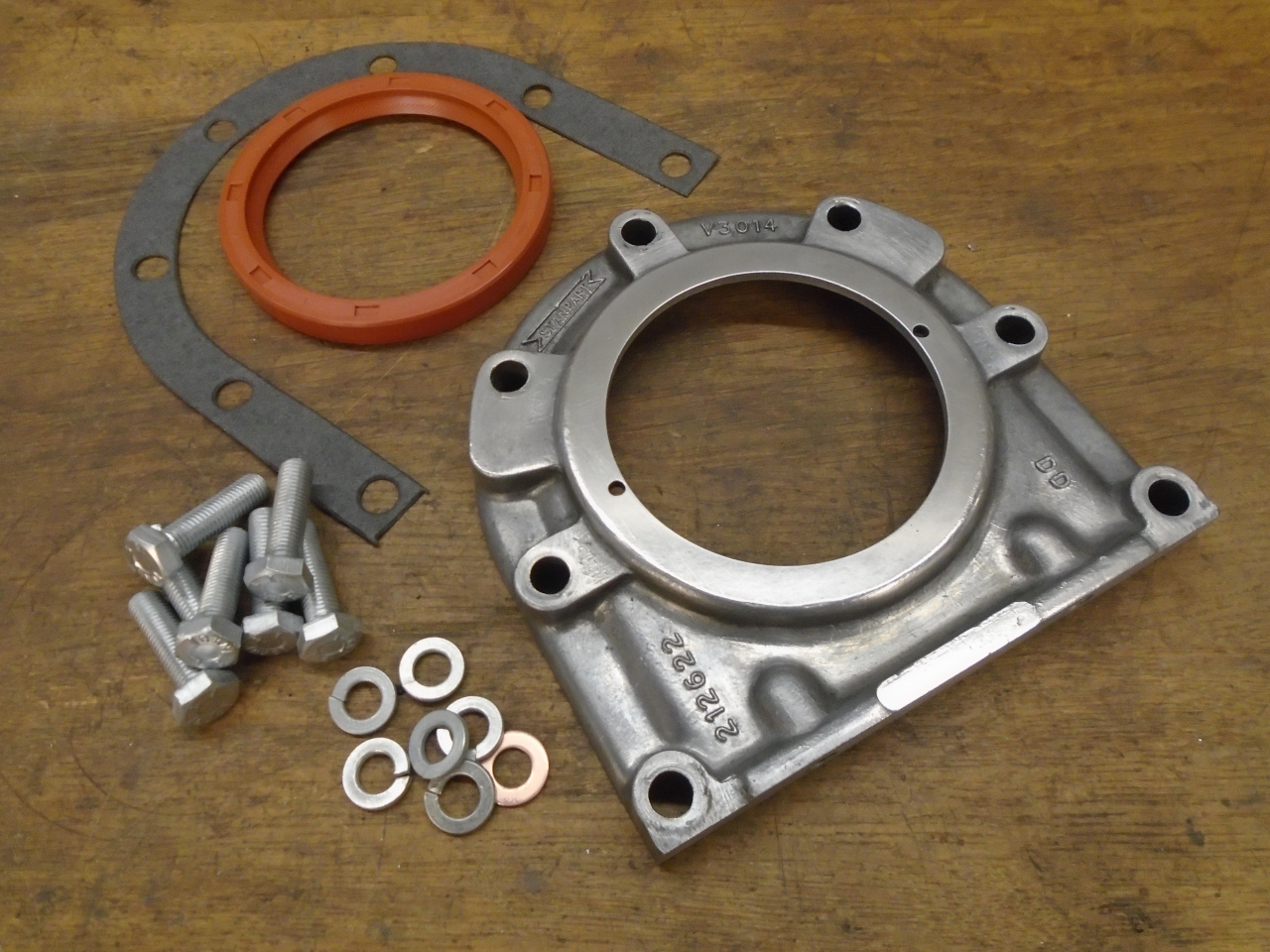

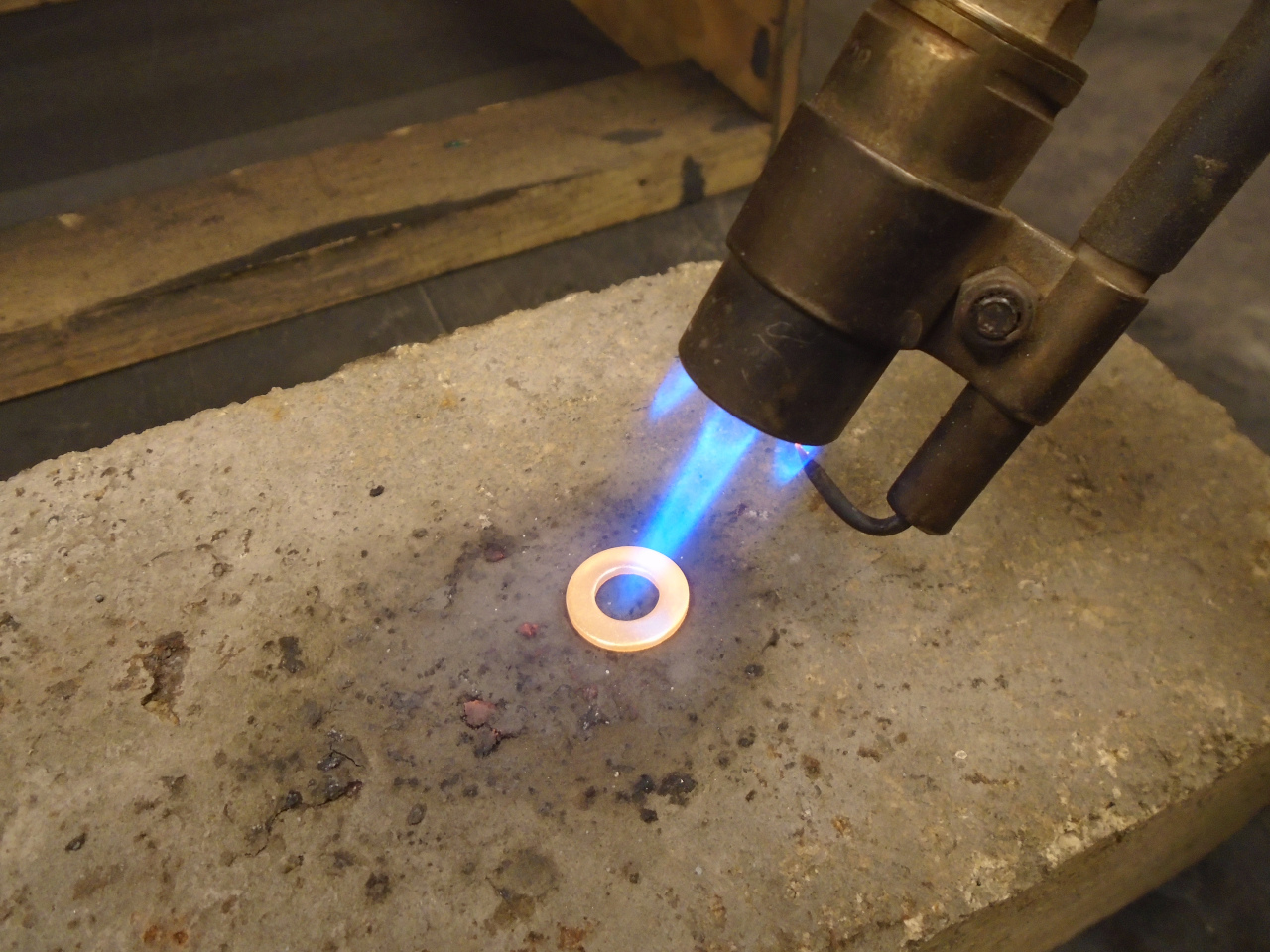

So I gathered all the parts necessary to install the rear

seal. Those are the original bolts, but new washers.

Since one of the attachment holes actually opens to the inside of

the crankcase, its bolt gets a copper sealing washer instead of a

split lock washer. I normally anneal copper washers, even if

they are new.

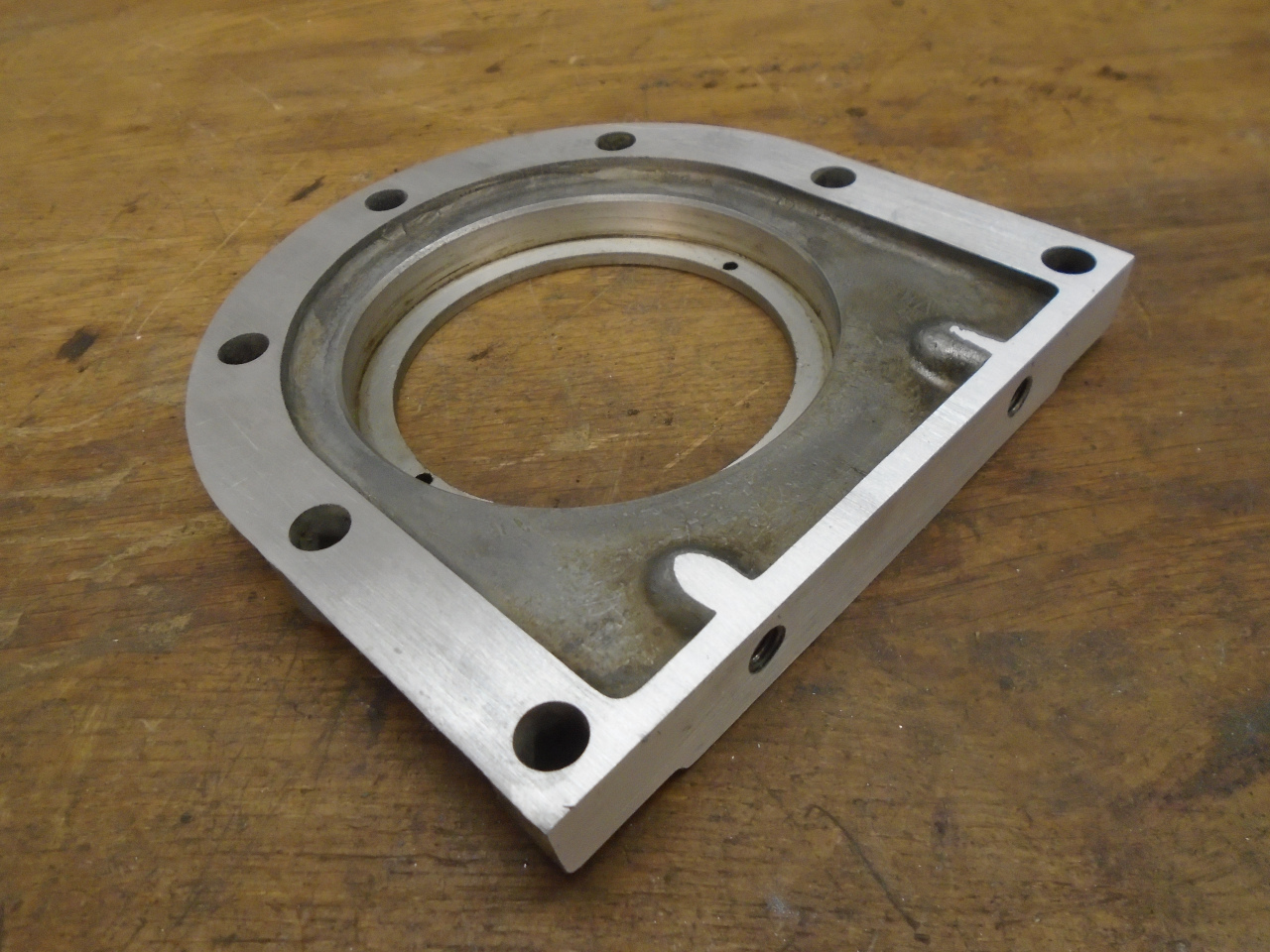

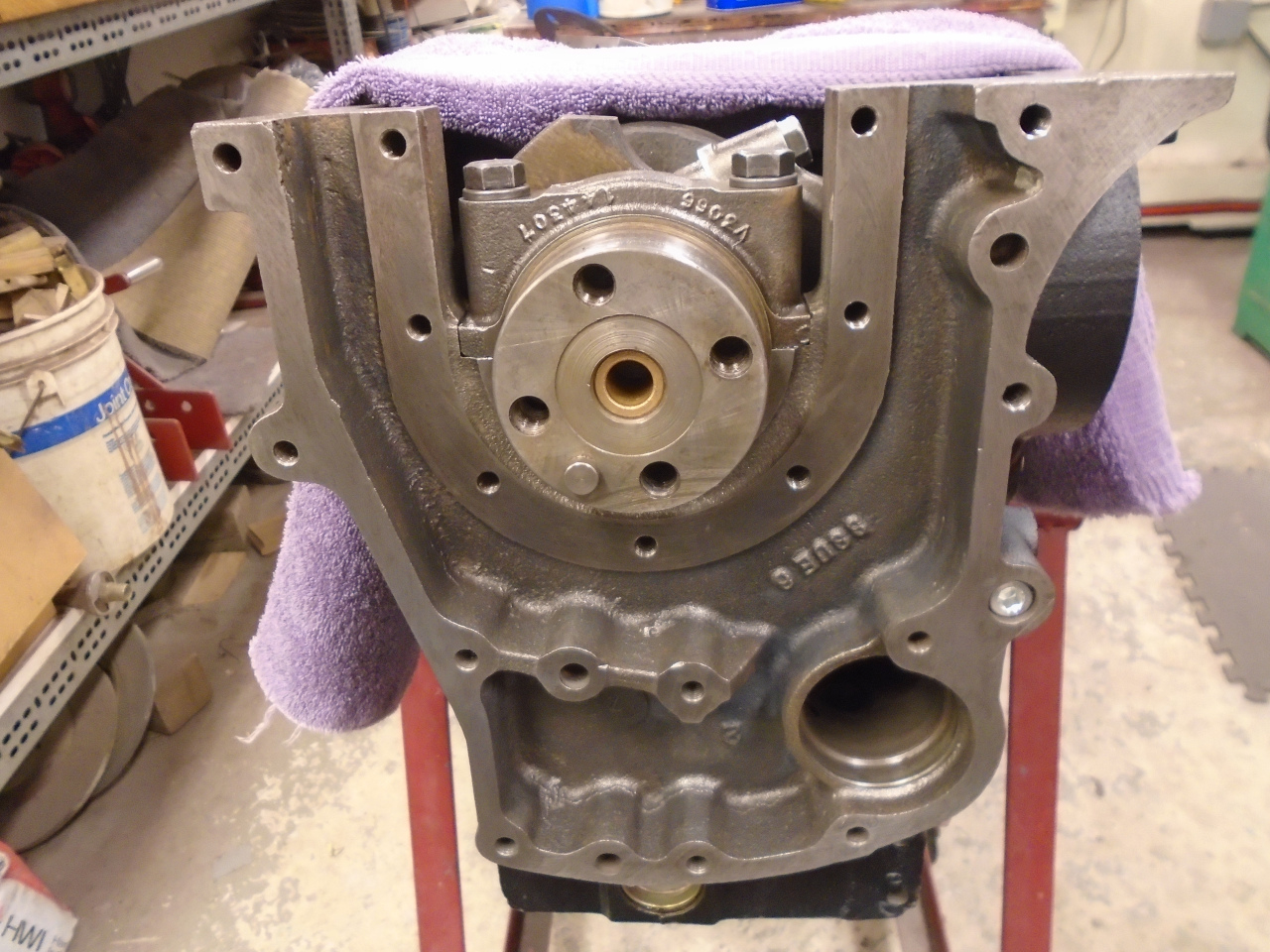

So this is where the seal and housing go. The engine is

upside down in many of the pics below.

The seal was then installed in the housing, the gasket applied,

and the assembly was slipped over the crank end.

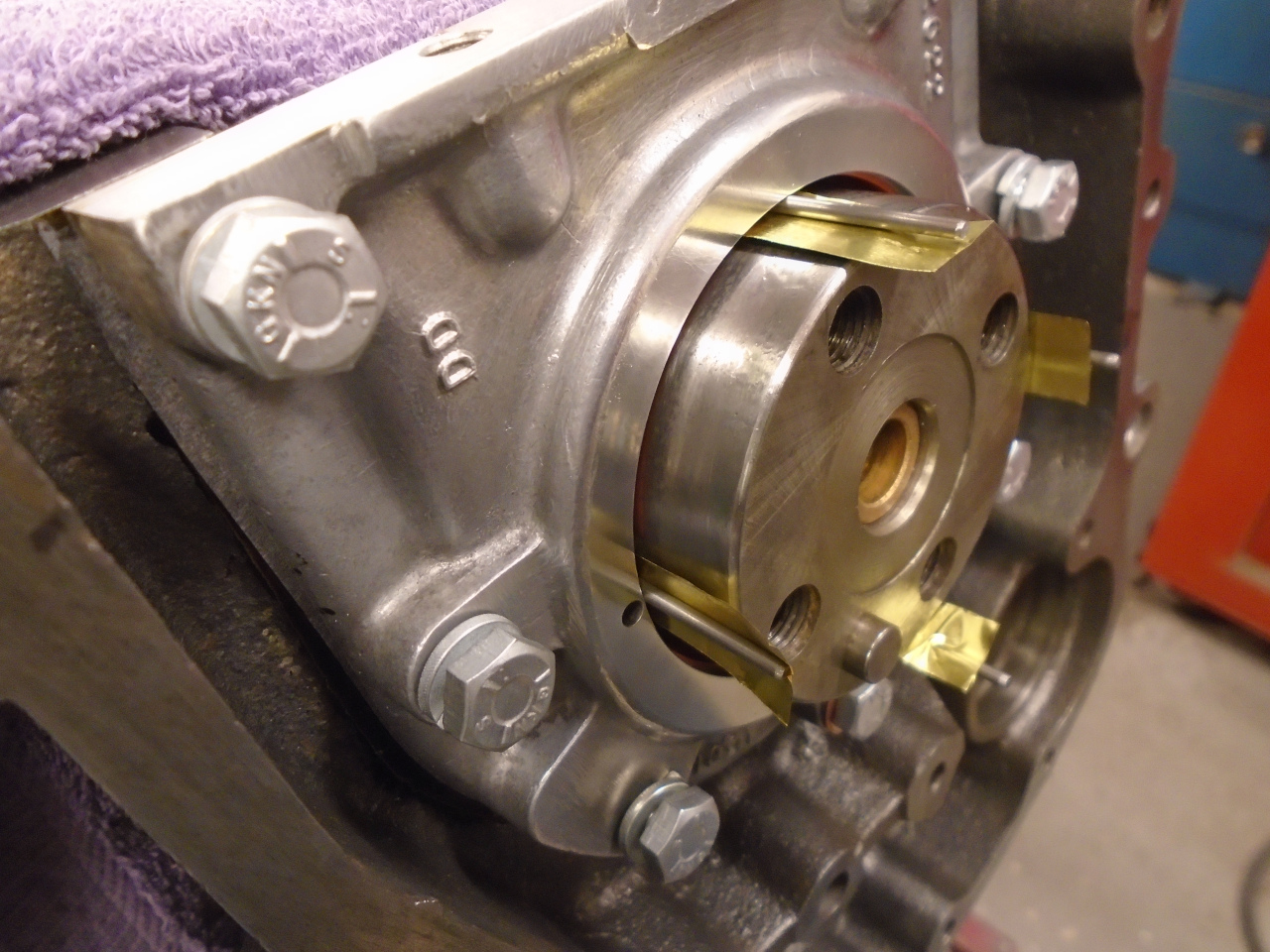

The seal of course is self centering on the crank, but there is

the possibility of shifting the housing to one side slightly when

tightening the bolts,which could result in an oil leak. The

factory apparently thought centering was important enough that

they specified a special tool for the job. The tool is

obviously not available today, and I'm not even sure what it

looked like. The principle is simple, though. The

crank end is 2 7/8" in diameter, while the opening in the housing

is 3 1/16". So the space between the crank and housing needs

to be 3/32" all around. I found some 3/32" gas welding rod

and cut a few pieces but, not being precision material, they were

a little loose. Four little pieces if 0.001" brass shim

stock was all it took to make them a snug fit.

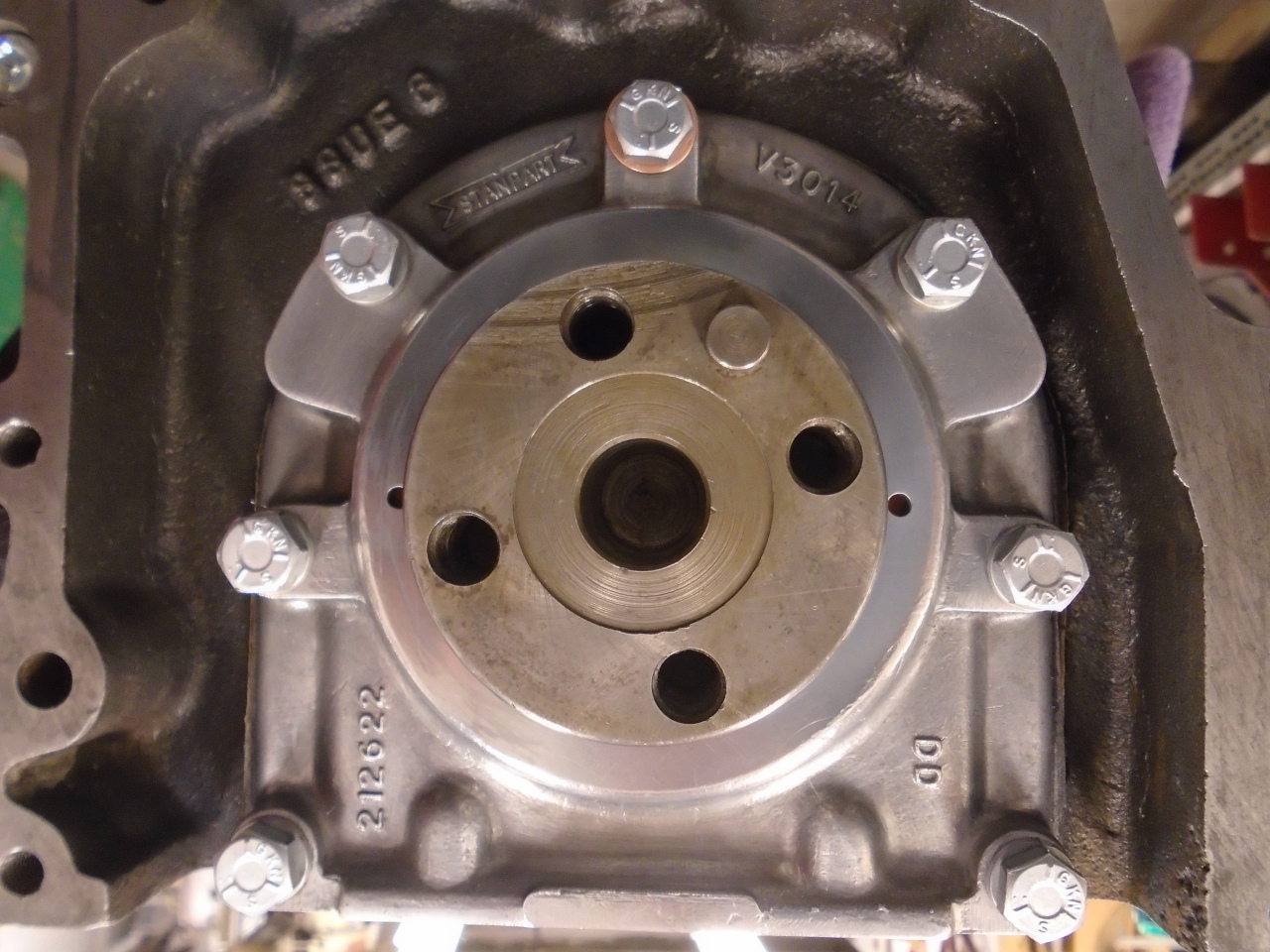

Torqued the bolts, and checked this task off the list.

This was a simple little job, but I thought the centering

operation might be of interest to some.

Comments to elhollin1@yahoo.com

To my other GT6

pages.